Patents

Literature

46results about How to "Realize anti-collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tracking method and system of time-varying formation of unmanned aerial vehicles

ActiveCN108983825AImprove tracking accuracyRealize anti-collisionPosition/course control in three dimensionsMassive gravityUncrewed vehicle

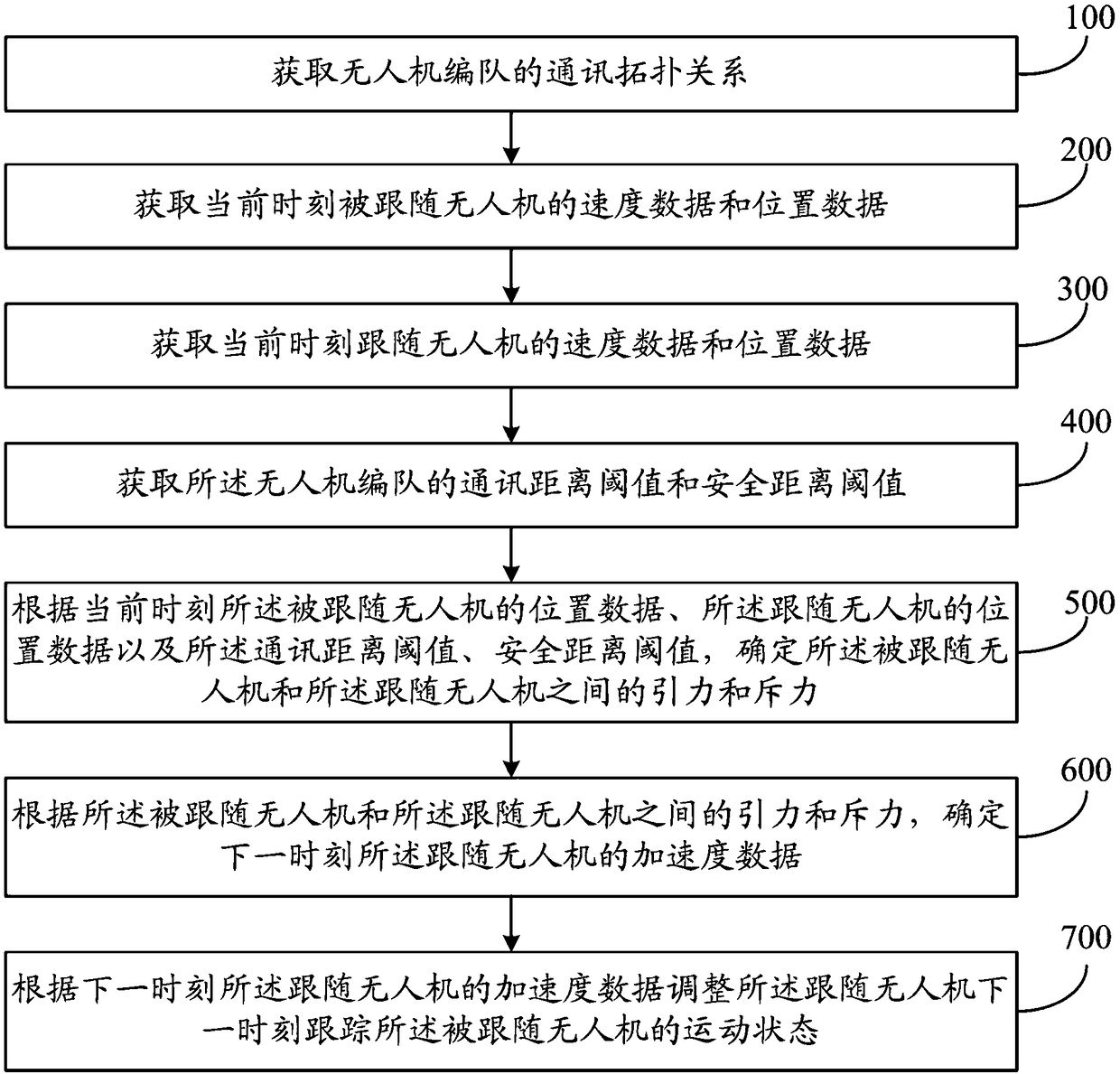

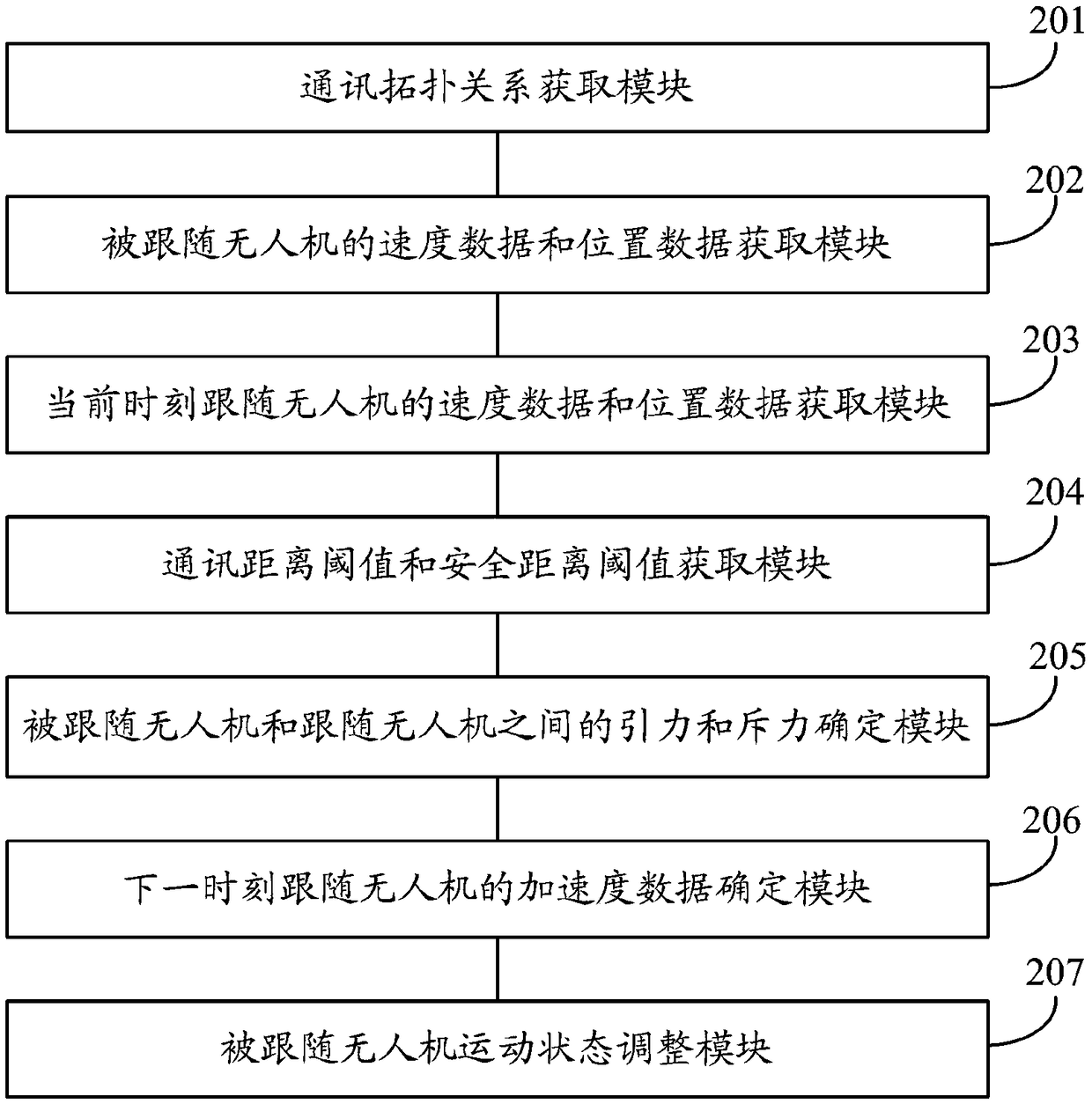

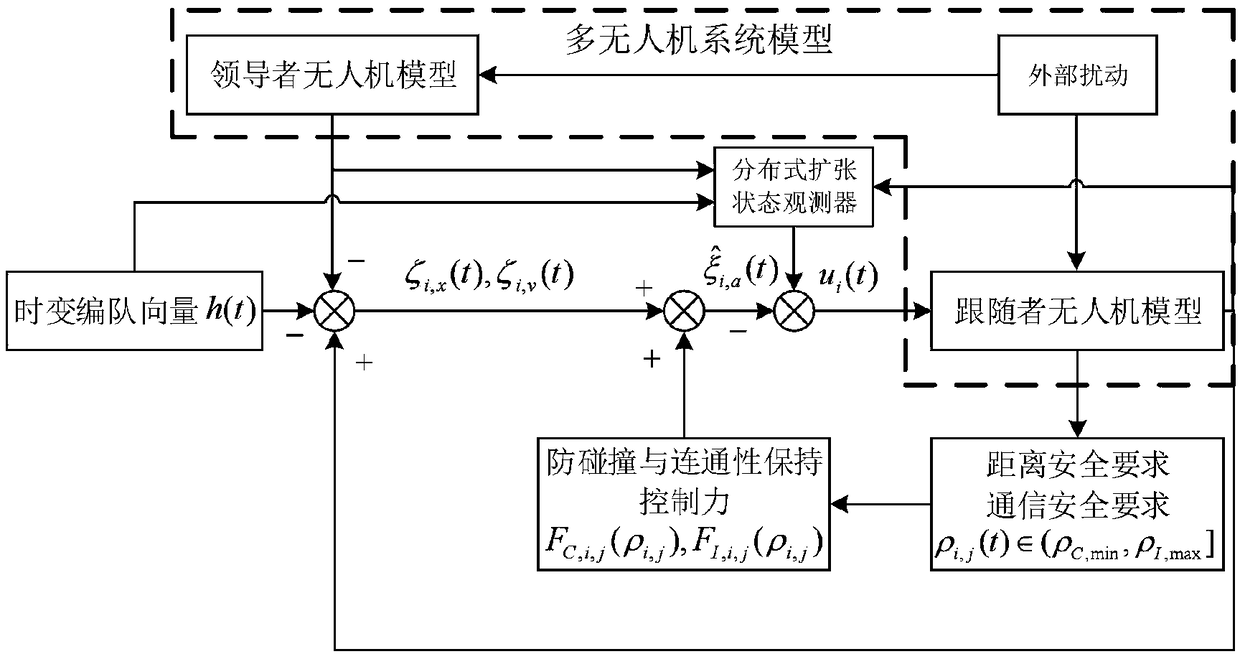

The invention discloses a tracking method and system of time-varying formation of unmanned aerial vehicles. The tracking method includes steps: obtaining a communication topology relation of formationof the unmanned aerial vehicles; obtaining speed data and position data of a followed unmanned aerial vehicle of a current moment; obtaining speed data and position data of a following unmanned aerial vehicle of the current moment; obtaining a communication distance threshold and a safety distance threshold of formation of the unmanned aerial vehicle; determining an attraction and a repulsion between the following unmanned aerial vehicle and the followed unmanned aerial vehicle according to the position data of the followed unmanned aerial vehicle and the position data of the following unmanned aerial vehicle at the current moment, the communication distance threshold and the safety distance threshold; determining acceleration data of the following unmanned aerial vehicle at a next moment; and adjusting the motion state of the following unmanned aerial vehicle following the followed unmanned aerial vehicle at the next moment according to the acceleration data of the following unmannedaerial vehicle at the next moment. By employing the tracking method and system, the formation tracking effects of anti-collision and connectivity maintenance can be realized.

Owner:BEIHANG UNIV

Method and device for remotely monitoring SAGD (steam assisted gravity drainage) horizontal well

The invention relates to a method and a device for remotely monitoring an SAGD (steam assisted gravity drainage) horizontal well. An MGT (metal gate transistor) magnetic source is placed on a target position of a producing well after drilling completion, an MWD (measuring while drilling) device with an additionally-mounted MGT magnetic-induction sensor is placed in a gas injection well during drilling, the MGT magnetic source and the MWD device are combined to measure the size of a magnetic field generated by the MGT magnetic source and measure and calculate well track relative positions between the gas injection well and the producing well and calculate well track interval by using measured hole drift angles, azimuth angles and well depth variation, vector parallelism of the two wells is monitored integrally. By adopting the mode of matched using of MWD and MGT, well track parameters are measured in real time, and a variation trend curve chart can be displayed in monitoring software in real time; the well track interval is calculated by applying a novel algorithm through data analysis on the basis of a database, and well track collision preventing and deviation prewarning are realized; and fused comparison of static data and MWD data is realized, and well site and base monitoring integration is realized.

