Patents

Literature

68 results about "Uricotelic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A uricotelic organism excretes uric acid or its salts as a result of deamination. Among the three major forms of excretion of nitrogenous waste in organisms, uric acid is the least toxic and the least soluble in water. It can be stored in cells and body tissues without toxic effects and requires only a tiny amount of water, about 0.001 L, per 1 g of nitrogen. A single molecule of uric acid can also remove four atoms of nitrogen, making it more efficient than ammonotelism and ureotelism. Uricotelic organisms typically have white pasty excreta. Uricotelic organisms include terrestrial arthropods, lizards, snakes, and birds.

Variant Forms of Urate Oxidase and Use Thereof

ActiveUS20090169534A1Retains uricolytic activityImprove stabilityBacteriaPeptide/protein ingredientsUracilVariant form

Owner:HORIZON THERAPEUTICS USA INC

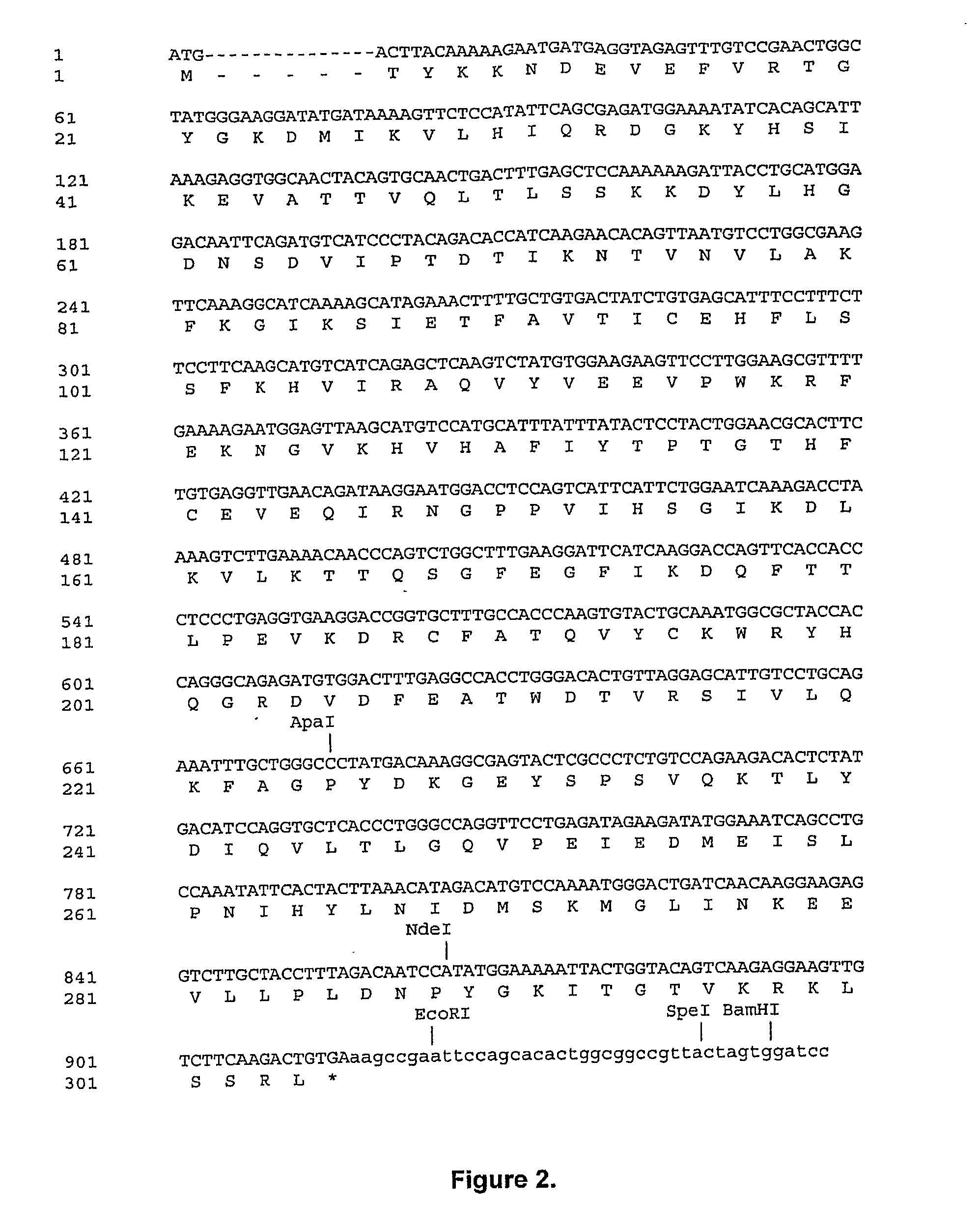

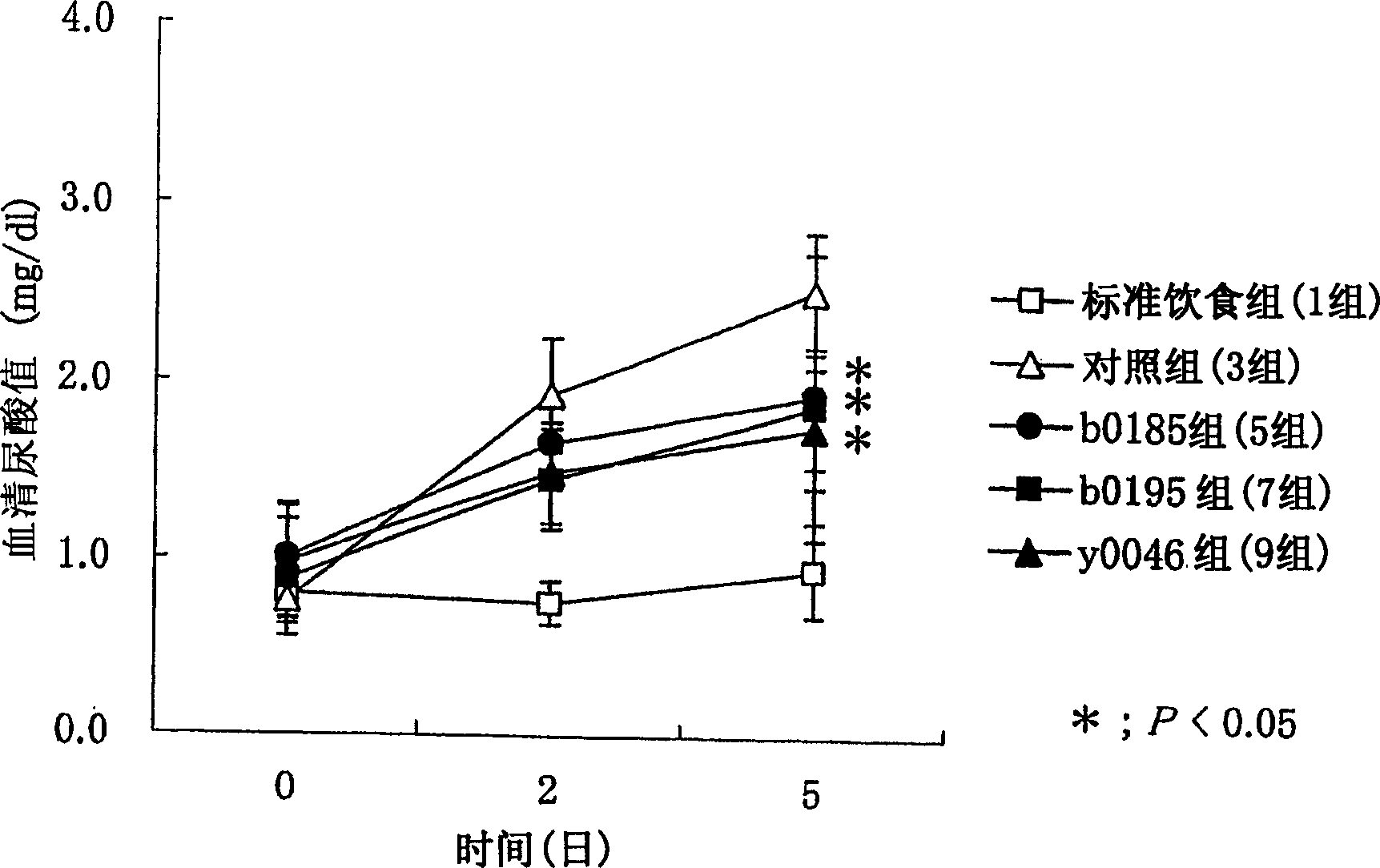

Composition for lowering serum uric acid level

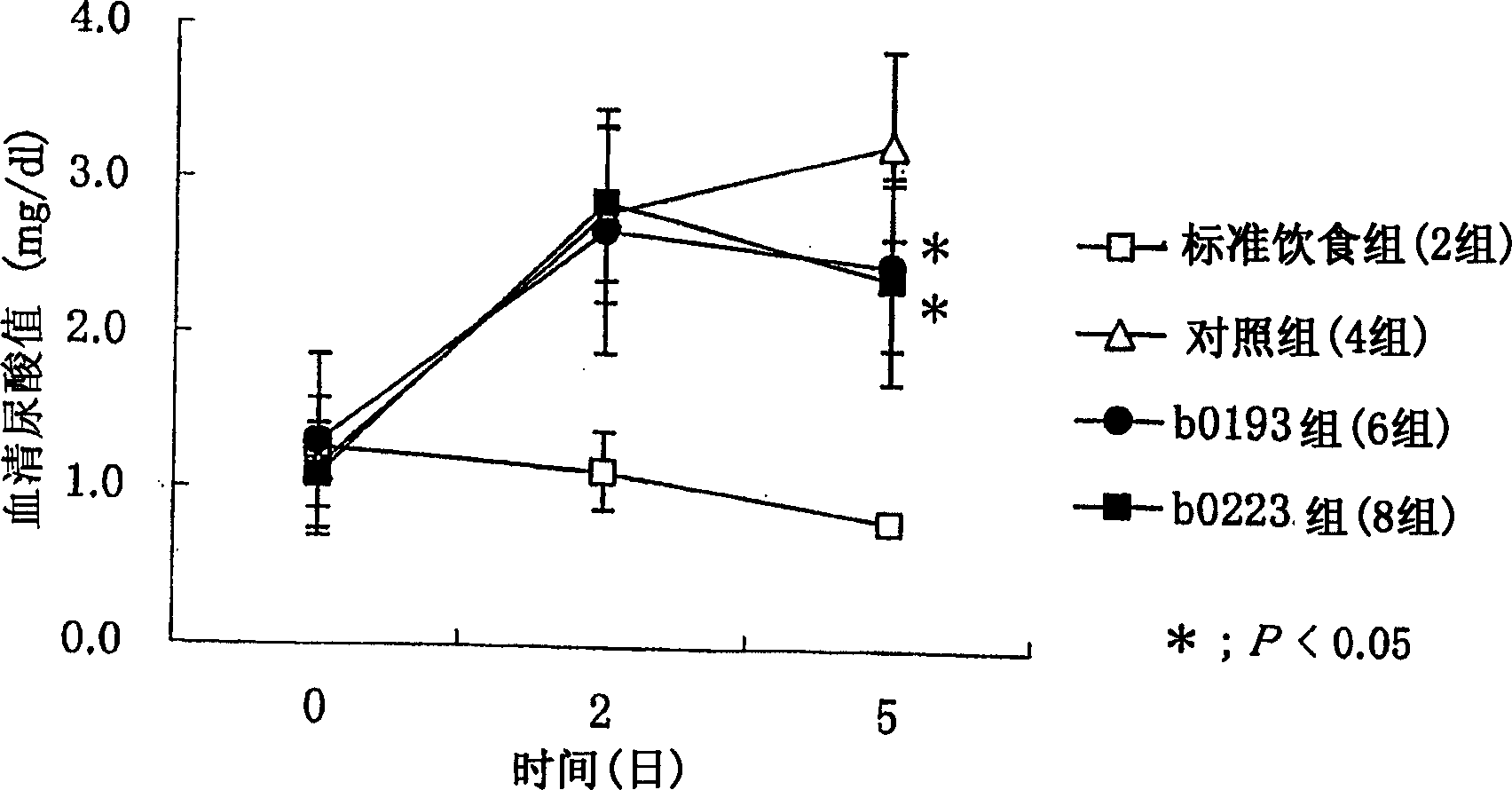

The present invention provides a composition comprising at least one microorganism selected from the group consisting of lactic acid bacteria and yeasts that have an ability to decompose purines and an action of lowering serum uric acid level and in particular, such a composition in a food, beverage or pharmaceutical form. Such a composition is effective in the prevention and amelioration of hyperuricemia.

