A kind of high-temperature-resistant flaky iron-cobalt-germanium absorbing material and its preparation method and application

A wave absorbing material, high temperature resistant technology, applied in magnetic field/electric field shielding, antennas, electrical components, etc., can solve the problems of high hardness of FeCo alloy, thick wave absorbing coating, difficult to break and other problems, and reach the usable temperature. The effect of high, low absorption frequency and high Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

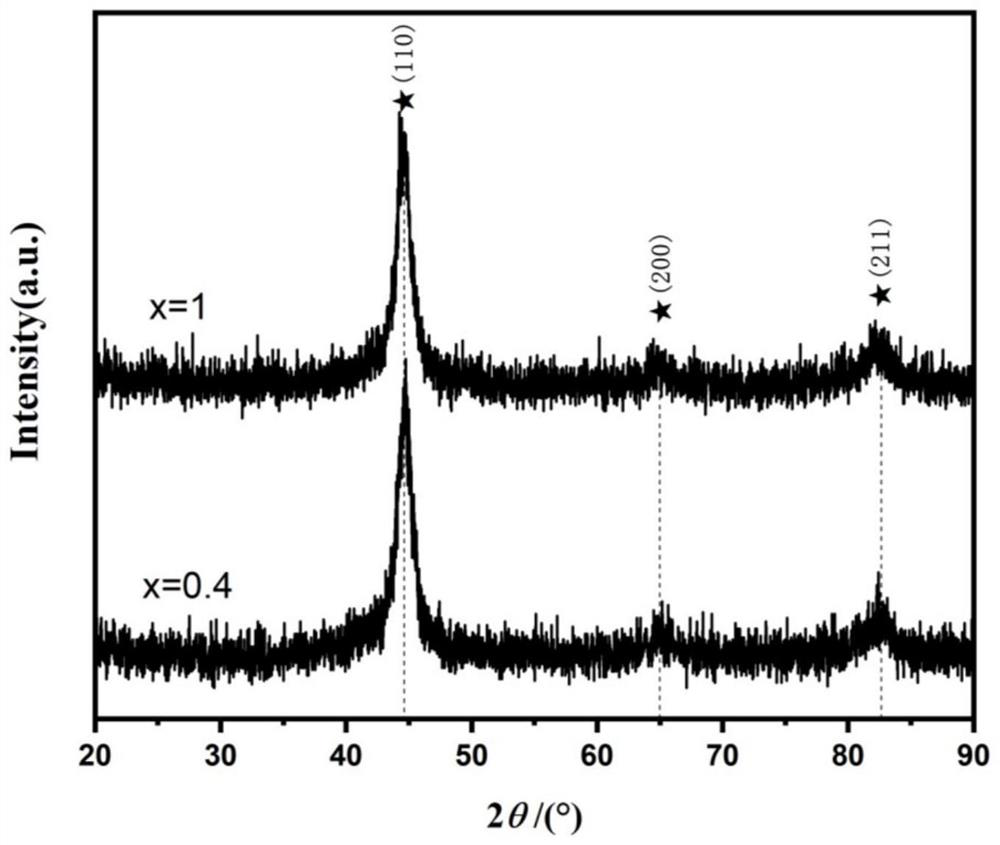

[0043] Ge-doped flaky Fe in this example 6.5 co 3.5 Ge x (x=0.2), its preparation method comprises the following steps:

[0044] (1) Using an electronic balance with an accuracy of 0.1mg, the stoichiometric ratio is 6.5:3.5:0.2, and weigh 3.1091g iron particles (99.9% purity), 1.7665g cobalt flakes (99.9% purity) and 0.1244g germanium Granules (purity: 99.9%), the error is within 0.5mg, as the raw material.

[0045] (2) Put the raw materials in step (1) into the vacuum electric arc furnace, and put the titanium ingot in the center at the same time, and extract it to 7×10 -4 Vacuum degree below Pa. Then, high-purity argon is introduced as a protective gas to smelt titanium ingots and fully absorb the possible residual oxygen in the furnace. Afterwards, the alloy is smelted. In order to ensure uniform composition, each alloy needs to be turned over after melting and cooling. This is repeated 5 times, and each smelting lasts for about 1 minute. After all is completed, wait ...