Owner:SOUTHWEST PETROLEUM UNIV

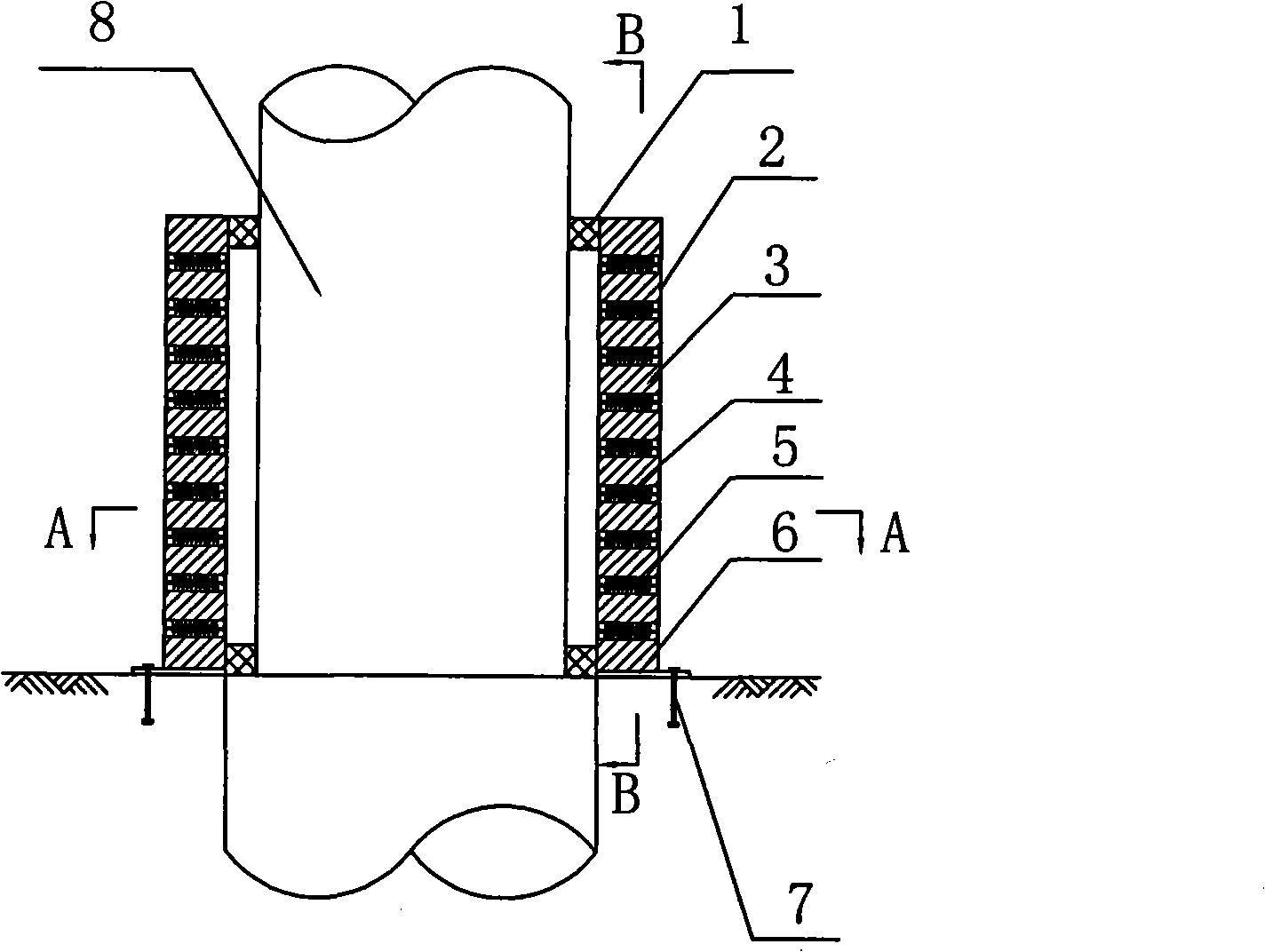

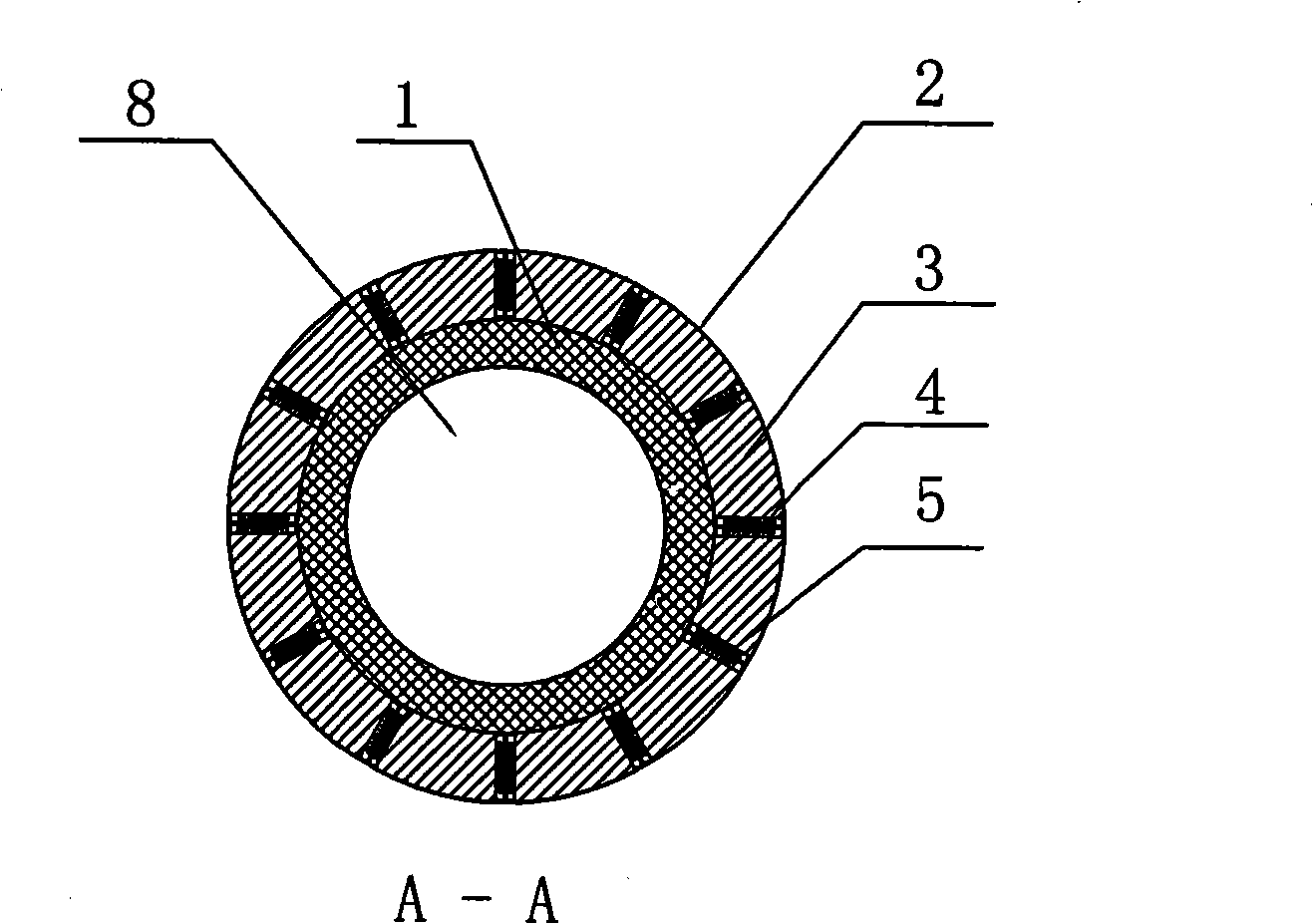

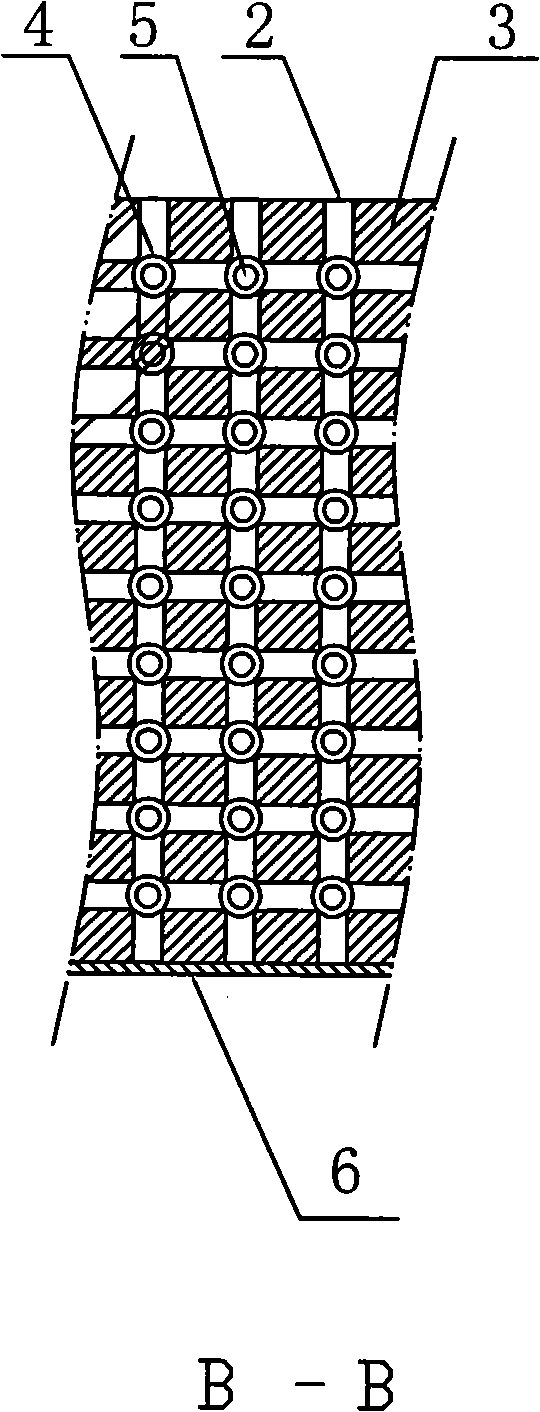

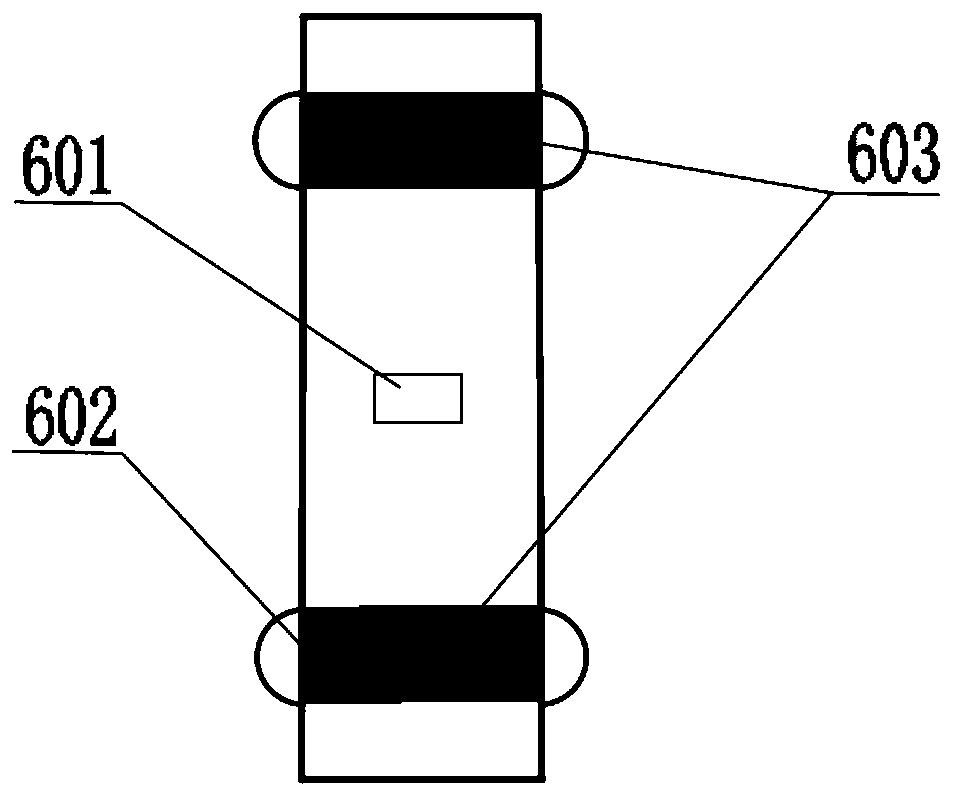

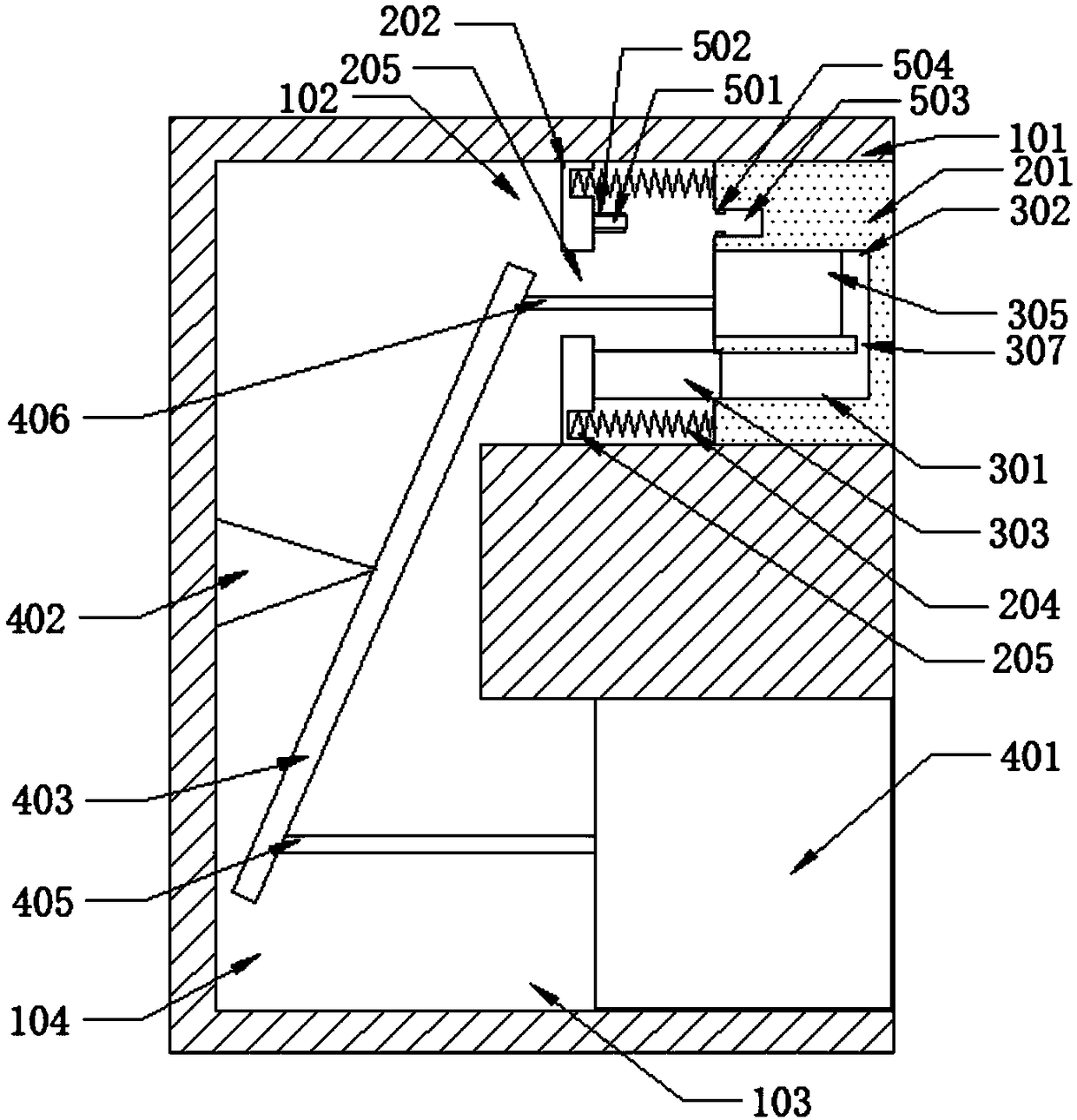

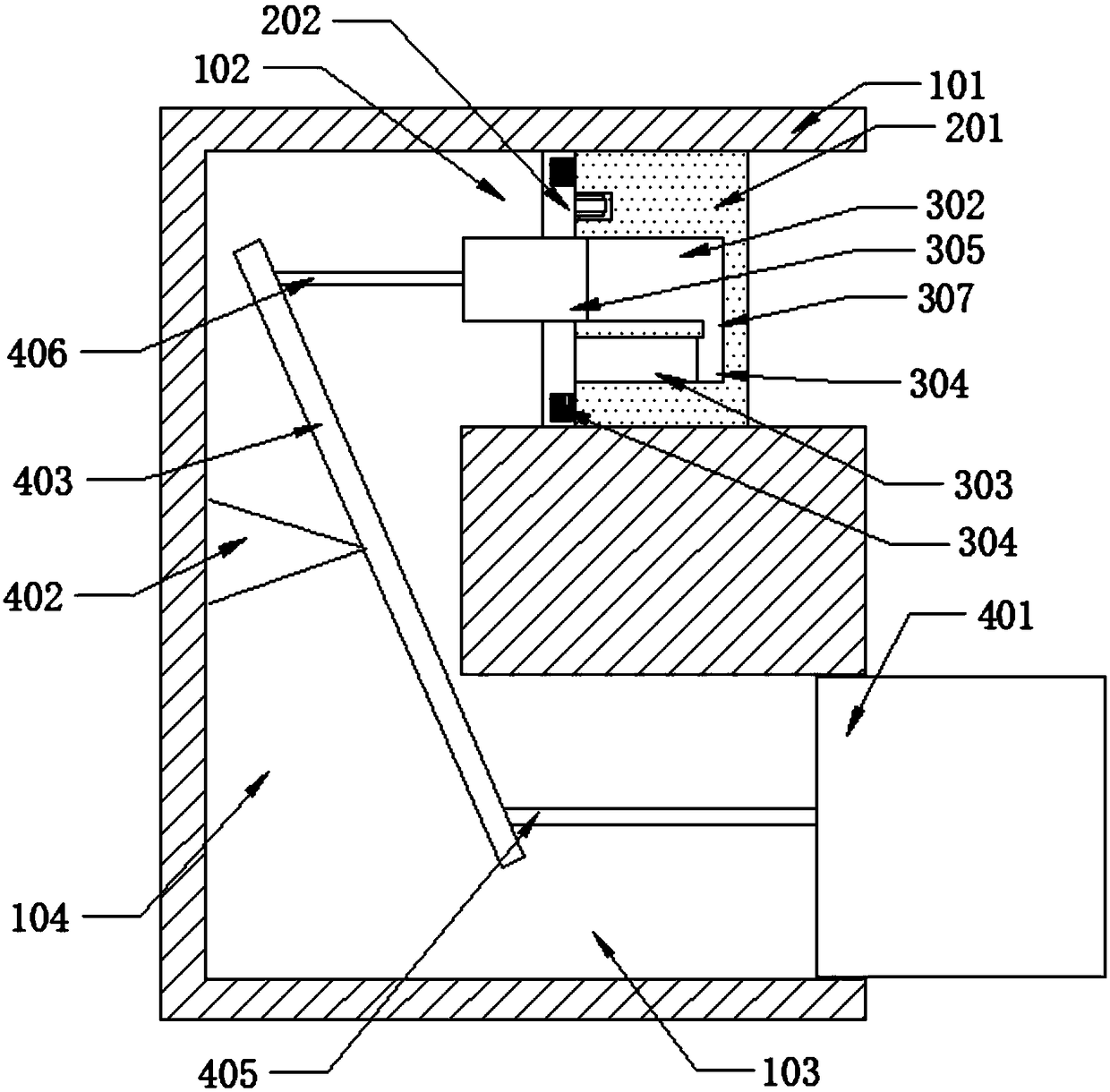

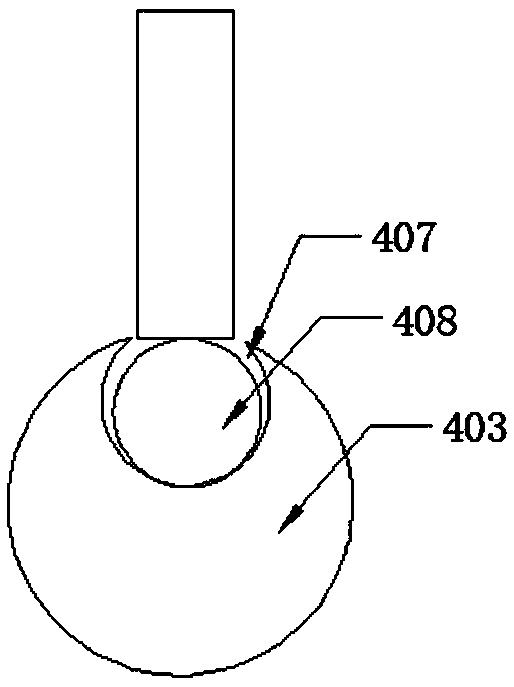

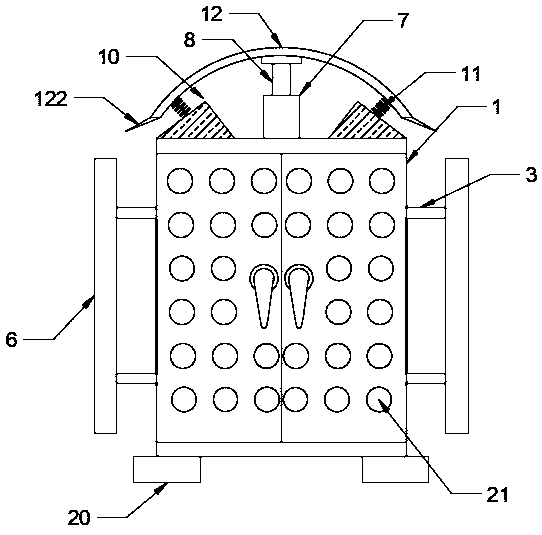

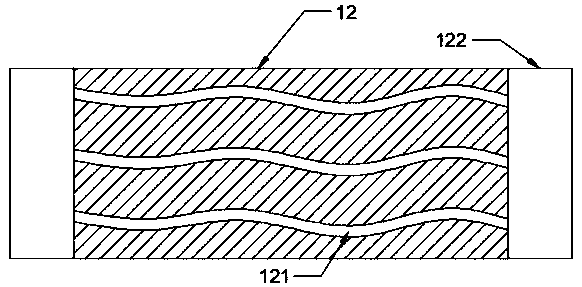

Flexible energy dissipation type pier anti-collision safety device with composite structure

ActiveCN101555682ARealize anti-collisionAvoid and reduce damageRoadway safety arrangementsSteel platesSheet steel

The invention relates to the technical field of a safety protection device in the bridge engineering construction, in particular to a flexible energy dissipation type pier anti-collision safety device with a composite structure. The invention aims at solving the problems that the safety of an automobile, pedestrians and a pier is difficult to be ensured when the automobile is rigidly collided with the pier in the prior art. The invention adopts a technical proposal at present: the flexible energy dissipation type pier anti-collision safety device with the composite structure comprises a steel anti-collision wall which takes the shape of a cylinder; the vertical hollow cross section of the anti-collision wall is rectangle; clamping arranged elastic energy dissipation material blocks along the horizontal direction are distributed in the anti-collision wall; a spring is arranged among every four elastic energy dissipation material blocks; the springs are horizontally clamped in the anti-collision wall; the bottom of the anti-collision wall is a base steel plate on which an anchor is arranged in a perforating way; and the upper end and the lower end of the inner side of the anti-collision wall are respectively provided with an energy dissipation piece horizontally. The invention has the advantages of: 1) high safety and good effect; 2) simple structure, easy construction, less engineering investment and convenient maintenance.

Owner:CCCC CIVIL ENG SCI & TECH

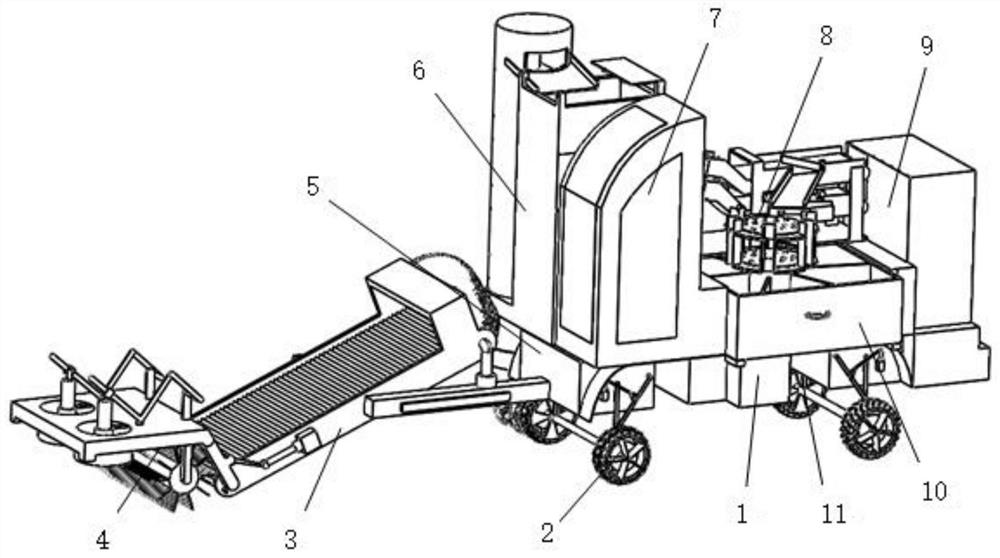

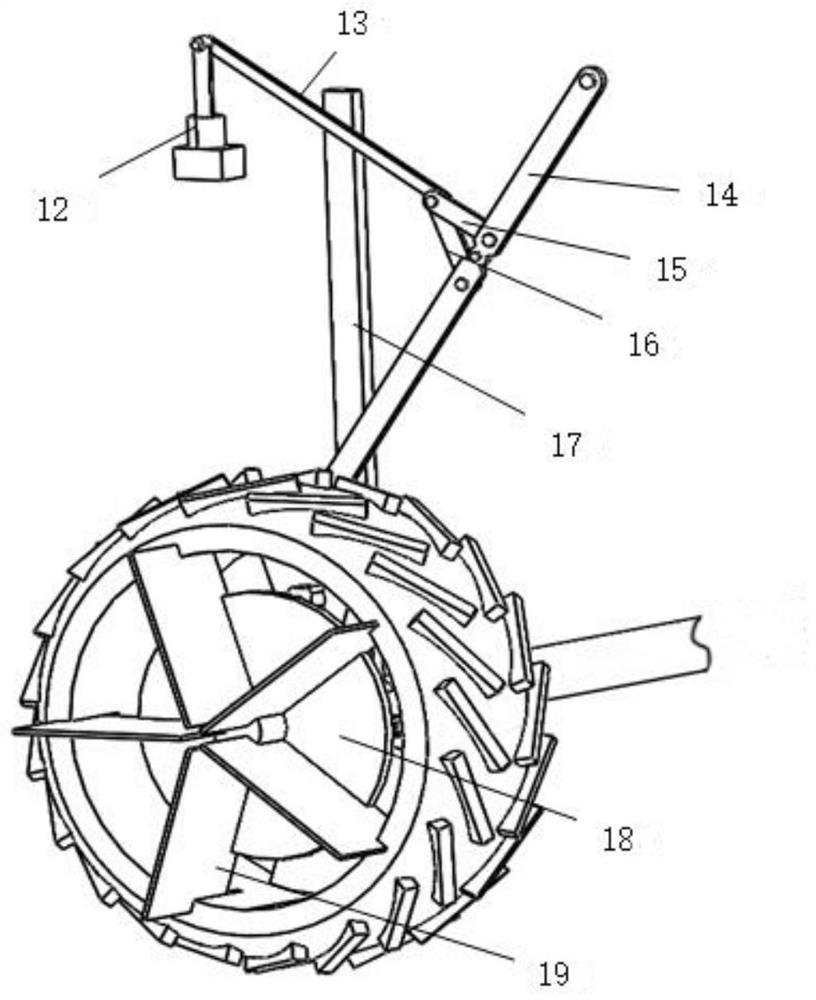

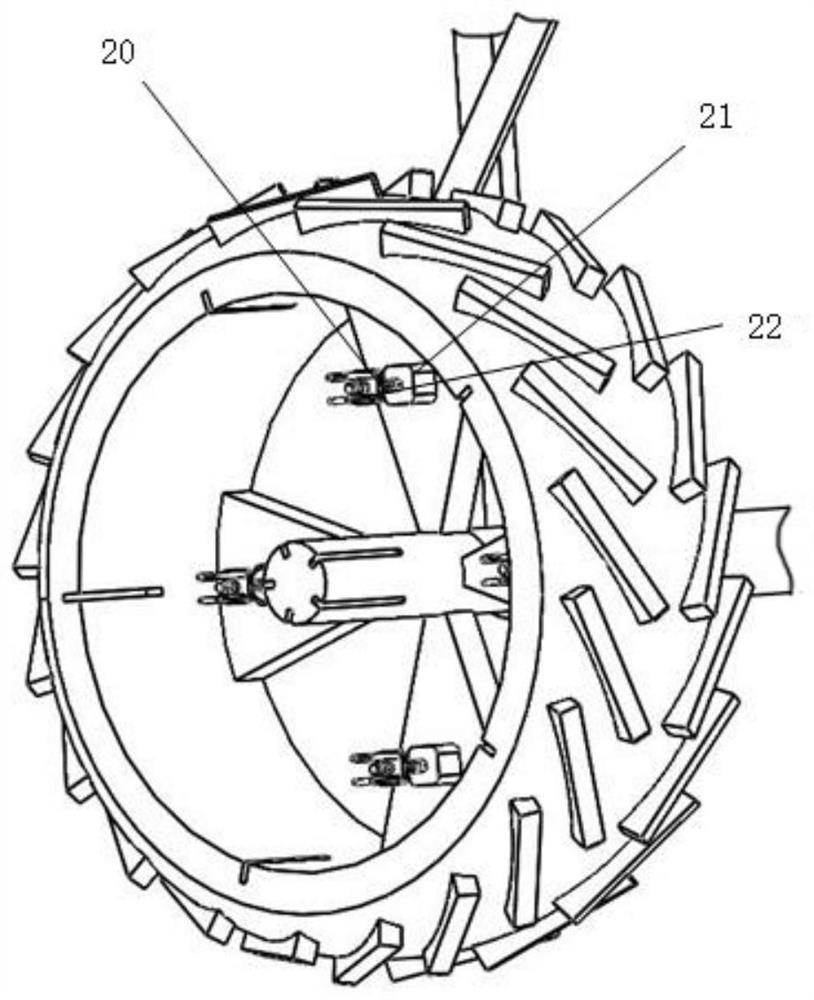

Amphibious garbage collection and classification vehicle

InactiveCN111676876AImplement classificationRealize automatic adjustmentWater cleaningMowersRefuse collectionProcess engineering

The invention discloses an amphibious garbage collection and classification vehicle. An existing cleaning vehicle cannot collect and classify garbage at the same time. The amphibious garbage collection vehicle comprises a floating device, amphibious wheels, a garbage conveying device, a garbage collection device, a vehicle body, a garbage screening device, a garbage classification device, an unrecyclable garbage recycling box and a recyclable garbage recycling box. Amphibious use is achieved, automatic adjustment of the height of the garbage collection device and automatic adjustment of the height of the garbage conveying device are achieved through sensors, so that operation under different working conditions is achieved, and grass cutting and collision prevention are achieved; classification of garbage of different volumes is achieved through the garbage screening device; classification of recyclable garbage and unrecyclable garbage by the garbage classification device is realized through a visual sensor; recyclable garbage is classified again through a wheel disc of the garbage classification device.

