Beverage production device

A technology for producing equipment and beverages, which is applied in the directions of dissolving, mixer, and food forming, etc., can solve the problem of not being able to stack raw materials, and achieve the effect of improving processing efficiency, improving direction and method, and speeding up mixing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

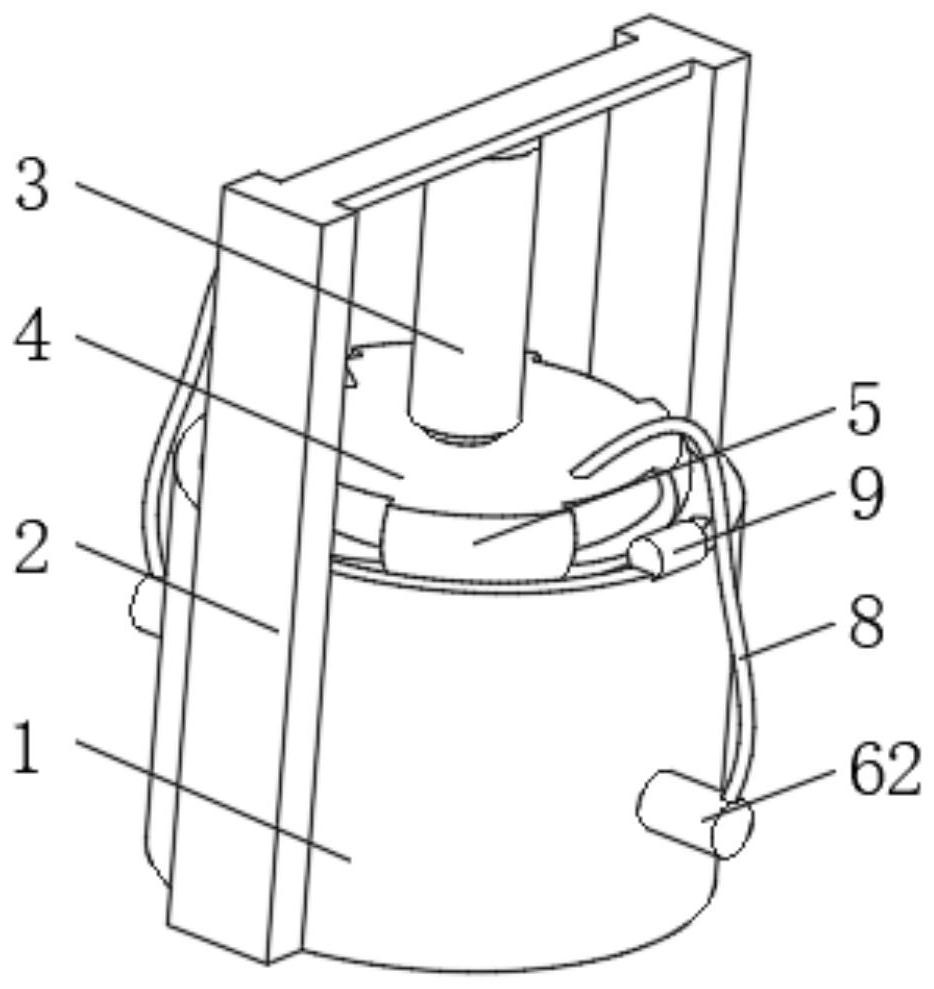

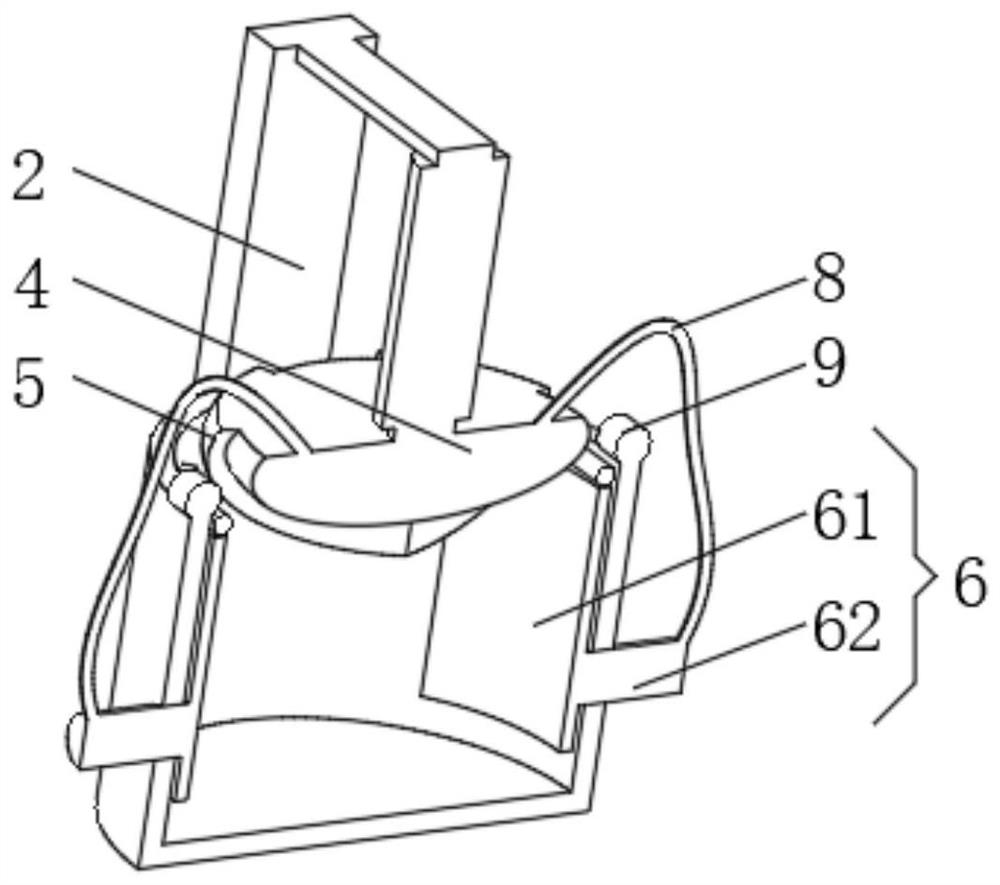

[0033] see Figure 1-4 , the present invention provides a technical solution: a beverage production device, including a processing barrel 1, a mounting frame 2 is installed on the outside of the processing barrel 1, a processing oil cylinder 3 is fixedly connected to the inner bottom of the mounting frame 2, and one end of the bottom of the processing oil cylinder 3 The processing block 4 is connected in rotation, and the outside of the processing block 4 is installed with:

[0034] Stacking device 6, the stacking device 6 has a swing plate 61, the swing plate 61 is the same as the inner wall radian of the processing barrel 1, a push rod 62 is installed on one side of the swing plate 61, and the push rod 62 runs through the processing barrel 1 and extends to the processing barrel 1. the exterior of bucket 1;

