Spring needle impedance detection machine and working method thereof

A pogo pin and testing machine technology, applied in the measurement of resistance/reactance/impedance, measurement device, measurement of electrical variables, etc., can solve problems such as low detection efficiency and improved testing efficiency, and achieve high detection efficiency, strong practicability, and design. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

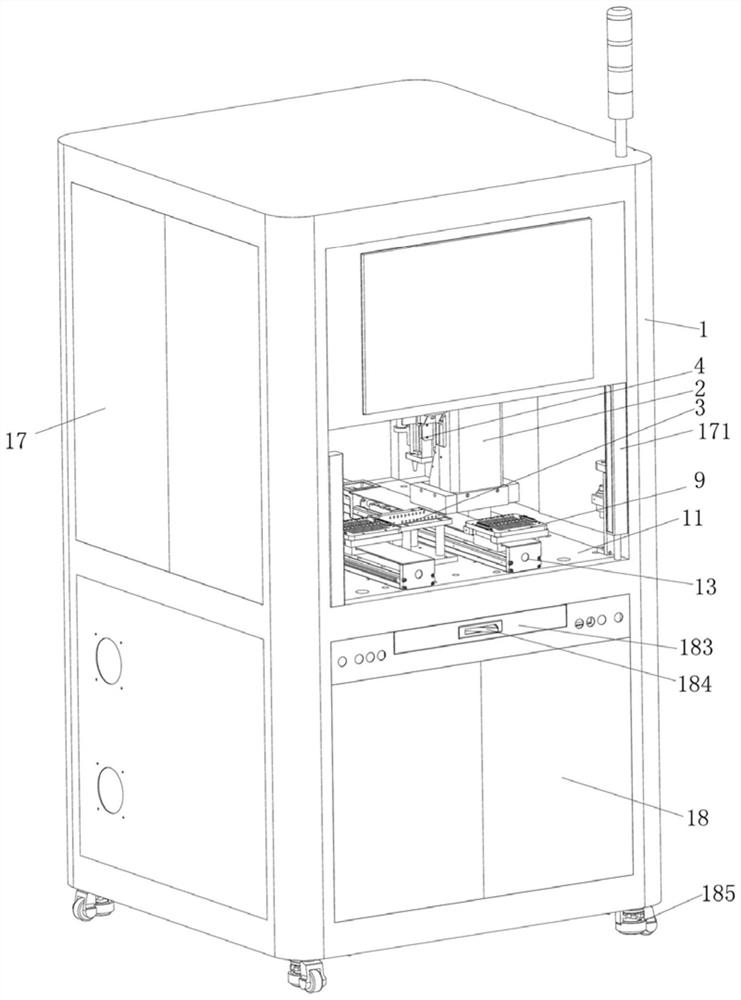

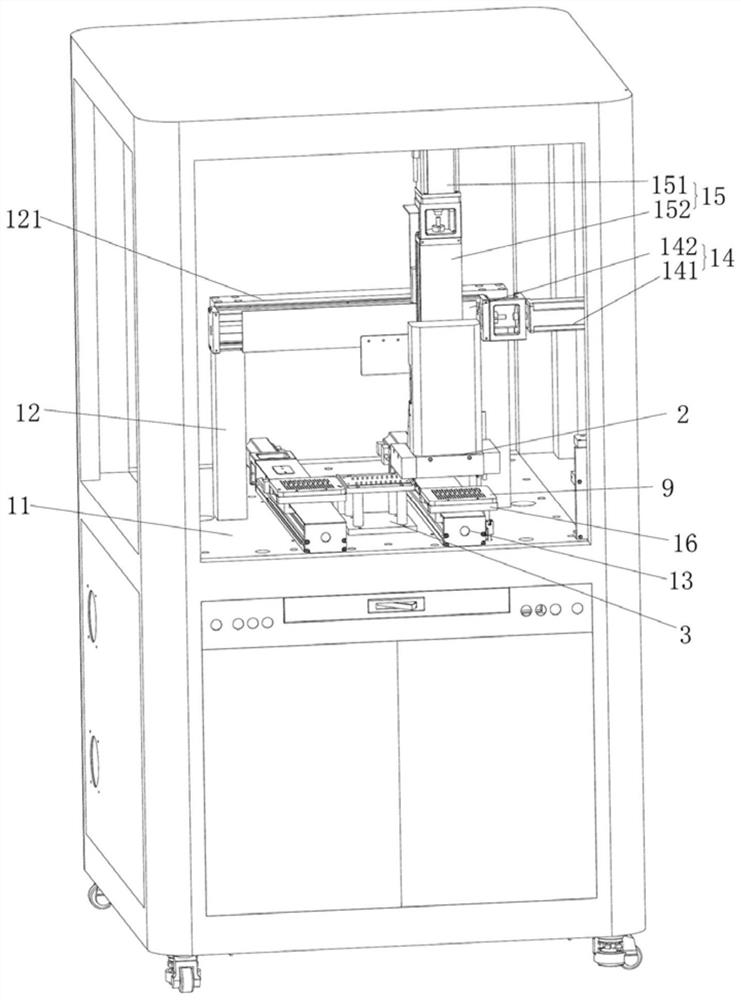

[0039] Specific embodiments of the present invention are described with reference to the accompanying drawings.

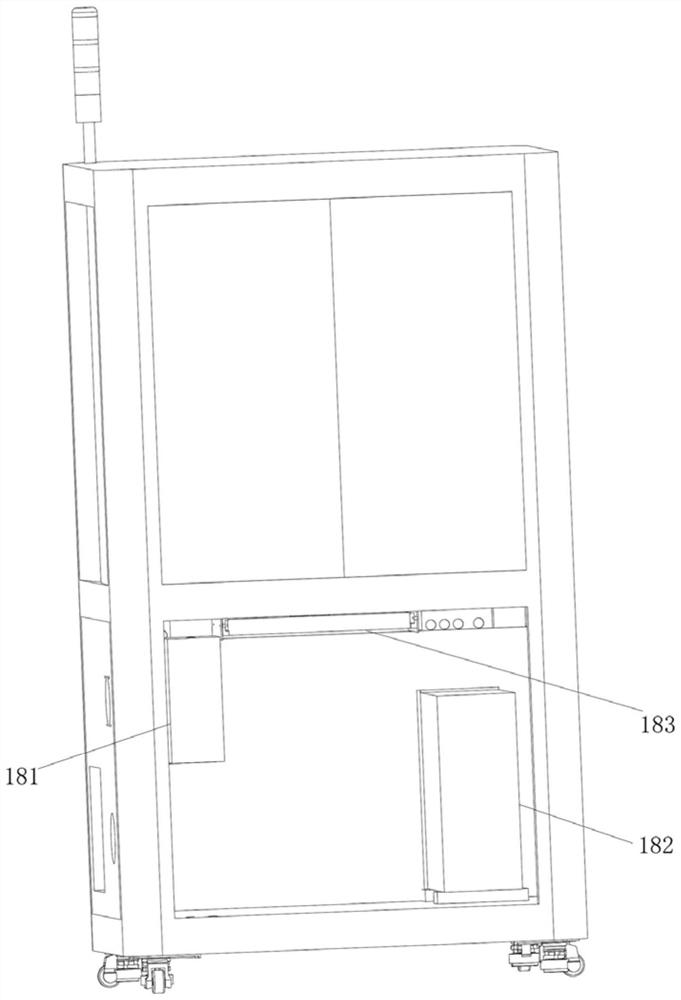

[0040] Such as Figure 1-9As shown, a pogo pin impedance detection machine includes a frame 1, a detection head 2, a spot inspection device 3, and a waste removal device 4. A gantry 12 is arranged on the workbench 11 of the frame 1, and the detection head 2 and The suction nozzle 45 of the waste rejecting device 4 is movably arranged on the crossbeam 121 of the gantry 12, and the inspection device 3 is fixed on the workbench 11 and located below the gantry 12, and the workbench 11 is on the left and right sides of the inspection device 3 Two linear drive mechanisms 13 are arranged symmetrically. The linear drive mechanism 13 is provided with a feeding table 16. The feeding table 16 is provided with a conductive tray loaded with pogo pins. The two feeding tables 16 pass through the two linear drive mechanisms 13 respectively. Separately driven to form alternate fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com