Owner:HANGZHOU DIANZI UNIV

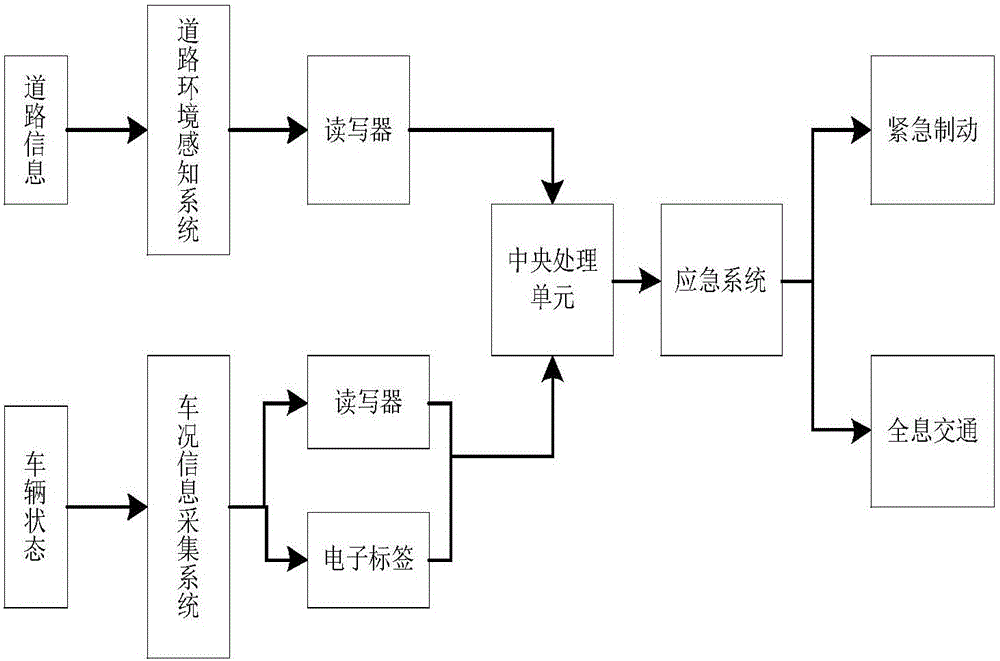

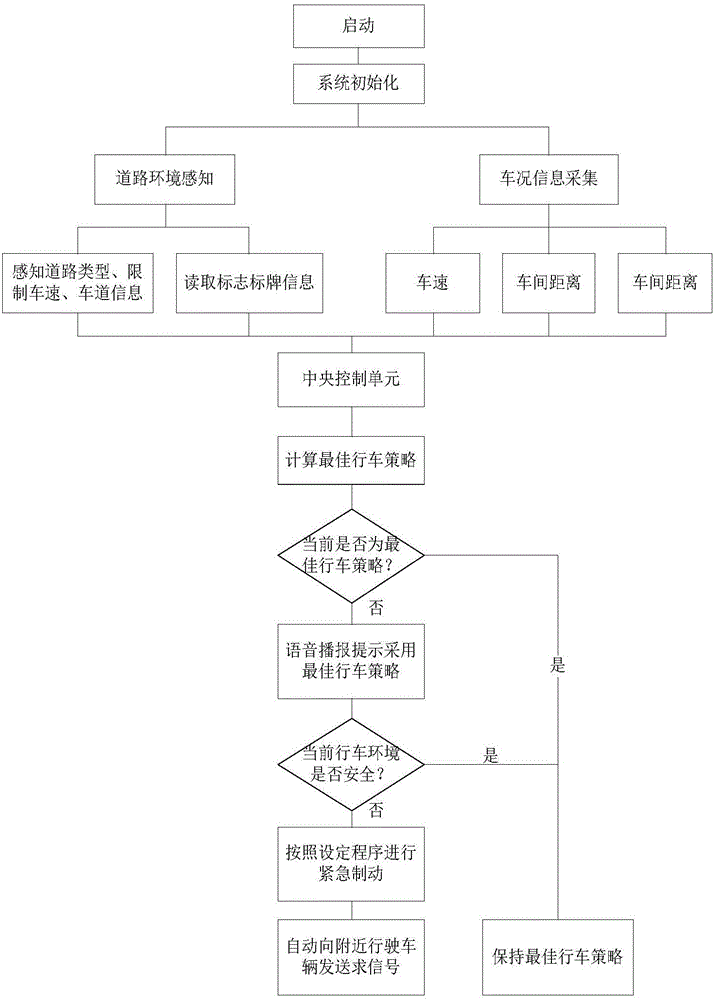

Safe driving system and method based on electronic license plate

InactiveCN106080592AImplement unique two-way interactive mappingRealize "visualization" controlExternal condition input parametersInformation spacePhysical space

The invention discloses a safe driving system and method based on an electronic license plate. According to the driving method, unique bi-directional interactive mapping from a physical space to an information space of vehicles is realized by perceiving and feeding back the current road-concerned information, operating condition information of the vehicles around a current lane and driving state information of the current vehicles in real time. Real-time driving change strategies are provided for drivers to effectively prevent the occurrence of road traffic accidents.

Owner:CHONGQING JIAOTONG UNIVERSITY

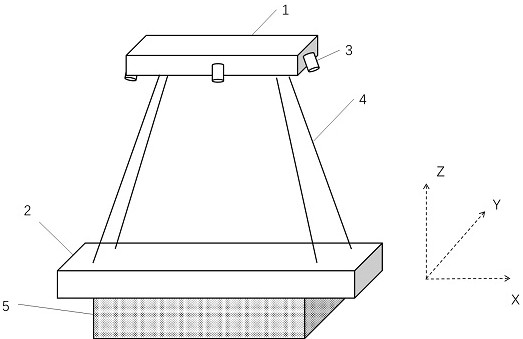

Anti-collision control method and system for stacker-reclaimer

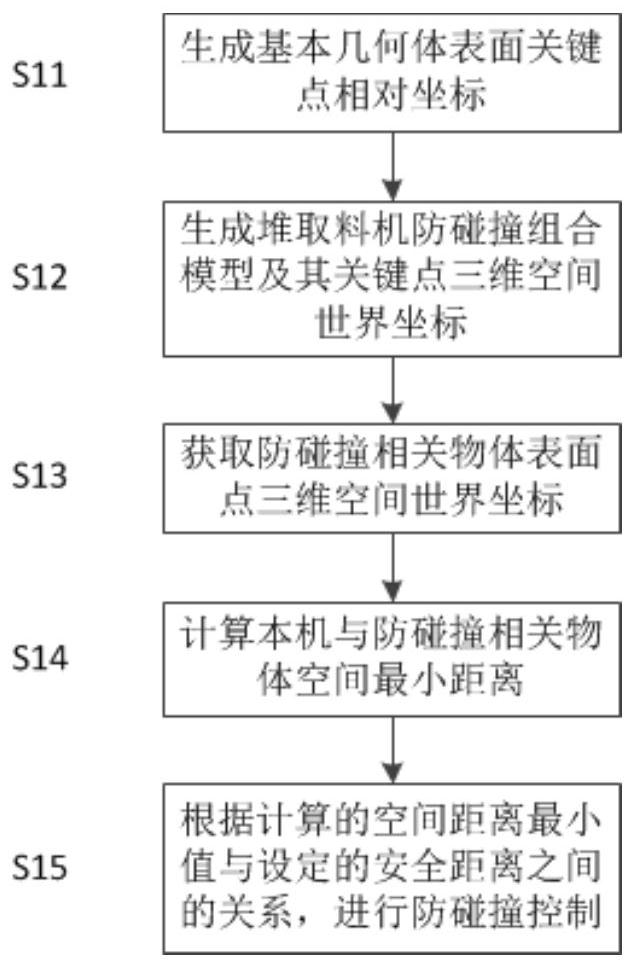

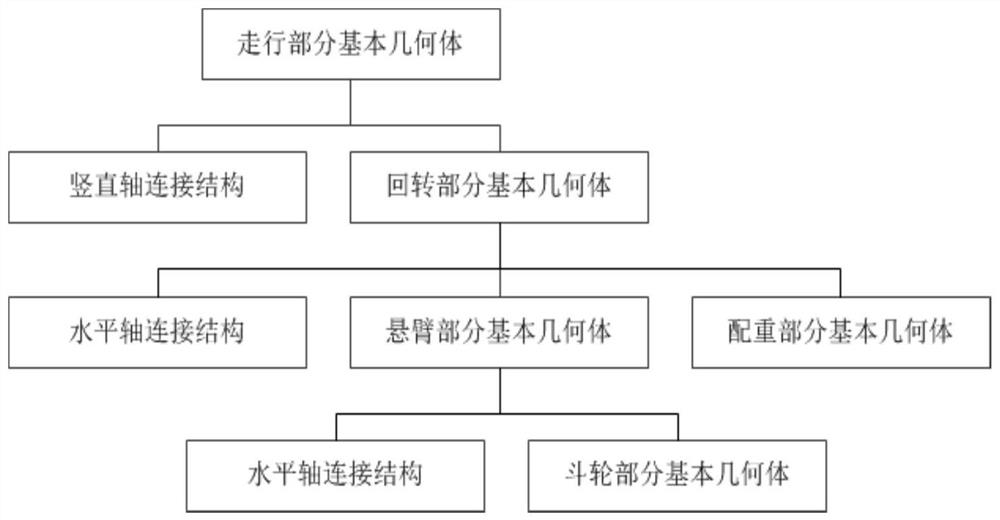

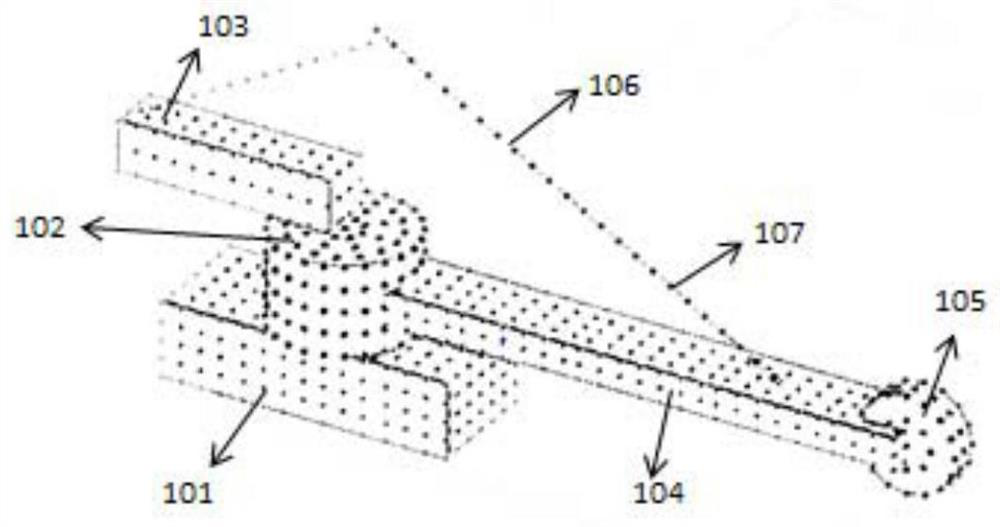

PendingCN112537661ARealize anti-collision in three-dimensional spaceRealize fully automatic collision avoidanceConveyorsControl devices for conveyorsThree-dimensional spaceStructural engineering

The invention discloses an anti-collision control method and system for a stacker-reclaimer. The anti-collision control method comprises the steps that a basic geometry comprising a mechanical structure is extracted according to the geometrical characteristics of the stacker-reclaimer, a key point is generated on the surface of the basic geometry, and the relative coordinates p1 of the key point are obtained; an anti-collision combination model of the stacker-reclaimer is established, and a three-dimensional space world coordinate p2 of the key point is calculated according to the combinationmode of the combination model and the mechanical size of the stacker-reclaimer; a three-dimensional space world coordinate p3 of the key point after walking, rotating and pitching actions of the stacker-reclaimer is calculated, and a world coordinate Q of a surface point of an anti-collision related object in a three-dimensional space is obtained; the spatial distance between the three-dimensionalspace world coordinates P of all the key points and the world coordinates Q of the surface points of the anti-collision related object in the three-dimensional space is calculated, and a minimum value of the spatial distance is obtained; and anti-collision control is conducted according to the minimum value of the spatial distance and a set safety distance.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

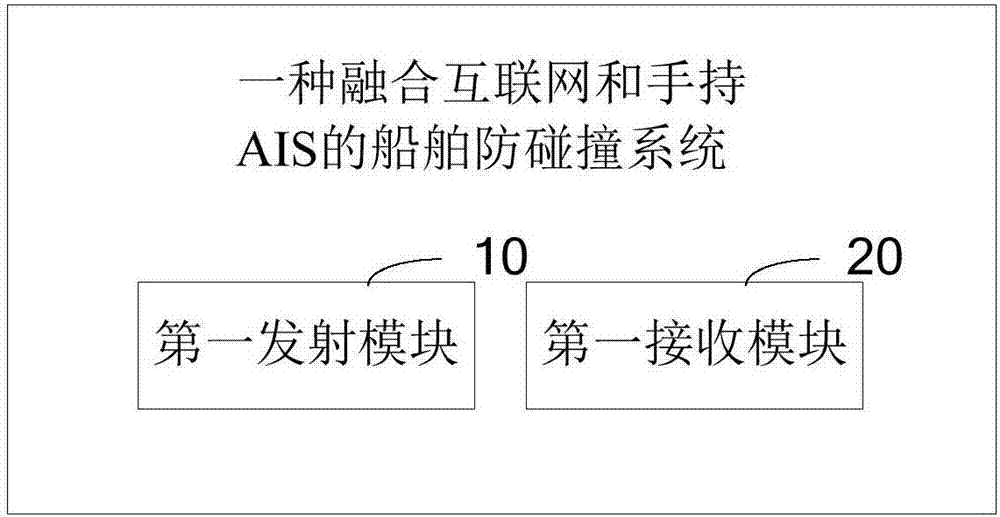

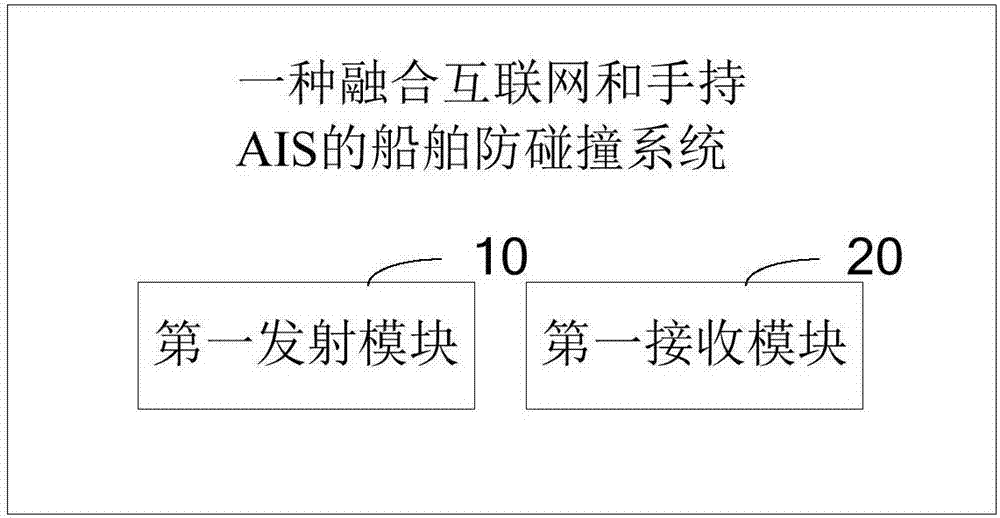

Ship collision avoidance method and system with integration of Internet and handheld AIS

InactiveCN107248322AIncreased power lossReduce power lossMarine craft traffic controlTelecommunicationsThe Internet

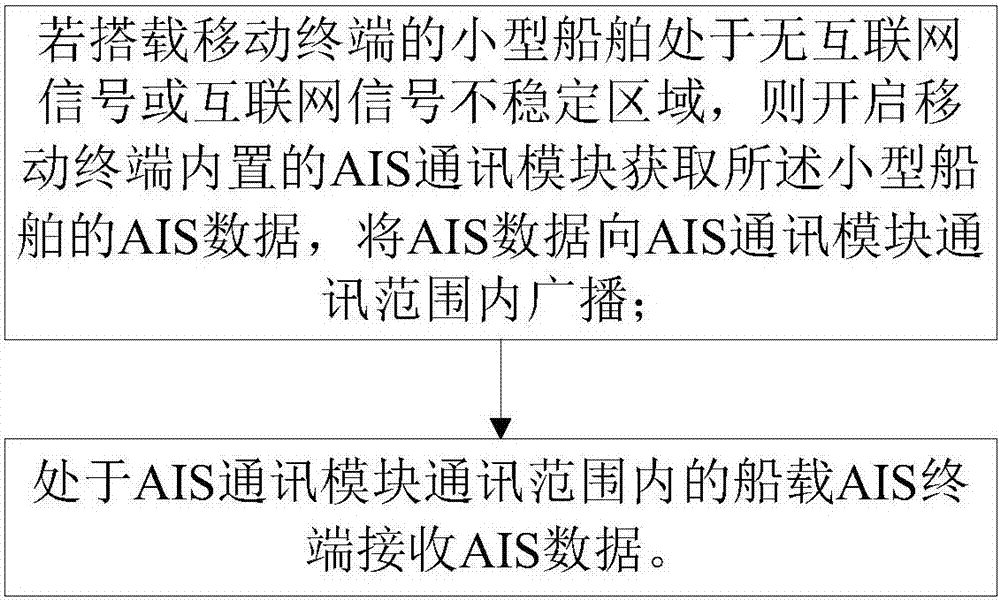

The invention relates to the field of the Internet and particularly relates to a ship collision avoidance method and system with the integration of the Internet and a handheld AIS. The method comprises a step of starting a built-in AIS communication module in a mobile terminal to obtain AIS data of a small ship if the small ship equipped with the mobile terminal is in an area without an Internet signal or with an instable Internet signal, and spreading the AIS data to an AIS communication module communication range; allowing a shipborne AIS terminal in the AIS communication module communication range to receive AIS data, a step of starting the built-in AIS communication module in the mobile terminal if the small ship is in the area without an Internet signal or with an instable Internet signal, and using very high frequency to communicate with the shipborne AIS terminal in the AIS communication module communication range to realized the collision avoidance of the small ship, and a step of closing the AIS communication module if the small ship is in the area with a stable Internet signal and starting an Internet AIS collision avoidance mode to realize the collision avoidance of the small ship.

Owner:FUJIAN NORTH STAR GALAXY COMM CO LTD

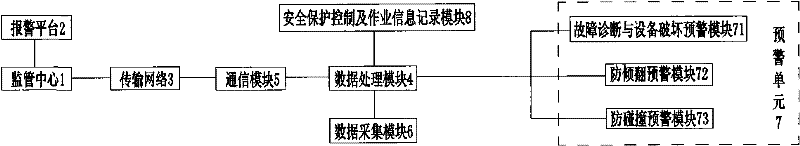

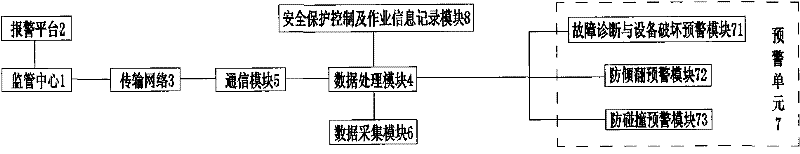

Intelligent early warning system for tower type crane

InactiveCN102530750ARealize remote early warning functionRealize anti-collision warning functionCranesData acquisitionDeep level

The invention discloses an intelligent early warning system for a tower type crane. The intelligent early warning system comprises a supervision center, an alarming platform, a transmission network, a data processing module, a communication module, a data acquisition module and an early warning unit, wherein the alarming platform and the transmission network are respectively connected with the supervision center; the data processing module is connected to the transmission network through the communication module; and the data acquisition module and the early warning unit are respectively connected with the data processing module. According to the intelligent early warning system disclosed by the invention, safety early warning equipment of the tower type crane is combined with wireless communication, so that the remote early warning function of the tower type crane is achieved and a technical support for deep-level fault diagnosis and performance estimation is provided; meanwhile, the multi-system cooperative work and multi-tower collision-preventing early warning function based on wireless communication of a local area network are achieved.

