Beam end hinged connecting assembly for bearing axial force in high-rise building

A technology for high-rise buildings and connecting components, applied in the direction of buildings and building structures, etc., can solve problems such as loss of cross-sectional area, cracking of welds, yielding of steel plates in node areas, etc., to reduce the loss of cross-sectional area and improve the effect of turning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

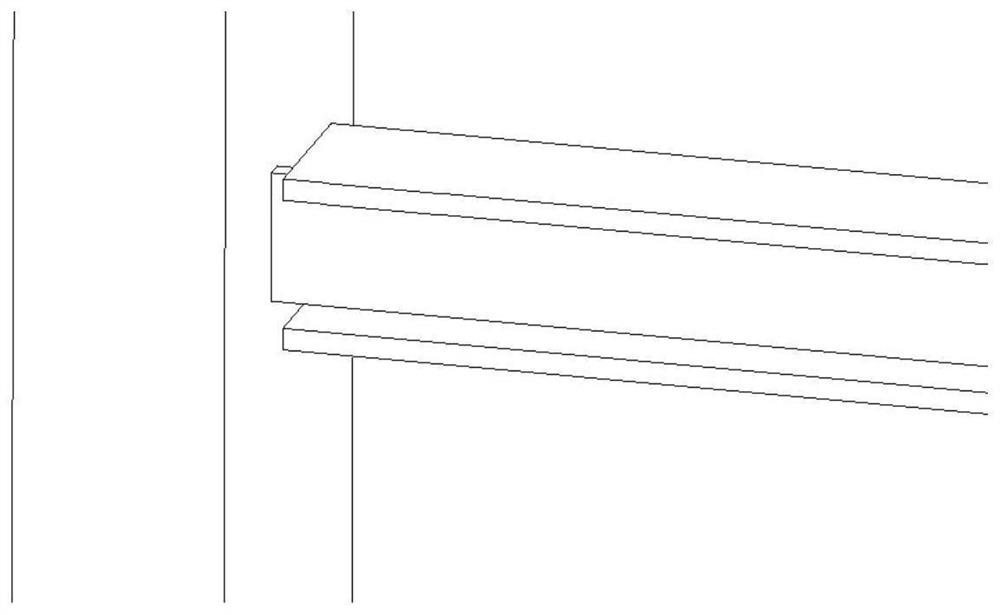

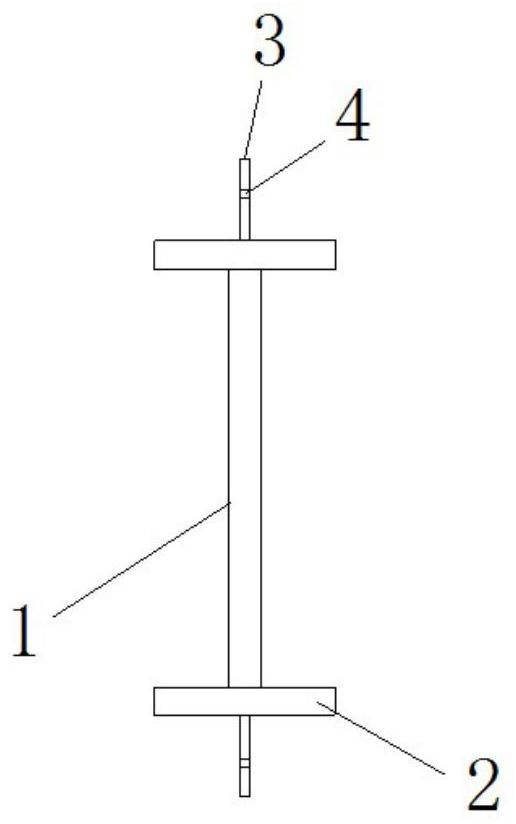

[0037] The axial force beam consists of a vertical web 1 located in the vertical direction, and a first flange plate 2 connected to both ends of the vertical web 1. The first flange plate 2 is located in the horizontal direction, and the whole is in the shape of "I". .

