Universal hanging basket type excavating and protecting assembly for amphibious special vehicle

A special vehicle and basket-type technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as limited capacity and slow speed on water, and achieve weight reduction, Reduce processing and manufacturing costs, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

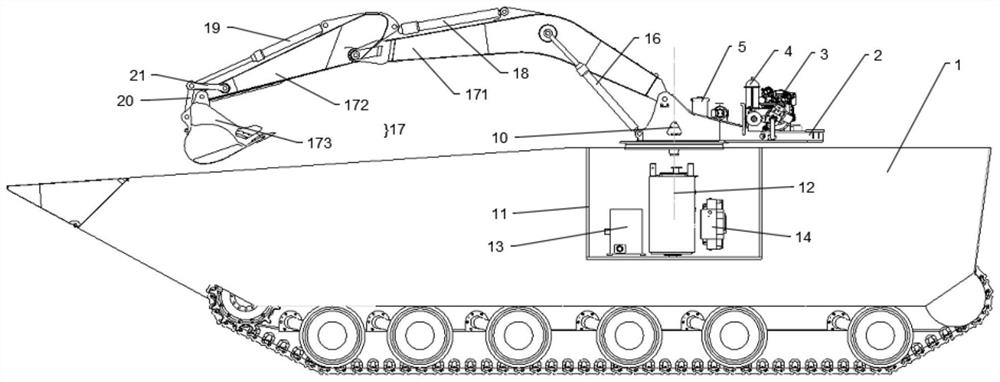

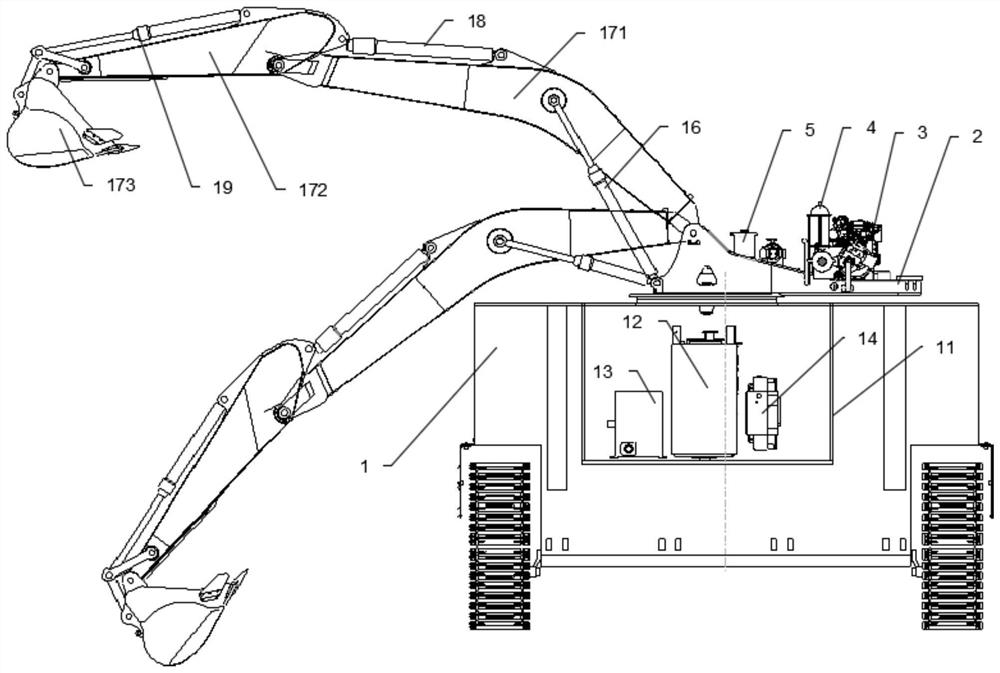

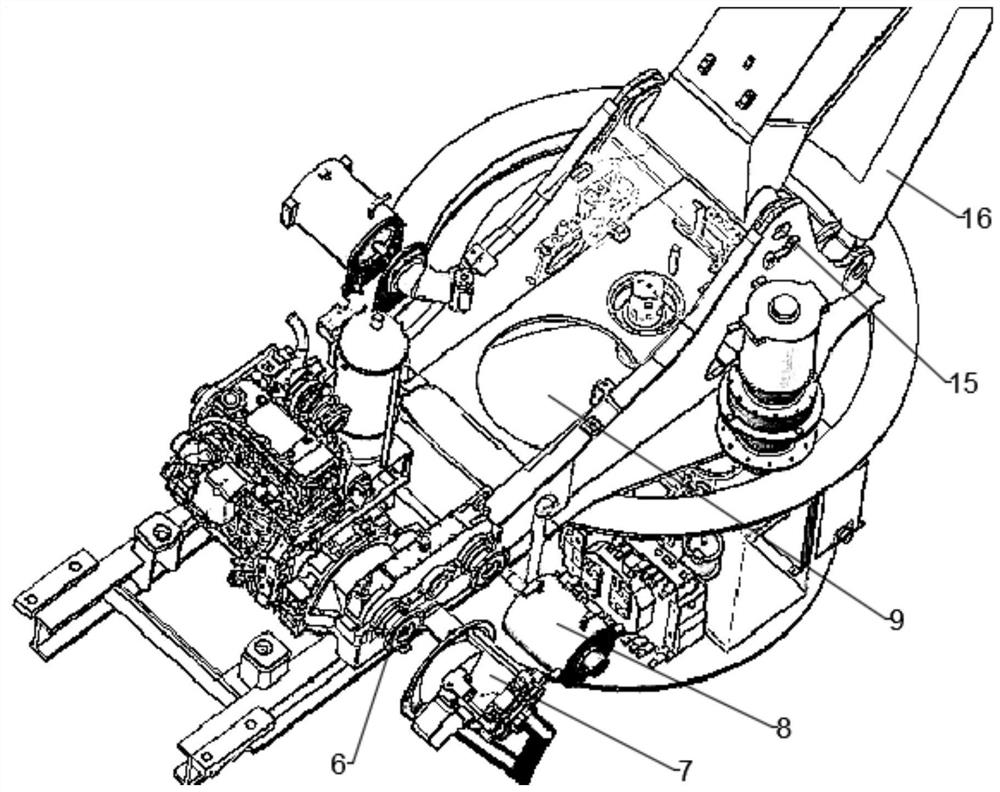

[0026] like Figure 1-3 As shown, a universal hanging basket excavation and protection assembly for amphibious special vehicles includes a vehicle body 1 and a mounting bracket 2, the mounting bracket 2 is connected to the vehicle body 1 through a slewing support, and an engine 3 is installed on the mounting bracket 2 An accumulator 4 is installed on the left side of the engine 3, a rotary motor 5 is installed on the left front of the accumulator 4, a transmission device 6 is installed behind the engine 3, and a main pump is installed on the rear side of the transmission device 6 7. An air conditioner compressor 8 is installed on the left side of the main pump 7, a bulletproof glass observation window 9 is installed in the middle of the installation bracket 2, a smoke grenade launcher 10 is installed on the front side wall of the installation bracket 2, and the installation The bottom of the bracket 2 is connected with a hanging basket 11 through a suspender. An explosion-proo...

Embodiment 2

[0028] On the basis of Embodiment 1, the mounting bracket 2 is made of integrally cast titanium alloy.

Embodiment 3

[0030] On the basis of Embodiment 1, the main pump 7 is a variable variable swash plate plunger double pump, which can provide hydraulic oil sources for the main oil circuit and the servo oil circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com