Owner:常州益利亚重工机械科技有限公司

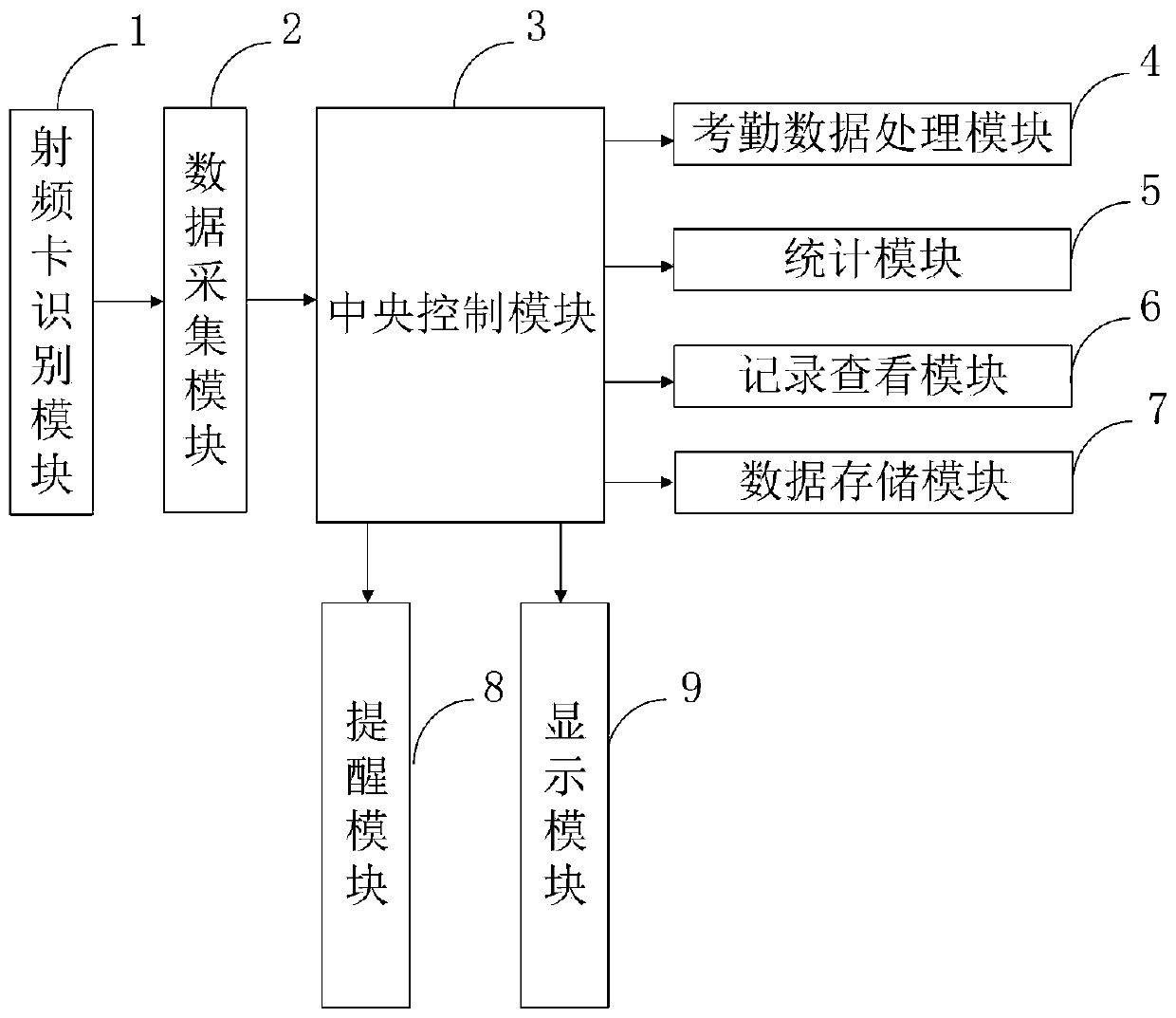

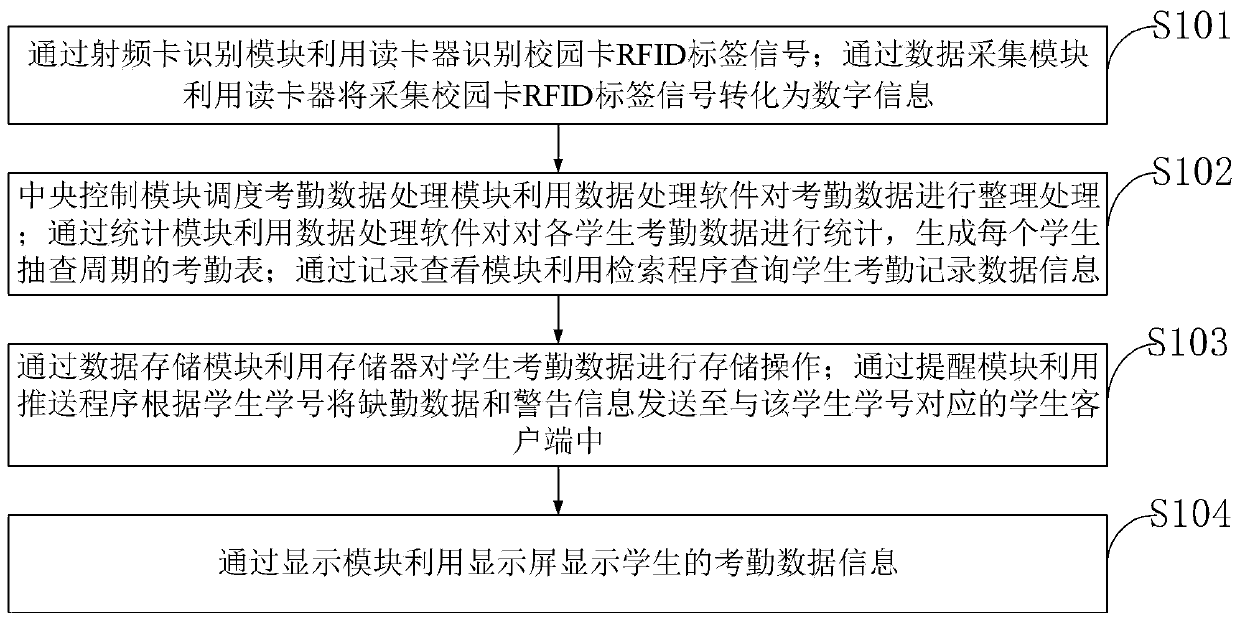

RF technology based electronic attendance system and method specially used for students

InactiveCN109949432ARealize anti-collisionAvoid Privacy LeakageRegistering/indicating time of eventsDatabase distribution/replicationPasswordSoftware engineering

The invention discloses an RF technology based electronic attendance system and method specially used for students, and belongs to the technical field for student attendance. The system comprise an RFcard identification module, a data acquisition module, a central control module, an attendance data processing module, a statistics module, a record checking module, a data storage module, a prompting module and a display module. The RF card identification module divides information in an RFID label of a campus card into three authority levels that password is not needed, password is needed for verification, and password as well as face / fingerprint is needed for verification, verification may not need password or need strengthened password in different occasions, and convenient and rapid useof the campus card is kept while the privacy and interests of a card owner are protected; the attendance data processing module does not cause system abnormity due to small size of a file, and normalsystem operation is ensured; and the query performance for the attendance data is improved.

Owner:BEIHUA UNIV

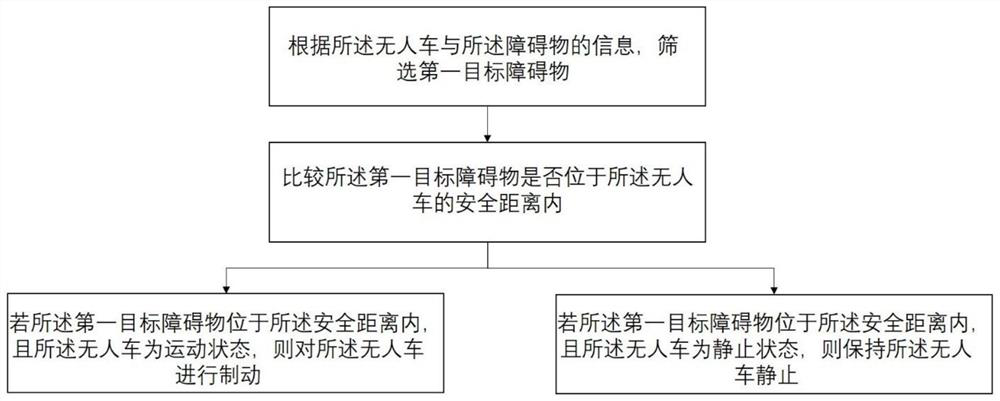

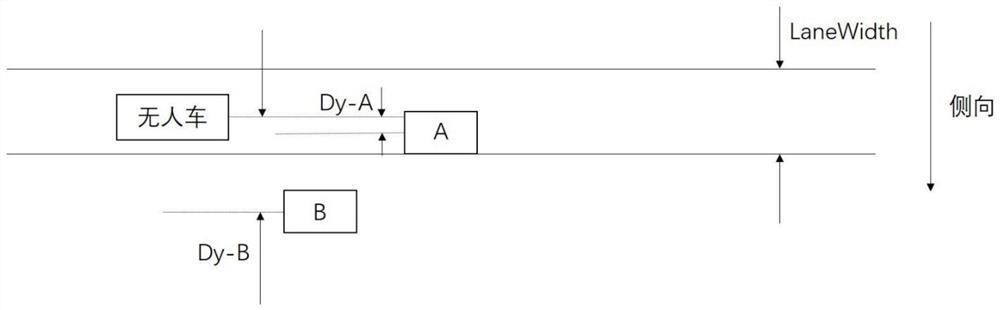

Anti-collision method for unmanned vehicle

ActiveCN111703420AAvoid false braking and false startRealize anti-collisionSpeed controllerAutomatic initiationsRolloverControl engineering

The invention relates to the field of unmanned vehicles, namely the field of unmanned driving or automatic driving, in particular to an anti-collision method for an unmanned vehicle. The method comprises the following steps of: acquiring obstacle information around the unmanned vehicle; screening a first target obstacle according to the information of the unmanned vehicle and the obstacle; comparing whether the first target obstacle is located within the safe distance of the unmanned vehicle or not; if the first target obstacle is located within the safe distance and the unmanned vehicle is ina moving state, the unmanned vehicle is braked; and if the first target obstacle is located within the safe distance and the unmanned vehicle is in a stationary state, the unmanned vehicle kept stationary. According to the method, the target can be accurately screened, slow braking of the unmanned vehicle can be achieved, and rollover caused by braking is avoided.

Owner:NEOLIX TECH CO LTD

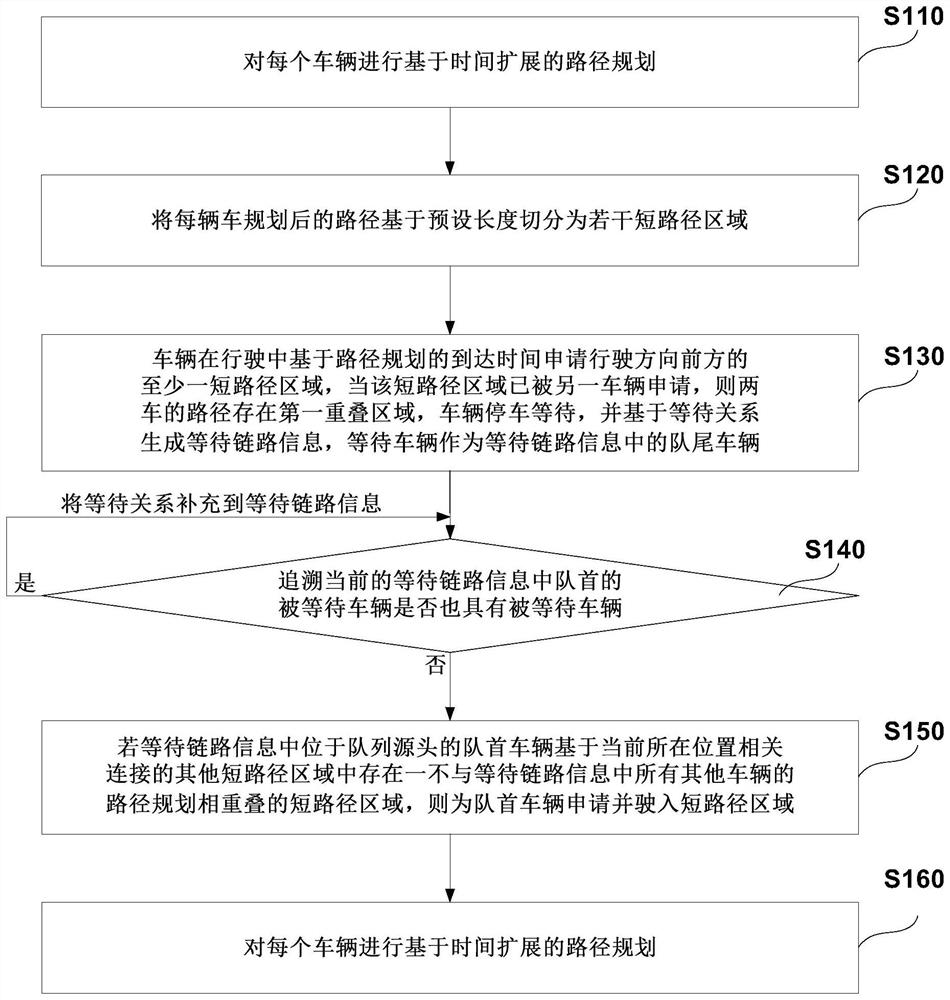

Multi-vehicle anti-deadlock method, system and equipment based on short path, and storage medium

PendingCN113899383ARealize anti-collisionImprove transportation efficiencyInstruments for road network navigationNavigational calculation instrumentsSimulationPath plan

The invention provides a multi-vehicle anti-deadlock method, system and equipment based on a short path, and a storage medium. The method comprises the following steps: performing path planning based on time extension on each vehicle; segmenting the planned path of each vehicle into a plurality of short path areas based on a preset length; enabling the vehicle to apply for at least one short-path area in front of the driving direction based on the passing time of the path planning in the driving process, and when an overlapping area exists, generating waiting link information; tracing the vehicle at the head of the queue of the current waiting link information, and supplementing the waiting link information; if the vehicle at the head of the queue can obtain a short-path area which is not overlapped with the path plans of all other vehicles in the waiting link information, applying for the vehicle at the head of the queue and driving into the short-path area; and after the vehicle at the tail of the queue passes through the overlapping area, releasing the vehicle at the head of the queue in the waiting link information. The method, the system and the equipment can be applied to path collaborative planning among multiple unmanned vehicles, deadlock is effectively prevented, vehicle collision prevention and deadlock avoidance are achieved, and the overall transportation efficiency of a motorcade is improved.

Owner:SHANGHAI WESTWELL INFORMATION & TECH CO LTD

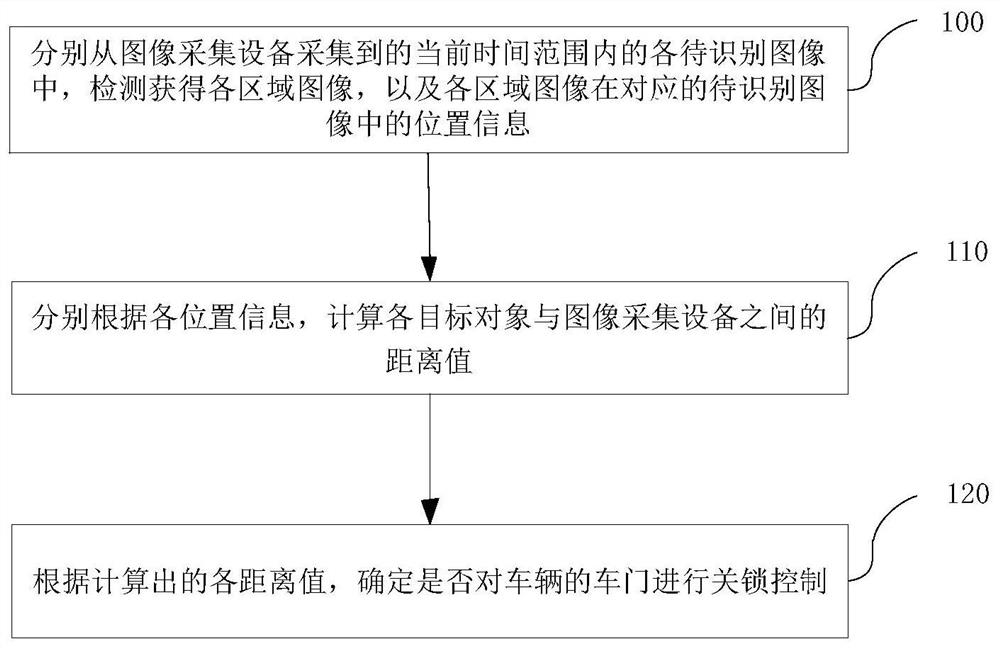

Vehicle door lock control method and device

InactiveCN112561967ARealize anti-collisionImplement anti-collision controlImage enhancementImage analysisAcquisition apparatusEngineering

The invention relates to the technical field of vehicle safety protection, in particular to a vehicle door lock control method and device, and the method comprises the steps of obtaining each region image and the position information of each region image in a corresponding to-be-recognized image through detection from each to-be-recognized image, collected by image collection equipment, in a current time range, wherein the region image comprises a target object, and the image acquisition equipment faces the advancing direction of the target object; calculating a distance value between each target object and the image acquisition equipment according to each piece of position information; and according to the calculated distance values, determining whether locking control is carried out on the vehicle door of the vehicle or not, so that anti-collision control over the vehicle door can be achieved on the premise that the cost is low.

Owner:NANJING LINGXING TECH CO LTD

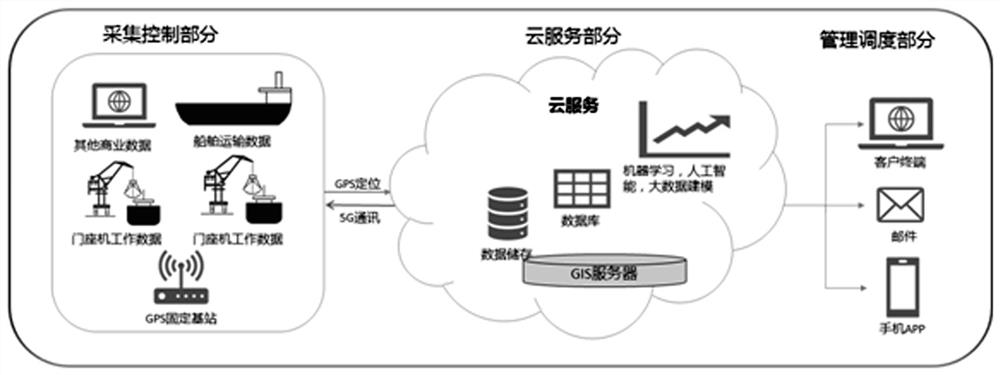

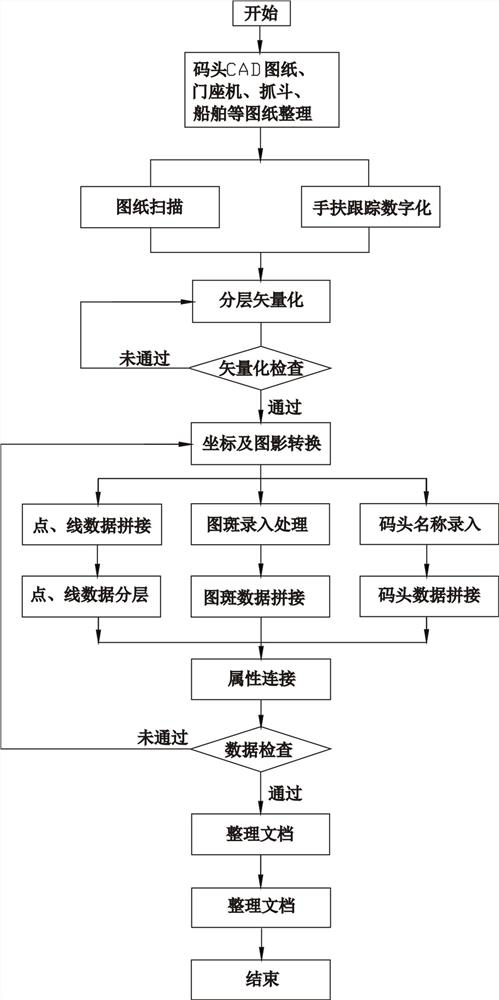

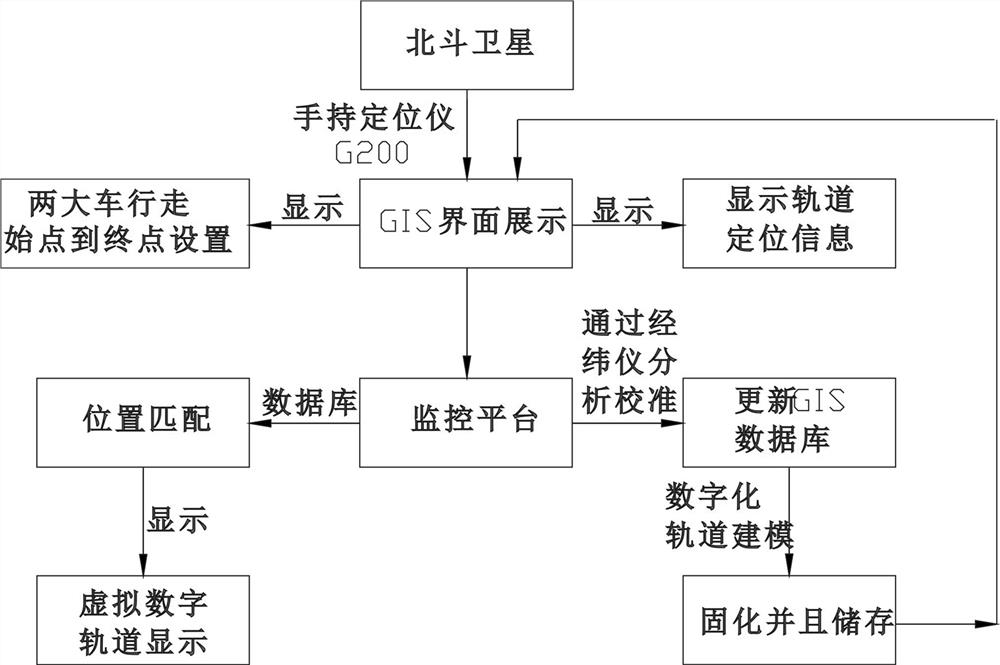

Remote control system for gantry crane

PendingCN112758827ARealize the whole process of digital operationAutomate operationsSafety gearTechnical supportGantry crane

The invention relates to a remote control system for a gantry crane. The remote control system comprises a cloud server platform, a client, a remote control operation table, a fixed base station, a gantry machine monitoring terminal, a grab bucket monitoring part and a bow and stern positioning device. The cloud server platform is connected with the client and the remote control operation table through a fifth switch. The cloud server platform is connected with the portal machine monitoring terminal through a 5G communication module, and the portal machine monitoring terminal is connected with the grab bucket monitoring part. The portal machine monitoring terminal, the grab bucket monitoring part and the bow and stern positioning device are all in communication connection with the fixed base station. According to the remote control system for the gantry crane, remote control of the gantry crane is achieved, communication networking with a production dispatching system can be achieved, and the technical support is provided for unmanned operation of a wharf, cost reduction and efficiency improvement.