Owner:OTSUKA PHARM CO LTD

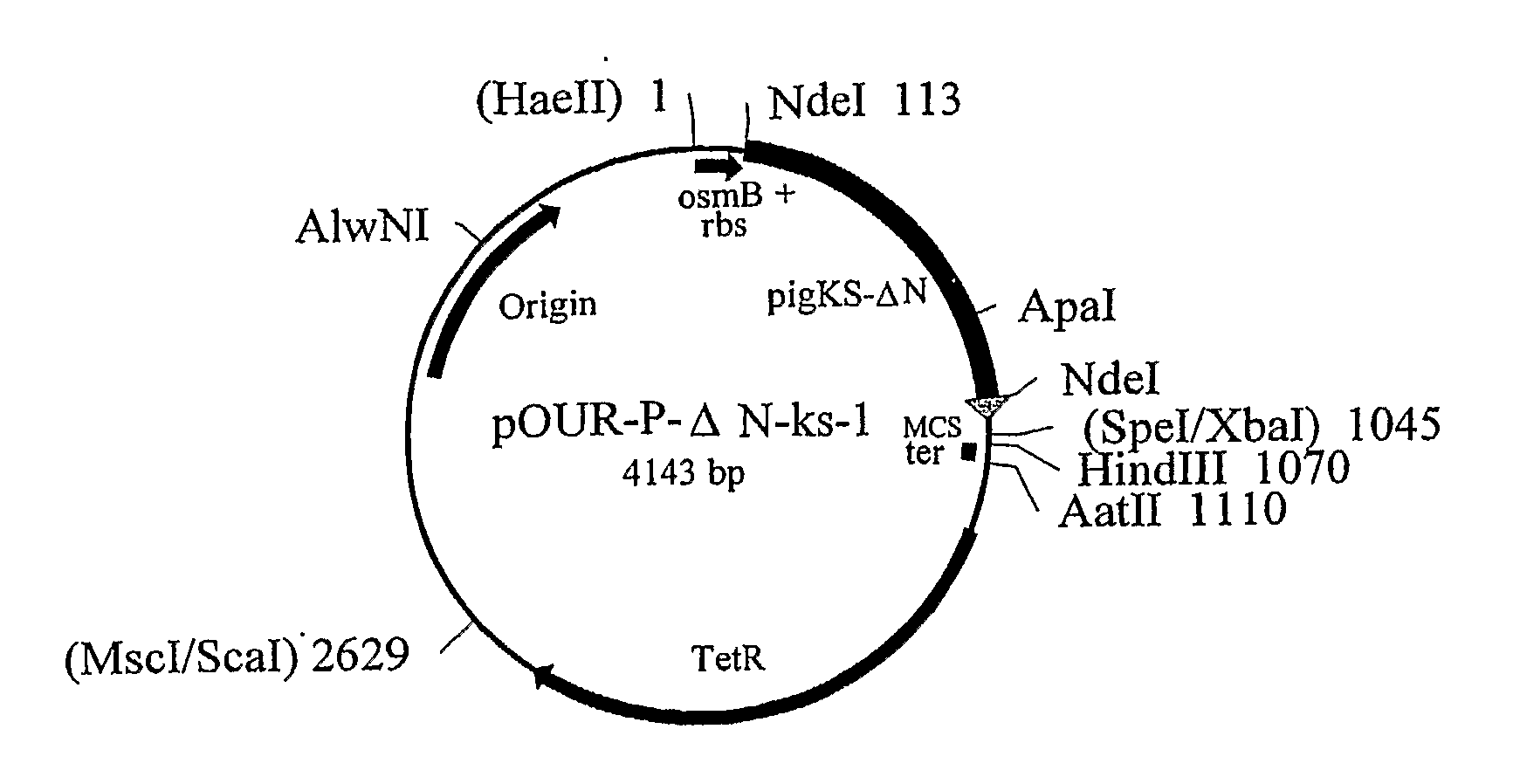

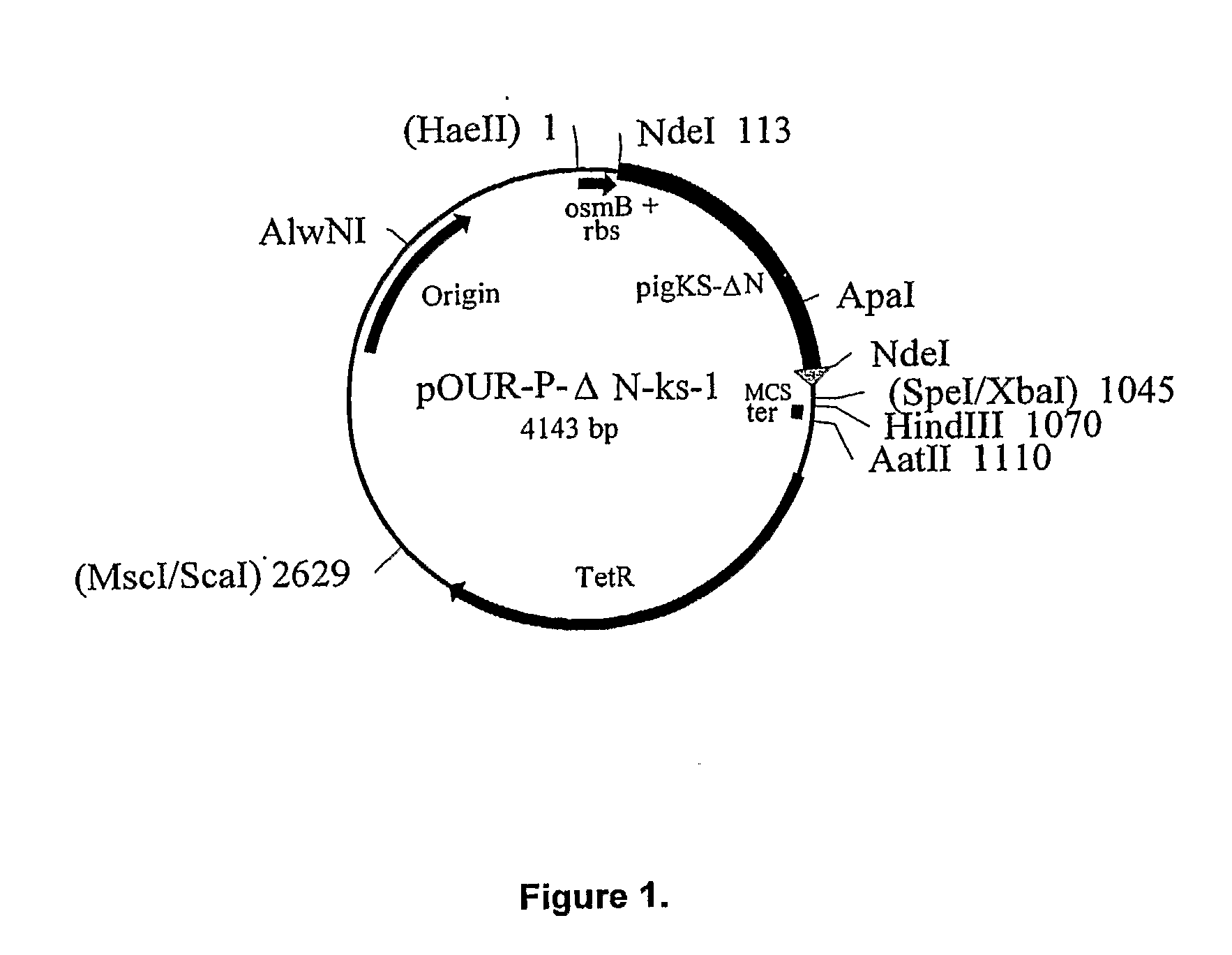

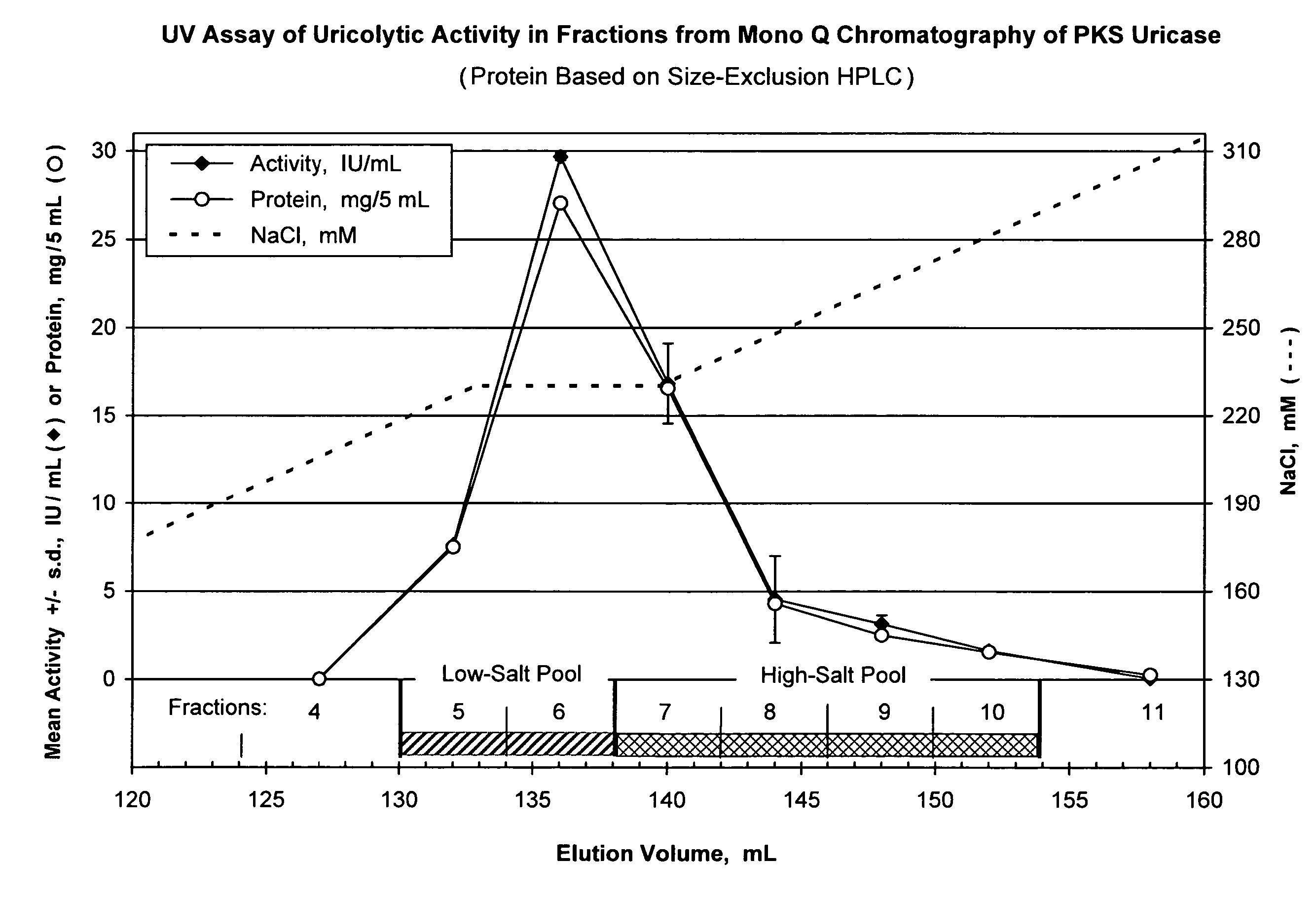

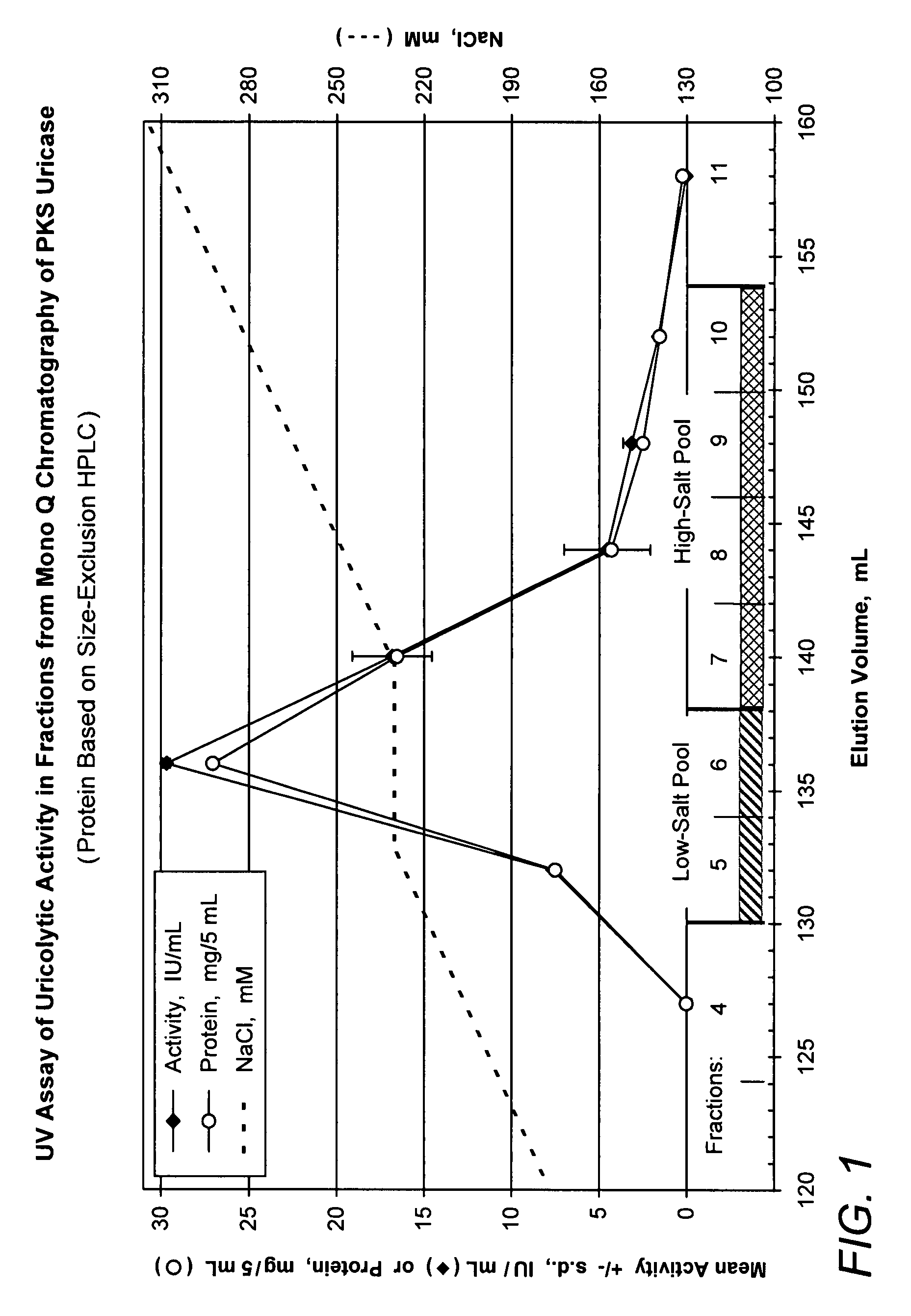

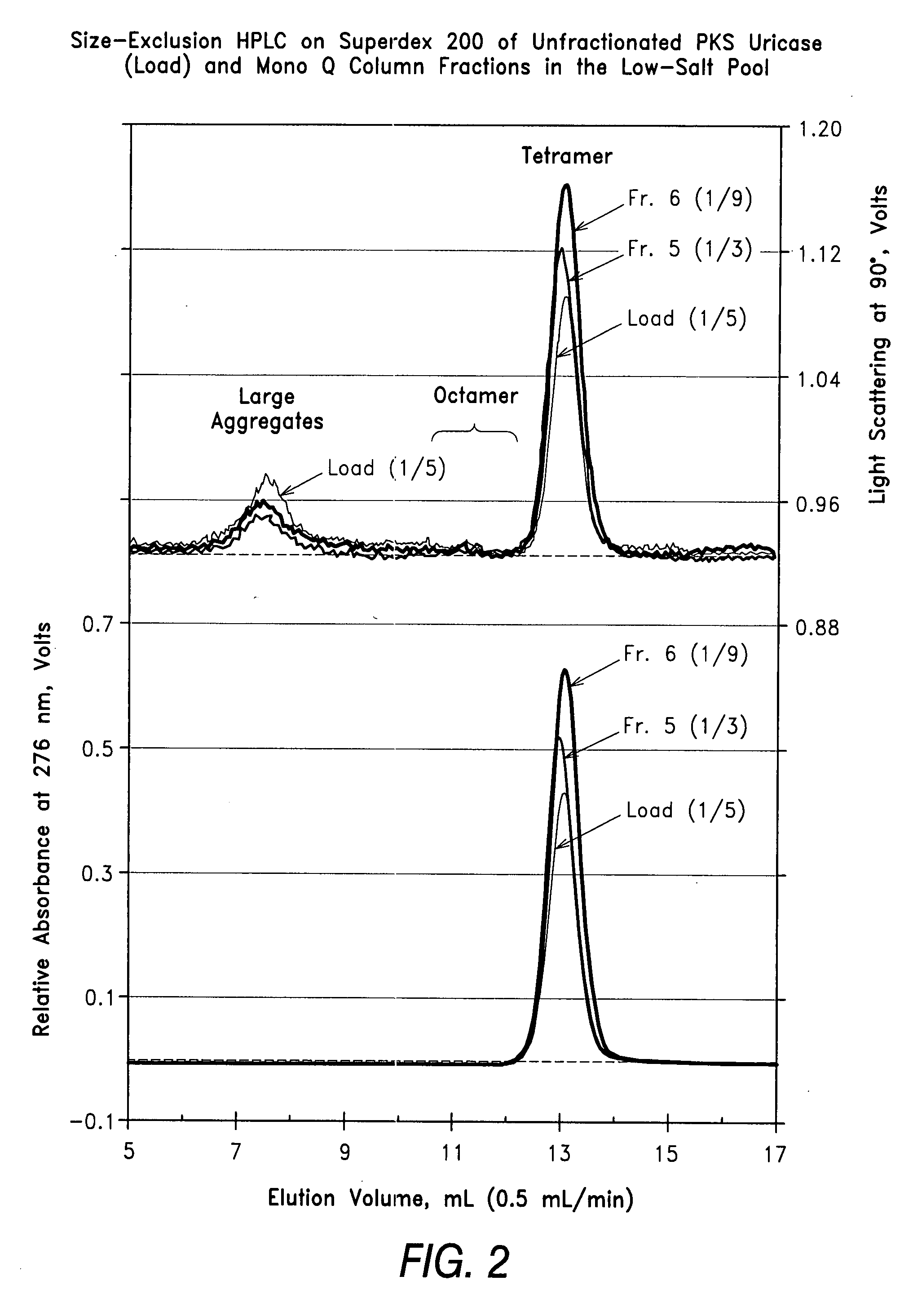

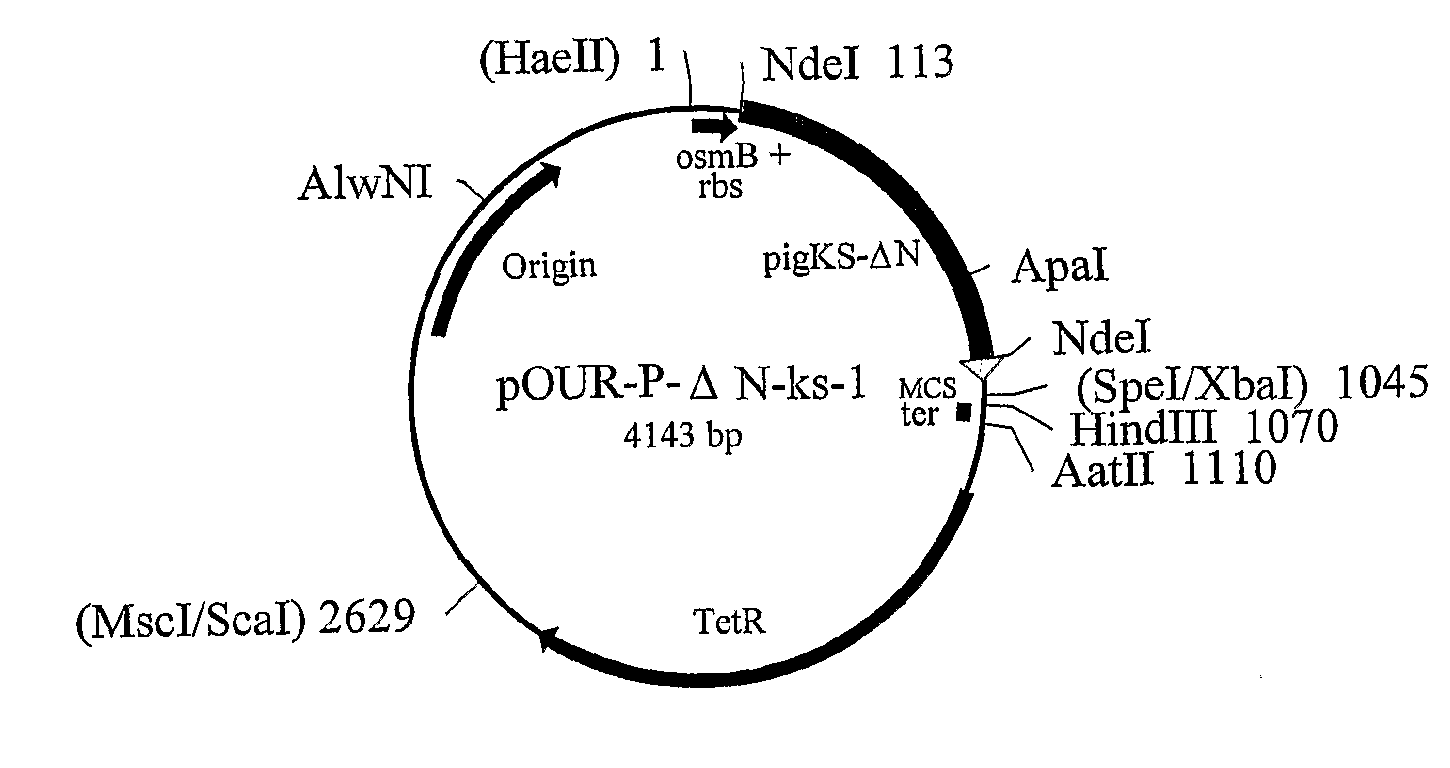

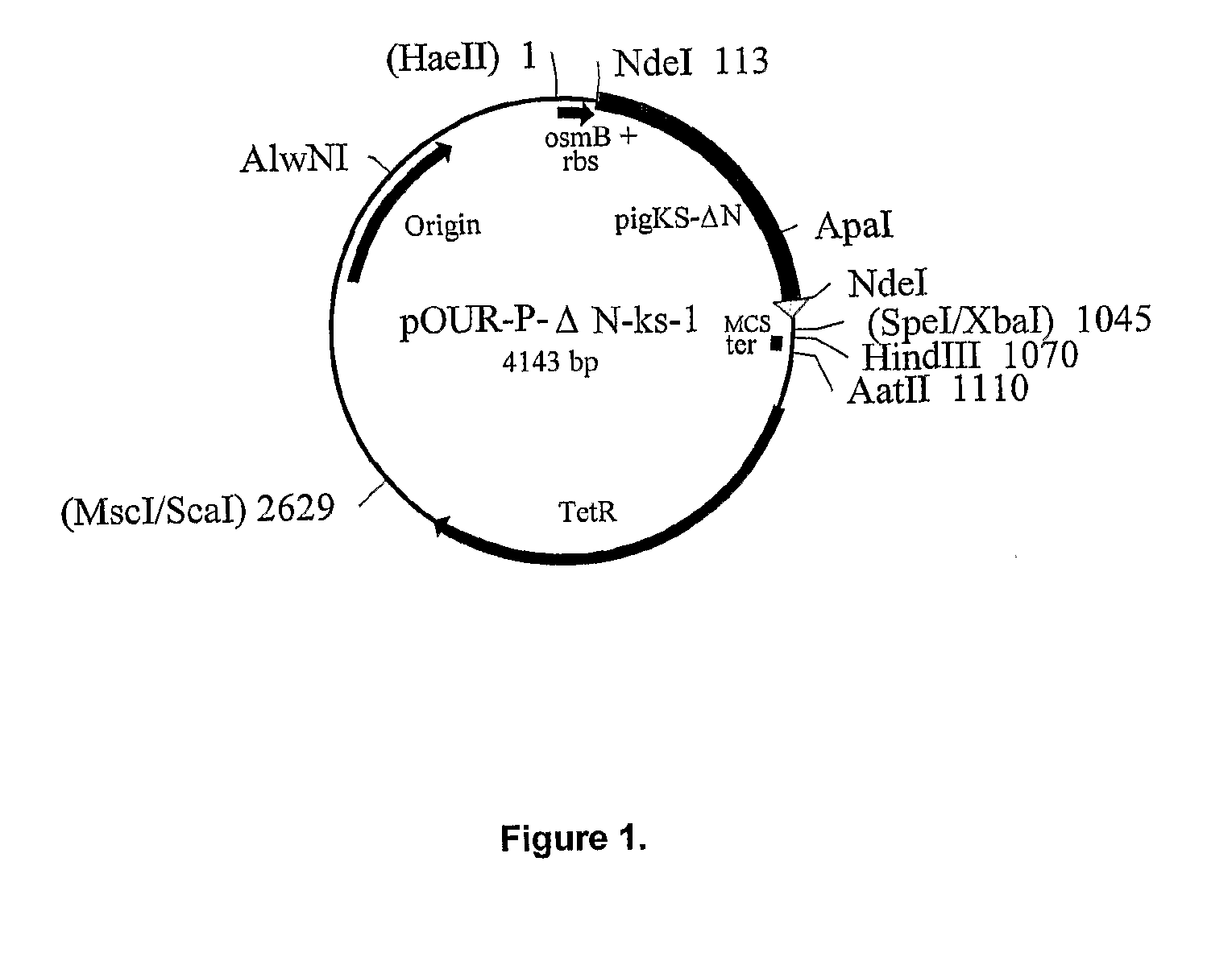

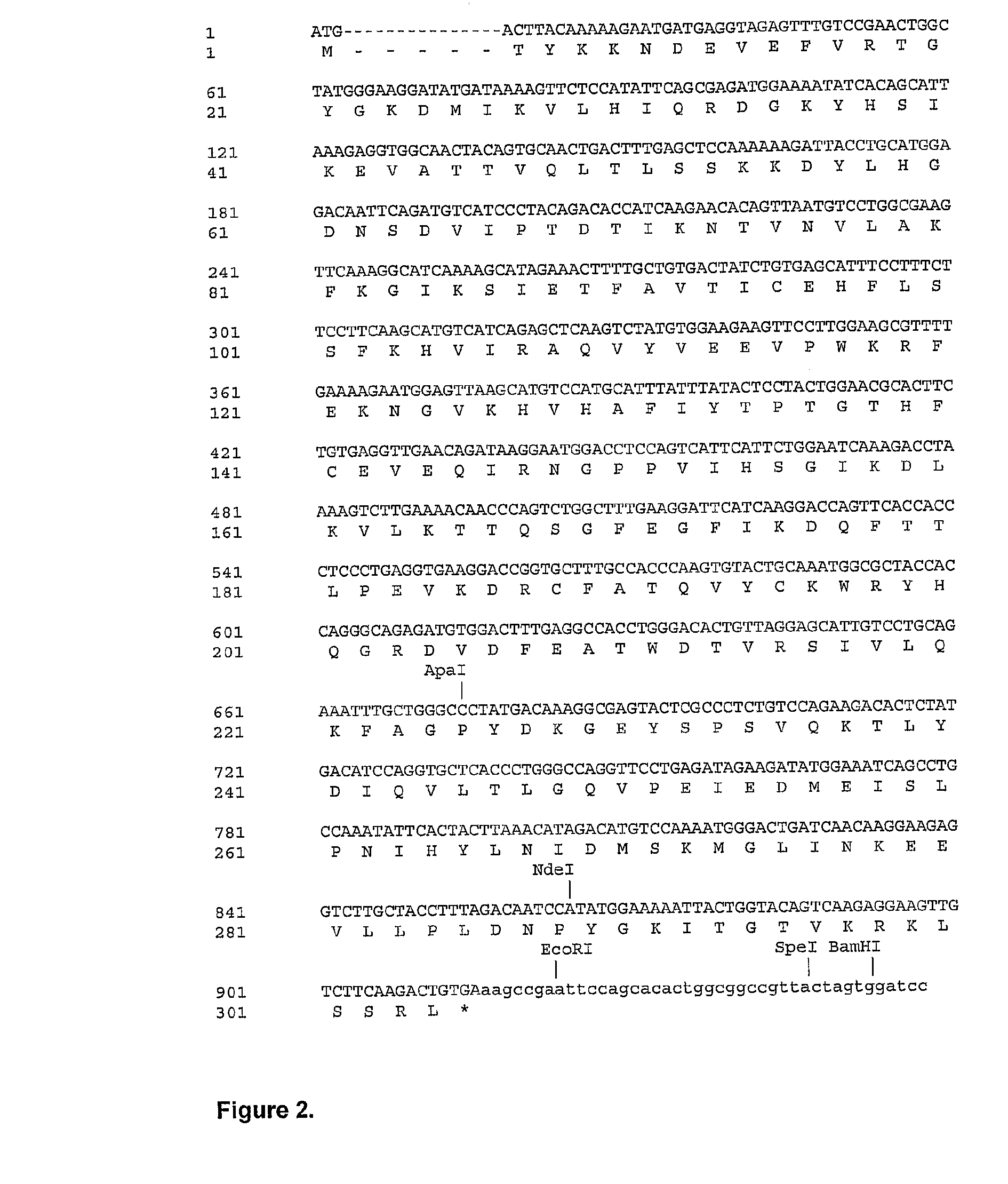

Aggregate-free urate oxidase for preparation of non-immunogenic polymer conjugates

InactiveUS20080057048A1Reduce immunogenicityIncrease persistencePeptide/protein ingredientsSkeletal disorderMutant proteinImmunogenicity

A naturally occurring or recombinant protein, especially a mutein of porcine urate oxidase (uricase), that is essentially free of large aggregates can be rendered substantially non-immunogenic by conjugation with a sufficiently small number of strands of polymer such that the bioactivity of the protein is essentially retained in the conjugate. Such conjugates are unusually well suited for treatment of chronic conditions because they are less likely to induce the formation of antibodies and / or accelerated clearance than are similar conjugates prepared from protein preparations containing traces of large aggregates.

Owner:HORIZON THERAPEUTICS USA INC +1

Variant form of urate oxidase and use thereof

Owner:HORIZON THERAPEUTICS USA INC

High-efficiency expression and purification method of aspergillus flavus uricase in Pichia pastoris

InactiveCN103160522AN-terminal nativeHigh medicinal valueEnzymesFermentationIndustrial scaleDouble stranded

The invention discloses a high-efficiency expression and purification method of aspergillus flavus uricase in Pichia pastoris. The method comprises the steps of: on the basis of the nucleotide composition of an uricase gene, splicing the double-stranded DNA (DeoxyriboNucleic Acid) of the uricase and the double-stranded DNA of alpha-factor signal peptide via SOE-PCR (Splicing Overlap Extension-Polymerase Chain Reaction) to obtain a fusion gene alpha-factor-uricase; and inserting the fusion gene into plasmid pPIC3.5k to obtain recombinant plasmid pPIC3.5k-alpha-factor-uricase and carrying out electrotransformation on the Pichia pastoris to obtain high-expression clone strain Pichia pastoris SMD1168. The expressed recombined aspergillus flavus uricase has the advantages of completely natural N terminal, no any unnecessary amino acid, low production cost, high enzyme activity, simpleness and convenience in the purification step, high yield, high purity, easiness in industrial scale production and greater practical application value.

