Purification and regeneration process and equipment of waste refrigerator plastic

A technology for plastics and refrigerators, which is applied in the field of purification and recycling of waste refrigerator plastics and equipment, which can solve the problems of poor recycling of plastics, and achieve the effects of solving poor purification grades, improving regeneration quality, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

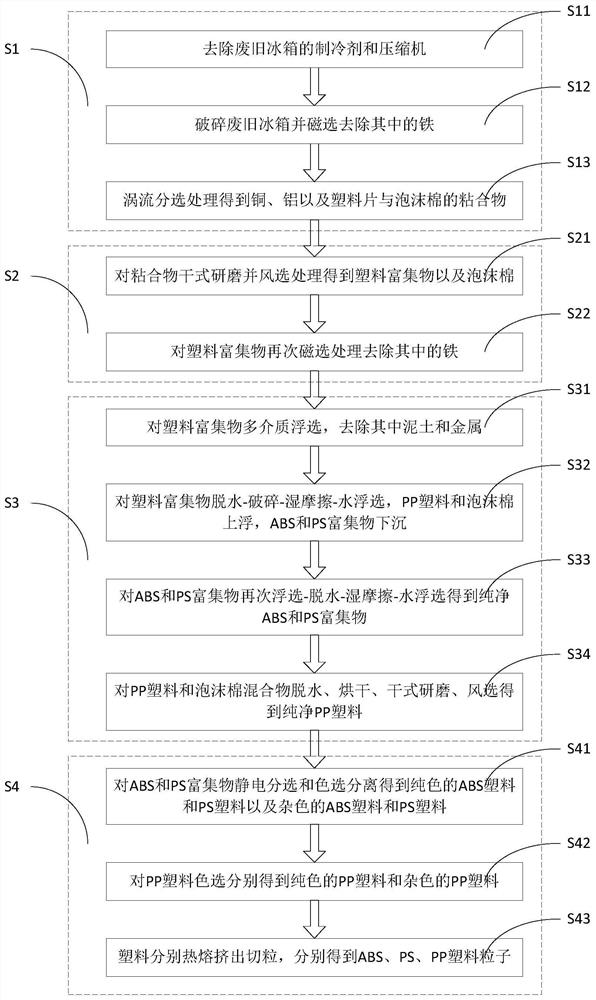

[0029] See figure 1 , The purification and regeneration process of waste refrigerator plastics includes four major steps: S1 crushing and sorting, S2 dry sorting, S3 wet sorting and S4 purification and granulation.

[0030] Among them, step S1 includes three sub-steps: S11 extracts the refrigerant of the used refrigerator and removes the compressor of the used refrigerator. This step is to recover the refrigerant in the used refrigerator to avoid environmental pollution caused by refrigerant leakage. In addition, the compressor, as a high-value component, is generally disassembled and dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com