Owner:宜昌市创星电子技术发展有限公司

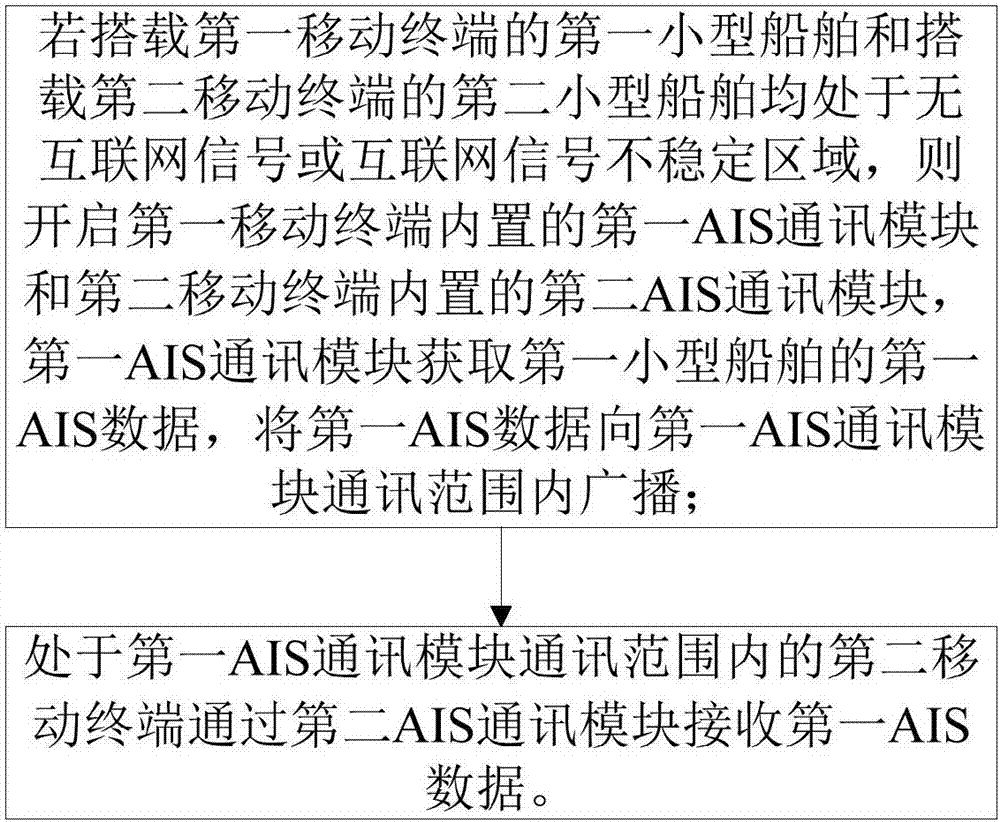

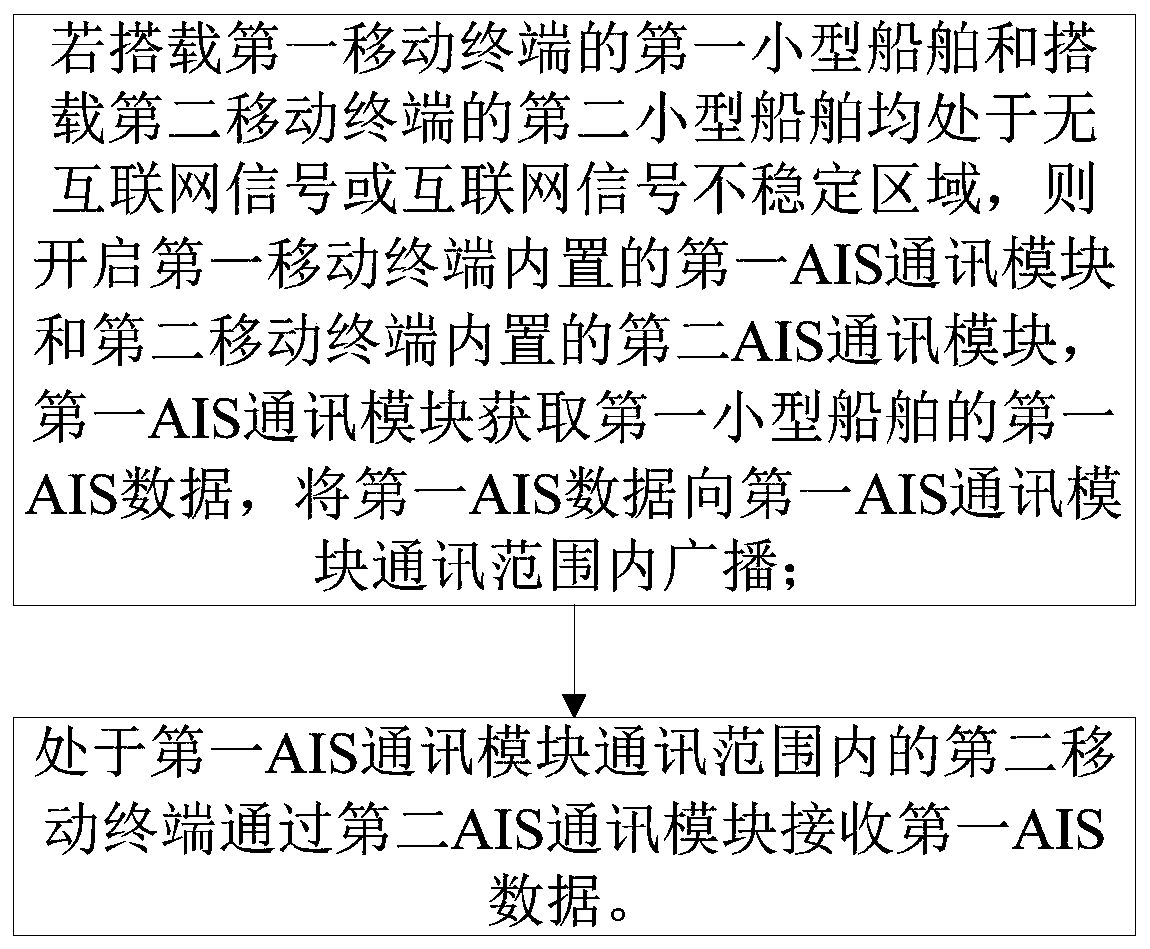

Combined internet and handheld AIS (automatic identification system) marine anti-collision method and system

ActiveCN107103789ARealize anti-collisionIncreased power lossPower managementMarine craft traffic controlTelecommunicationsThe Internet

The invention relates to the field of internet, in particular to a combined internet and handheld AIS (automatic identification system) marine anti-collision method and system; the method comprises: if both a first small ship carrying a first mobile terminal and a second small ship carrying a second mobile terminal are in an area with no internet signal or with instable signal, starting a first AIS communication module built in the first mobile terminal and a second AIS communication module built in the second mobile terminal so that the first AIS communication module acquires first AIS data of the first small ship and broadcasts the first AIS data to a communication range of the first AIS communication module; when the small ships are in the area with zero internet signal or with instable internet signal, starting the first AIS communication module to use very high frequency to communicate second mobile terminals of other small ships in the communication range of the first AIS communication module so that collision of the small ships is prevented.

Owner:FUJIAN NORTH STAR GALAXY COMM CO LTD

Crane with anti-collision control system

ActiveCN112978579ARealize large-scale anti-collision controlRealize anti-collisionSafety gearControl systemMechanical engineering

The invention discloses a crane with an anti-collision control system. The crane is characterized in that the crane is started; a positioning camera is started, and a buckle plate is positioned and leveled through a standard database; and the anti-collision control system is started, and all-around anti-collision protection on an inhaul cable, the buckle plate and a container is formed by rotating a laser radar. By means of the method, all-around protection can be achieved, particularly the thin inhaul cable can be protected, and the safety problem is avoided.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

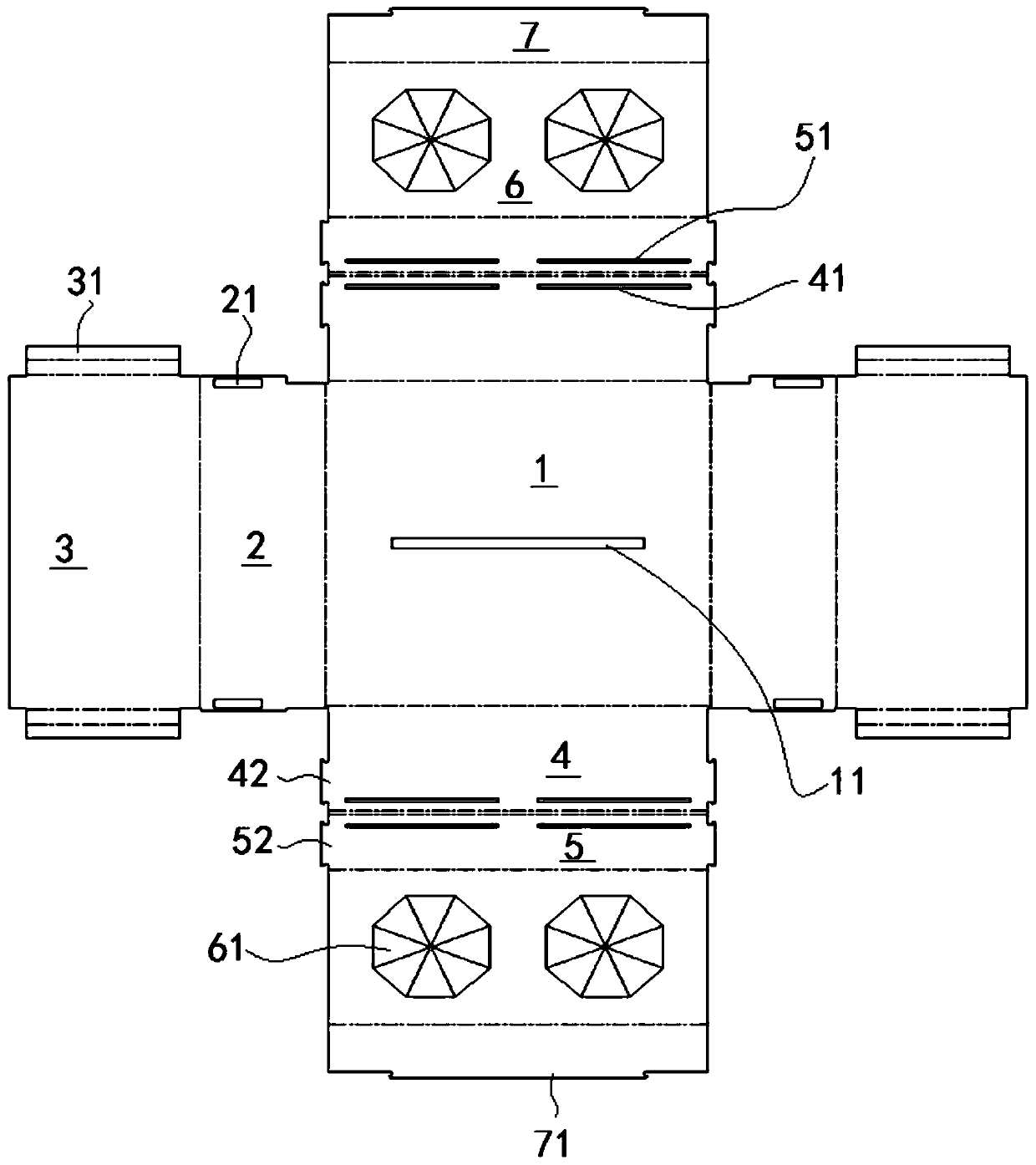

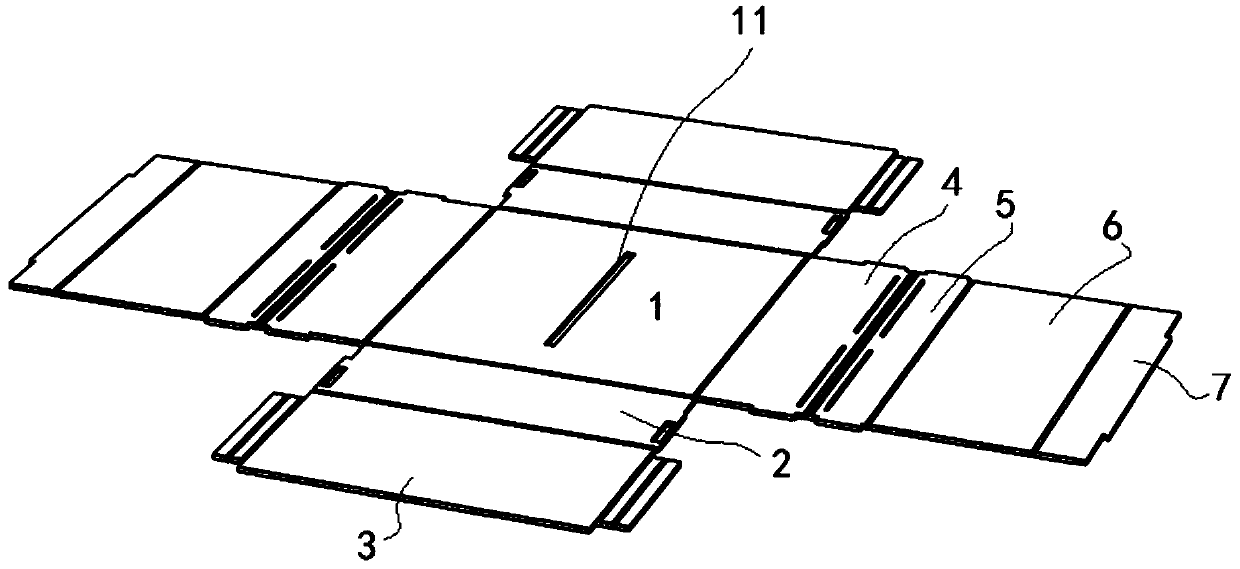

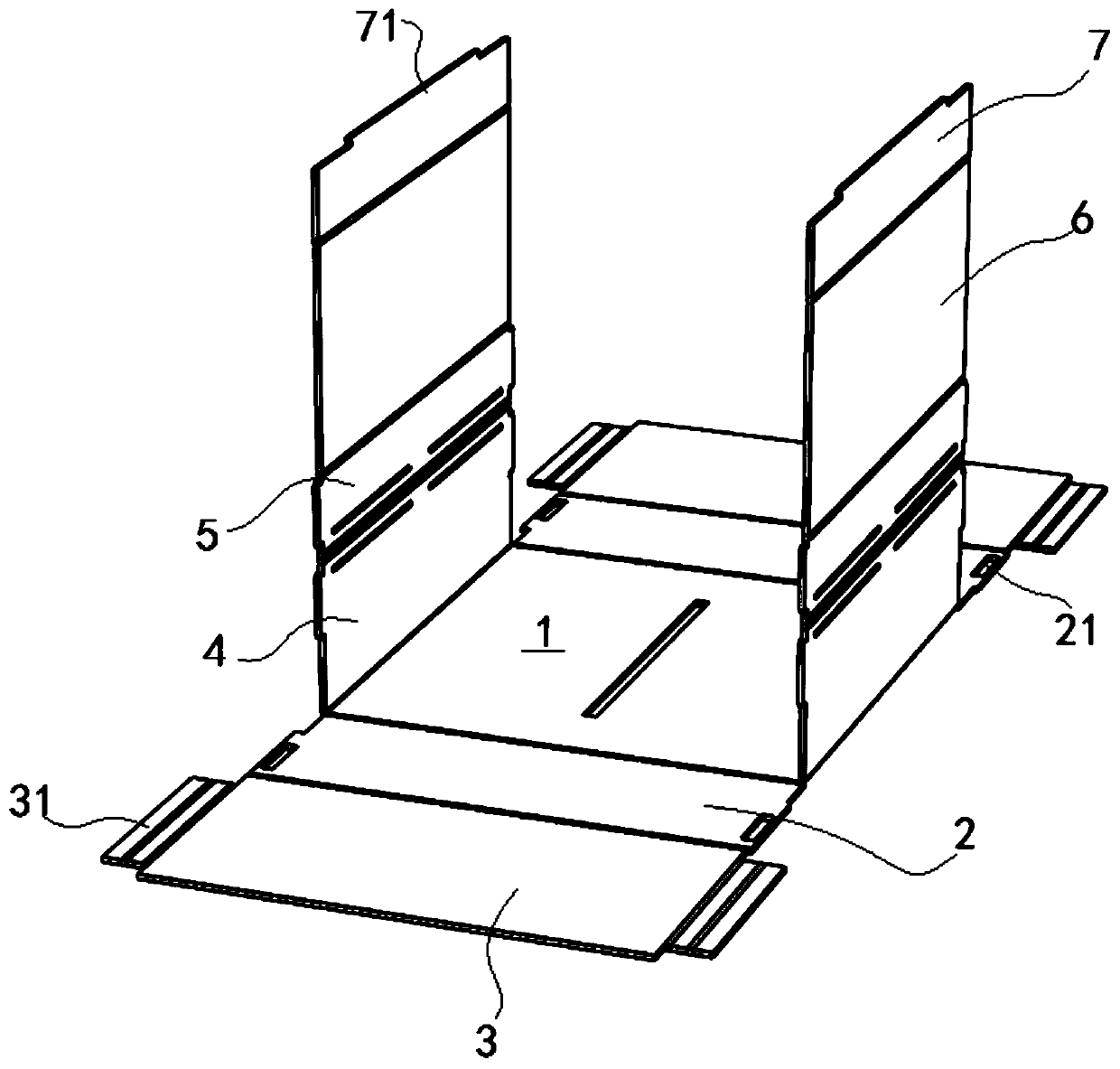

Tape-free buckle type protective transport packing box

PendingCN109987306ARealize anti-collisionImprove buffering effectRigid containersEngineeringSurface plate

Owner:GUANGDONG UNIV OF TECH

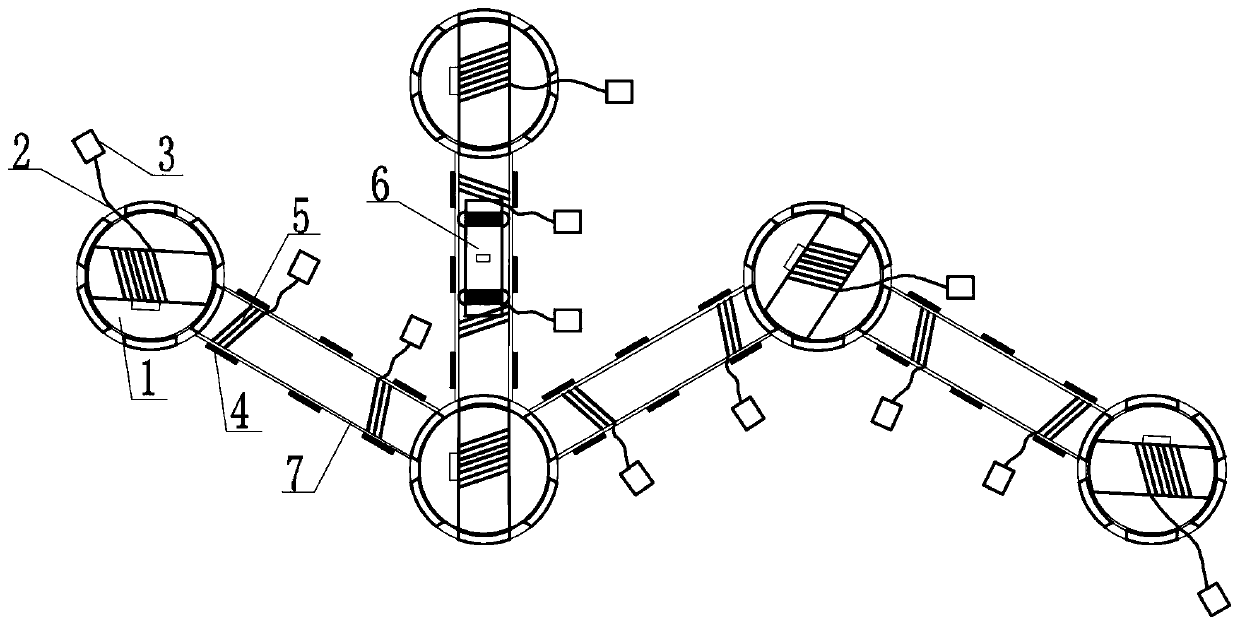

Railway cold chain logistics electromagnetic node reversing pipeline system and control method

PendingCN110104442AImplement pipeliningAvoid collisionControl devices for conveyorsNon-mechanical conveyorsCold chainLogistics management

The invention discloses a railway cold chain logistics electromagnetic node reversing pipeline system. Railway cold chain logistics distribution bases and / or upstream and downstream are connected through a cold chain transmission pipeline. The system further comprises multi-hole steering bases; the multi-hole steering bases are provided with steering tables for steering cold chain containers, andthe steering tables are configured to rotatably switch, receive and deliver the cold chain containers among different hole positions; and the railway cold chain logistics pipeline system further comprises an electromagnetic acceleration and deceleration unit used for carrying out electromagnetic deceleration stop on the approaching cold chain containers as well as electromagnetic acceleration start on the cold chain containers to be delivered in a goods parking bin. Path planning of the different cold chain containers is achieved through coordination and control, and collision between the coldchain containers is avoided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Novel active radio frequency identifying system and its operation method

InactiveCN101051356BImprove anti-interference abilityHigh sensitivityCo-operative working arrangementsSensing record carriersEngineeringRadio frequency