Owner:HUBEI UNIV OF TECH

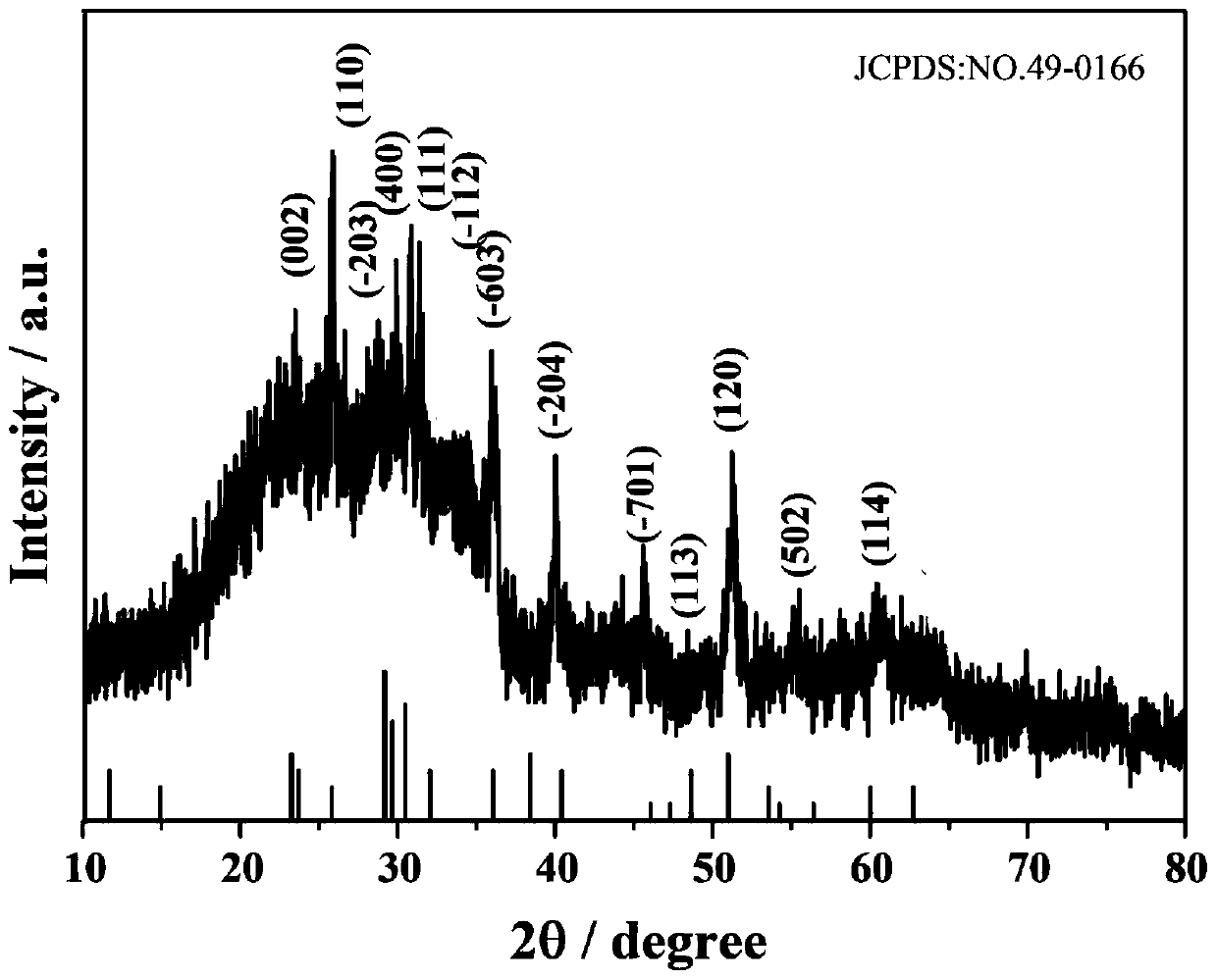

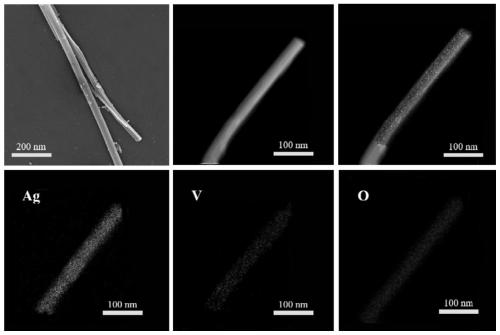

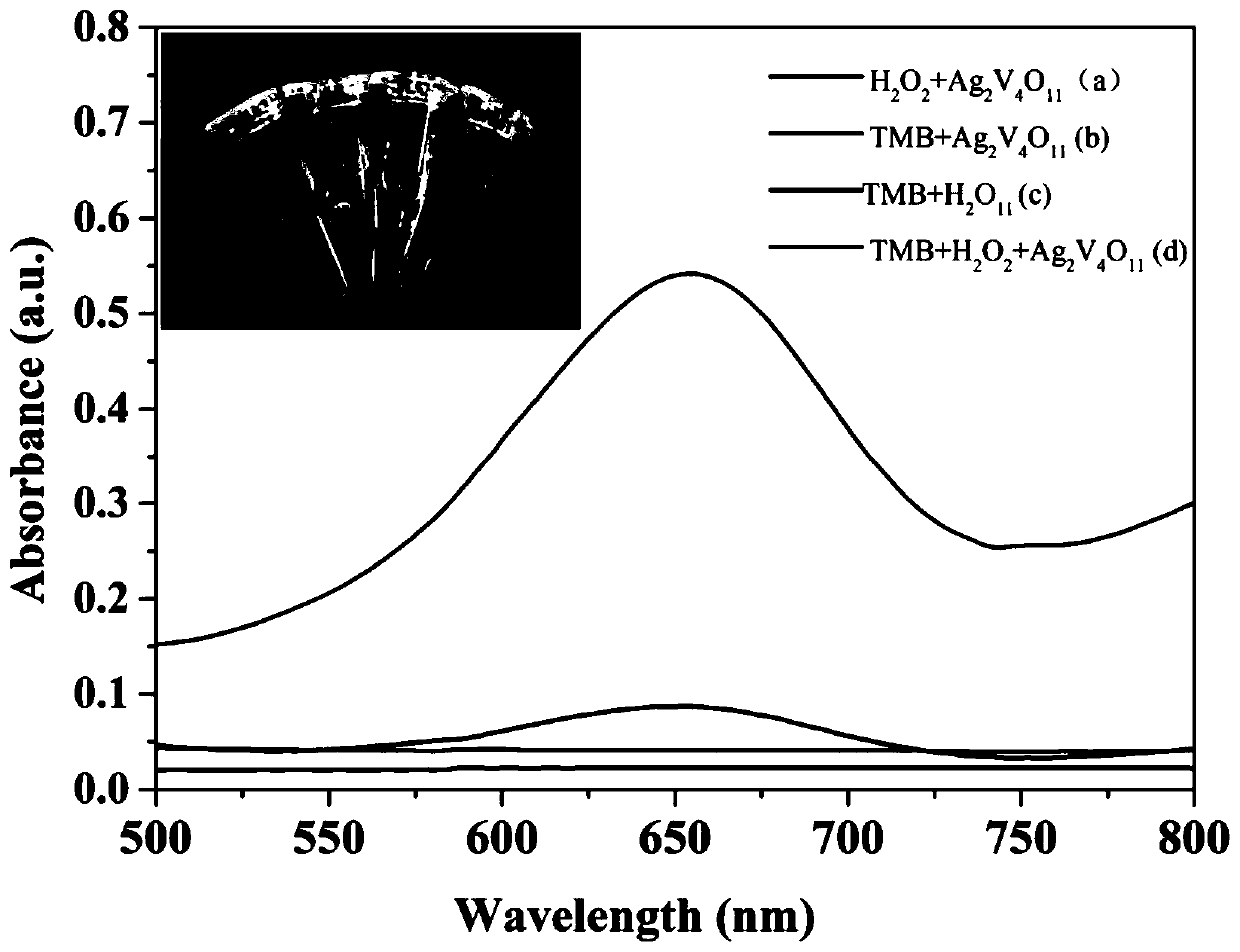

Silver vanadate, preparation method thereof and application of silver vanadate in detection of uric acid as peroxidase-like enzyme

ActiveCN111439783AHas peroxidase-like activityLow costMaterial nanotechnologyPreparing sample for investigationPeroxidasePhysical chemistry

The invention discloses silver vanadate, a preparation method thereof and application of silver vanadate in detection of uric acid as a peroxidase-like enzyme. The molecular formula of silver vanadateis Ag2V4O11. The preparation method of silver vanadate is characterized by comprising the following steps: (1) respectively dissolving 0.002mol of NH4VO3 and 0.001mol of AgNO3 in 50mL and 20mL of deionized water under the condition of magnetic stirring; (2) dropwise adding the AgNO3 solution obtained in the step (1) into the NH4VO3 solution under the condition of magnetic stirring; (3) adjustingthe pH value of the solution obtained in the step (2) to 3 by using a 1mol / L HNO3 solution; (4) continuing to stir the reaction solution at room temperature for 1 hour and cure the reaction solution for 4 hours; (5) transferring the reaction solution into a 80mL hydrothermal kettle, and carrying out hydrothermal treatment at 150 DEG C for 24 hours; and (6) cooling the reaction solution to room temperature, carrying out vacuum filtration to obtain a product, cleaning the product with deionized water for many times, and drying the product in a drying oven at 70 DEG C for 12 hours to obtain the silver vanadate with the molecular formula of Ag2V4O11. The preparation method has the advantages and beneficial effects that the synthesized Ag2V4O11 nanobelt is proved to have the activity of a peroxidase-like enzyme for the first time, and the cost is reduced compared with the cost of detection by simply adopting noble metal as mimic enzyme.