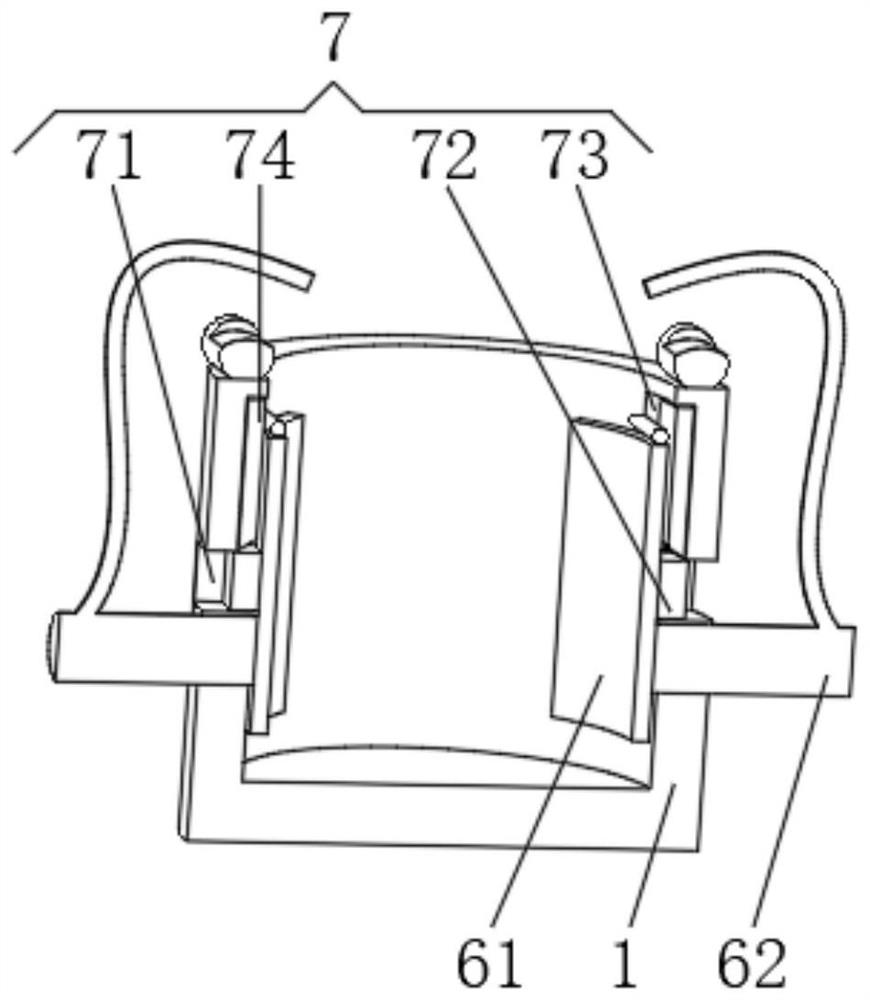

[0035] Inflatable device 7, the inflatable device 7 has an inflation hole 71, one side of the swing plate 61 is fixedly connected with a sealing protrusion 72 suitable ...

Embodiment 2

[0040] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, a side cutting device 5 is installed on the outside of the processing block 4, the side cutting device 5 has a backing plate 51, and the bottom of the backing plate 51 is equipped with a guide plate through an elastic plate 52 53 , a guide spring 54 is fixedly connected between the backing plate 51 and the guide plate 53 , and a side cutting sawtooth piece 55 is fixedly connected to one side of the backing plate 51 .

[0041] The top of the guide plate 53 is fixedly connected with a tilting rod 10 , and the end of the tilting rod 10 away from the guide plate 53 is fixedly connected with a booster plate 11 .

[0042] A stirring tank 12 is provided on the side of the sealing protrusion 72 far away from the swing plate 61 , a stirring rod 13 is mounted inside the stirring tank 12 , and a stirring blade 14 is mounted on one end of the stirring rod 13 .

[0043] One side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com