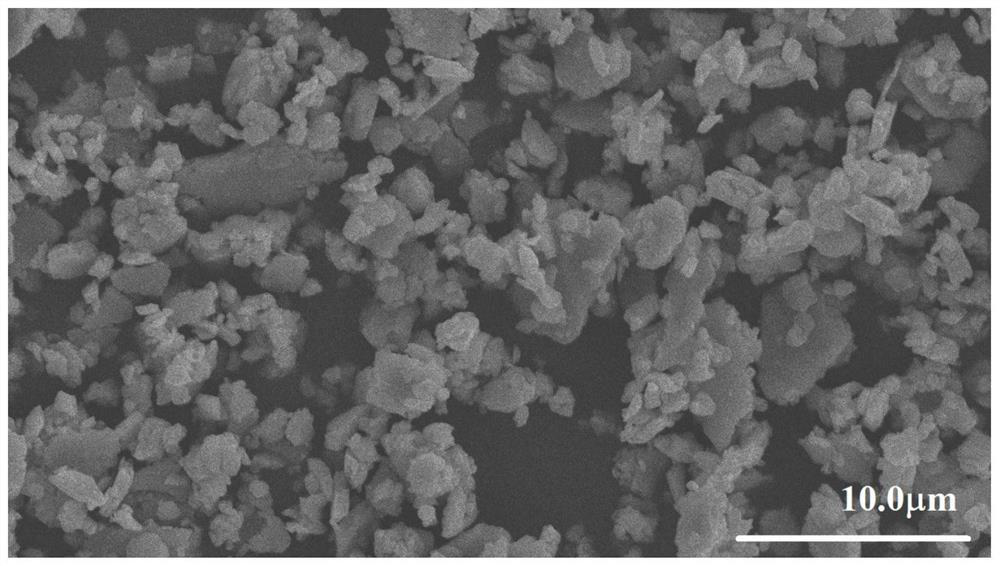

Embodiment 2

[0049] (1) Using an electronic balance with an accuracy of 0.1mg, the stoichiometric ratio is 6.5:3.5:0.4, and weigh 3.0337g iron pellets (99.9% purity), 1.77236g cobalt flakes (99.9% purity) and 0.2427g germanium Granules (purity: 99.9%), the error is within 0.5mg, as the raw material.

[0050] (2) Put the raw materials in step (1) into the vacuum electric arc furnace, and put the titanium ingot in the center at the same time, and extract it to 7×10 -4 Vacuum degree below Pa. Then, high-purity argon is introduced as a protective gas to smelt titanium ingots and fully absorb the possible residual oxygen in the furnace. Afterwards, the alloy is smelted. In order to ensure uniform composition, each alloy needs to be turned over after melting and cooling. This is repeated 5 times, and each smelting lasts for about 1 minute. After all is completed, wait until the bulk alloy is completely cooled, fill with air, open the furnace door, and take out the bulk alloy.

[0051] (3) Put...

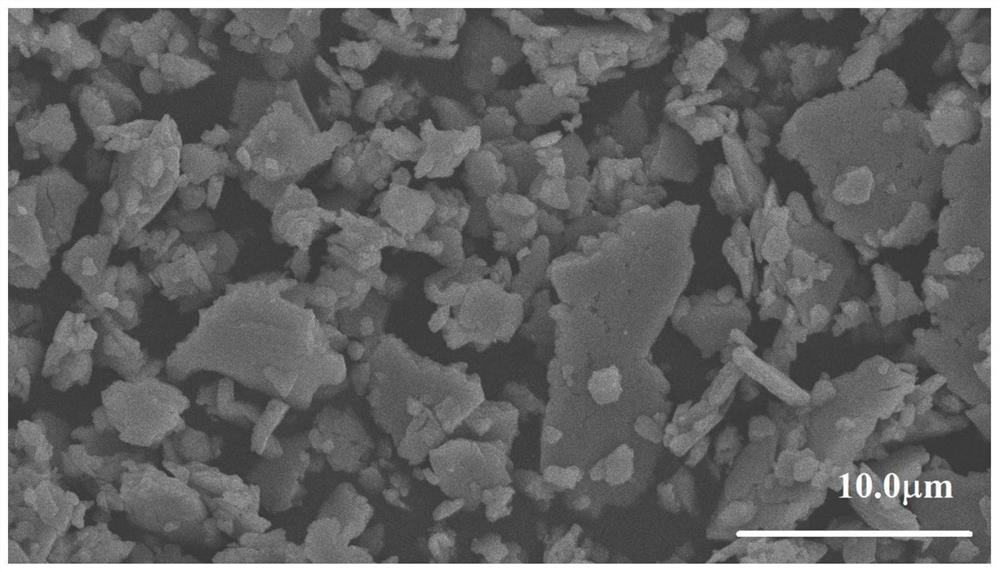

Embodiment 3

[0054] (1) Using an electronic balance with an accuracy of 0.1mg, the stoichiometric ratio is 6.5:3.5:0.6, and weigh 2.9618g iron pellets (99.9% purity), 1.6828g cobalt flakes (99.9% purity) and 0.3554g germanium Granules (purity: 99.9%), the error is within 0.5mg, as the raw material.

[0055] (2) Put the raw materials in step (1) into the vacuum electric arc furnace, and put the titanium ingot in the center at the same time, and extract it to 7×10 -4 Vacuum degree below Pa. Then, high-purity argon is introduced as a protective gas to smelt titanium ingots and fully absorb the possible residual oxygen in the furnace. Afterwards, the alloy is smelted. In order to ensure uniform composition, each alloy needs to be turned over after melting and cooling. This is repeated 5 times, and each smelting lasts for about 1 minute. After all is completed, wait until the bulk alloy is completely cooled, fill with air, open the furnace door, and take out the bulk alloy.

[0056] (3) Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com