Owner:WENZHOU MEDICAL UNIV

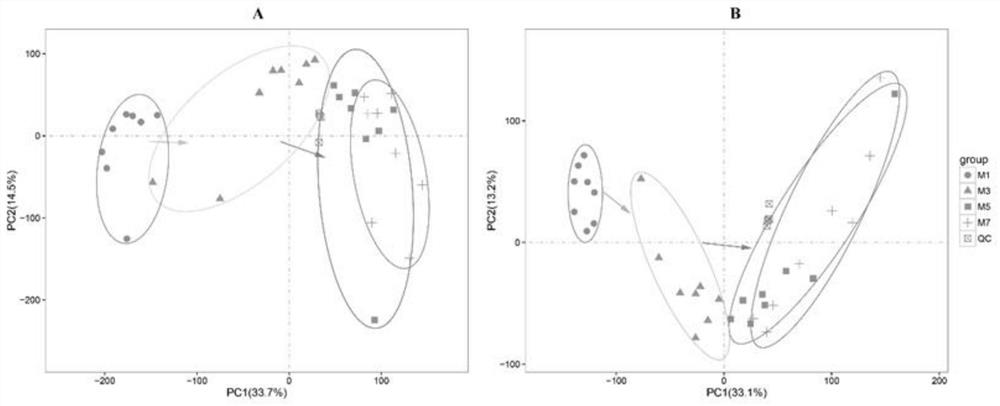

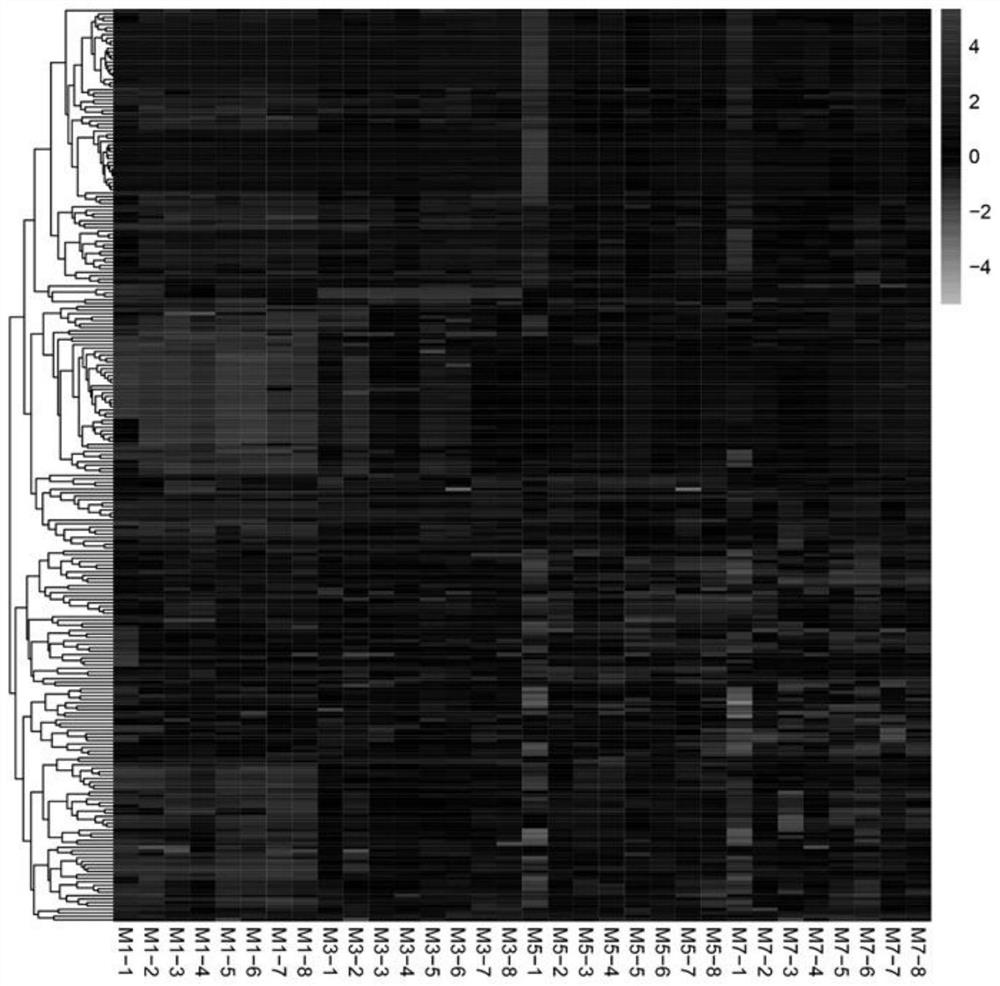

Chilled fresh meat freshness marker and screening and prediction model fitting method and application thereof

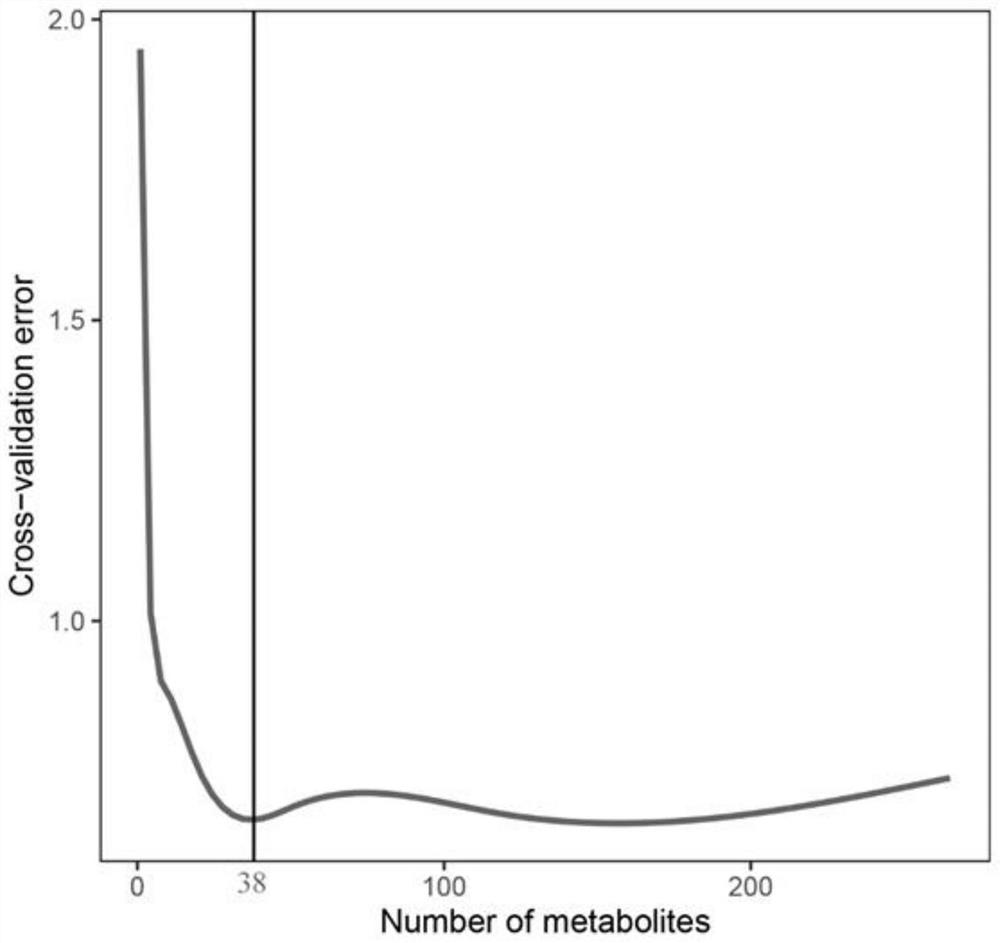

ActiveCN111830181AAccurate detectionHigh resolutionComponent separationCharacter and pattern recognitionBiotechnologyMetabolite

The invention discloses a metabonomics-based chilled fresh meat freshness marker and a screening and prediction model fitting method and application thereof. The marker is prepared from indole-3-formaldehyde, uridine monophosphate, phenylmercaptouric acid, gluconic acid, tyramine and serine-phenylalanine. The prediction model is: Y=3.964+1.97E<-7>X1- 4.22E<-7>X2-3.37E<-7>X3+8.80E<-8>X4+1.26E<-8>X5-5.57E<-7>X6. According to the method, an Agilent 1290 UHPLC is connected with a Q Exactive Orbitrap high-resolution mass spectrum in series, the method has higher resolution, more substances can be detected more accurately, metabolites in the preservation process of the chilled fresh chicken can be illustrated more comprehensively, and the obtained result is more reliable.

Owner:YANGZHOU UNIV

Collagen peptide lubricating fluid and preparation method thereof

ActiveCN107789611AGood biocompatibilityNo drug resistanceAntibacterial agentsOrganic active ingredientsAdemetionineFermentation

The invention relates to collagen peptide lubricating fluid and a preparation method thereof. The collagen peptide lubricating fluid is prepared from the following raw materials in parts by weight: 5-20 parts of tea fungus fermentation liquor, 0.5-1.2 parts of hyaluronic acid, 1-2 parts of tea fungus fermentation membrane modifiers, 8-12 parts of collagen peptides, 0.3-0.5 part of cananga odorataessential oil, 3-5 parts of water soluble camellia oleosa seed oil, 0.5-1 part of hydroxyethyl urea, 0.5-1 part of hexanediol and 60-80 parts of deionized water. The collagen peptide lubricating fluidis prepared from natural plants, is carried and used conveniently and has the effects of effectively cleaning and improving sexual excitation, and therefore, the collagen peptide lubricating fluid isa lubricating product which can be used for a long time.

Owner:FUJIAN NORMAL UNIV

Autologous collagen hydro-optical injection and preparation method thereof

InactiveCN113368027APromote growthPromote proliferation and differentiationCosmetic preparationsToilet preparationsUricotelicGlucan

The embodiments of the invention disclose an autologous collagen hydro-optical injection and a preparation method thereof. The autologous collagen hydro-optical injection is prepared from the following components in parts by weight: 10 to 20 parts of autologous collagen, 10 to 20 parts of hyaluronic acid, 5 to 10 parts of biological polysaccharide gum, 5 to 10 parts of a sheep placenta extract, 3 to 8 parts of an L-C stock solution, 2 to 3 parts of a grape seed extract, 2 to 5 parts of fructan, 2 to 5 parts of beta-glucan, 1 to 5 parts of vitamin C, 2 to 5 parts of amino acid, 2 to 3 parts of coenzyme, 2 to 4 parts of an anti-allergy agent, 2 to 5 parts of an antioxidant, 1 to 3 parts of a sun-screening agent and 3 to 8 parts of a humectant. The hydro-optical injection is prepared from autologous collagen extracted from human venous blood, is derived from autologus, does not generate exclusion, contains various nutritional ingredients required by cell repair and growth, and has relatively strong effects in the aspects of accelerating skin and mucosa wound healing, promoting cell growth, promoting wound healing and enhancing an immune system.

