Heat dissipation type explosion-proof structure of laser scanner

A laser scanner and explosion-proof structure technology, applied in the field of laser scanners, can solve the problems of low explosion-proof performance and poor heat dissipation, and achieve the effects of improving heat conduction efficiency, excellent surface heat dissipation structure, and preventing temperature accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

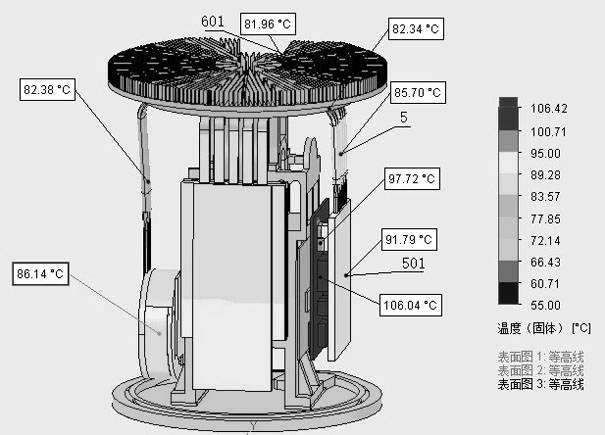

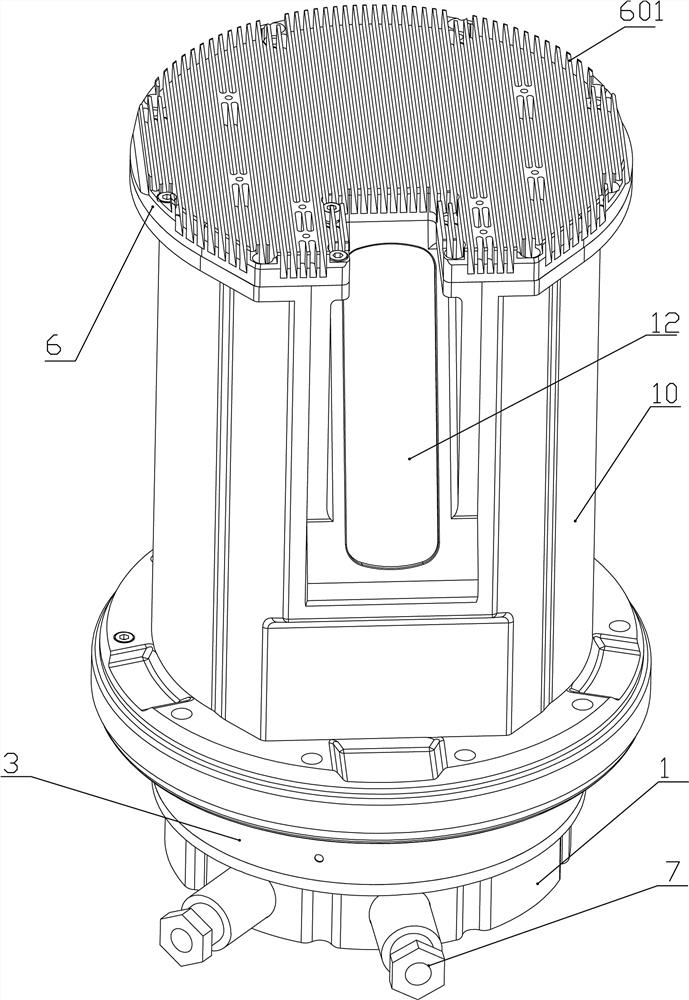

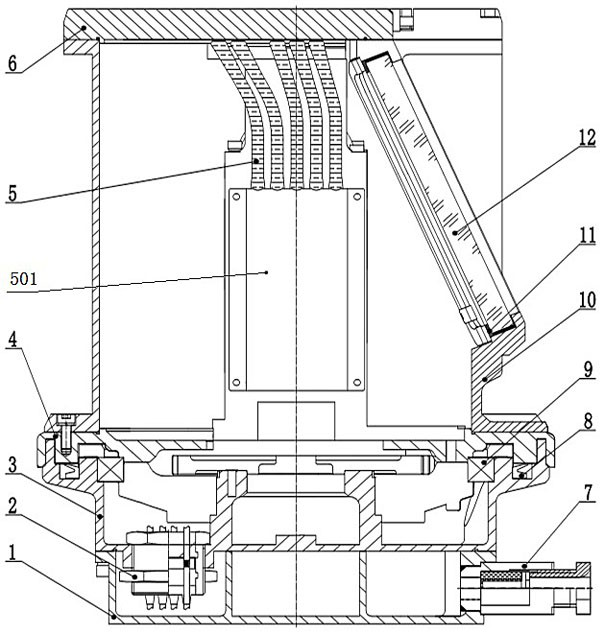

[0025] Such as Figure 1-6 Among them, a laser scanner heat dissipation explosion-proof structure, including a hollow shell 10, the shell 10 is provided with a heat dissipation module 5, the heat dissipation module 5 includes a heat absorbing sheet 501, and one end of the heat absorbing sheet 501 is provided with a heat pipe, and the shell 10 A heat dissipation structure 601 is provided on the outside, and the heat pipe is connected to the heat dissipation structure 601 so that the heat inside the casing 10 is transferred to the outside of the casing 10, effectively avoiding heat accumulation.

[0026] The internal heat dissipation module 5 is installed on the circuit board, and silicone grease with high thermal conductivity is installed on the components with high heat generation. The working fluid in the body undergoes repeated physical phase changes to transfer heat; multiple heat pipes are designed to contact the top cover 6 through a heat-conducting medium, and the top co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com