Visual measuring device for rock mechanics experiment

A measuring device and technology of rock mechanics, applied in measuring devices, applying stable tension/pressure to test the strength of materials, scientific instruments, etc., can solve the problems of inability to effectively monitor rock damage micro-signals and inability to visually observe rock compression failure process, etc. , to achieve the effect of accurate positioning and accurate monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

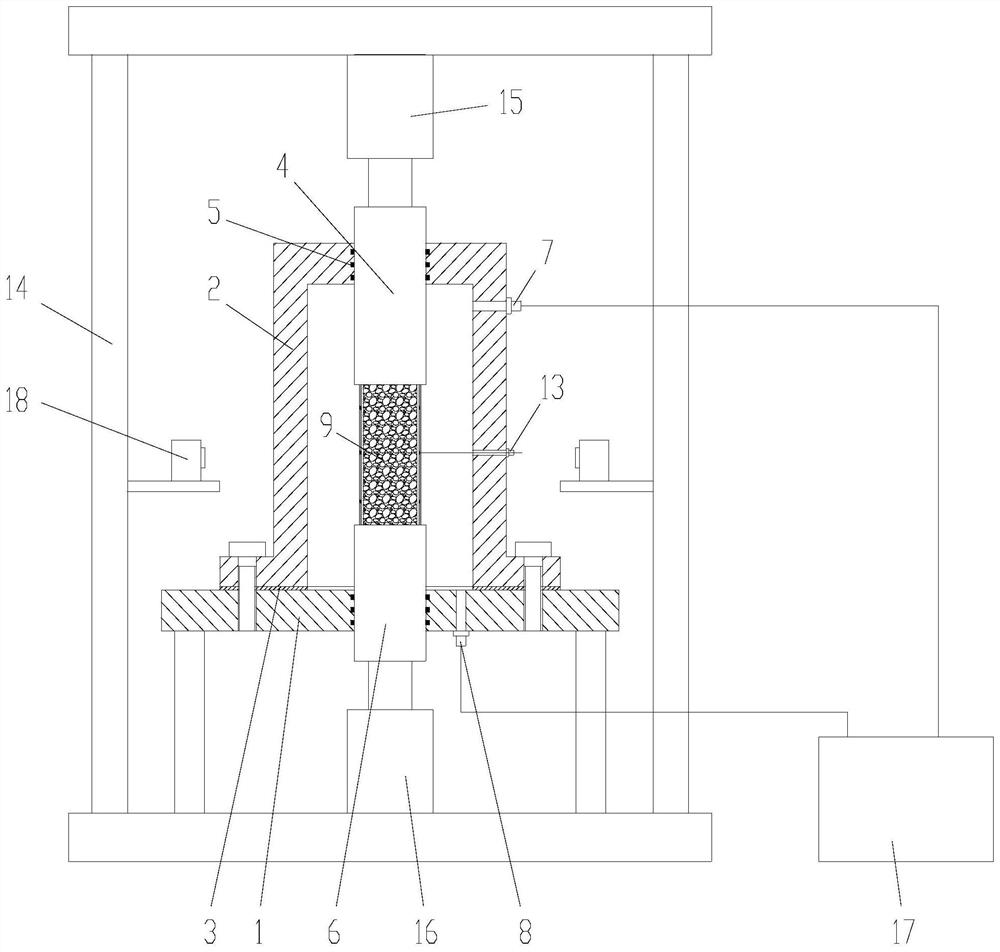

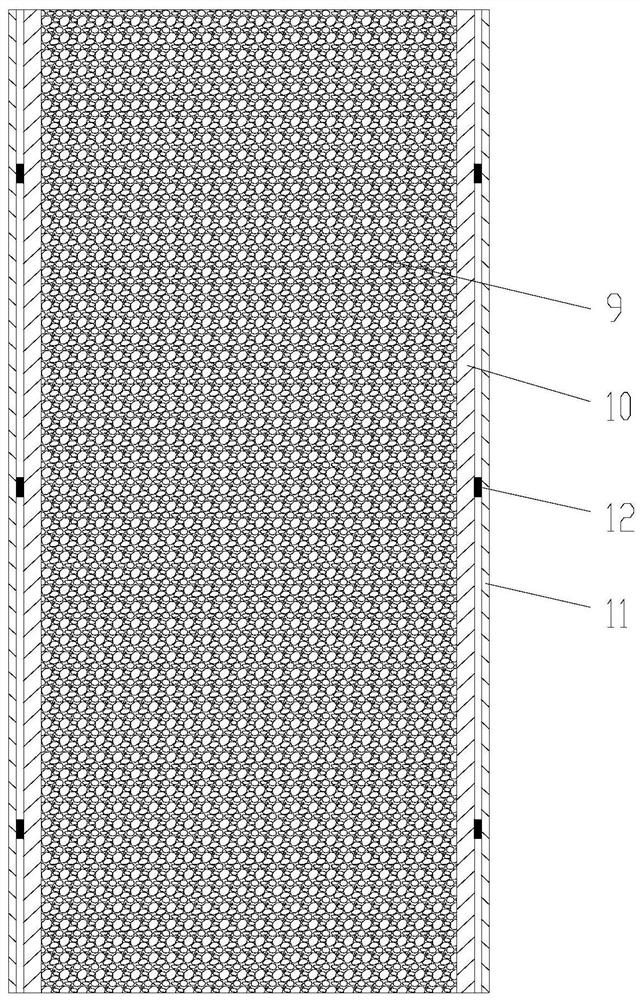

[0015] As shown in the figure, the visual measurement device for rock mechanics experiments in this embodiment includes a confining pressure chamber, which includes a horizontal bottom plate 1, a transparent enclosure 2 connected to the horizontal bottom plate by bolts, and the top surface of the horizontal bottom plate The sealing gasket 3 between the lower end surface of the transparent enclosure, the upper middle part of the upper end of the transparent enclosure is provided with an upper pressure head 4, and the transparent enclosure is also provided with a sealing ring 5 that slides and seals up and down with the upper pressure head. The middle part of the lower end is provided with a lower pressure head 6, and a sealing ring is provided on the horizontal bottom plate which slides and cooperates with the lower pressure head up and down; the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com