Atomization device based on cotton core

An atomizing device and cotton core technology, applied in tobacco and other directions, can solve the problems of poor e-liquid taste reduction, poor user experience, expensive ceramic core, etc., to achieve good oil storage, full smoke, and reduce oil leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

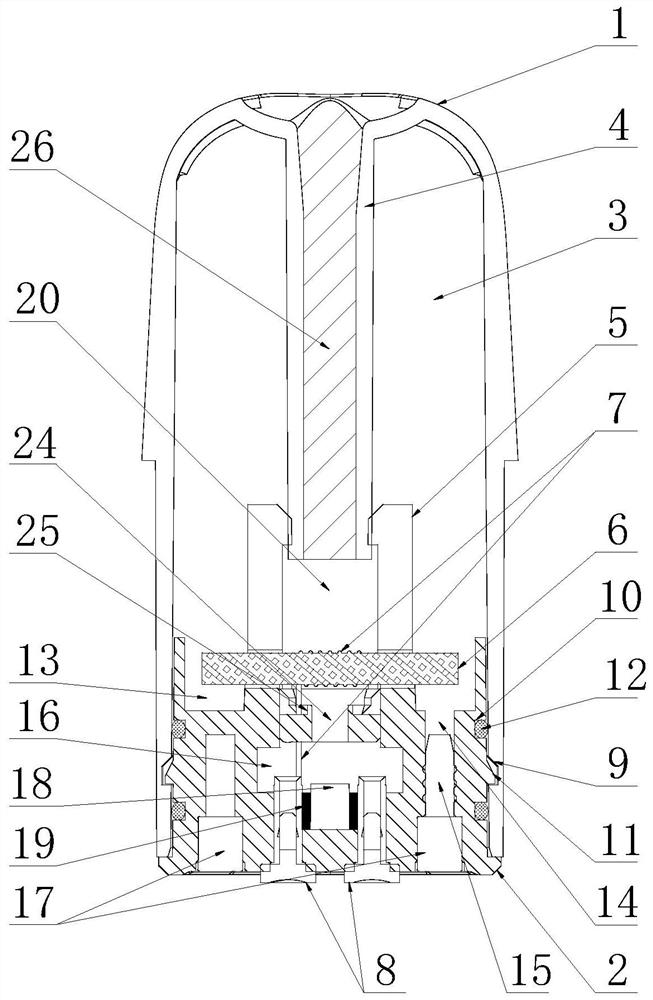

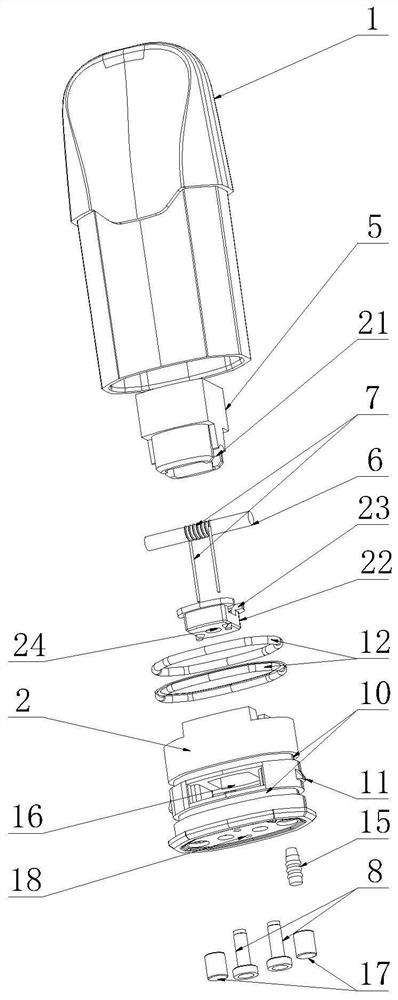

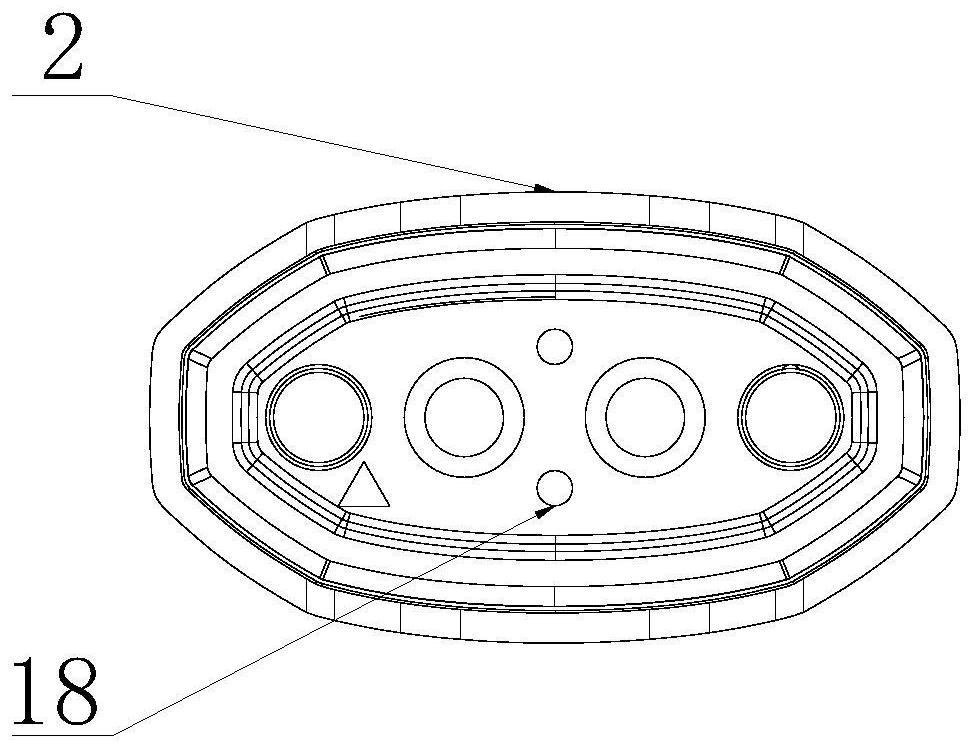

Embodiment 1

[0027] Embodiment 1 of the present invention: an atomizing device based on a cotton core, comprising a housing 1 and a lower bracket 2, the inner surface of the bottom opening of the housing 1 is in close contact with the outer surface of the lower bracket 2, the housing The inner cavity of 1 includes an oil tank 3 and an air passage 4, the bottom end of the air passage 4 is provided with an oil tank seal 5, and a cotton core 6 is provided between the bottom end surface of the oil tank seal 5 and the top of the lower bracket 2, The cotton core 6 is provided with a heating wire 7, and the bottom of the lower bracket 2 is provided with an electrode 8, and the heating wire 7 is connected to the electrode 8; the oil tank seal 5 prevents oil and gas from entering the air passage 4, and the cotton core 6 stores Good oiliness, less oil leakage, no frying phenomenon, and fuller smoke, improving user experience.

Embodiment 2

[0028] Embodiment 2 of the present invention: an atomizing device based on a cotton core, comprising a housing 1 and a lower bracket 2, the inner surface of the bottom opening of the housing 1 is in close contact with the outer surface of the lower bracket 2, and the housing The inner cavity of 1 includes an oil