Owner:白晋

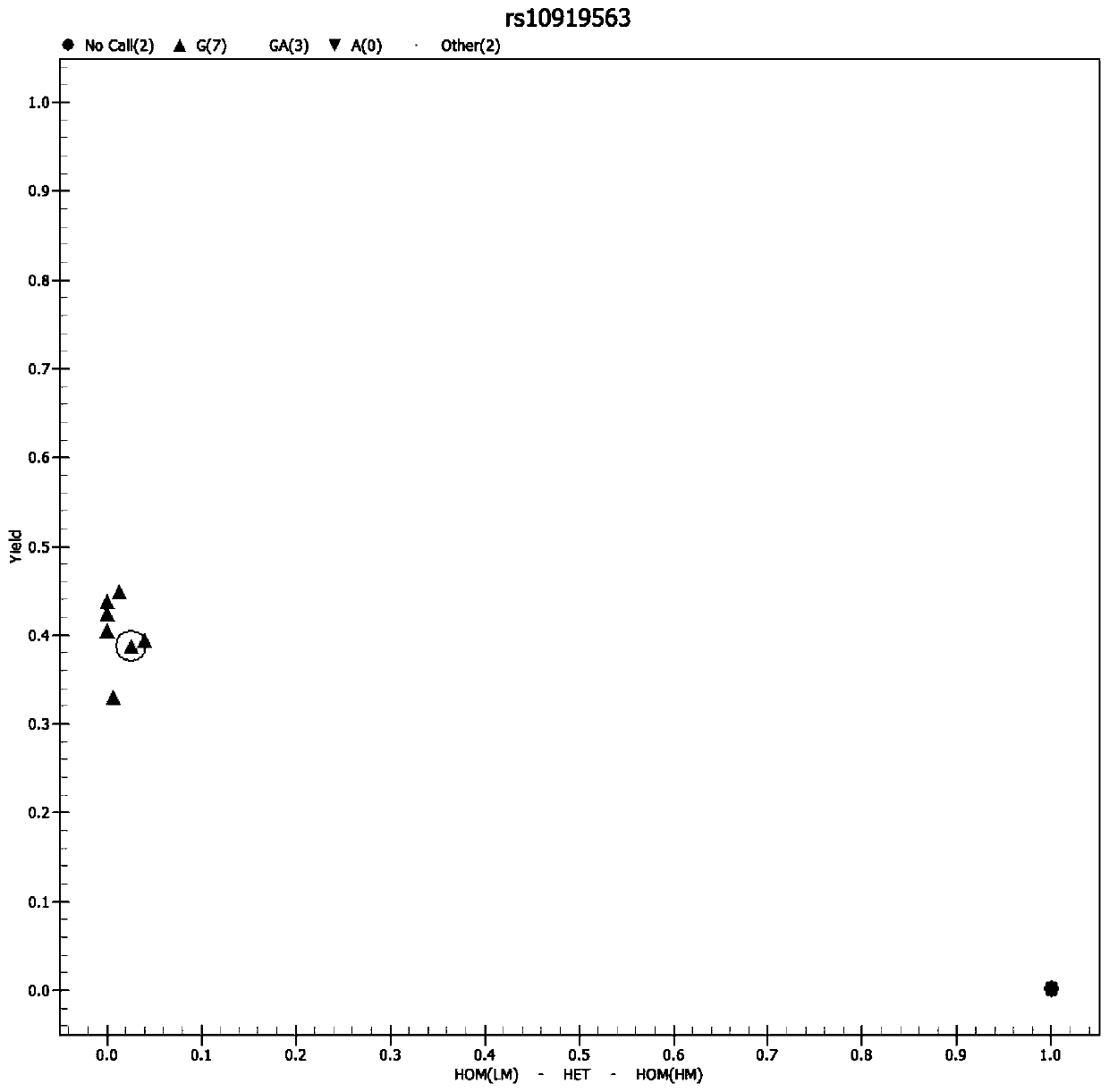

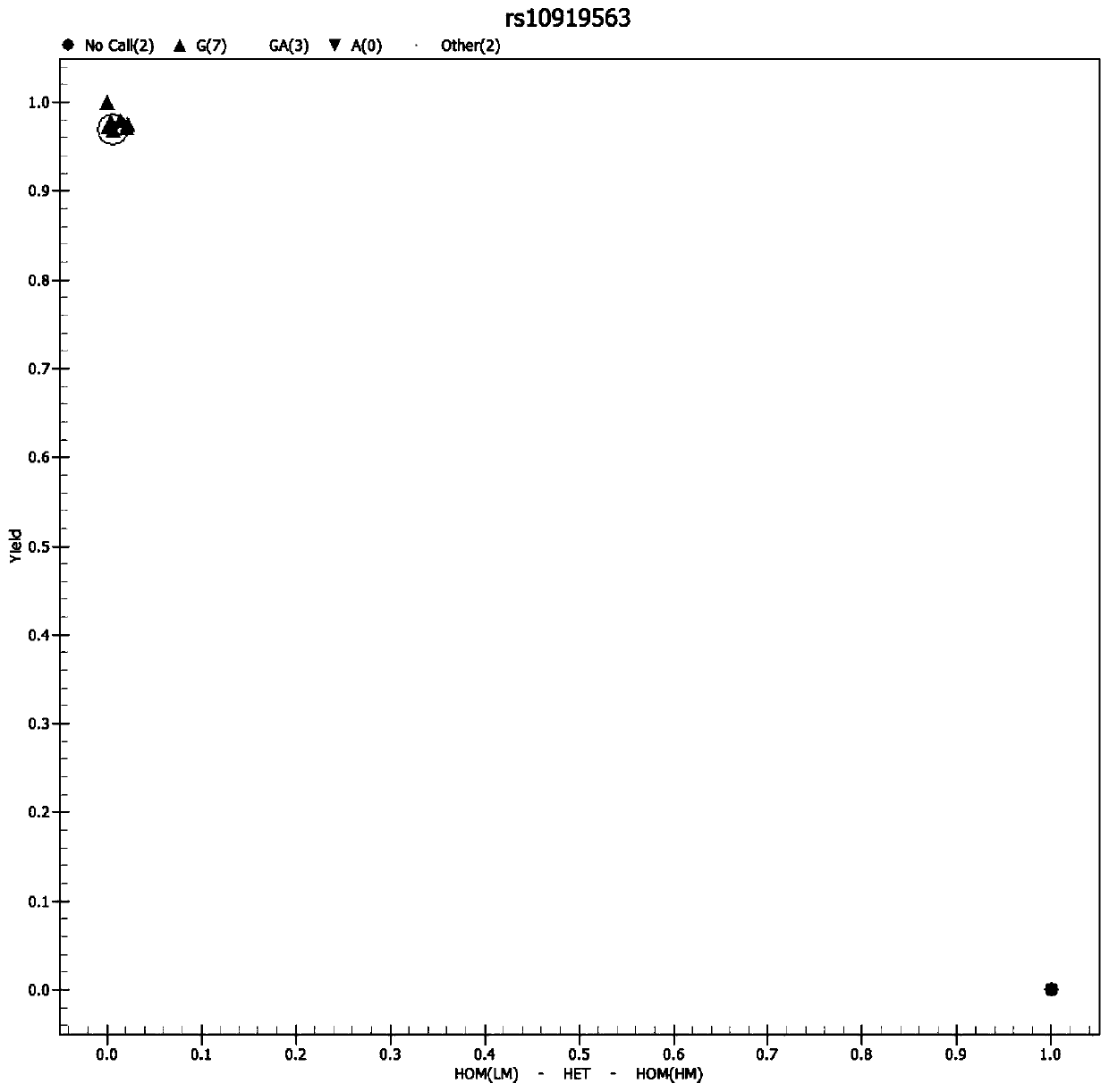

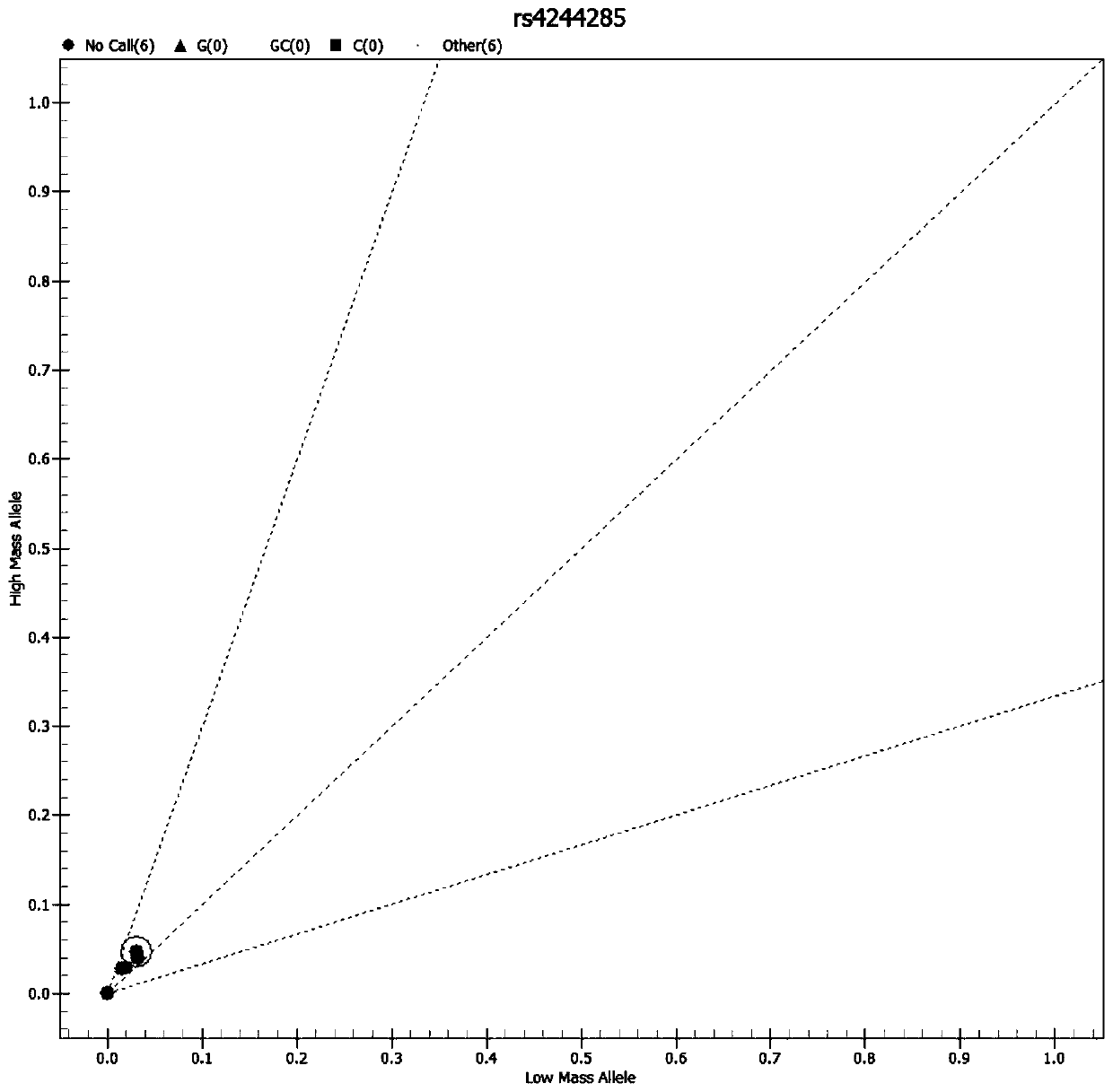

Primer set, application, product and method for detecting related SNP sites of drug metabolism ability of rheumatic immune diseases

ActiveCN110551813BImprove accuracyShort detection cycleMicrobiological testing/measurementDNA/RNA fragmentationIMMUNE SUPPRESSANTSImmunomodulating Agent

Owner:JIANGSU SIMCERE MEDICAL DEVICE CO LTD +2

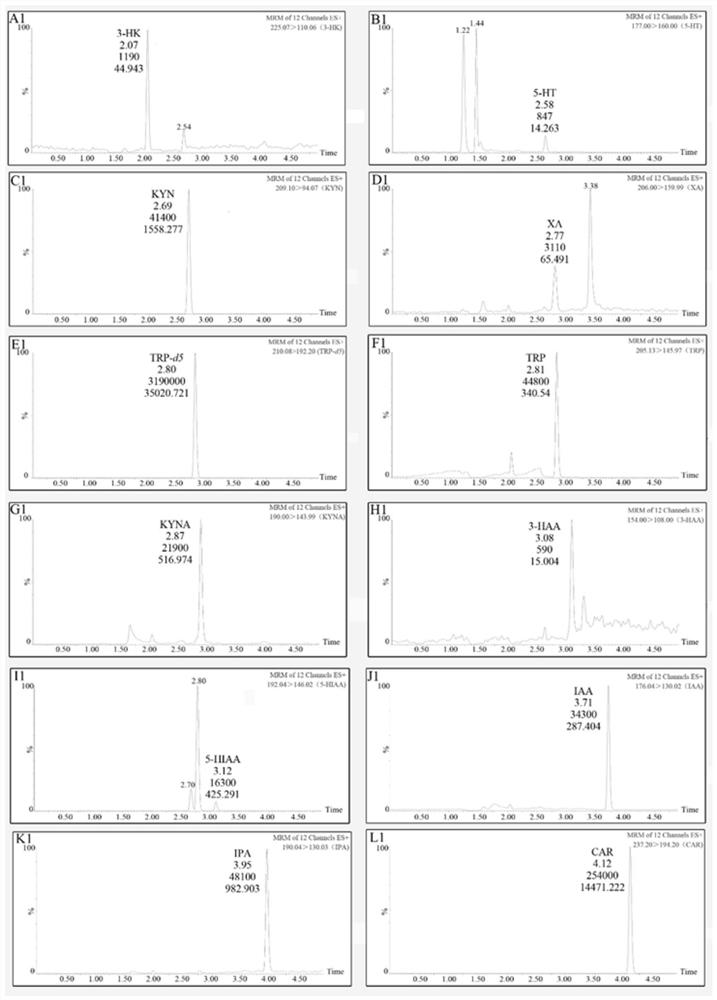

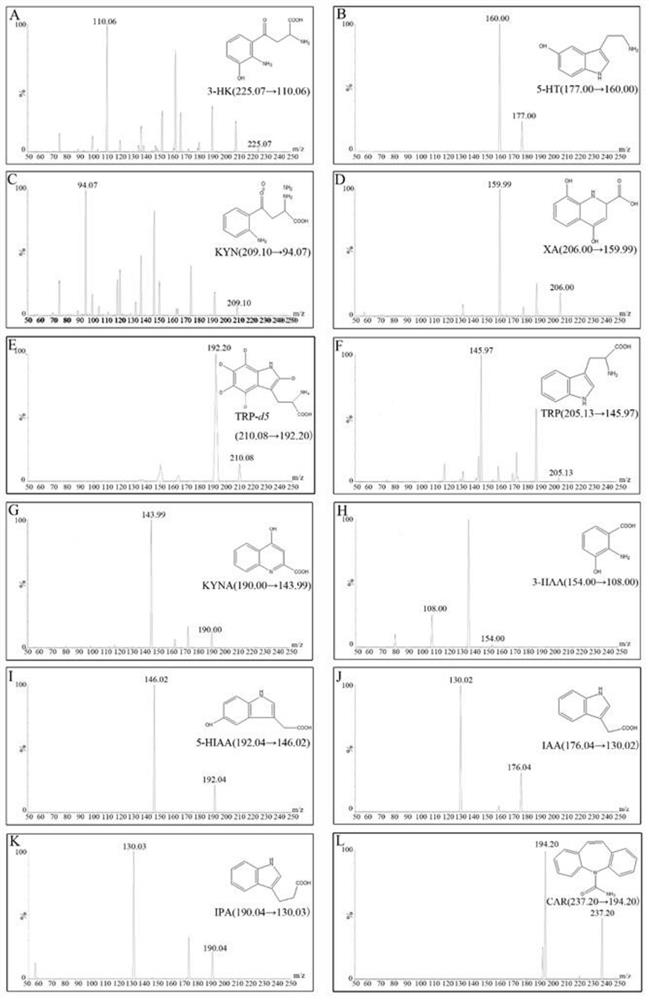

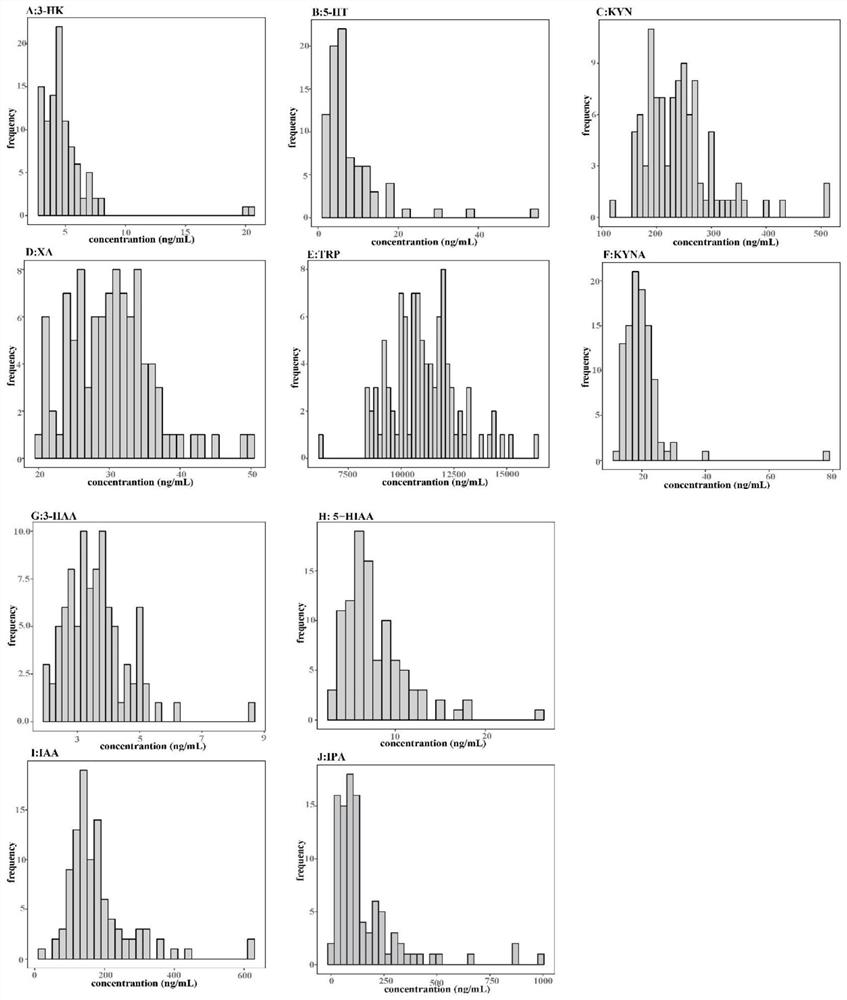

Kit and method for detecting tryptophan and metabolites thereof based on UPLC-MS/MS

PendingCN113406235AMeet quantitative analysis requirementsReduce consumptionComponent separationBenzoic acidMetabolite

The invention discloses a kit and a method for simultaneously detecting tryptophan and metabolites thereof in a biological sample based on ultra-high performance liquid chromatography-tandem mass spectrometry (UPLC-MS / MS), which belong to the technical field of UPLC-MS / MS detection. The kit comprises standard substances of tryptophan and metabolites of the tryptophan, and the tryptophan and the metabolites of the tryptophan comprise 3-hydroxyl kynurenine, 5-hydroxytryptamine, kynurenine, yellow uric acid, tryptophan, kynurenic acid, 3-hydroxyl o-aminobenzoic acid, 5-hydroxyl indoleacetic acid, 3-indoleacetic acid and 3-indolepropionic acid. According to the method, the tryptophan and the metabolites of the tryptophan are detected by utilizing UPLC-MS / MS, and a standard curve is established according to a peak area, so that the contents of the tryptophan and the metabolites of the tryptophan are obtained. The method for detecting the tryptophan and the metabolites of the tryptophan is simple to operate, has the characteristics of high sensitivity, good selectivity and the like, can accurately and quickly detect the tryptophan and the metabolites of the tryptophan at the same time, and has wide application value.

Owner:广州市红十字会医院

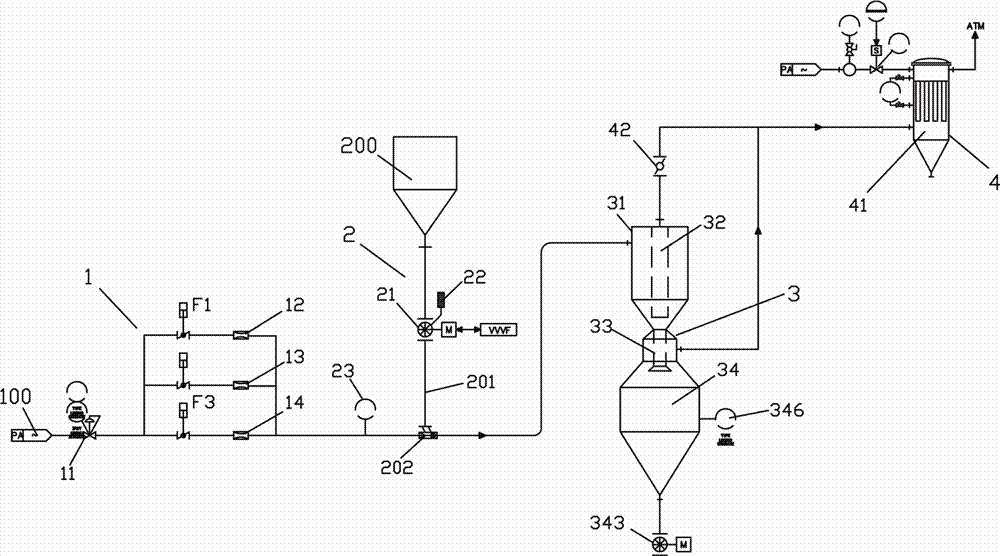

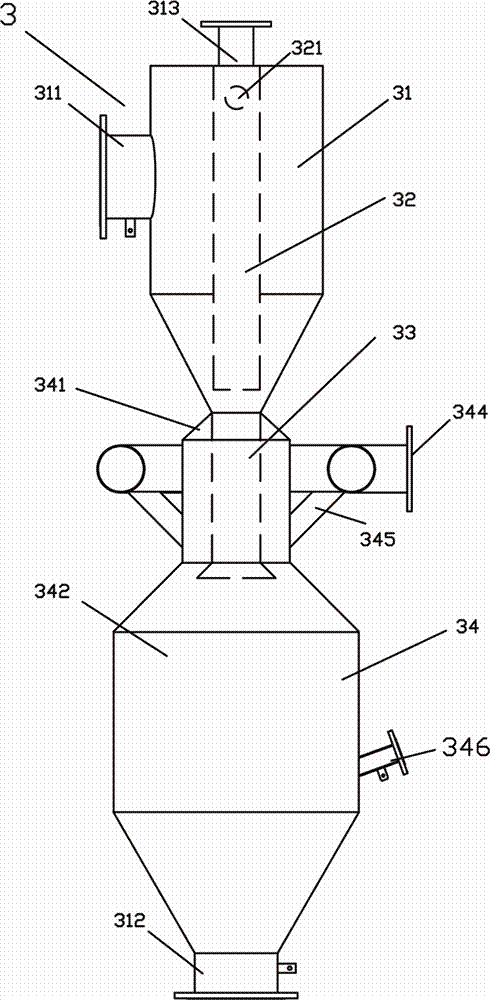

Urea granule dense-phase conveying method and system

The invention relates to a urea granule dense-phase conveying method and system. The urea granule dense-phase conveying system comprises a dense-phase conveying air source control unit, a rotating discharge valve unit, a dense-phase elutriator and a tail gas treatment unit. The granule dense-phase conveying method comprises the following steps: urea granular materials are fed by a urea granule hopper into a dense-phase conveying pipeline through a rotating discharge valve, a plug and delivery air in the dense-phase conveying pipeline tangentially enter a feed cylinder of the dense-phase elutriator to form continuous materials and air at the upper part of the feed cylinder, the material flow is accelerated through an accelerating tube, the granular material discharged from the accelerating tube is separated from the air flow due to inertia, the separation of the granular material from the powdered material is realized, the granular material enters a collecting hopper and is fed into a downstream storage bin through a gravity rotary valve; the powdered material enters an exhaust gas pipeline to be entrained from the hopper along the reverse direction of air flow; powdered material-entrained delivery tail gas enters a bag filter, the powdered material is captured, and the gas is discharged after being filtered. According to the urea granule dense-phase conveying method and system, the concept of the dense-phase elutriator is put forward for the first time, after the plug in the pipeline passes through the system, continuous separation of the uric acid powered material from granular material under the dense-phase condition can be realized.

