Weld joint tensile force testing machine

A tensile testing machine and pressure sensor technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Pull force shows accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

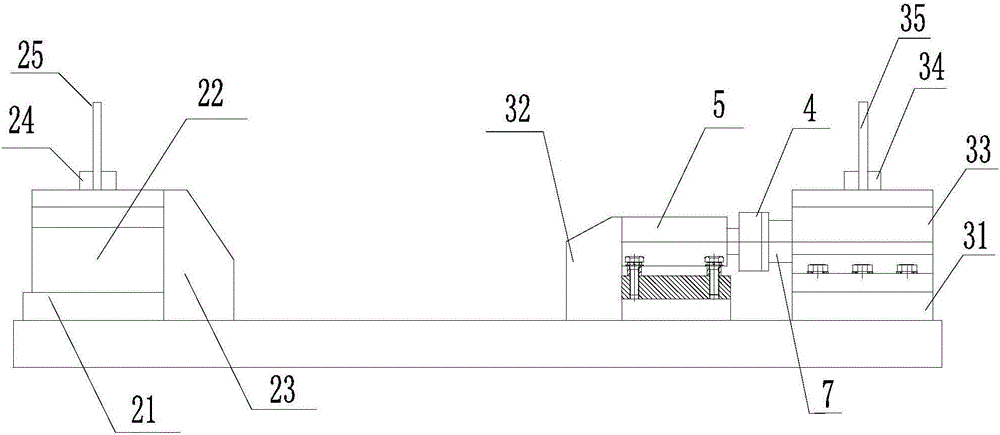

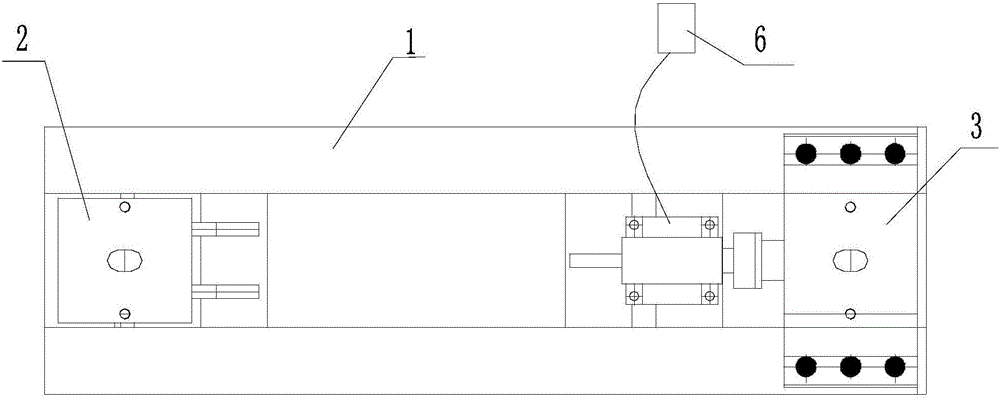

[0018] Such as figure 1 with figure 2 As shown, this embodiment includes a base 1, a stationary fixed end 2, a movable fixed end 3, a pressure sensor 4, a hydraulic cylinder 5, and a manual oil pump 6; the stationary fixed end 2 is fixed on one end of the base 1, and the movable fixed end 3 is movable on the other end of the base 1, the stationary fixed end 2 and the movable fixed end 3 are respectively provided with mounting blocks, the hydraulic cylinder 5 is fixed on the base 1, and the piston rod of the hydraulic cylinder 5 is connected to the movable fixed end 3 , the pressure sensor 4 is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com