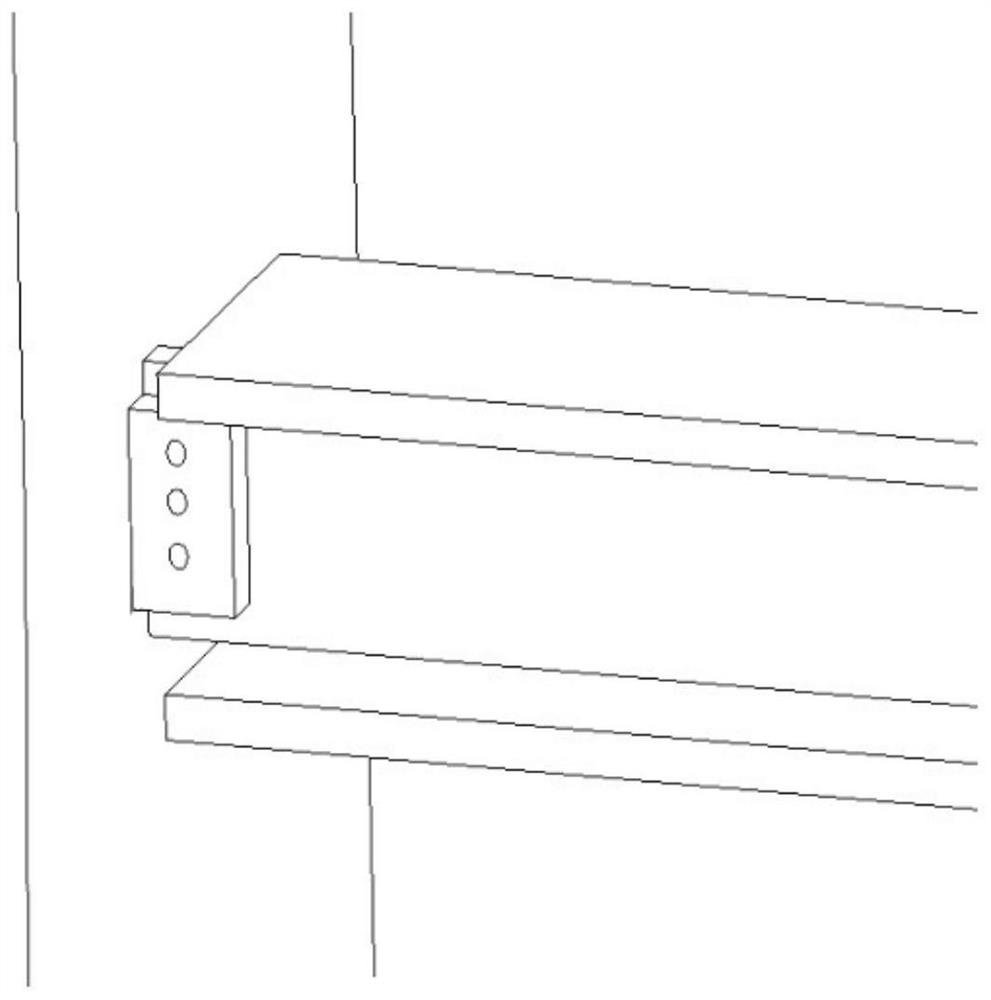

[0038] The connection assembly, the connection assembly includes a cross steel plate 7 with a cross-shaped longitudinal section, one end of the cross steel plate 7 is welded on the vertical steel frame 15 of the lateral force-resistant member, and the other end of the cross steel plate 7 is welded with an end plate 14 . Preferably, the height of the vertical plate of the cross steel plate 7 is equal to the height of the vertical web 1 but smaller than the height of the end plate 14 .

[0039] A first connecting plate 9 is provided on the end faces of the cross steel plate 7 on both sides of the upper and lower sides, and a first bolt hole 8 is opened on the first connecting plate 9; the first flange plate 2 of...

specific Embodiment 2

[0042] The axial force beam consists of a vertical web 1 located in the vertical direction, and first flange plates 2 connected to both ends of the vertical web 1 , and the first flange plate 2 is located in the horizontal direction. The axial force beam also includes a horizontal web 5 in the horizontal direction, and the horizontal web 5 crosses the vertical web 1, so that the longitudinal section of the overall structure formed by the vertical web 1 and the horizontal web is cross-shaped. The longitudinal section of the entire axial beam is in the shape of a "king". The increased horizontal web can effectively increase the area of the end of the axial beam, thereby increasing the area of the net section of the beam end node.

[0043] The connection assembly, the connection assembly includes a cross steel plate 7 with a cross-shaped longitudinal section, one end of the cross steel plate 7 is welded on the vertical steel frame of the lateral force-resistant member, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com