Pneumatic rotary damping device

A technology of rotating damping device and air chamber, which is applied to switches with brakes, door/window accessories, wing parts, etc., and can solve problems such as no damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

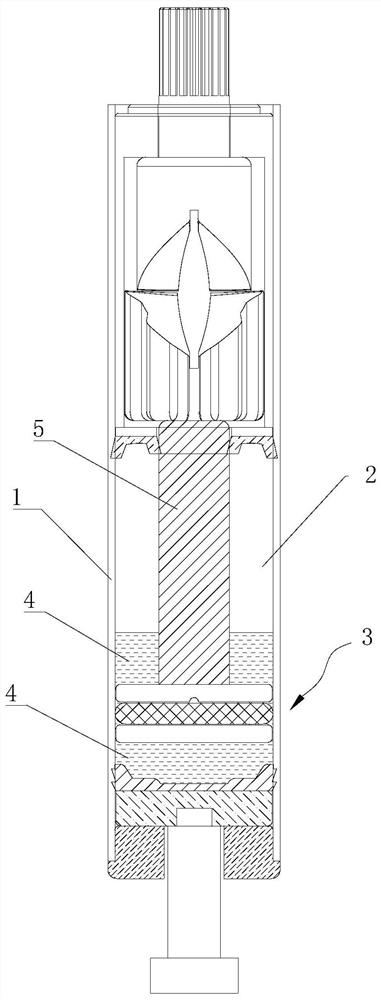

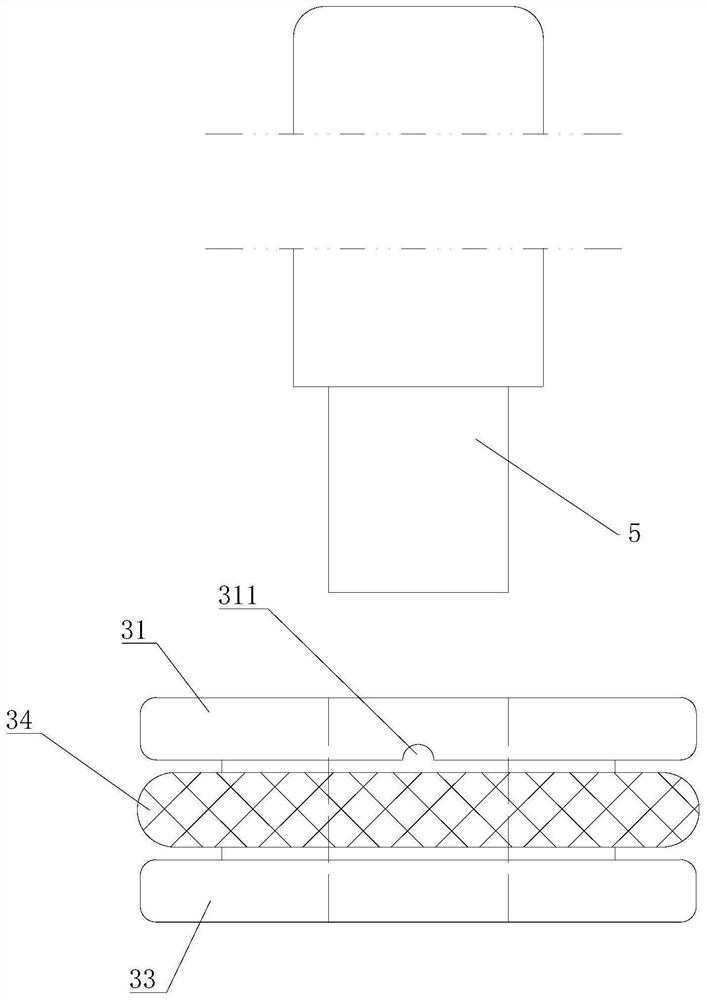

[0034] Such as image 3 and Figure 4 As shown, the piston 3 includes an upper end plate 31, a central column 32 and a lower end plate 33, and the piston 3 here is a split structure, namely Figure 5 As shown, the upper end plate 31 and the middle column 32 are fixed as one, and the lower end plate 33 is separately integrated, and the middle positions of the upper end plate 31, the middle column 32 and the lower end plate 33 are all provided with a through hole 35, and the lower end of the guide rod 5 Penetrating through the through hole 35 and sealingly fit with it.

[0035] The outer diameter of the middle column 32 is smaller than the outer diameter of the upper end plate 31 and the lower end plate 33, the piston 3 formed by the three is dumbbell-shaped, and the outer diameter of the upper end plate 31 and the lower end plate 33 is also smaller than the inner diameter of the airtight chamber 2, so that A gap is left between the upper end plate 31 and the airtight chamber ...

Embodiment 2

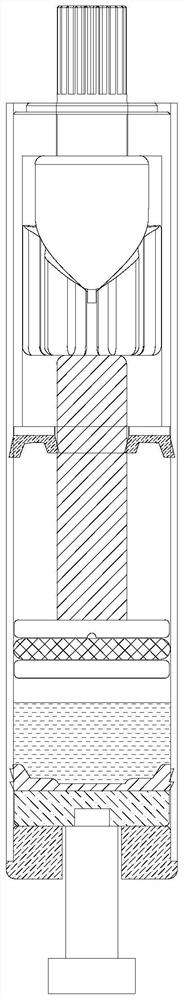

[0042] What the piston 3 in this embodiment adopts is Figure 6 In the one-piece structure shown, that is, the upper end plate 31 , the middle column 32 and the lower end plate 33 are fixed as a whole, and the rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0044] The oil passing structure of the lower end plate 33 in this embodiment no longer adopts the second oil passing groove 331, but adopts Figure 10 As shown in the second oil hole 332, the number of the second oil hole 332 is at least two (three are shown in the figure), and these second oil holes 332 are evenly distributed on the lower end plate 33 in the circumferential direction, and the The second oil hole 332 penetrates the lower end plate 33 up and down, and is arranged in a misalignment with the O-ring 34 , that is, the second oil hole 332 is just located between the O-ring 34 and the center column 32 .

[0045] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com