Protective safety shoe production equipment

A technology for production equipment and safety shoes, applied in the field of shoe product processing, can solve the problems of scratched leather, inconvenient accurate detection, inconvenient and rapid appearance of the leather surface, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

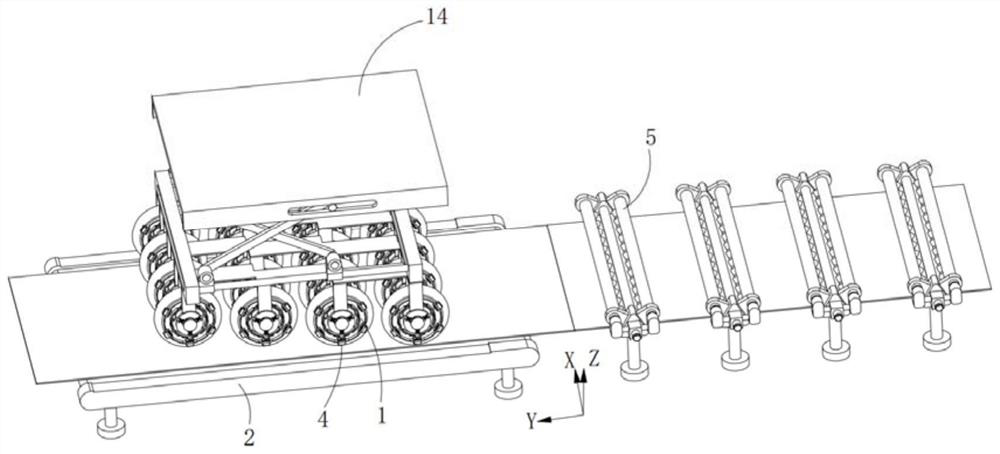

[0043] Such as figure 1 , 2 Shown in and 6, a kind of protective safety shoes production equipment comprises:

[0044] Pressing bladders 1, the pressing bladders 1 are equidistantly arranged along the width direction of leather conveying;

[0045] A pad 2, the pad 2 is provided on the side opposite to the pressure bag 1 on the leather;

[0046] A detection piece 3, the detection piece 3 is arranged in the pressure bag 1 along the leather thickness direction, and the lower end of the detection piece 3 is elastically pressed on the contact surface between the pressure bag 1 and the leather; and

[0047] Marking assembly 4, the marking assembly 4 is arranged on both sides of the pressure bag 1 along the circumferential direction of the pressure bag 1;

[0048] When the detection part 3 detects that the thickness of the leather is less than a predetermined value, the marking print 4 linearly marks both sides of the pressure bag 1 along the leather conveying direction.

[0049]...

