Remote control system for gantry crane

A portal crane, remote control technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of restricting remote transmission, improving productivity, labor intensity of operators, and small amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

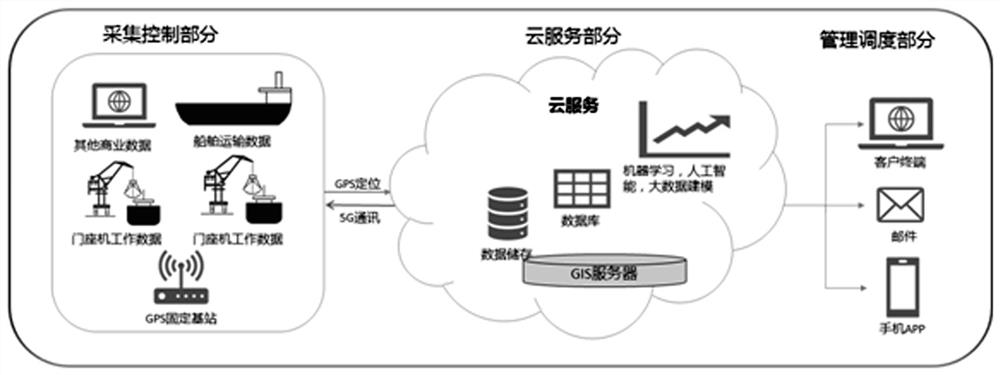

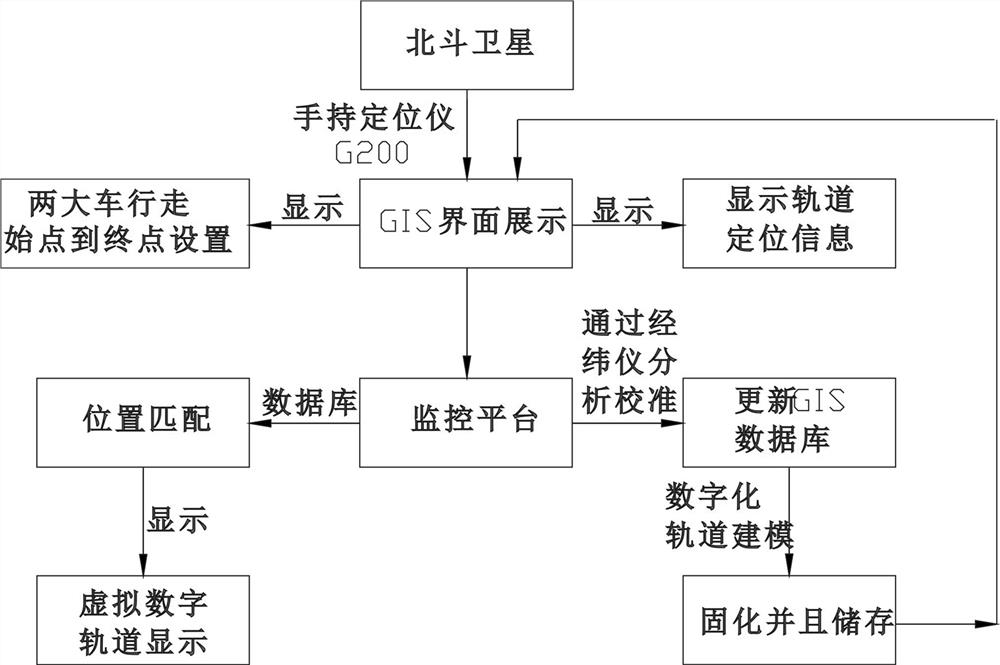

[0060] A remote control system for portal cranes. The working characteristics and working conditions requirements of portal cranes adopt SOA technology architecture and B / S structure to build an automatic monitoring and management platform for portal cranes. GIS electronic information technology, big data and AI technology are used to provide portal cranes. Landline automatic control provides a basis for digitalization and visualization; then advanced means such as GPS positioning, 3D digital scanning, CAE online monitoring and analysis, and 5G communication are used to realize door machine anti-swing, space anti-collision, material identification, obstacle identification, and mechanical structure fatigue predictive maintenance, etc.

[0061] (1): The overall structure of the system is as follows: figure 1 Shown:

[0062] The system is divided into three parts: data acquisition and control part, cloud service part, management scheduling part; the data acquisition and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com