Owner:SHANGHAI BOLONG EQUIP TECH CO LTD

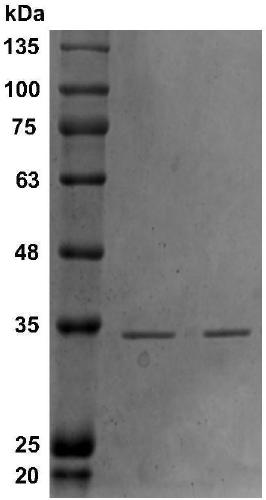

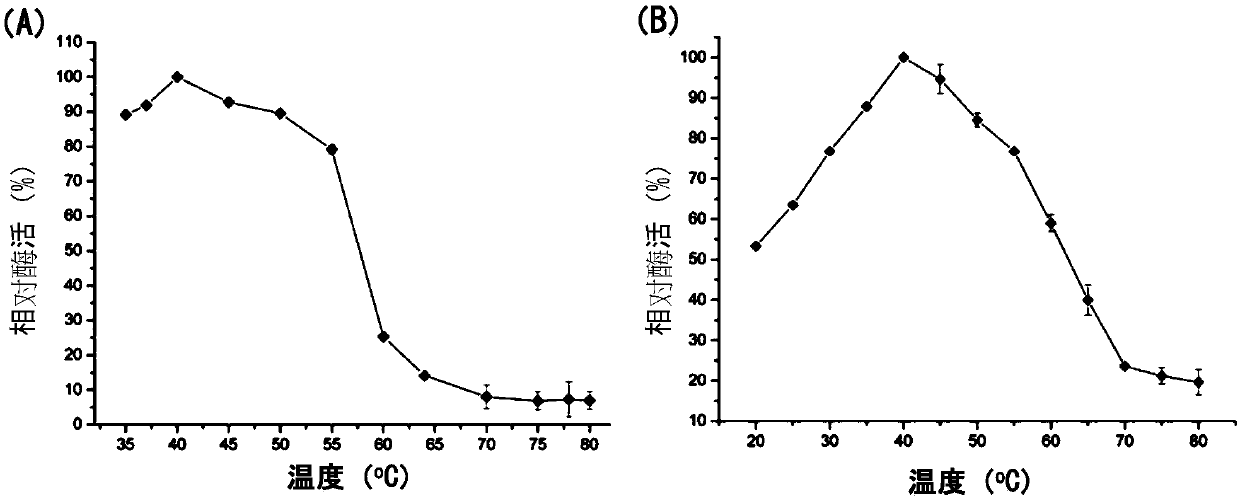

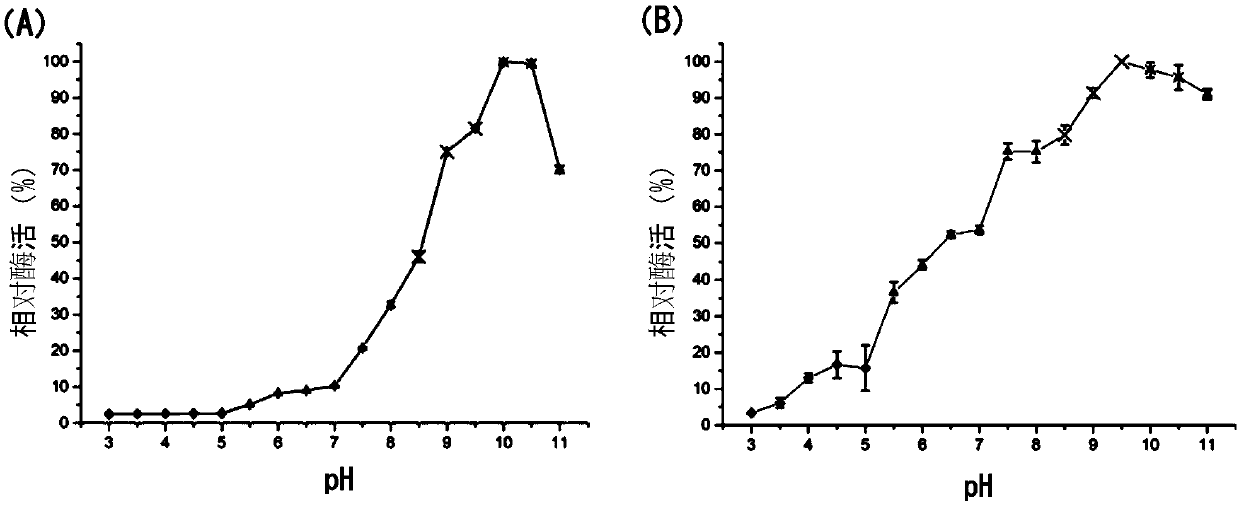

Alkaline urate oxidase and applications thereof to detection kit and reduction of uric acid in foods

ActiveCN109554376ABroad alkaline environmentSolve the problem of pH effective rangeMicrobiological testing/measurementOxidoreductasesYeastNucleotide

The invention relates to an alkaline urate oxidase and applications thereof to a detection kit and the reduction of uric acid in foods. The nucleotide sequence is as shown in the sequence SEQ ID No.1,and the amino acid sequence is as shown in the sequence SEQ ID No.2. A yeast urate oxidase is recombined into the highly-activity alkaline urate oxidase which is capable of degrading, measuring and detecting samples in an alkaline environment, has a wider alkaline measurement range and higher catalytic efficiency than previously-reported enzymes, and is advantageous for improving production efficiency, reducing costs and facilitating industrial application better. According to the kit which utilizes the alkaline urate oxidase and detects uric acid content by a colorimetric method, the kit hasstrong specificity, high sensitivity and simple method. The alkaline urate oxidase is used to develop low-purine foods, and has high application value in low-purine foods.

Owner:GUANGXI UNIV

Application of mulberroside in preparing medicament for inhibiting uric acid reabsorption transporter

InactiveCN101502527AInhibition regulationThe active ingredient is exactOrganic active ingredientsSkeletal disorderChemical synthesisPharmaceutical preservatives

The invention discloses a novel application of a mulberroside-A compound in the preparation of drugs for inhibiting uric acid re-absorption transporters, and a combination with the active component being the mulberroside-A compound for preparing the drugs for inhibiting the uric acid re-absorption transporters, so that the mulberroside-A compound with the chemical structure being 3-[2-[4-(Beta-D-glucopyranosyl-oxygen-2-hydroxyphenyl)]-(E)-ethenyl]-5-hydroxyphenyl-Beta-D-glucopyranoside is applicable in the preparation of the drugs for inhibiting the uric acid re-absorption transporters. The mulberroside-A can be either extracted from plants, traditional Chinese medicinal materials and traditional Chinese medicinal decoction pieces containing the mulberroside-A, or obtained through chemical synthesis. The drug preparation for inhibiting the uric acid re-absorption transporters can be either prepared separately from the mulberroside-A compound as the effective component or combined with pharmaceutically acceptable excipient, and further prepared into the drug forms of mulberroside-A, such as oral liquid, capsules, tablets, granules, targeting preparations and the like on the basis of the conventional preparation method.

Owner:ZHEJIANG CONBA PHARMA +1

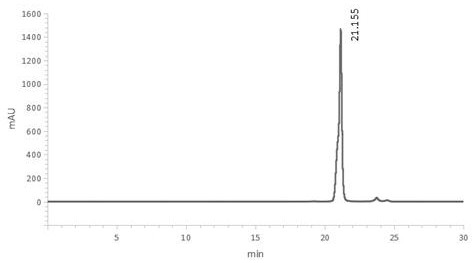

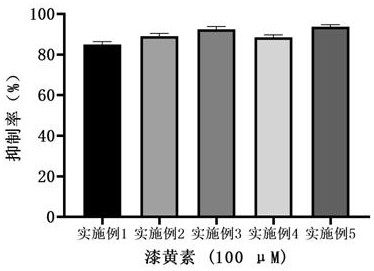

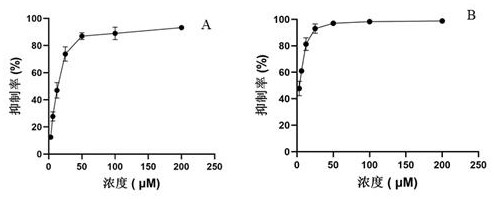

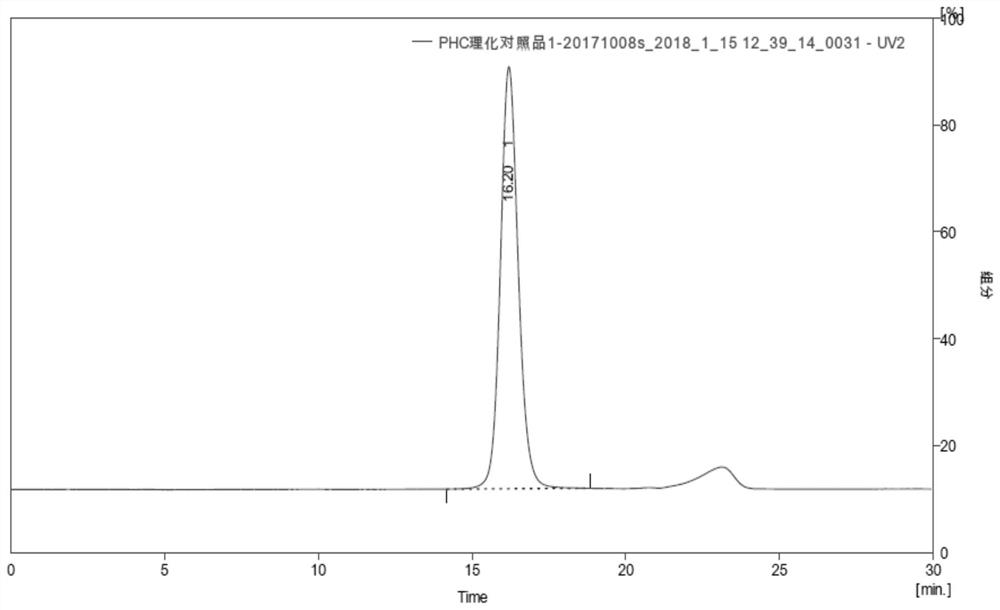

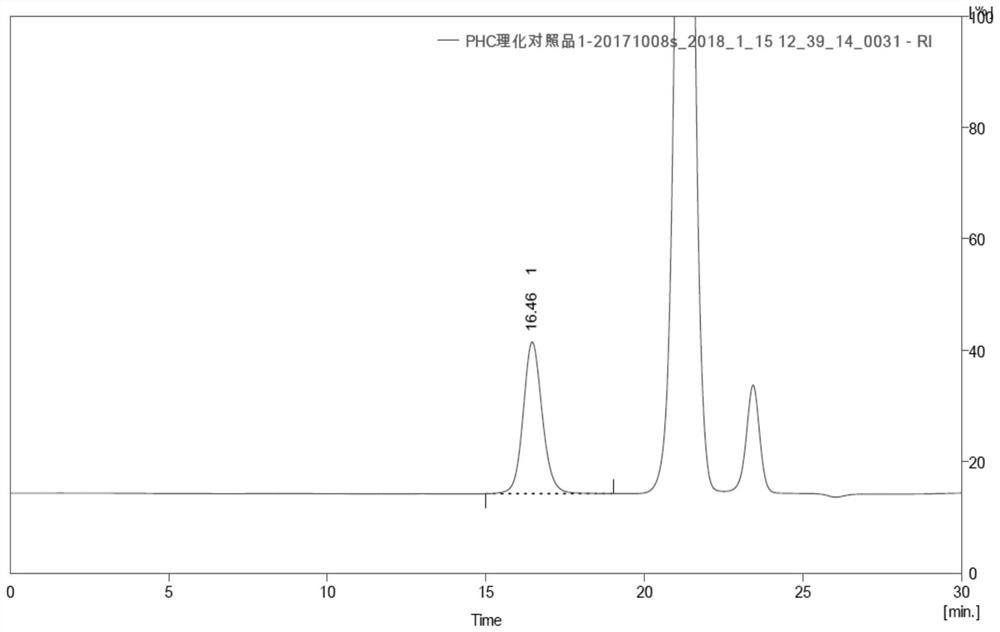

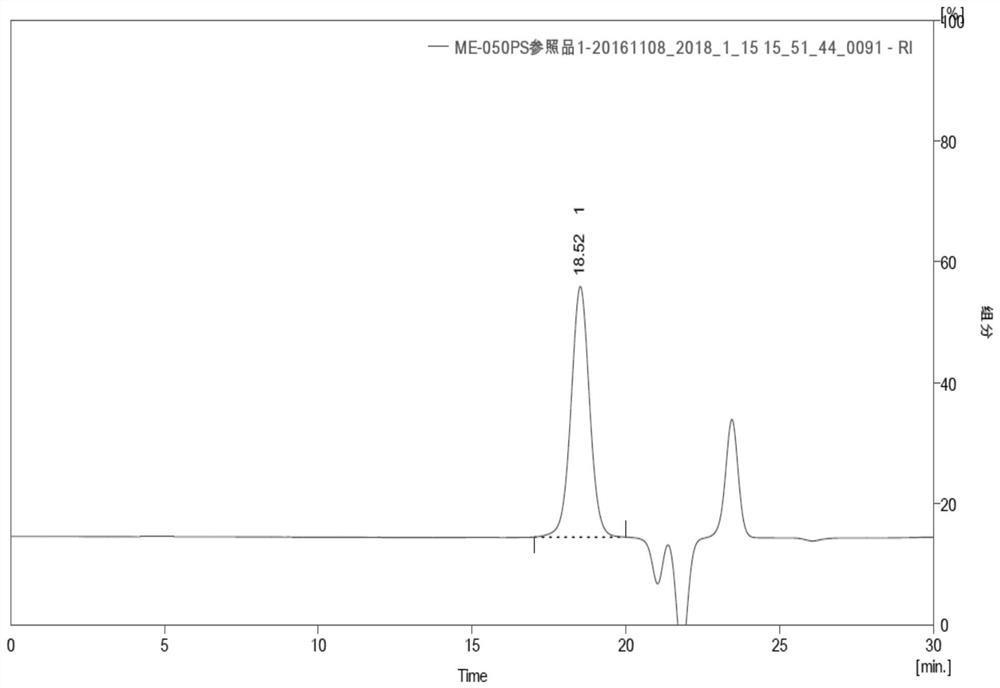

Fisetin with urate transporter 1 inhibitory activity as well as preparation method and application of fisetin

ActiveCN114644608AHigh purityEasy to prepareOrganic active ingredientsOrganic chemistryOrganosolvLicorice roots

The invention discloses fisetin with urate transporter 1 inhibitory activity and a preparation method and application thereof. The preparation method comprises the following steps: carrying out superfine grinding on licorice roots, and sieving to obtain superfine powder; soaking the superfine powder in ethanol, performing ultrasonic-assisted extraction, filtering and collecting filtrate, repeatedly extracting and filtering, and merging the filtrate to obtain a crude extract; concentrating the crude extract under reduced pressure to obtain an extract, redissolving the extract with water, extracting with an organic solvent, separating to obtain extract liquor, repeatedly extracting and combining the extract liquor; and carrying out macroporous resin coarse separation, chromatographic column fine grading and high performance liquid chromatography purification on the extract, and drying to obtain fisetin. The preparation method disclosed by the invention is simple and strong in specificity, the obtained fisetin has in-vitro urate transporter 1 inhibitory activity, and a new application of the glycyrrhiza uralensis fisetin is developed.

