Method and device for remotely monitoring SAGD (steam assisted gravity drainage) horizontal well

A remote monitoring and horizontal well technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve the problems of static data comparison and verification, scattered data information, failure to ensure the authenticity of wellbore trajectory, etc., and achieve parameters The monitoring system is intuitive to ensure effective implementation and authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

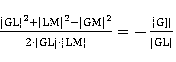

[0018] In the SAGD horizontal well remote monitoring method, the MGT magnetic source is placed on the target position of the completed production well, and the MWD measuring device equipped with the MGT magnetic induction sensor is placed in the gas injection well being drilled. In order to measure the magnetic field generated by the MGT magnetic source, at the same time, use the measured inclination angle, azimuth angle and well depth change to calculate the relative position of the wellbore trajectory between the gas injection well and the production well and calculate the distance between the wellbore trajectory; The vectors of the two wells are paralleled for overall monitoring.

[0019] The MGT magnetic induction sensor is used to measure the magnetic field change generated by the MGT magnetic source in the production well, and obtain the relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com