Highway subgrade maintenance pavement crack pouring device

A technology for subgrades and highways, which is applied in the direction of road surface cleaning, roads, roads, etc. It can solve the problems of easy generation of air bubbles, affecting the effect of filling joints, and the great influence of the adhesion performance of potting glue, etc., so as to increase the frequency of reciprocation and improve the effect of joint filling , Improve the effect of reset speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

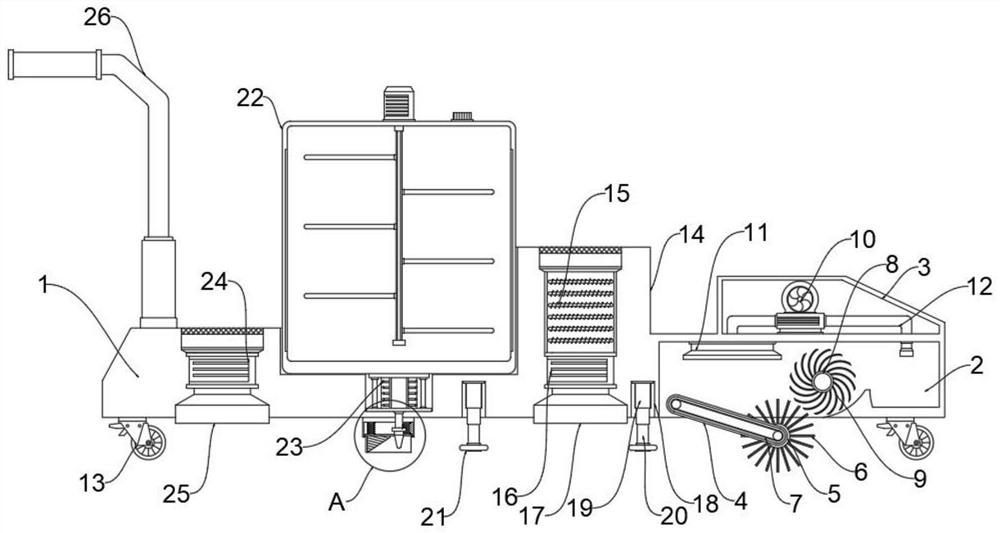

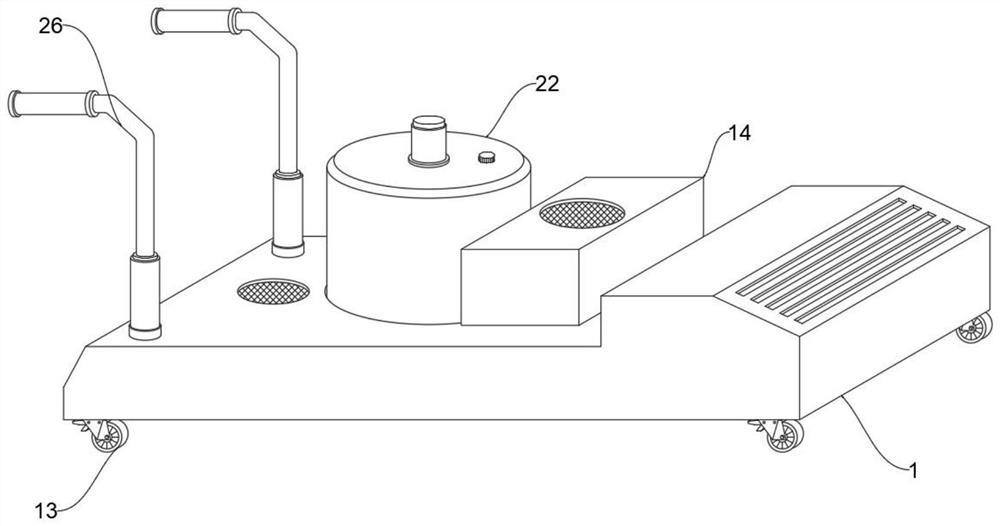

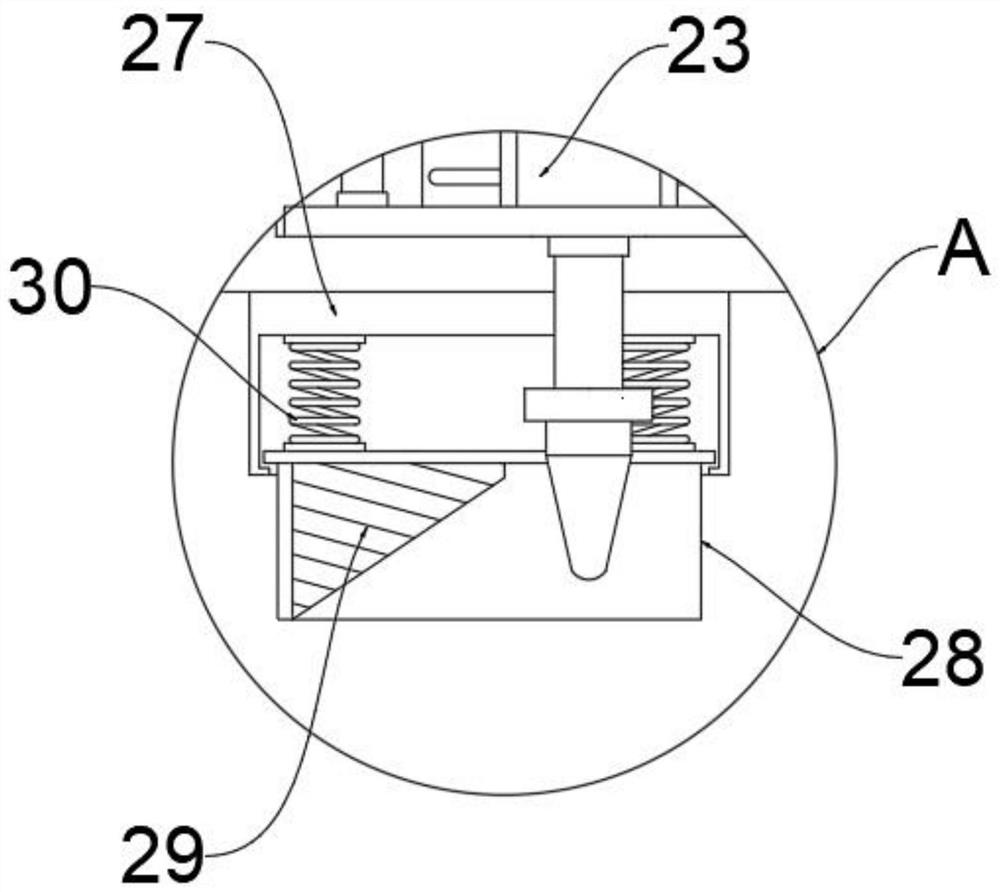

[0033] Such as Figure 1-5 As shown in the figure, a pavement filling device for roadbed maintenance includes: a base 1, and a stone dust collection chamber 2 arranged at the front end of the bottom of the base 1, and two damping adjustment rods 4 are mounted on the rear end of the stone dust collection chamber 2 for rotation. The first rotating roller 5 is installed between the lower ends of the damping adjustment rod 4, and several groups of first brushes 6 are arranged on the outside of the first rotating roller 5; the protective shell 3 is arranged above the stone dust collection chamber 2, The upper end of one side of the stone dust collection chamber 2 is fixedly equipped with a dust collection cover 11, and the upper end of the dust collection cover 11 extends to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com