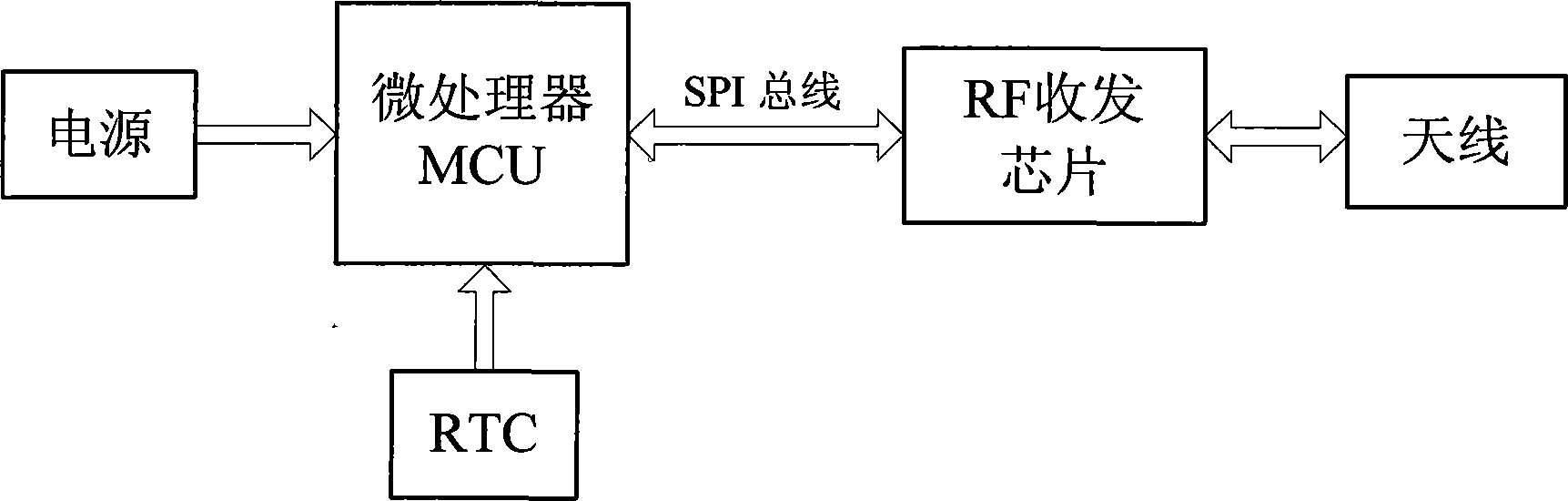

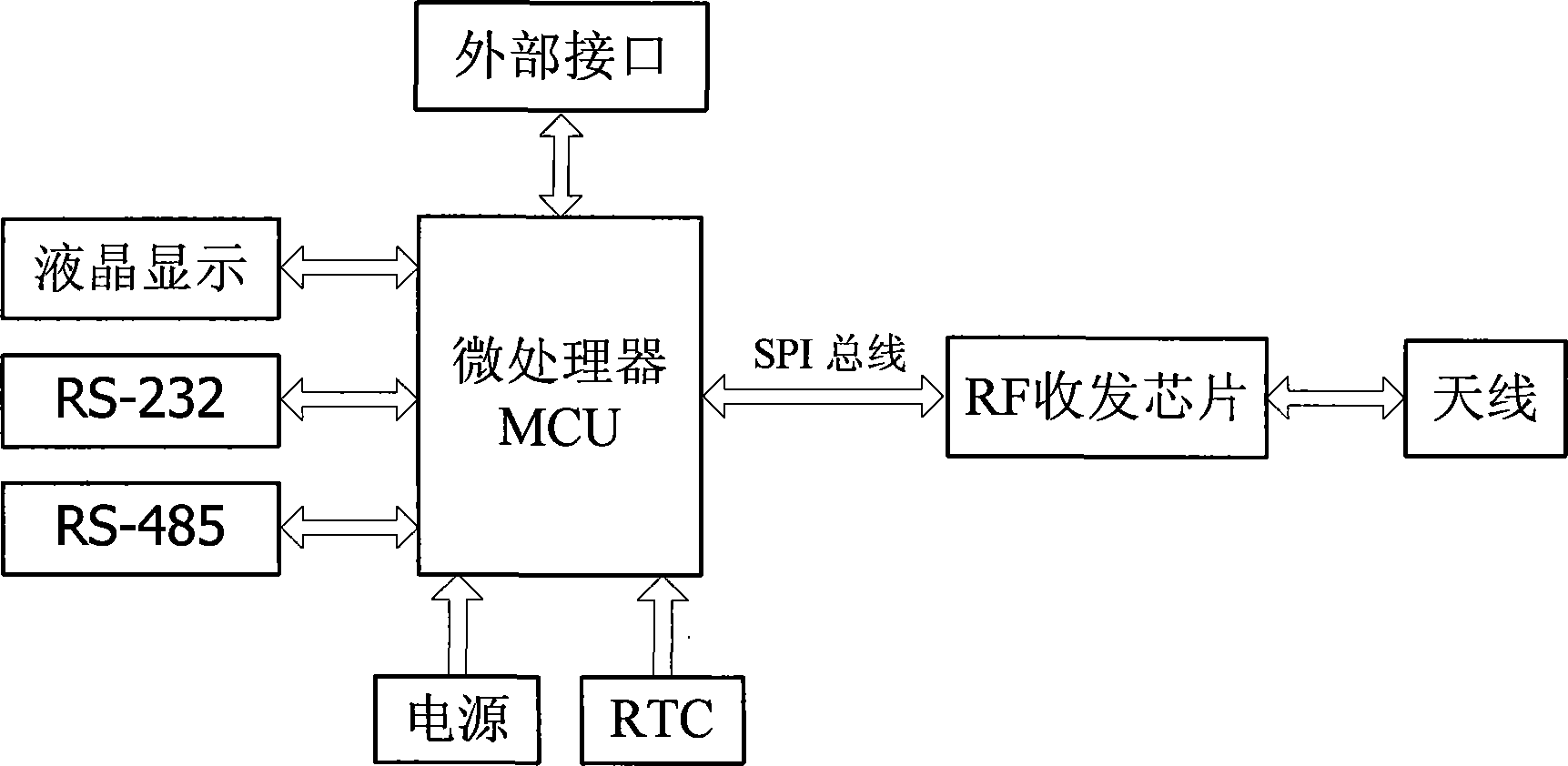

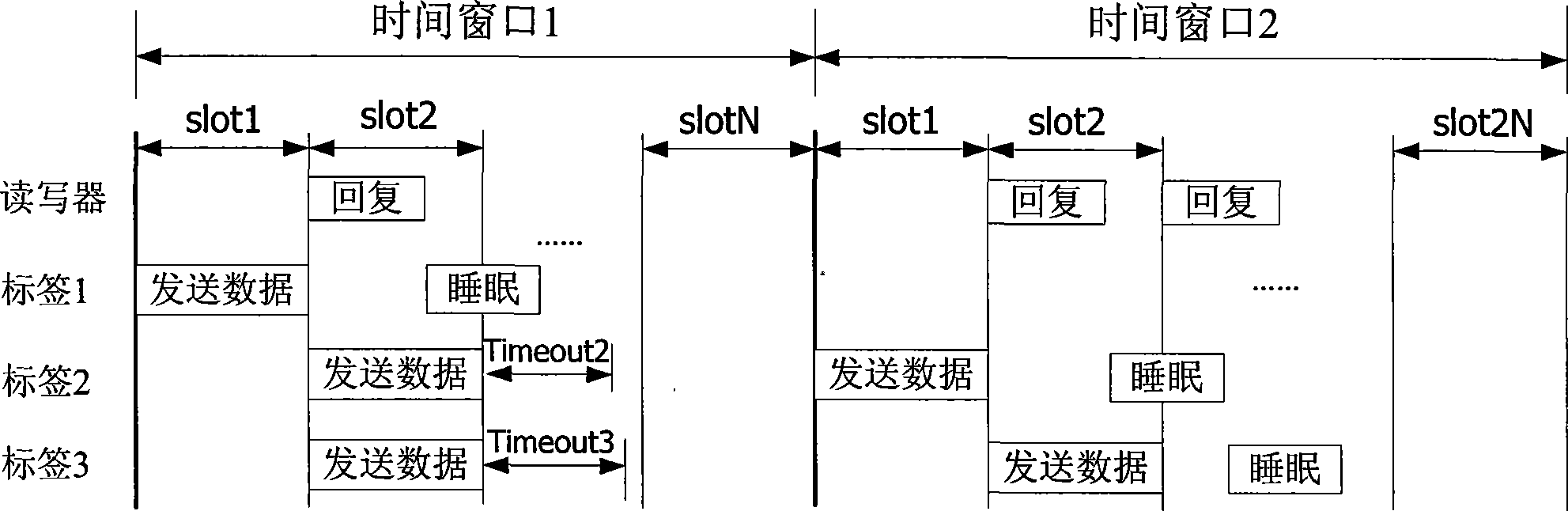

The present invention discloses a new type active radio frequency identification (RFID) system and its operation method. The described system includes active RFID tag, active reader and its communication protocol. Said system is worked at 2.45 GHz of ISM frequency channel, the described tag portion includes microprocessor, radio frequency receiving / sending chip, power supply management, real timeclock (RTC) and antenna. The described reader mainly includes microprocessor, radio frequency receiving and sending chip, power supply management, real-time clock (RTC), liquid crystal display, external interface module and antenna, etc. At the same time it provides RS-232 interface, and can implement communication with PC machine.

Owner:SHANGHAI HUALONG INFORMATION TECH DEV CENT

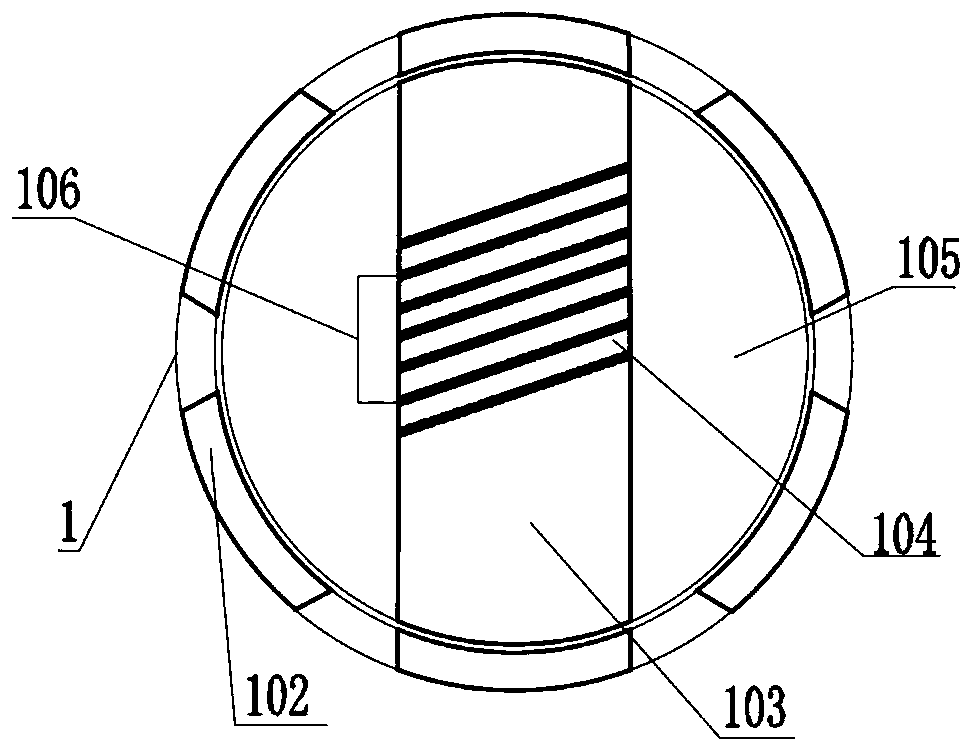

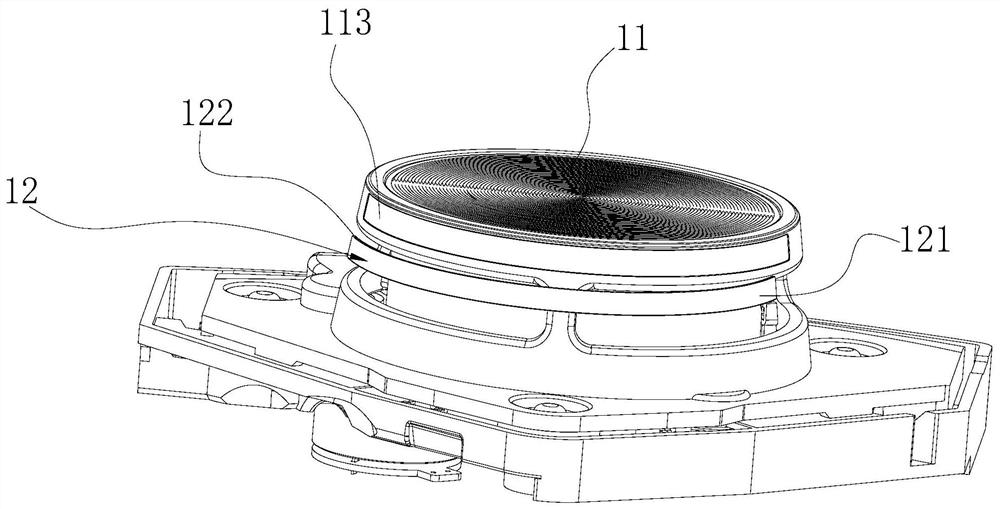

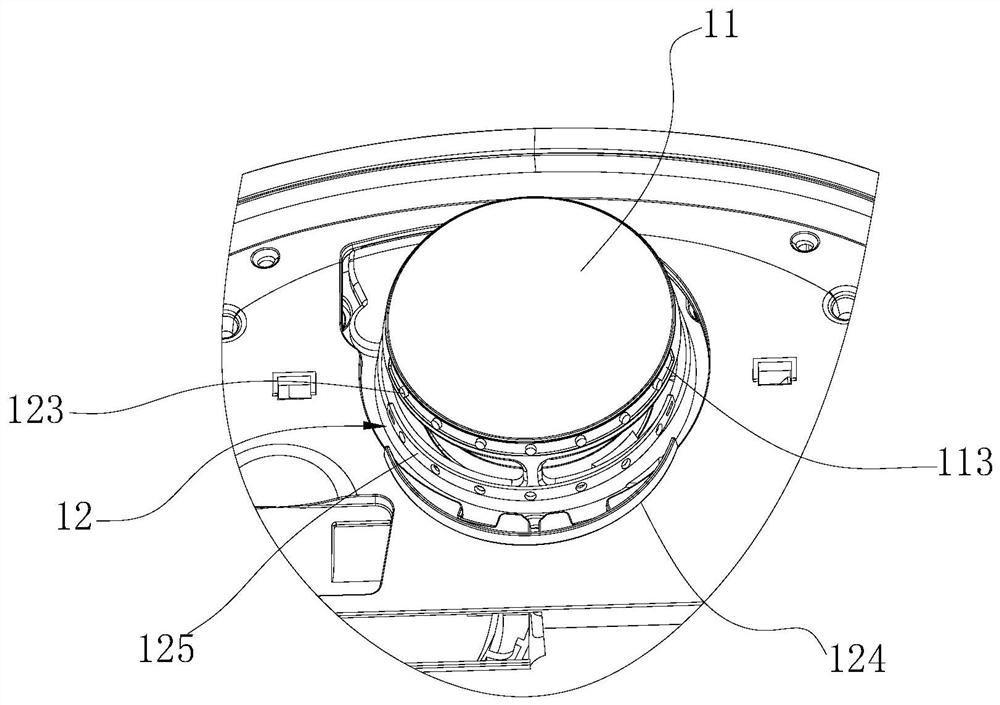

Cover body assembly, radar assembly and cleaning robot

PendingCN112704442AAvoid damageReliable judgmentAutomatic obstacle detectionTravelling automatic controlControl systemRadar

The invention relates to a cover body assembly, a radar assembly and a cleaning robot. The cover body assembly comprises a cover body, which is provided with a collision part, which is provided with a central axis; and an induction part arranged on the circumferential side wall of the collision part in a surrounding mode in the circumferential direction of the collision part, wherein the surrounding angle of the induction part is smaller than or equal to 180 degrees; the surface of the side, away from the collision part, of the induction part is constructed to be a collision face which is arranged around the central axis and protrudes outwards out of the circumferential side wall. When an obstacle occurs, the collision surface of the sensing part located on the front side of the collision part of the cover body firstly makes contact with and collides with the obstacle, the collided sensing part can generate a sensing signal, and a control system of the machine body can know that the obstacle exists in front according to the sensing signal and avoid the obstacle. Compared with the prior art, collision can be prevented, the collision sensitivity of the radar cover is improved, and the machine body can judge obstacles more reliably. In addition, the whole machine is easy to assemble, materials are few, the assembling efficiency is improved, and the production cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

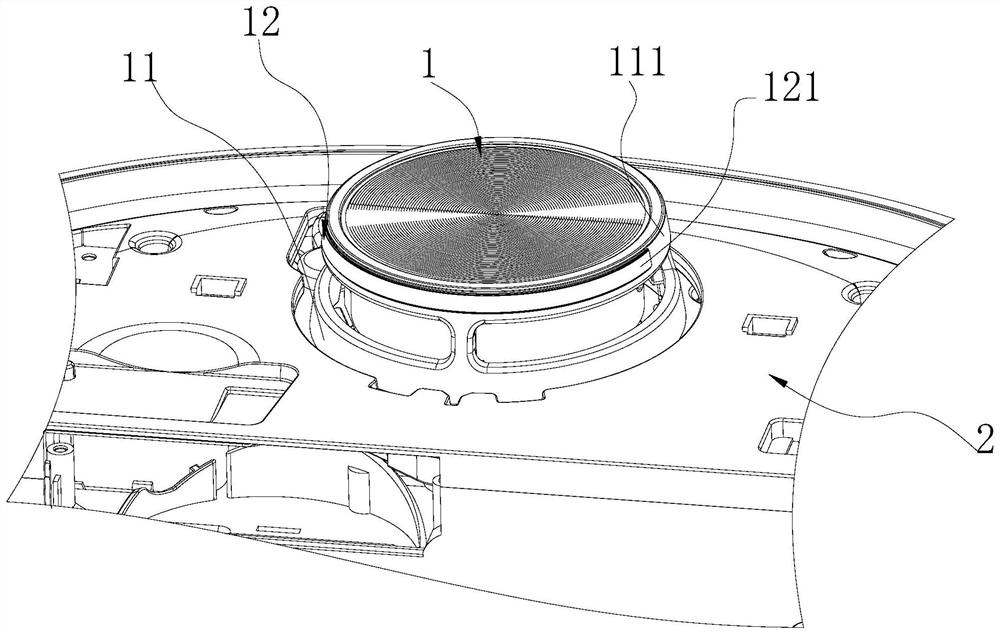

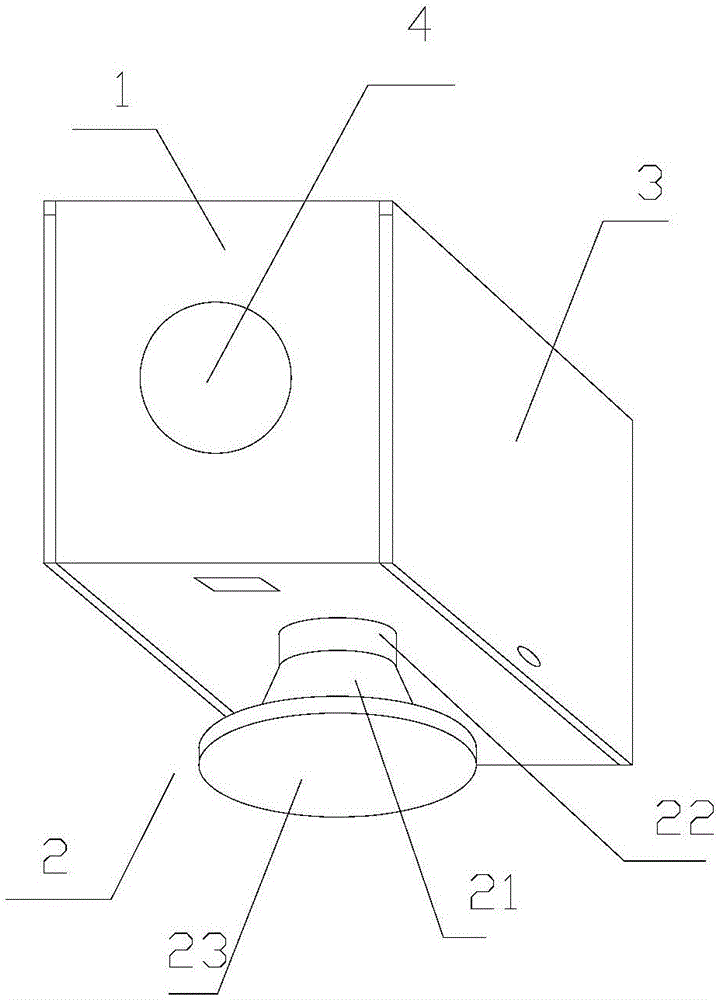

Car insurance information acquisition device

InactiveCN106791651ASo as not to damageImprove integrityTelevision system detailsColor television detailsFree rotationEngineering

The invention discloses a car insurance information acquisition device. The car insurance information acquisition device comprises a shell (1), a rotary support column (2), a video acquirer, a storage and a sealing cover (3), wherein the rotary support column (2) is arranged at the bottom of the shell (1), and can freely rotate; a through hole (4) matched with the lens of the video acquirer is arranged on the shell (1); an opening is also arranged on the side surface of the shell (1); the sealing cover (3) is hinged with the shell (1), and used for sealing the opening by rotation; and the storage is connected to the video acquirer, and used for storing video acquisition data. By means of the car insurance information acquisition device disclosed by the invention, the problem that a camera can be easily damaged in an accident in the prior art can be overcome; and thus, car anti-collision is realized.