tank 3 and an air passage 4, the bottom end of the air passage 4 is provided with an oil tank seal 5, and a cotton core 6 is provided between the bottom end surface of the oil tank seal 5 and the top of the lower bracket 2, The cotton core 6 is provided with a heating wire 7, and the bottom of the lower bracket 2 is provided with an electrode 8, and the heating wire 7 is connected to the electrode 8; the oil tank seal 5 prevents oil and gas from entering the air passage 4, and the cotton core 6 stores Good oiliness, less oil leakage, no fried oil phenomenon, and fuller smoke, improving user experience; the top of the lower bracket 2 is provided with an annular infiltrat...

Embodiment 3

[0029] Embodiment 3 of the present invention: an atomizing device based on a cotton core, comprising a housing 1 and a lower bracket 2, the inner surface of the bottom opening of the housing 1 is in close contact with the outer surface of the lower bracket 2, the housing The inner cavity of 1 includes an oil tank 3 and an air passage 4, the bottom end of the air passage 4 is provided with an oil tank seal 5, and a cotton core 6 is provided between the bottom end surface of the oil tank seal 5 and the top of the lower bracket 2, The cotton core 6 is provided with a heating wire 7, and the bottom of the lower bracket 2 is provided with an electrode 8, and the heating wire 7 is connected to the electrode 8; the oil tank seal 5 prevents oil and gas from entering the air passage 4, and the cotton core 6 stores Good oiliness, less oil leakage, no fried oil phenomenon, and fuller smoke, improving user experience; the top of the lower bracket 2 is provided with an annular infiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com