Owner:OCEAN UNIV OF CHINA

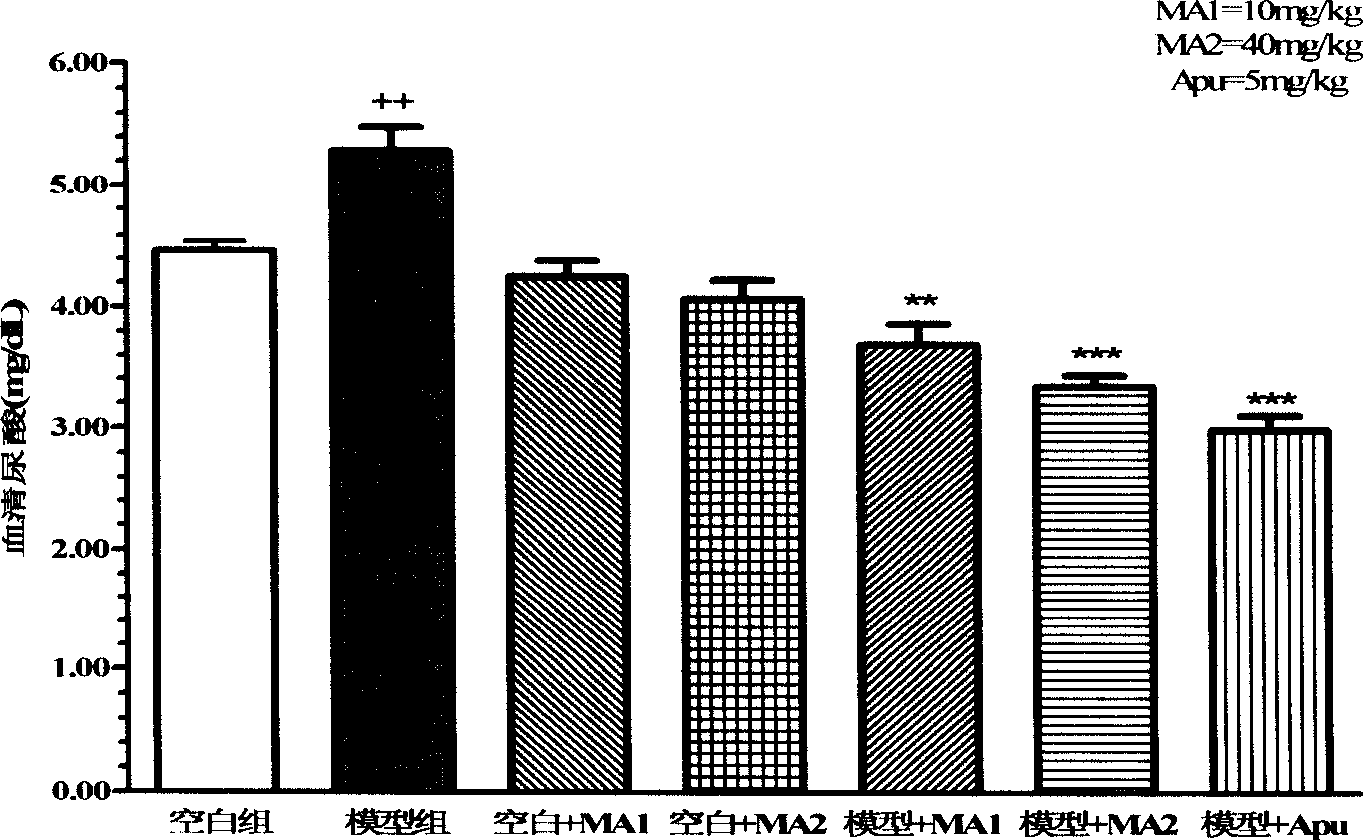

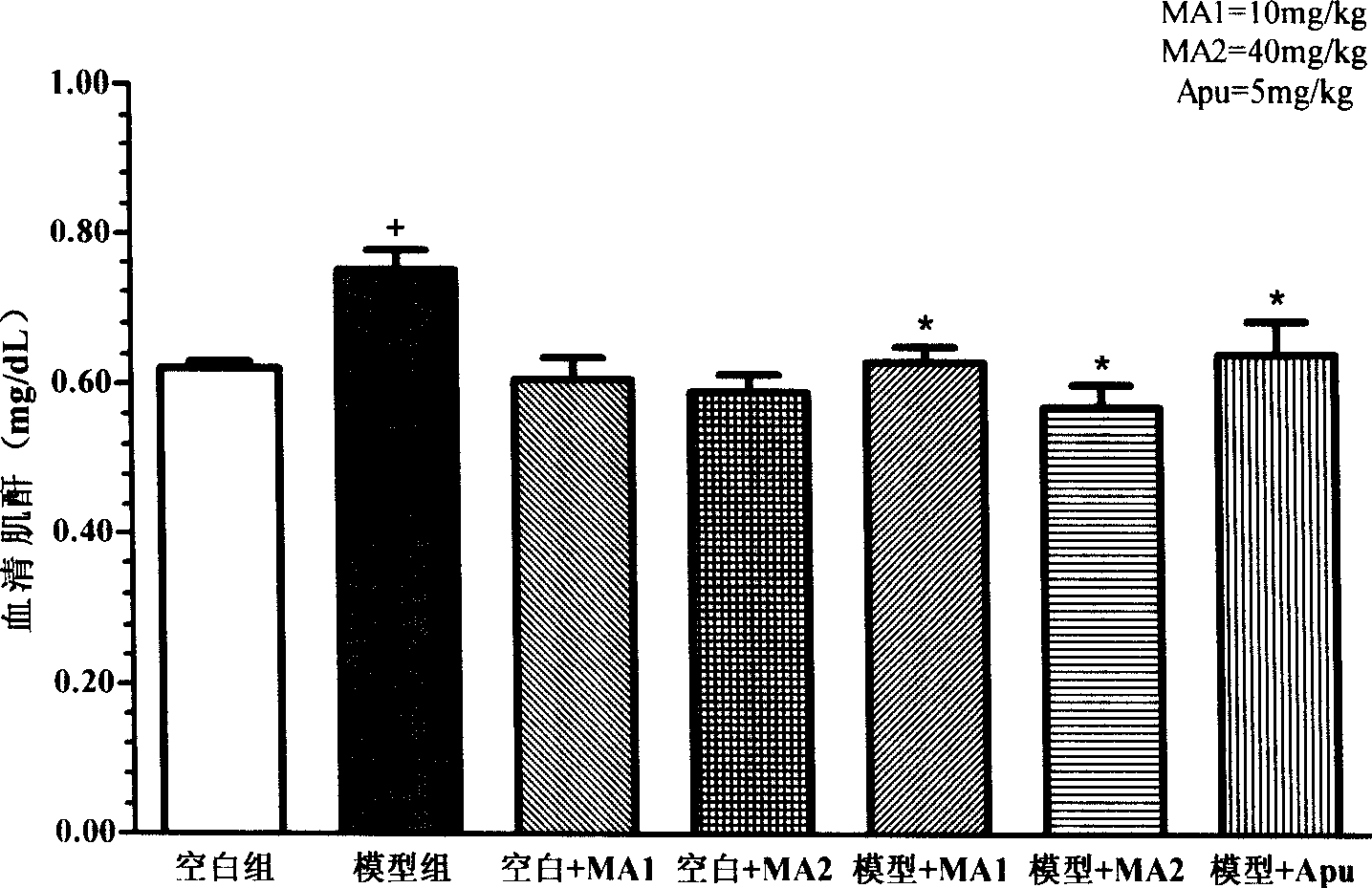

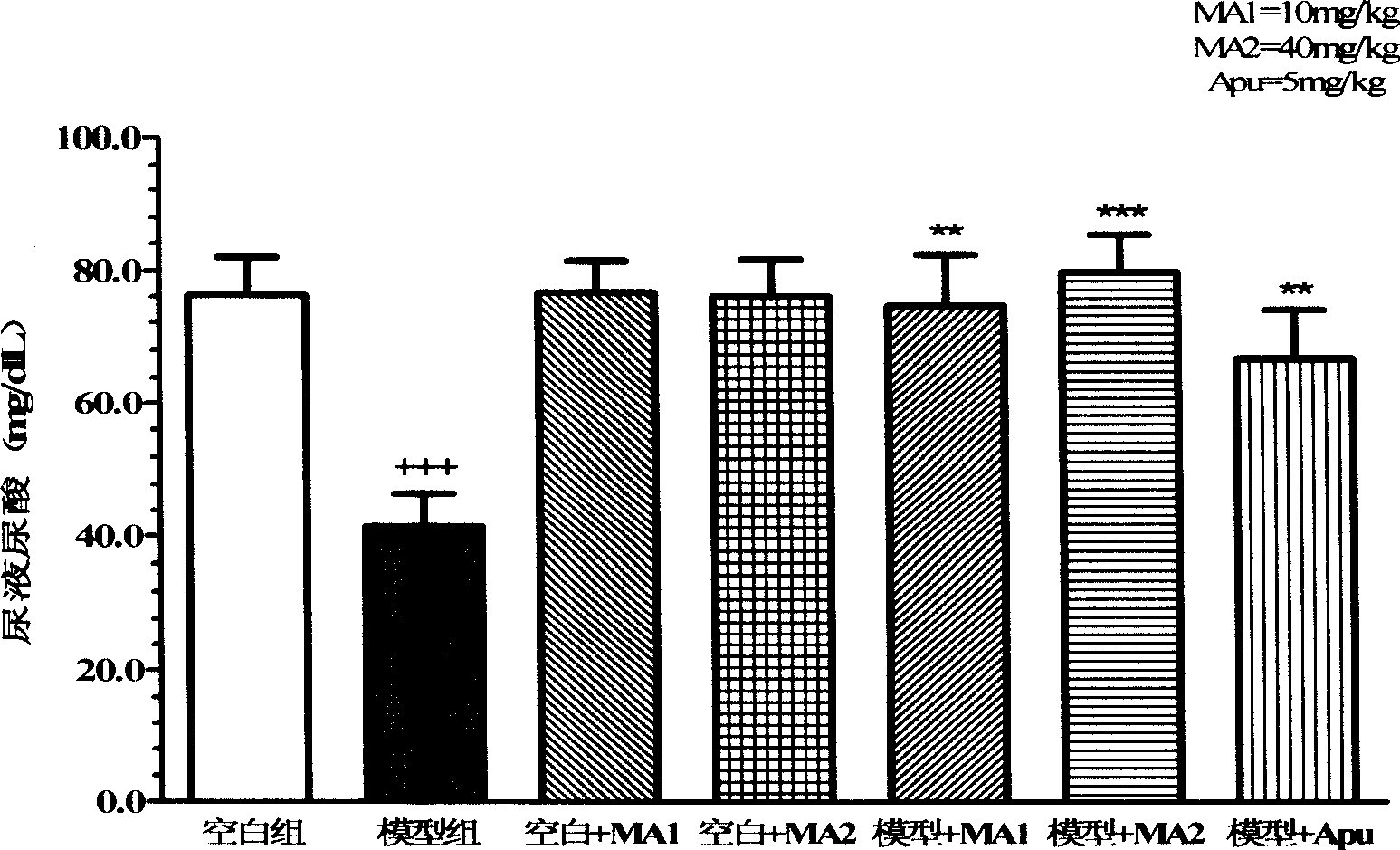

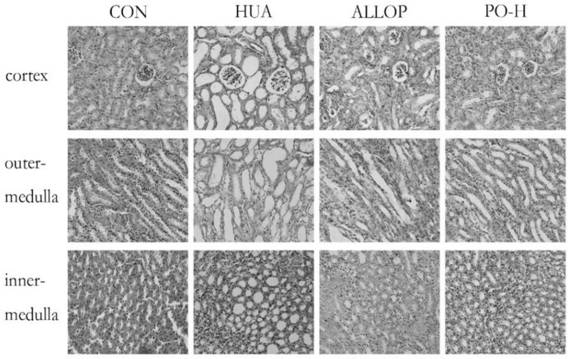

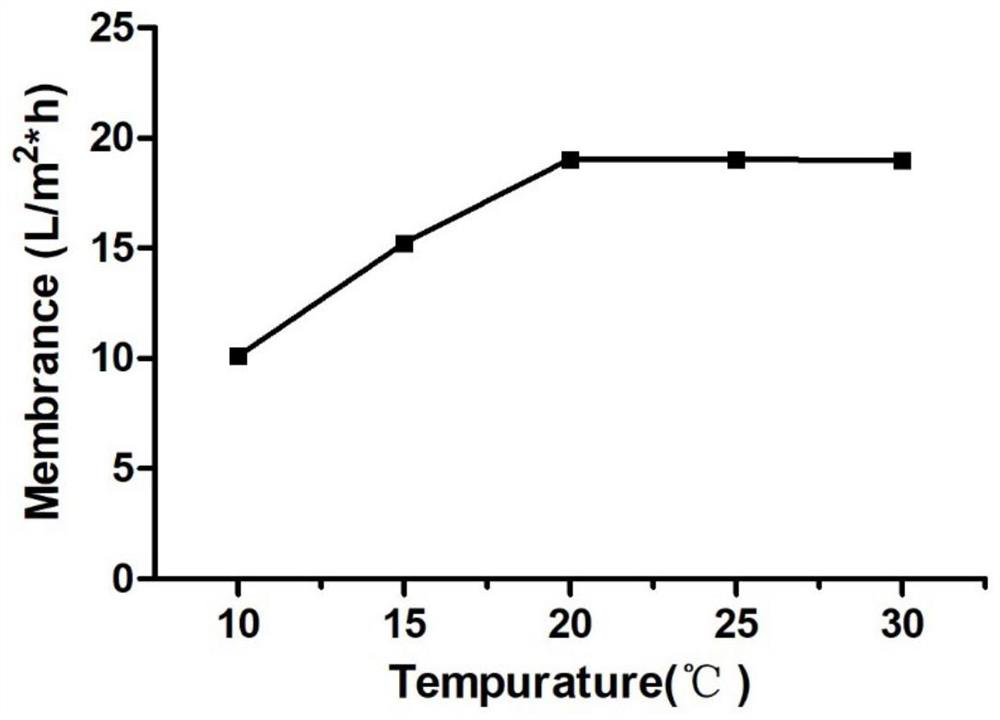

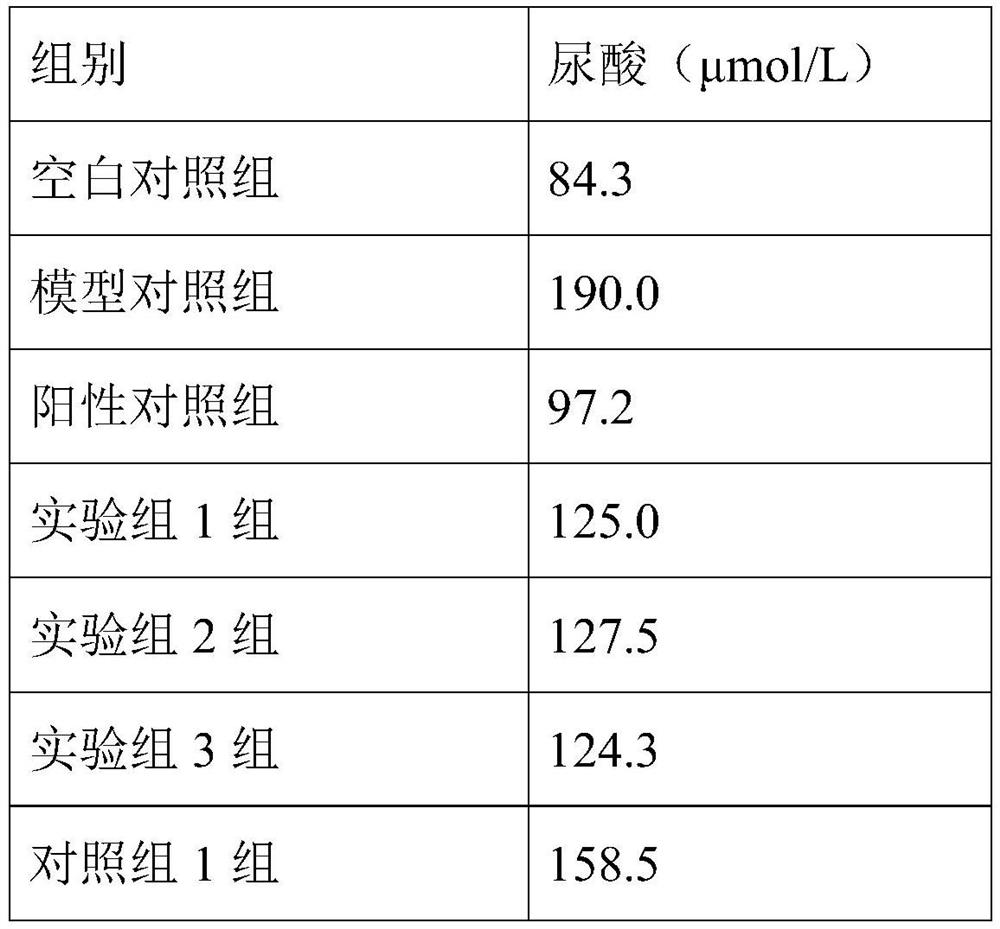

Portulaca oleracea active component and preparation method and application thereof

ActiveCN112043736AGood anti-inflammatory and analgesic effectGood uric acid-lowering effectAntipyreticAnalgesicsDiseaseTherapeutic effect

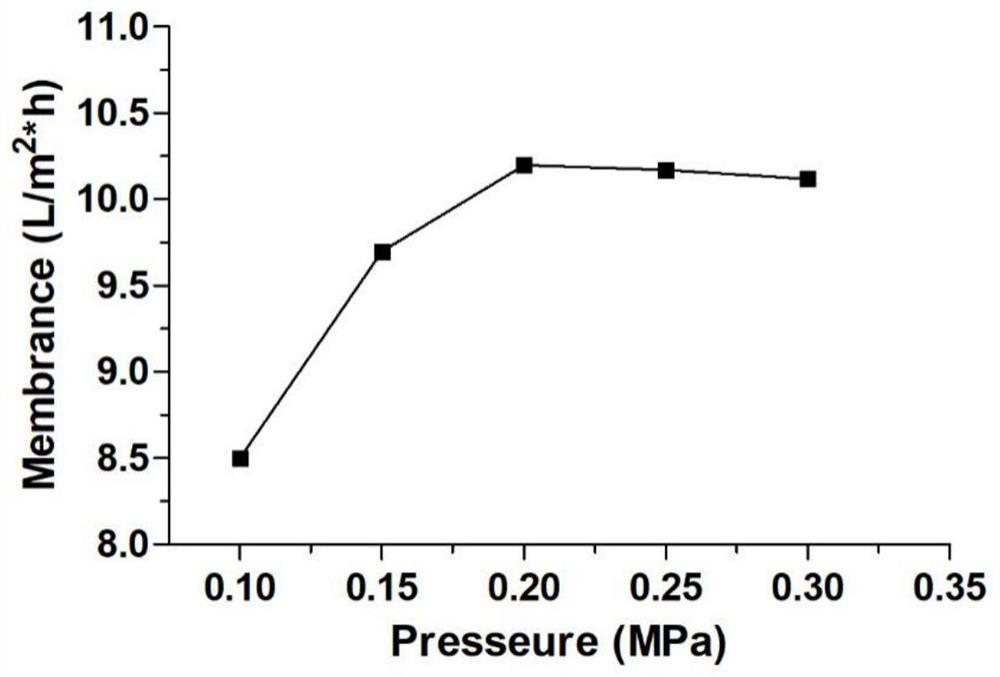

The invention relates to a portulaca oleracea active component and a preparation method and application thereof, and belongs to the technical field of natural active components. The preparation methodof the portulaca oleracea active component comprises the following steps of performing extraction: taking portulaca oleracea, adding water as a solvent, and performing heating extraction to obtain awater extract solution; and performing ultrafiltration: filtering the water extract solution through an ultrafiltration membrane with the molecular weight cutoff of 5K-15K, and taking a filtrate, so that the portulaca oleracea active component is obtained. The preparation method of the portulaca oleracea active component adopts an ultrafiltration mode for extraction and purification and has the advantages of simple and feasible process, experiments prove that the obtained portulaca oleracea active component has good anti-inflammatory and analgesic effects, and biochemical index detection and pathological analysis of animal experiments prove that the component has a good urate-lowering effect and a good kidney protecting effect. Furthermore, the therapeutic effect of PO on gouty diseases isexplored, and a basic theory and a scientific basis are provided for subsequent research and patent medicines of the PO.

Owner:BEIHUA UNIV

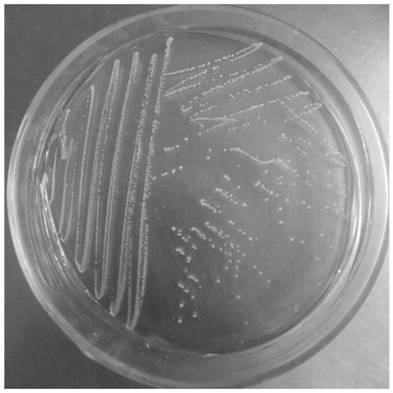

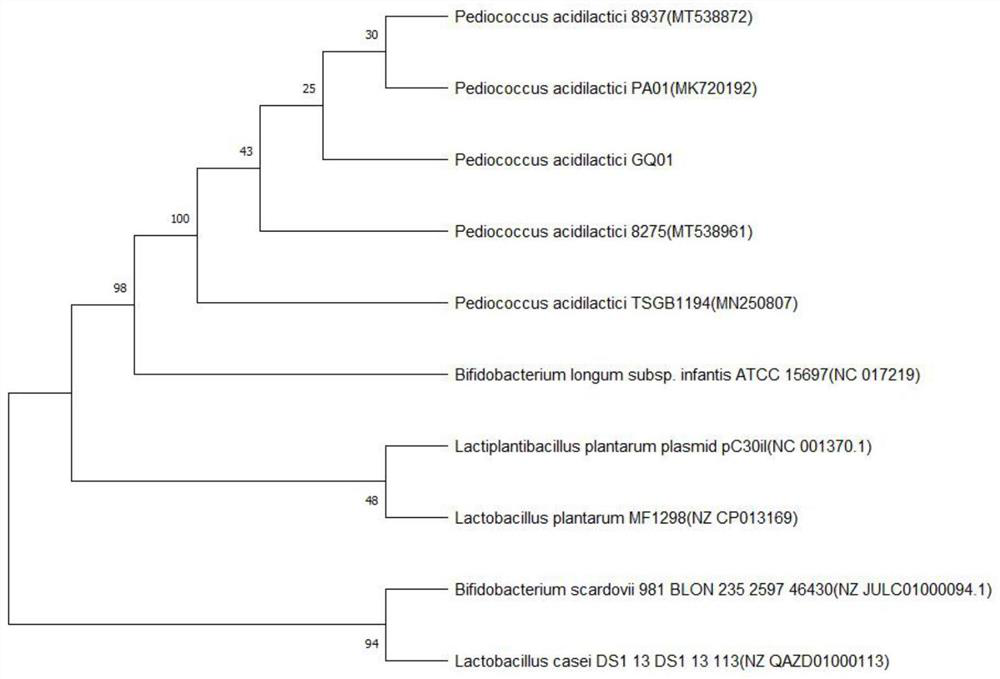

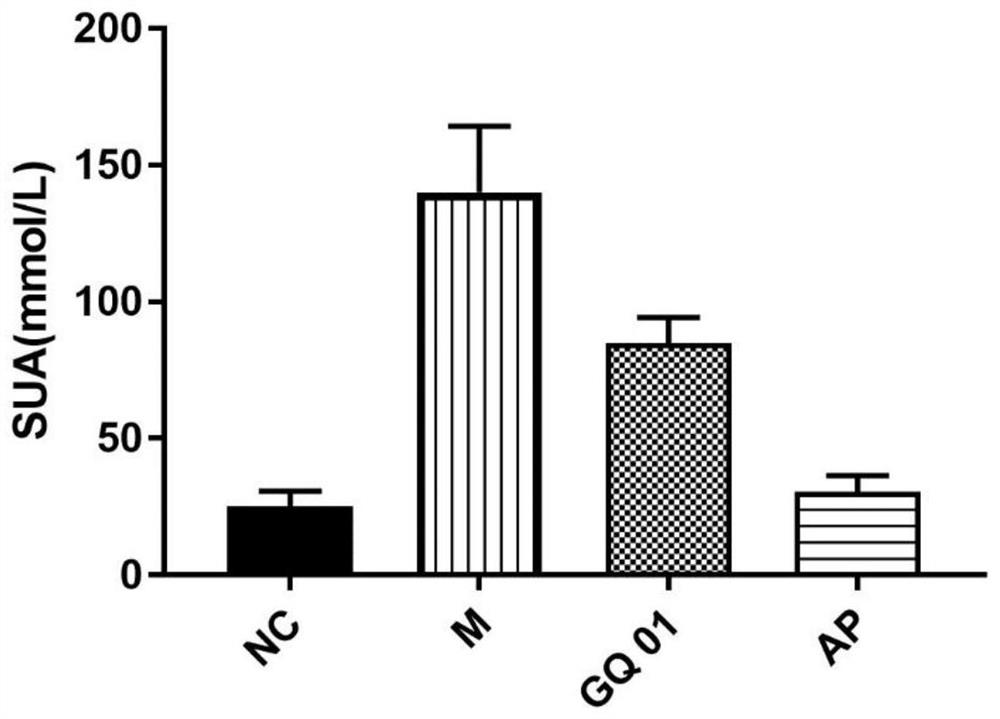

Pediococcus acidilactici derived from wolfberry enzyme and having uric acid reducing effect and application of pediococcus acidilactici