Owner:保腾网络科技有限公司

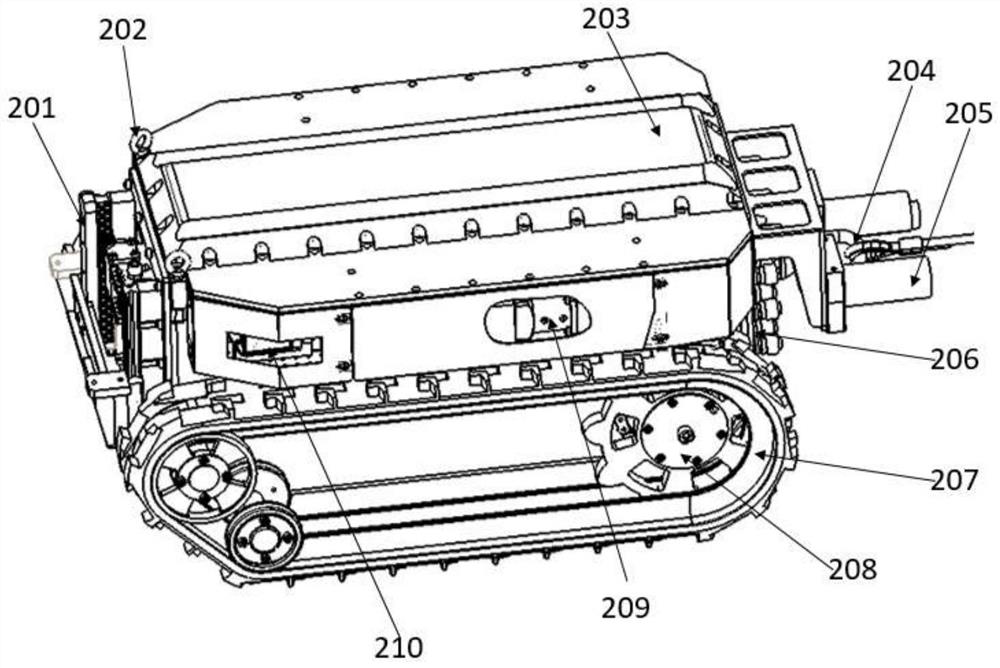

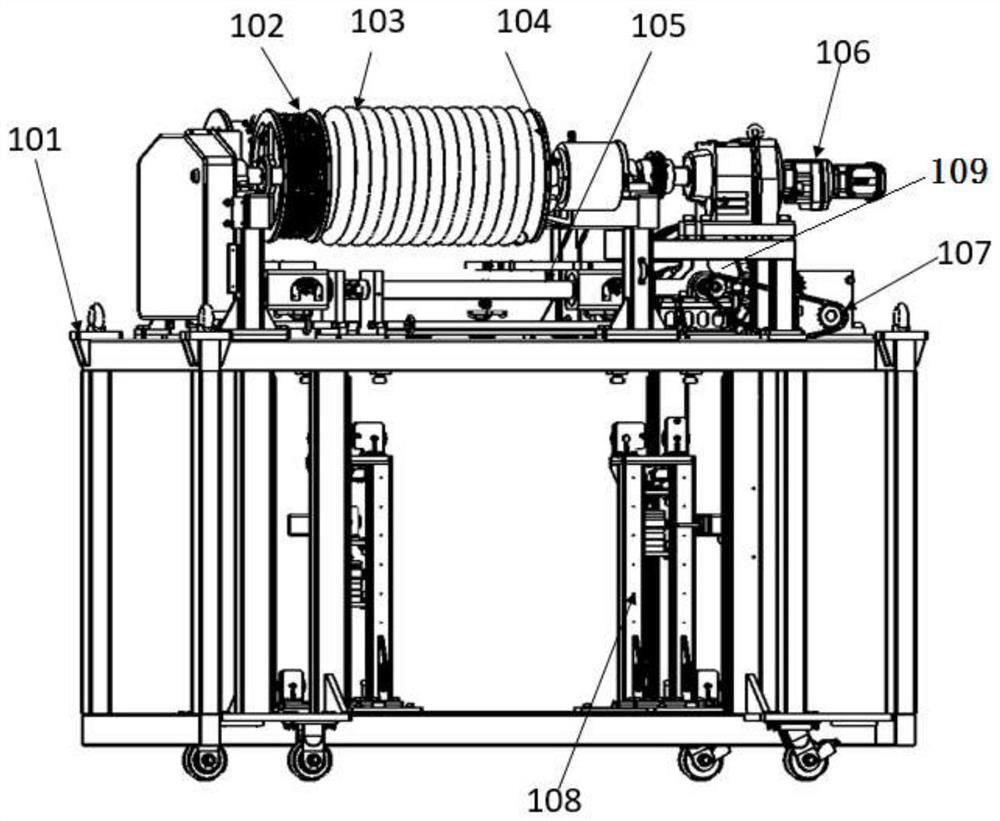

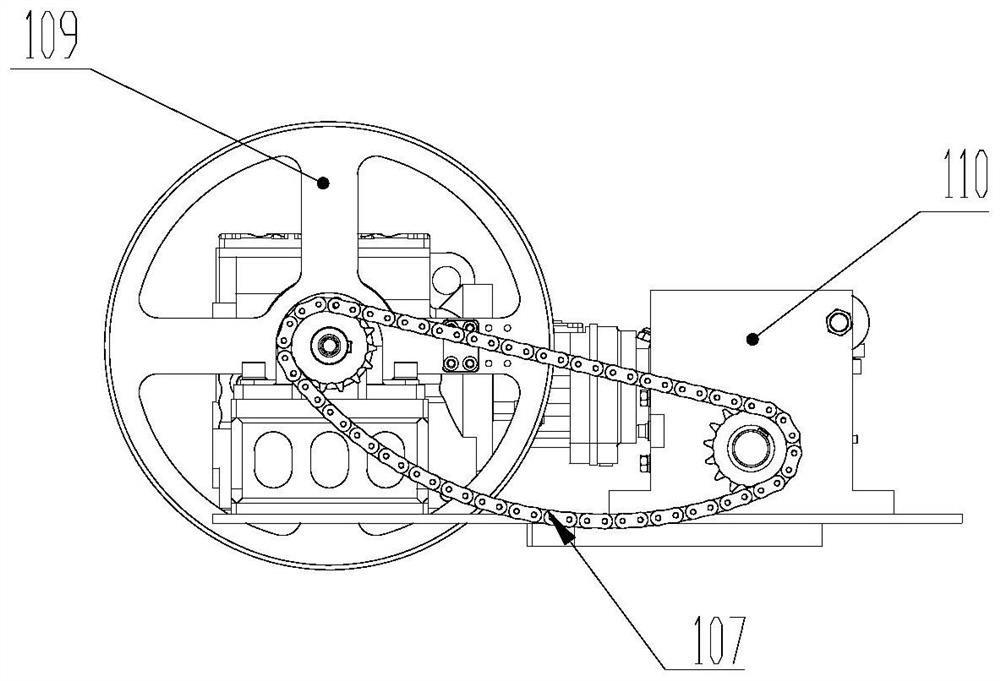

Novel tracked robot

PendingCN114087422AMeet Synchronous CoordinationGood waterproof sealingPipe laying and repairLifting devicesTele operationRemote control

The invention relates to the technical field of robots, in particular to a novel tracked robot. The novel tracked robot comprises a tracked robot and a pipeline dragging and winding and unwinding system, a lifting mechanism is arranged at the front end of the tracked robot, and the lifting mechanism can achieve tool carrying and tool obstacle crossing; and the pipeline dragging and winding and unwinding system is used for providing a power supply and dragging and winding and unwinding power for the tracked robot. A larger carrying space and excellent waterproof sealing performance of the robot are met; synchronous coordination of robot walking and pipeline dragging is achieved through the pipeline dragging and winding and unwinding system; anti-collision, anti-overturning, remote control and local autonomous operation are realized by using an environment measurement sensing system, a local electrical control cabinet, a remote operation platform and an advanced software algorithm.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

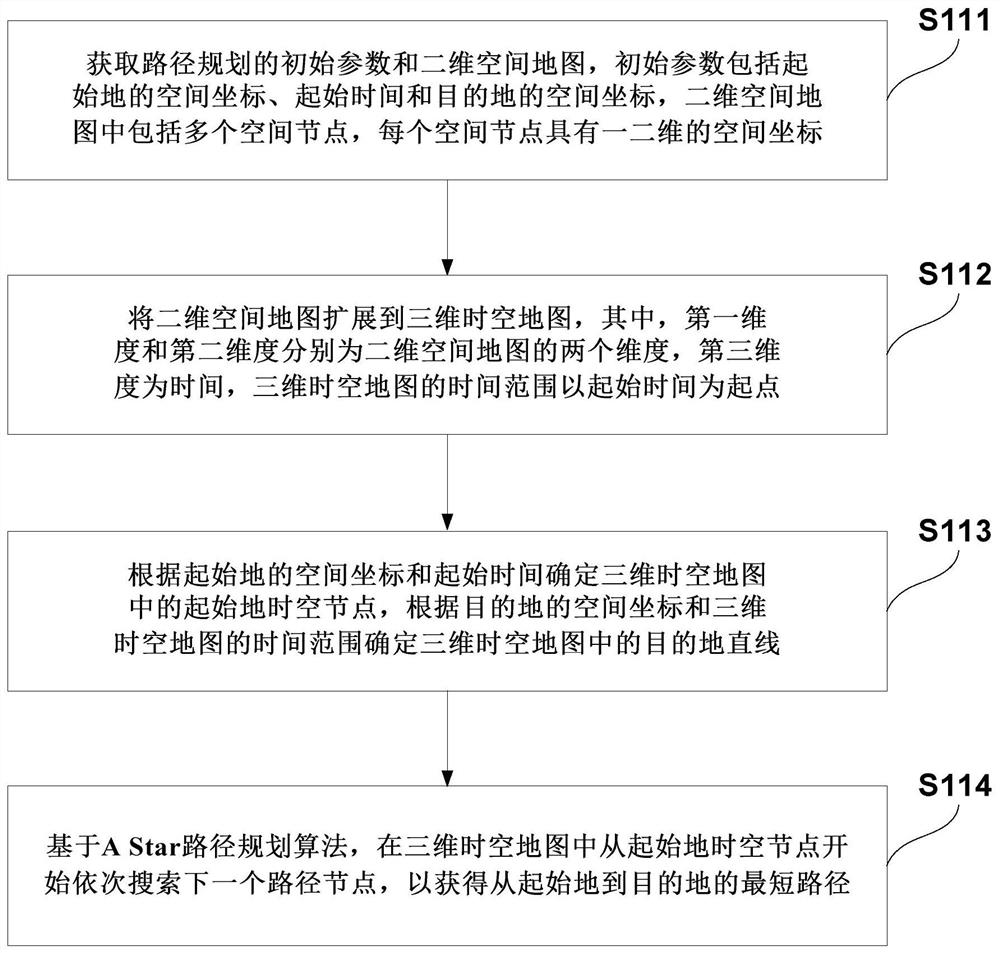

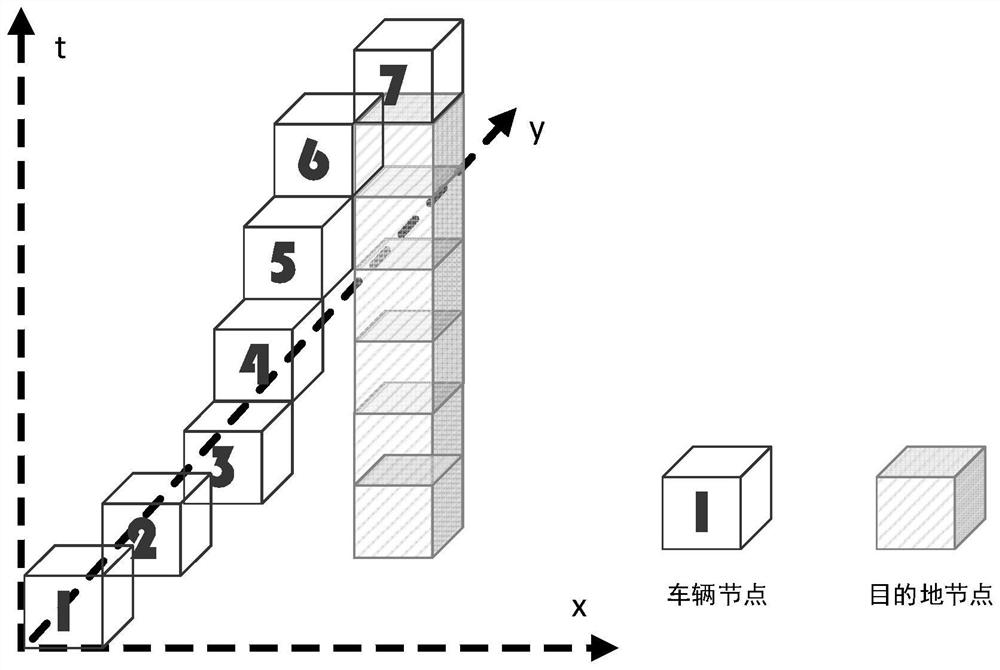

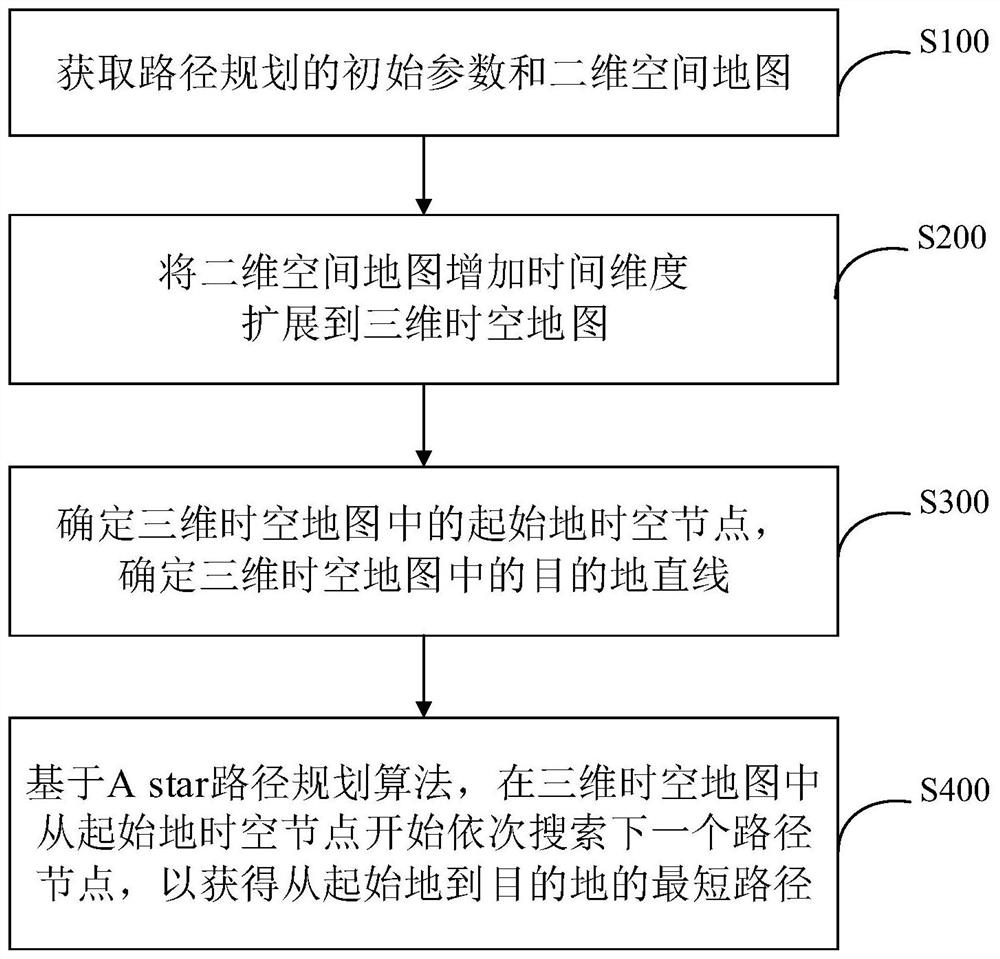

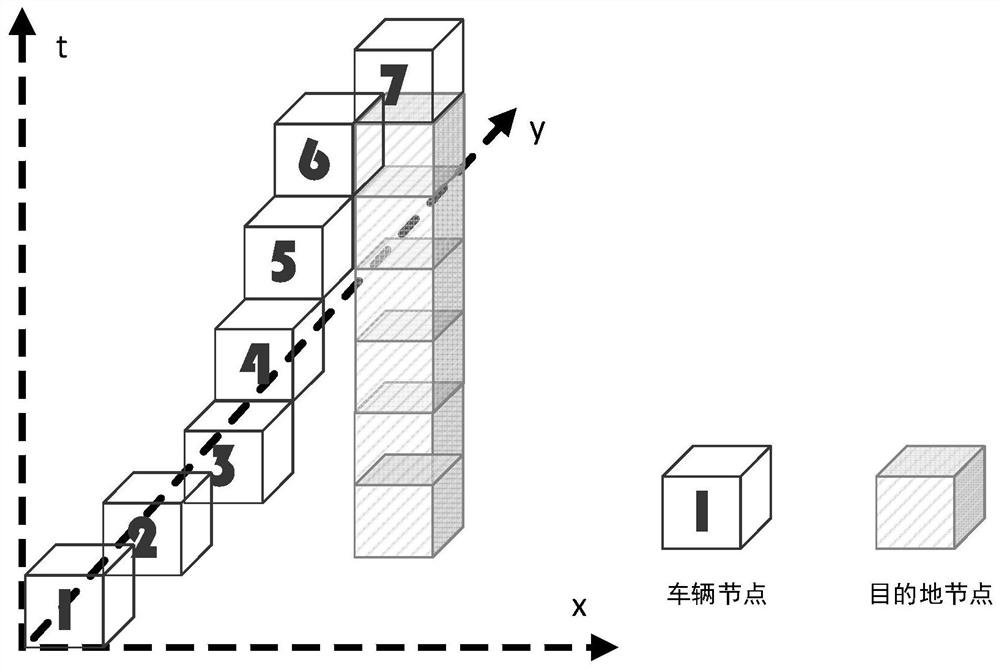

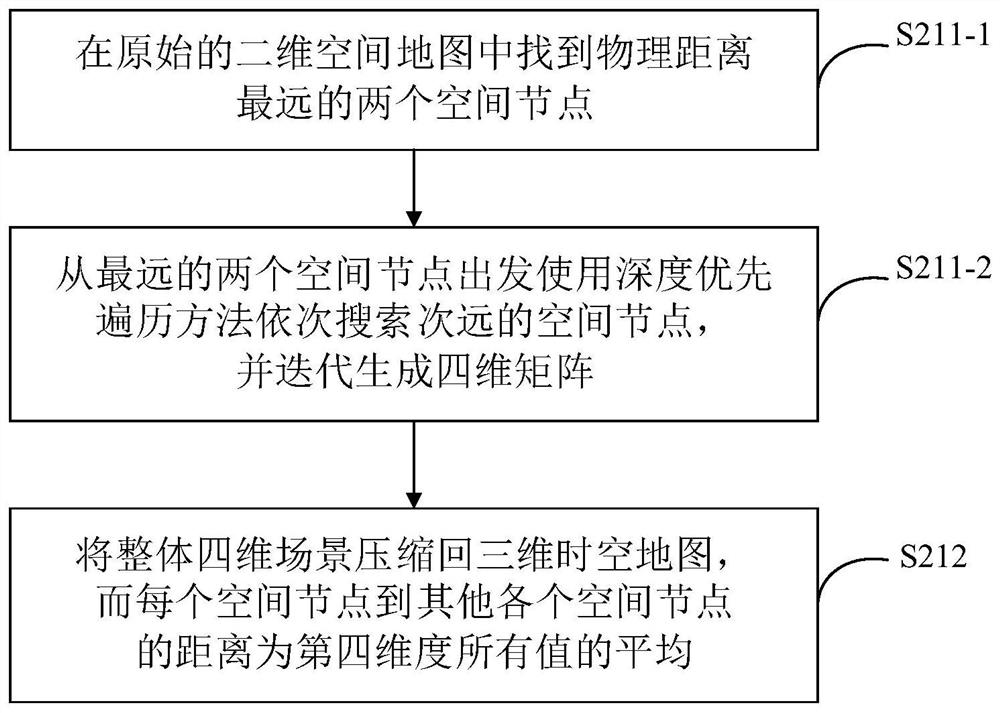

Path planning method, system, device and storage medium based on time expansion

ActiveCN111928867BRealize anti-collisionAdd time dimensionInstruments for road network navigationSimulationTransportation plan

The present invention provides a method, system, device and storage medium for path planning based on time expansion. The method includes: obtaining initial parameters of path planning and a two-dimensional space map; The Star path planning algorithm searches the next path node sequentially from the starting point space-time node in the three-dimensional space-time map to obtain the shortest path from the starting point to the destination. The invention can be well applied to multi-vehicle route planning, realizes vehicle anti-collision and deadlock avoidance, and at the same time satisfies the constraint of the fastest transportation plan.

Owner:SHANGHAI WESTWELL INFORMATION & TECH CO LTD

Lifting, transferring, and conveying device and method for lifting, transferring, and conveying precision parts

ActiveCN113602949BSolve for constant low temperatureAvoid collisionTrolley cranesVibration suppression adjustmentsCooling pipeHigh pressure gas

A precision parts lifting and transporting device and a lifting and transporting method, the device includes a cart, a trolley, a lifting device, and a magnetic attraction device. The magnetic attraction device includes a magnetic core, steel claws, cooling pipes, air-filling pipes, and buffer components; the cooling pipe extends from the lifting arm to the magnetic core, and surrounds the outside of the magnetic core and between the steel claws to cool the magnetic core; the air-filling pipe It is connected with the buffer part and is used to fill the buffer part with high-pressure gas, so that the buffer part can generate air floating buffer between the steel claw and the precision parts. The invention can realize the avoidance of mechanical deformation and temperature deformation of the precision parts during the process of lifting and transferring, and ensure that the size of the precision parts conforms to the specification.