Embodiment 2

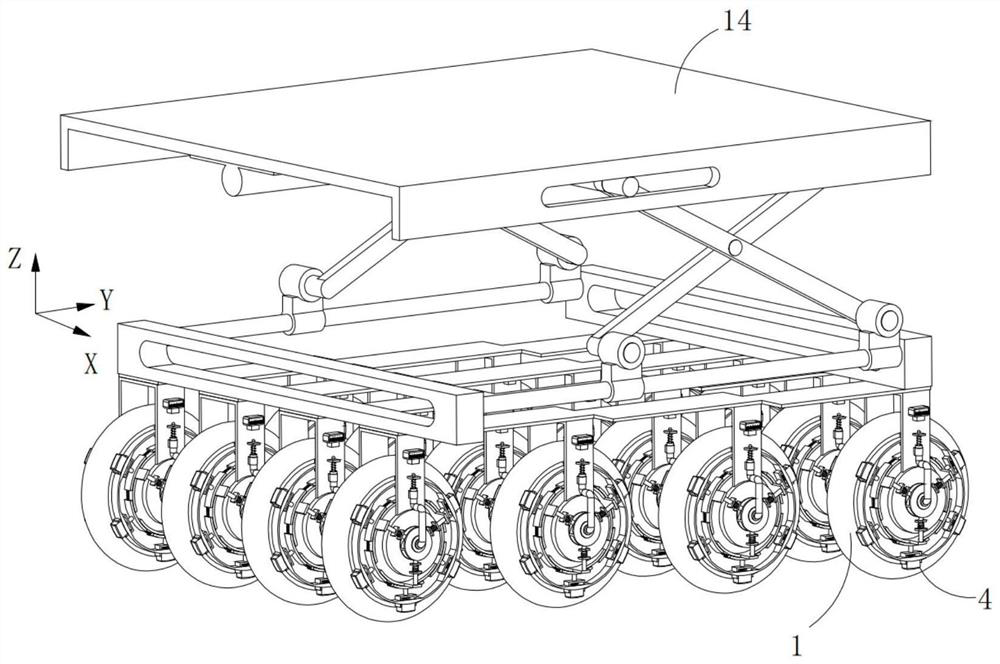

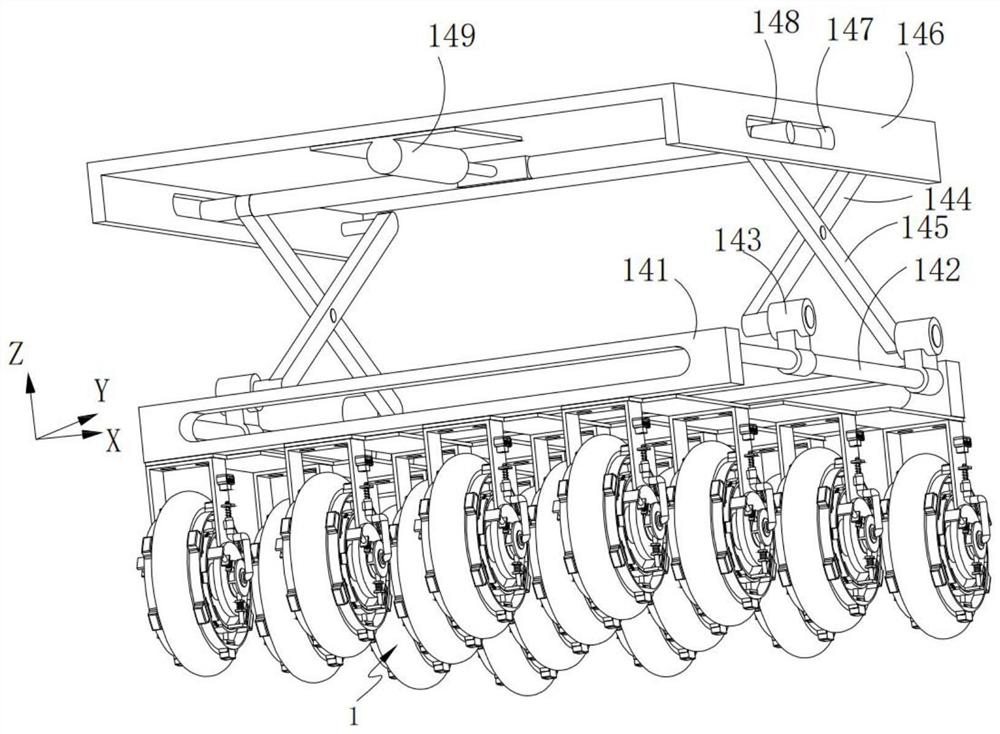

[0075] Such as Figure 6 and 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the pressure bag 1 includes:

[0076] A capsule 11, the capsule 11 is a wheel-shaped structure;

[0077] Insertion shaft 12, the insertion shaft 12 runs through the center of both sides of the capsule 11;

[0078] The second mounting base 13, the second mounting base 13 is fixedly connected to both ends of the insertion shaft 12; and

[0079] Lifting frame 14, described lifting frame 14 is positioned at the top of described second mounting base 12, and described second mounting base 12 is arranged on described lifting frame 13 along leather conveying width direction;

[0080] The lifting frame 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com