Narrow space ring groove inner diameter measuring device and use method thereof

A measuring device and narrow space technology, applied in the field of measurement, can solve the problem that the inner diameter of the ring groove on the end face of the valve seat cannot be accurately measured, and achieve the effect of ensuring matching requirements, flexible operation, and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

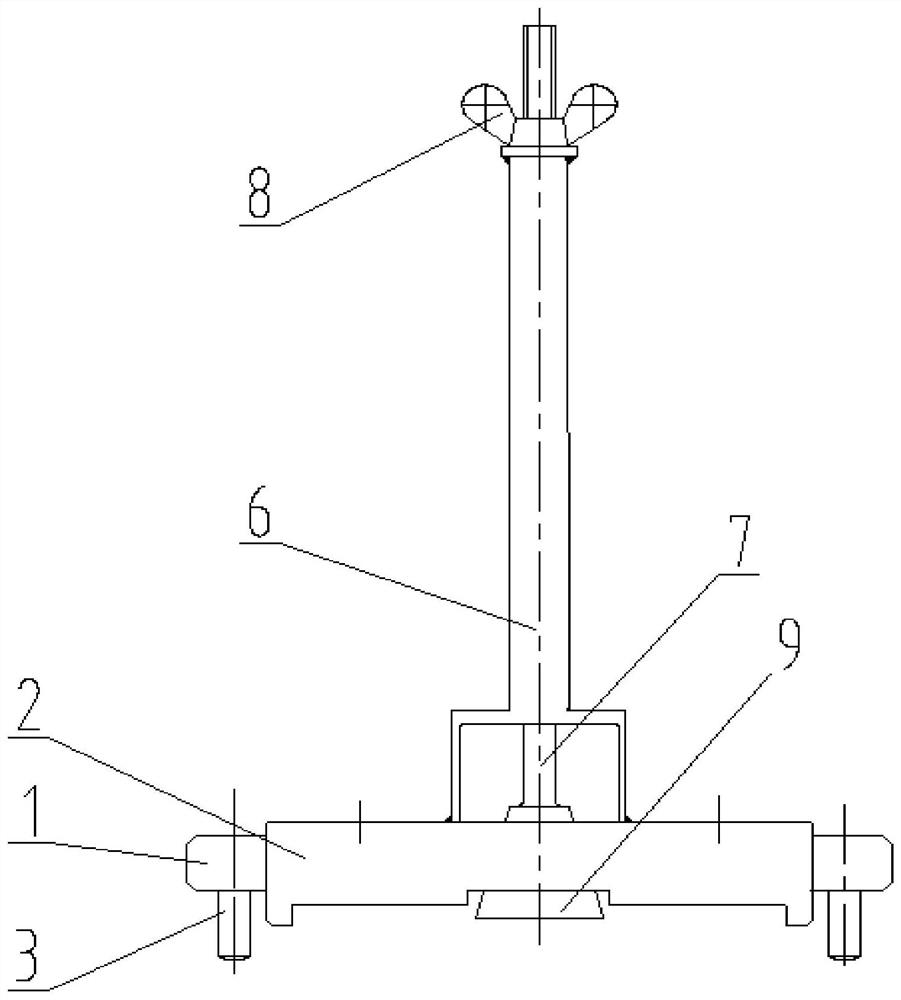

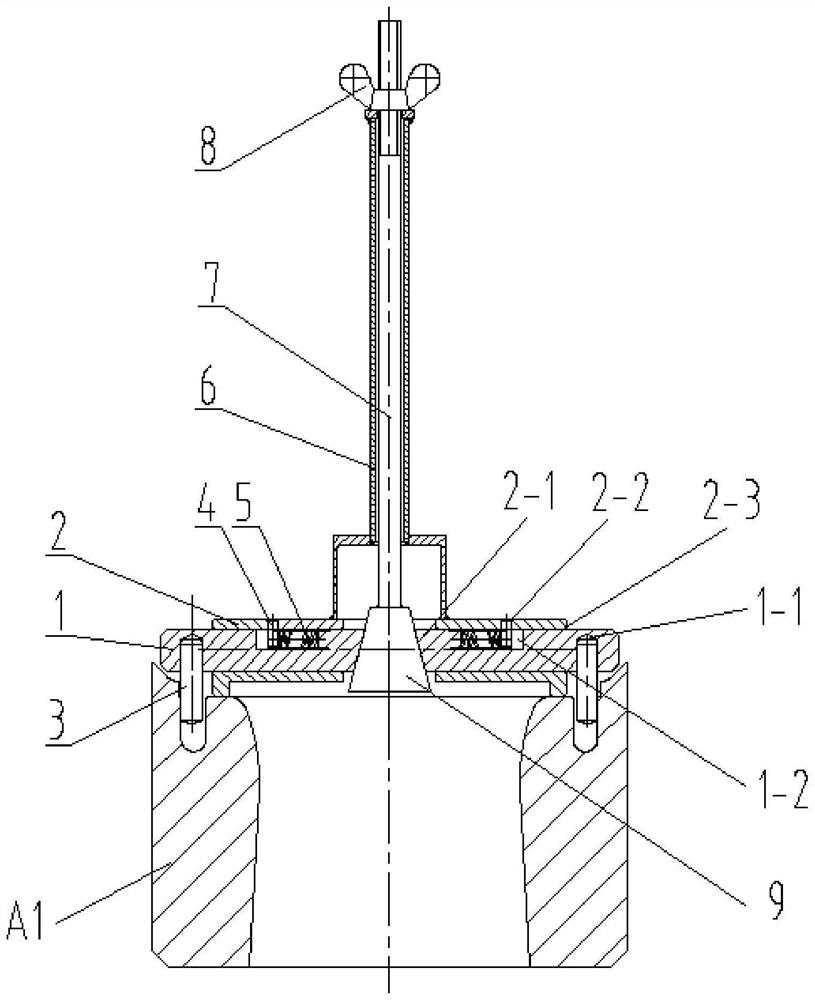

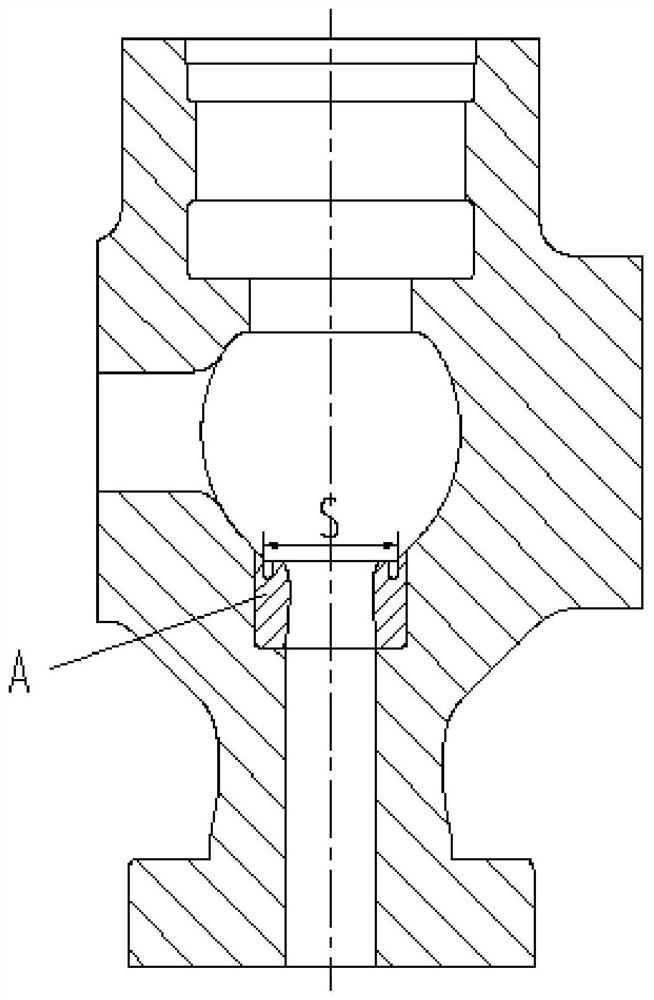

[0012] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment mode, a narrow space ring groove inner diameter measuring device described in this embodiment mode, which includes a sliding seat 2, a pull rod 7, a tapered block 9, a plurality of slider blocks 1, a plurality of cylindrical pins 3 and a plurality of stop pins 4. A tapered hole 2-1 is processed at the center of the sliding seat 2, and the tapered hole 2-1 is used to install the tapered block 9. Both the tapered hole 2-1 and the tapered block 9 are narrow at the top and wide at the bottom. On the one hand, the seat 2 provides guidance for the slider 1, and on the other hand, it plays the role of positioning the entire measuring device on the valve seat A1; a plurality of first through holes 2-2 are symmetrically processed around the tapered hole 2-1, each Each of the first through holes 2-2 is used to place the stop pin 4, and the inside of the slide seat 2 is processed with a second th...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the device for measuring the inner diameter of a ring groove in a narrow space described in this embodiment, the central axis of the second through hole 2-3 on the slide seat 2 is perpendicular to the central axis of the tapered hole 2-1, so set, The relative position between the tapered block 9 at the bottom end of the pull rod 7 and each slider 1 is ensured, so that the pull rod 7 can drive the slide block 2 to slide outward when in use, thereby completing accurate measurement. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, a device for measuring the inner diameter of an annular groove in a narrow space described in this embodiment, it also includes a plurality of springs 5, the springs 5 provide elastic force for the contraction of the slider 1, so that the measuring device can automatically return to its original shape after use , easy to use, each spring 5 is installed in the groove 1-2, and each spring 5 is located between each stop pin 4 and the side wall of the groove 1-2, the other is the same as the specific embodiment one or two same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com