Owner:新乡市恒德机电有限公司

A ship anti-collision method and system integrating the Internet and handheld ais

ActiveCN107103789BRealize anti-collisionIncreased power lossPower managementMarine craft traffic controlTelecommunicationsThe Internet

The invention relates to the field of the Internet, in particular to a method and system for ship collision prevention that integrates the Internet and hand-held AIS. The method includes: if both the first small ship carrying the first mobile terminal and the second small ship carrying the second mobile terminal are in an area with no Internet signal or an unstable Internet signal, starting the first AIS communication built in the first mobile terminal The module and the second AIS communication module built in the second mobile terminal, the first AIS communication module obtains the first AIS data of the first small ship, and broadcasts the first AIS data to the communication range of the first AIS communication module. When a small ship is in an area without Internet signal or an area with unstable Internet signal, turn on the first AIS communication module and use VHF to communicate with the second mobile terminal of other small ships within the communication range of the first AIS communication module to realize small ship Anti-collision.

Owner:FUJIAN NORTH STAR GALAXY COMM CO LTD

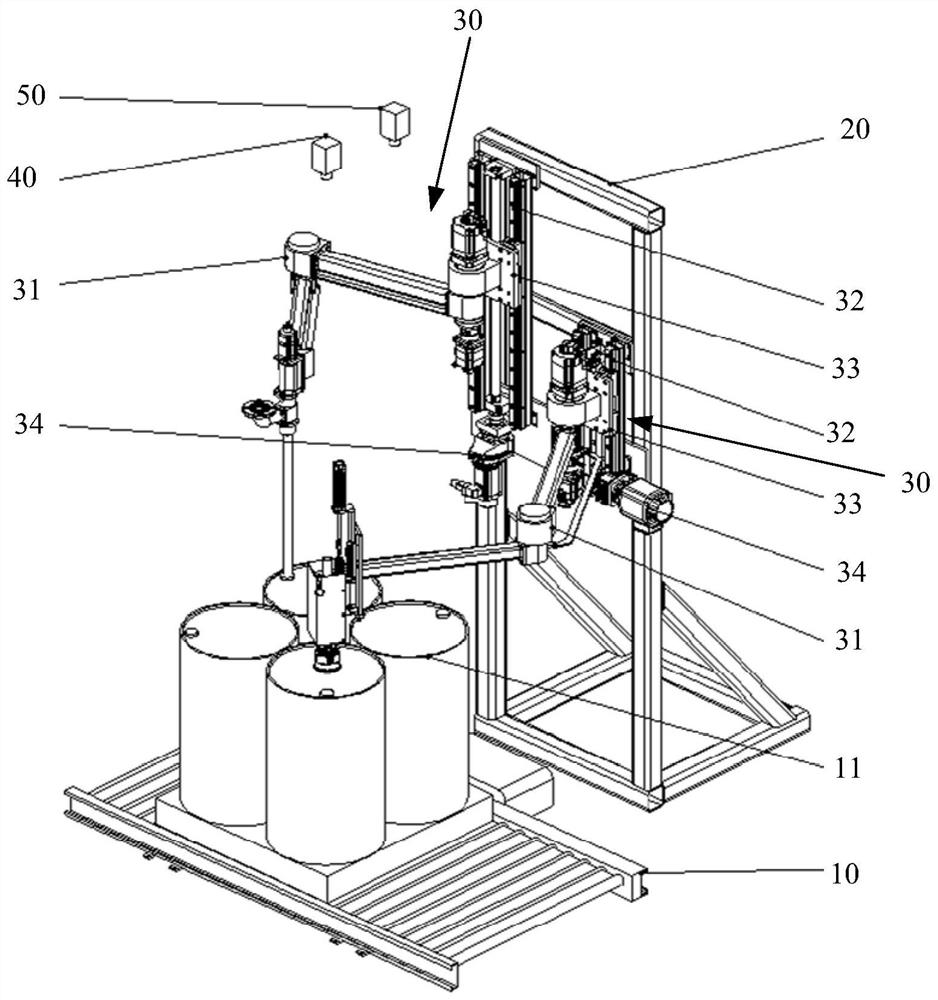

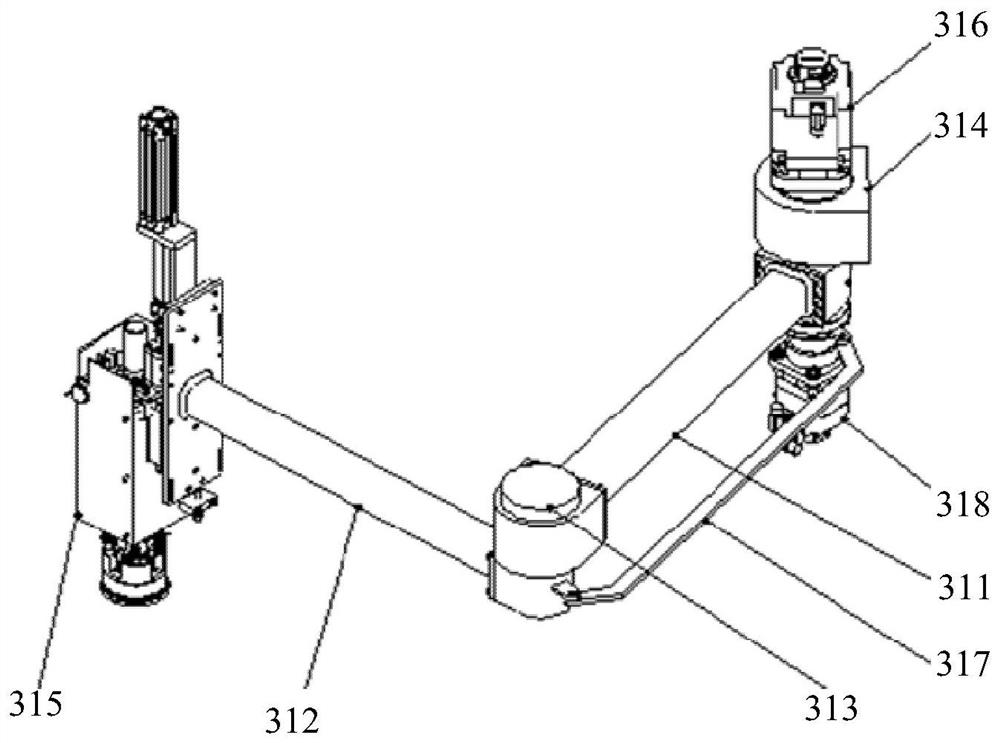

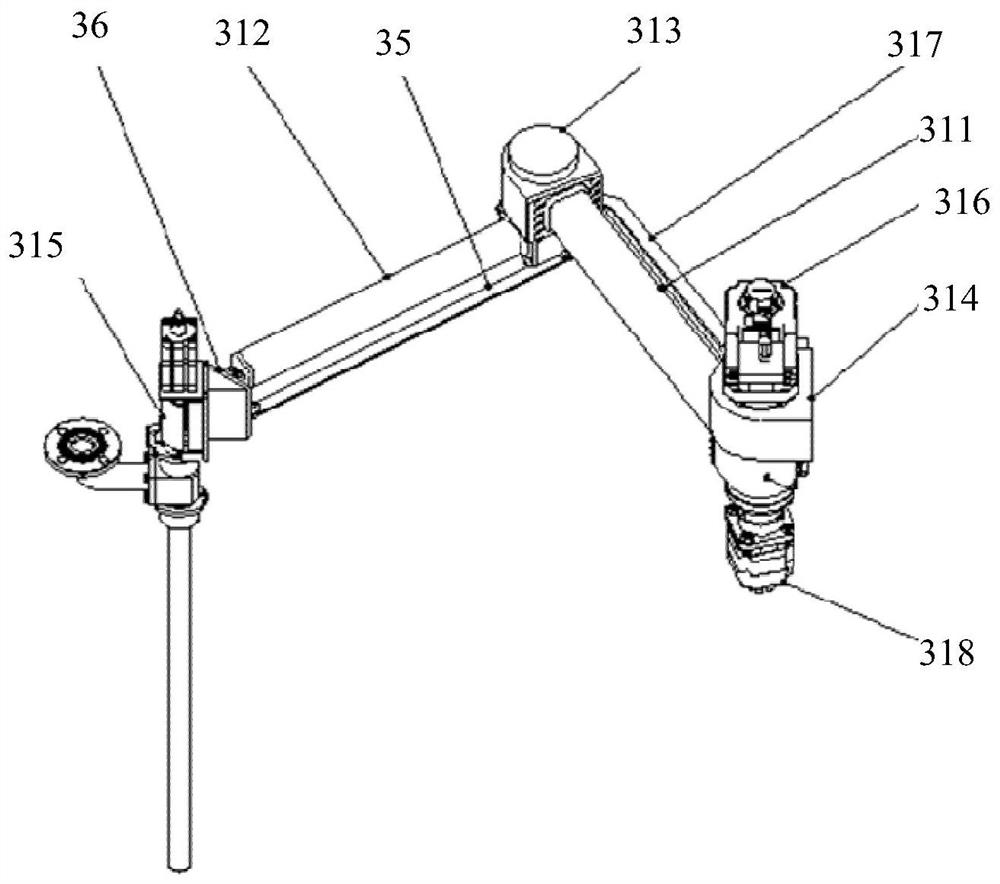

Full-automatic filling system and filling method thereof

PendingCN113562675AAchieve lightweightImplement extensionsBarrels/casks fillingSafety device in filling machineryControl systemControl engineering

The invention provides a full-automatic filling system. The full-automatic filling system comprises a conveying device, at least two multi-coordinate-axis rotating beam devices, at least one first camera, at least one second camera, a control and a visual identification system, and a plurality of rows of filling barrels are placed on the conveying device; a filling system support is arranged on the side part of the conveying device or the filling system stretches across the upper part of the conveying device; the at least two multi-coordinate-axis rotating beam devices are mounted on the filling system support and are positioned above the filling barrels; the at least one first camera are arranged above the working area of the filling barrels; the at least one second camera are arranged above the motion coverage area of the multi-coordinate-axis rotating beam devices; the control system is correspondingly connected with the conveying device, the multi-coordinate-axis rotating beam devices, the first cameras and the second cameras; and the visual identification system is connected with the first cameras and the second cameras and used for processing image information. According to the full-automatic filling system, a plurality of mutually independent filling tools capable of moving at multiple degrees of freedom are arranged in a working area of a single station to work together at the same time, so that the filling efficiency is improved. Anti-collision of a filling tool and a movement mechanism can be achieved when the filling tool and the movement mechanism cooperate together, and simple array expansion of multiple stations of the same work is achieved.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +1

Method for eliminating idle stroke and preventing collision for grinding processing

ActiveCN108000249AIncreased grinding efficiency and machine safetyImprove securityDrive motorCollision prevention

The invention discloses a method for eliminating an idle stroke and preventing collision for grinding processing. The method is characterized in that effective grinding is divided into a black skin grinding stage, a coarse-feeding grinding stage, an enhancement grinding stage and a light-delay grinding stage, wherein idle stroke eliminating is performed by adopting fast forwarding and fast trending in idle stroke feeding before effective grinding, and a real-time current signal of a grinding wheel shaft drive motor is acquired to determine a contact state between a grinding wheel and a workpiece; fast forwarding amount and fast trending amount of the idle stroke are defined according to settings of a to-be-processed part, fast forwarding speed and fast trending speed are preset, a fast trending function test is set before the first part of the whole batch of the parts of the same specification is processed, a current value of the grinding wheel shaft drive motor is no-load current whenfast trending function test is set for forwarding, the current value of the grinding wheel shaft drive motor is set as target current when fast trending is set to be ended, target current is three times that of no-load current, and collision prevention is realized by determining whether real-time current of the grinding wheel shaft drive motor in fast trending function test reaches fast forwarding amount and fast trending amount or not for regulating target current, so that grinding efficiency and machine tool safety are improved.

Owner:浙江盛达智能装备有限公司

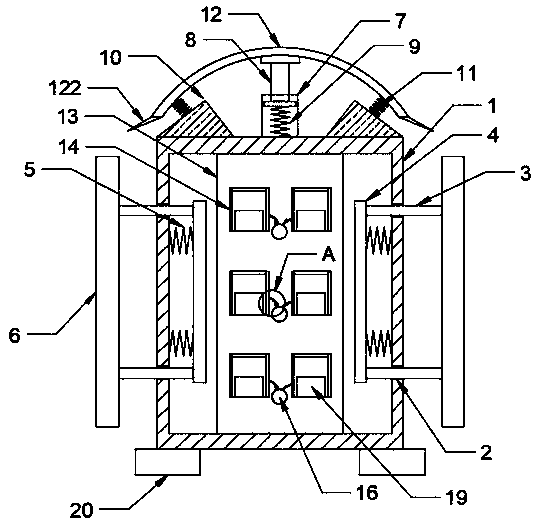

Anti-collision durable wardrobe

ActiveCN109276057ARealize anti-collisionReduce collisionWardrobesFittingEngineeringMechanical engineering

The invention discloses an anti-collision durable wardrobe. The wardrobe comprises a wardrobe body, a door plank, a fixing block, a pressing mechanism, a telescopic mechanism, an extension mechanism and a handle mechanism; the telescopic mechanism comprises a fourth sliding cavity and a rod body, and the rod body is vertically and fixedly connected with a partition plate; the extension mechanism comprises a fifth sliding cavity, a second sliding block, a sixth sliding cavity and a sliding rod, and the second sliding block is arranged in the fifth sliding cavity; the handle mechanism comprisesa handle body and a connecting assembly, the handle body is arranged in a second sliding cavity, the connecting assembly comprises a supporting block, a balance rod, two grooves, a first connecting rod and a second connecting rod, the balance rod is hinged to the supporting block, the first connecting rod is fixedly connected with the end of the second sliding block, and the second connecting rodis fixedly connected with the end of the handle body. According to the anti-collision durable wardrobe, the handle body partially protrudes out of the second sliding cavity, and the door plank is opened through the handle body; the handle body retracts into the second sliding cavity through first springs, and the collusion of the handle body is reduced.

Owner:杭州天时亿科技有限公司

Electronic equipment mounting cabinet with anti-collision function

InactiveCN111148381ASlow down the force of the fallTo achieve the purpose of collision avoidanceCircuit arrangements on support structuresCasings/cabinets/drawers detailsEngineeringStructural engineering

The invention discloses an electronic equipment mounting cabinet with an anti-collision function. The electronic equipment mounting cabinet comprises a cabinet body, wherein movable holes are formed in the two ends of the surfaces of the two sides of the cabinet body correspondingly, guide columns are movably mounted on the inner sides of the movable holes, a connecting plate is fixedly arranged at one end, close to the cabinet body, of the guide column, a first spring is fixedly arranged between the connecting plate and the inner side wall of the cabinet body, a buffer plate is fixedly arranged at the end, away from the connecting plate, of the guide column, an installation cylinder is fixedly arranged in the middle of the upper end of the cabinet body, a movable column is movably installed on the inner side of the installation cylinder, a second spring is fixedly arranged between the movable column and the bottom end of the inner side of the installation cylinder, and installation members are fixedly arranged on the two sides of the installation cylinder at the upper end of the cabinet body respectively. According to the invention, external force on the cabinet body is relieved through the first spring to achieve the anti-collision purpose, and the second spring and the third spring are compressed through the protection plate, so that the external force or the falling force of heavy objects is relieved so as to achieve the buffering purpose.

Owner:薛成

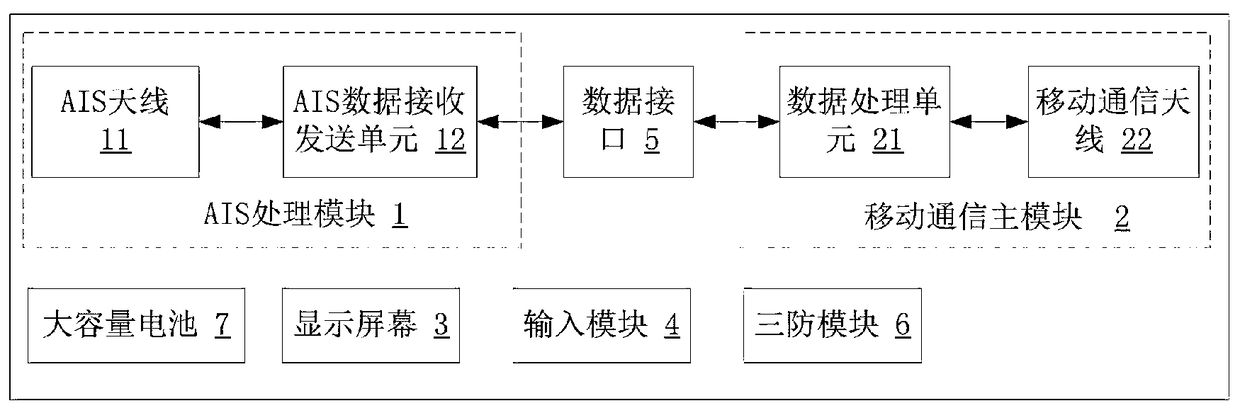

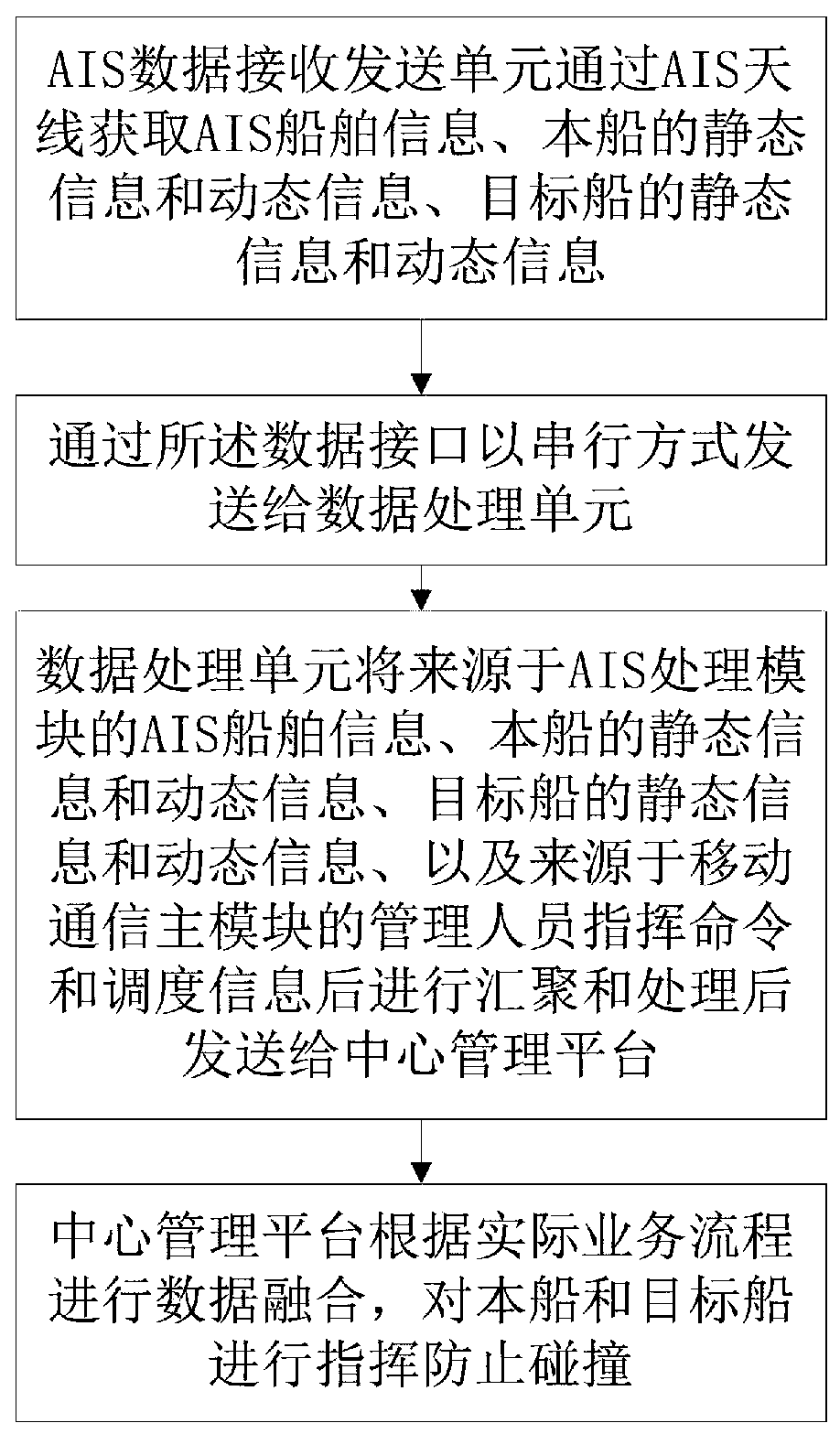

Method for mobile communication and AIS anti-collision based on handheld AIS communication terminal

ActiveCN106355956BExpand the scope of supervisionRealize anti-collisionMarine craft traffic controlComputer terminalData interface

The invention provides a method for carrying out mobile communication and AIS collision prevention based on a handheld AIS communication terminal. The handheld AIS communication terminal comprises an AIS processing module, a main mobile communication module, a display screen and a three-proofing module; an AIS data transceiving unit acquires AIS ship information by virtue of an AIS antenna as well as the static information and dynamic information of a local ship and the static information and dynamic information of a target ship, and the information is sent to a data processing unit through a data interface in a serial mode; the data processing unit integrates and processes the AIS ship information from the AIS processing module as well as the static information and dynamic information of the local ship and the target ship and then sends a result to a central management platform; and the central management platform carries out data fusion according to the actual business process, and thus the local ship and the target ship are guided for preventing collision. The method and the system which are provided by the invention have the advantages that an AIS function is integrated on the handheld communication terminal, so that a small ship also has a collision prevention function, the safety factor of ship navigation is improved, a marine accident is avoided, and no casualty is caused.

Owner:福建省枢建通信技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com