ActiveCN113174341AGood tolerance to bile saltsRich in compositionBacteriaMicroorganism based processesBiotechnologyMicrobiome

The invention relates to a pediococcus acidilactici GQ01 derived from wolfberry enzyme and having uric acid reducing effect, the name of the pediococcus acidilactici is GQ01, the classification name of the pediococcus acidilactici is pediococcus acidilactici, the preservation number of the pediococcus acidilactici is CGMCC No.21609, the preservation date of the pediococcus acidilactici is January 13, 2021, and the preservation unit of the pediococcus acidilactici is China General Microbiological Culture Collection Center, which is located at Institute of Biology, Chinese Academy of Sciences, No. 3, No.1 Yard, Beichen West Road, Chaoyang District, Beijing. The pediococcus acidilactici GQ01 disclosed by the invention is derived from the natural wolfberry enzyme, enriches the microbial composition in the fermented food, and has positive significance in promoting the development and industrial production of the fermented food such as the enzyme and the like. The pediococcus acidilactici GQ01 has better acid resistance and cholate resistance, has an obvious uric acid reducing effect, and can relieve side reactions such as inflammation caused by hyperuricemia.

Owner:TIANJIN UNIV OF SCI & TECH

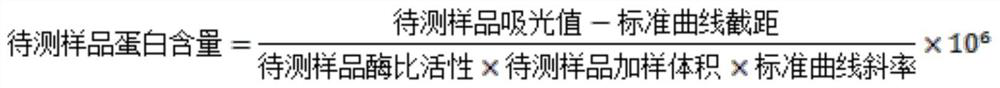

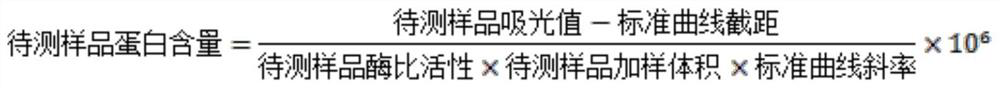

Method for detecting content of urate oxidase in serum

InactiveCN111751358AThe protein content results are close toClose to the resultMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsOxidative enzymeUricotelic

The invention provides a method for detecting the content of urate oxidase in serum, which is characterized by comprising the following steps: 1) preparation of a standard substance: taking urate oxidase with known enzymatic specific activity, and diluting with a Tris-HCl solution; 2) standard curve making: adding a working solution into a test tube, adding a standard substance and blank serum, adding a stop solution to stop the reaction after constant-temperature water bath reaction, and detecting a light absorption value; 3) sample detection: adding a working solution into the test tube, then adding a to-be-detected sample, adding a stop solution to stop the reaction after the constant-temperature water bath reaction, and detecting a light absorption value; 4) data determination and calculation: calculating the enzyme activity of the standard substance at each point according to the enzyme specific activity of the standard substance and the protein content of the standard substance at each point of the standard curve; fitting a standard curve for the enzyme activity of the standard substance at each point according to the light absorption value of each point of the standard curve; substituting the light absorption value of the to-be-detected sample into the standard curve, and obtaining the protein content of the to-be-detected sample through a calculation formula. The methodis accurate, simple and rapid, and the cost is greatly saved compared with an existing complex method.

Owner:修正生物医药(杭州)研究院有限公司

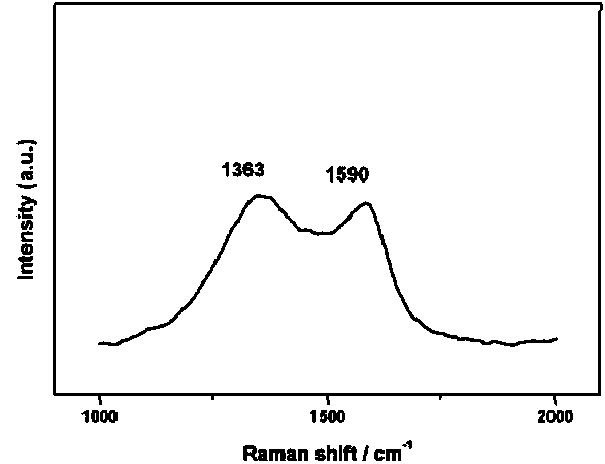

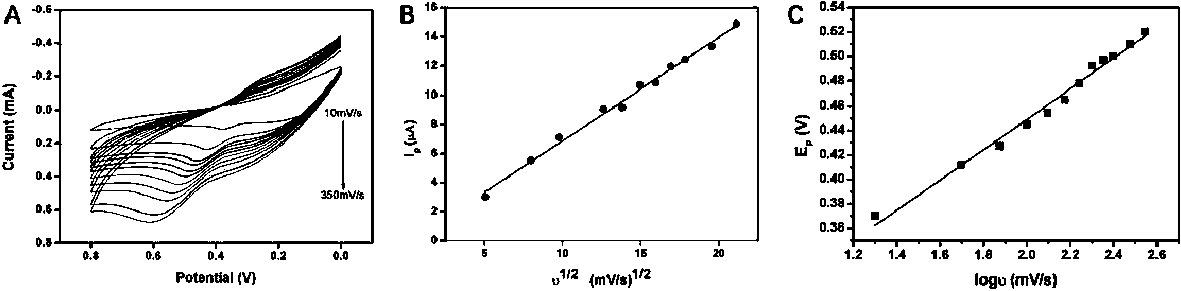

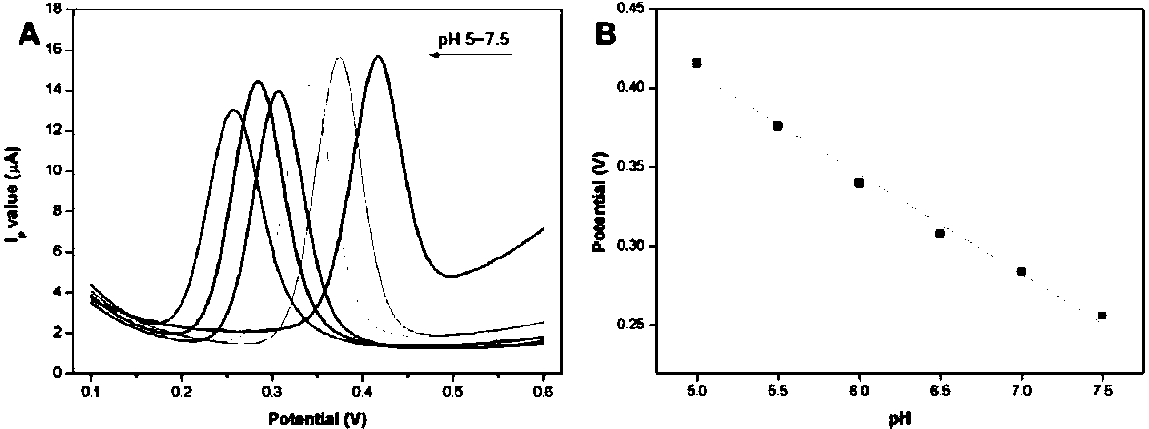

Preparation method and applications of flexible and high-selectivity non-enzymatic uric acid electrode carbon fiber membrane of self-supporting carbon fiber

ActiveCN110877902AGood flexibilityImprove electrocatalytic activityCarbon preparation/purificationFibre chemical featuresFiberCarbon fibers

The invention relates to a preparation method and applications of a flexible and high-selectivity non-enzymatic uric acid electrode carbon fiber membrane of self-supporting carbon fiber, wherein the flexible and high-selectivity non-enzyme uric acid electrode carbon fiber membrane of self-supporting carbon fibers is prepared and is used as an electrochemical sensor modification electrode to directly and rapidly determine non-enzymatic uric acid. The method comprises the following steps: dissolving PAN in DMF to prepare an electrospinning precursor with a PAN mass concentration of 10-14%, applying a voltage between a needle and an aluminum foil collector, carrying out electrospinning, carrying out vacuum drying on the prepared polymer nanofiber membrane to volatilize DMF, putting the carbonfiber membrane into a quartz tube furnace, carrying out heat treatment, cooling to a room temperature, fixing the obtained carbon fiber membrane by using a platinum electrode clamp, exposing, immersing into an H2SO4 solution, and activating by using a cyclic voltammetry to obtain a flexible carbon fiber membrane. With the application of the flexible and high-selectivity non-enzymatic uric acid electrode carbon fiber membrane as a non-enzyme UA sensor electrode, the electrode has characteristics of rapid determination, sensitivity, accuracy, stability, environmental protection and the like, and is an innovation in non-enzyme UA sensor measurement.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

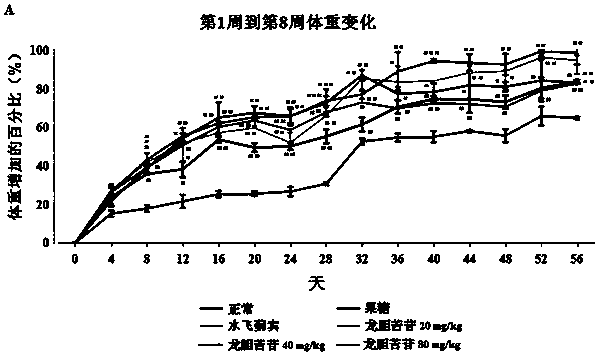

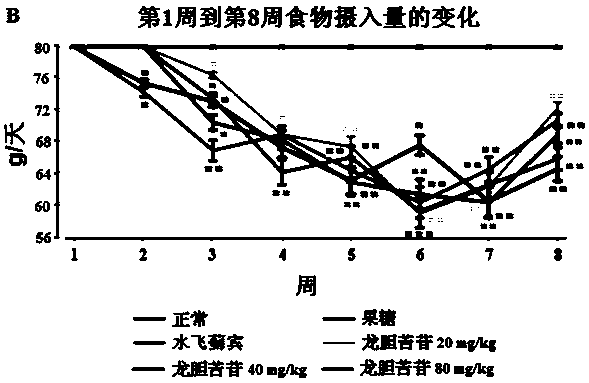

Application of gentiopicroside in treatment of non-alcoholic fatty liver diseases

InactiveCN107929304AReduce deteriorationPromote growthOrganic active ingredientsDigestive systemInterleukin 6Hepatocellular injury

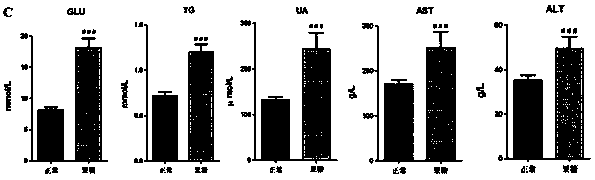

The invention relates to application of gentiopicroside in preparation of medicines for treating non-alcoholic fatty liver diseases. Experiments prove that the gentiopicroside can achieve the following effects in non-alcoholic fatty liver diseases caused by fructose: obviously limiting increase of mouse weight and decrease of food ration, lowering triglycerides (TG), uric acid (UA) and glucose (GLU) as well as levels of serum glutamic oxalacetic transaminase (AST) and glutamic-pyruvic transaminase (ALT), obviously alleviating vacuolar degeneration of hepatic cells and deposition of fatty acidscaused by fructose, lowering levels of tumor necrosis factors (TNF-alpha) and interleukin 6 (IL-6) in hepatic tissues, raising levels of superoxide dismutase (SOD) and glutathione peroxidase (GSH-Px)in the hepatic tissues and lowering levels of malondialdehyde (MDA) and superoxide anions (O2<->). Results show that the gentiopicroside can achieve the effects of obviously promoting metabolism of the liver on fat, obviously improving and increasing the antioxidant stress level of the liver and alleviating hepatocellular injury, so that the aim of treating the fatty liver diseases is achieved.

Owner:NORTHWEST UNIV

A kind of collagen peptide lubricating liquid and preparation method thereof

ActiveCN107789611BGood biocompatibilityNo drug resistanceAntibacterial agentsOrganic active ingredientsSexual arousalUricotelic

Owner:FUJIAN NORMAL UNIV

Method for preparing polyethylene glycol modified urate oxidase

The invention provides a method for preparing polyethylene glycol modified urate oxidase, at least 11 amino acid sites of the following amino acid sites of the polyethylene glycol modified urate oxidase have PEG modification, T1, K3, K4, K30, K35, K76, K79, K97, K112, K116, K120, K152, K179, K222, K231, K266, K272, K285, K291 and K293, the method comprises the following steps: coupling reaction is carried out on the urate oxidase and polyethylene glycol, the polyethylene glycol is provided in the form of an acidic solution, the coupling reaction is carried out in the form of an acidic solution, and the coupling reaction is carried out in the form of an acidic solution. The molar ratio of urate oxidase to polyethylene glycol is 1: (56-94), so as to obtain polyethylene glycol modified urate oxidase.

Owner:CHONGQING PEG BIO BIOTECH CO LTD +1

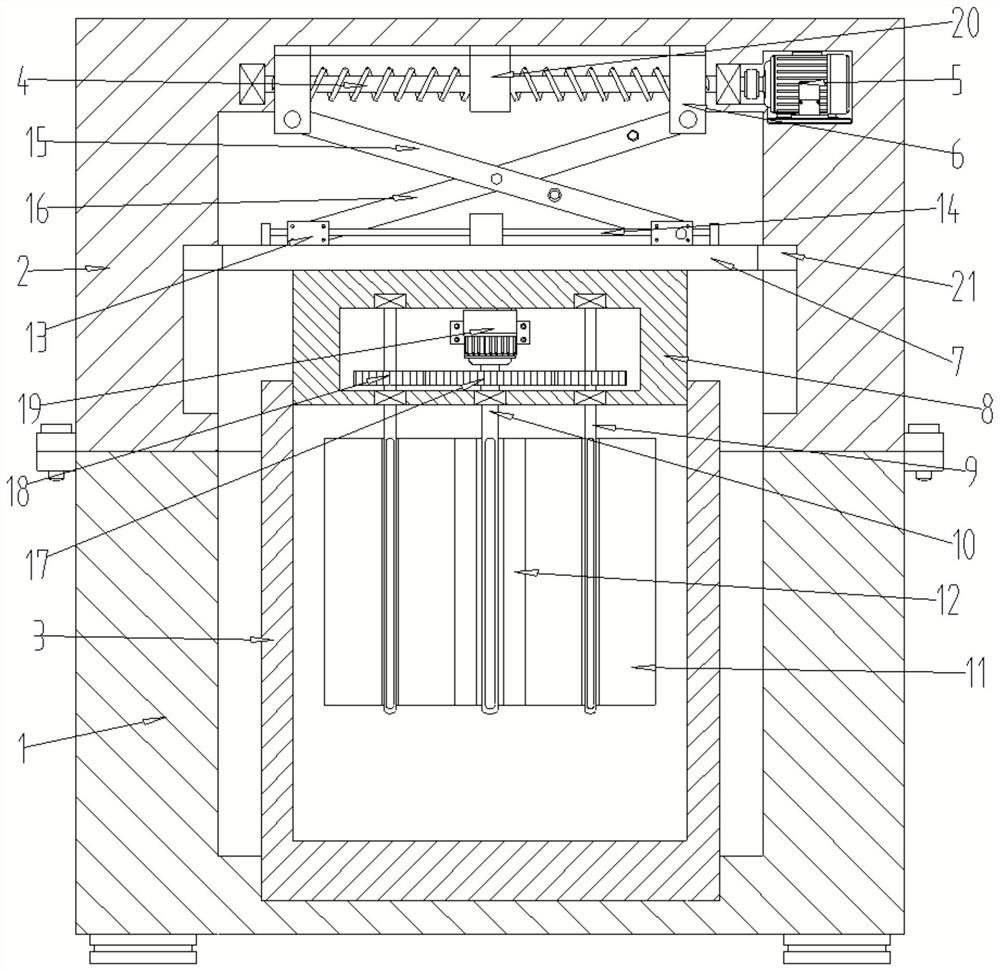

Uric acid reducing solid beverage and preparation method and processing equipment thereof

PendingCN111990570AReasonable designEasy to operateFood thermal treatmentRotary stirring mixersProcess engineeringUricotelic

The invention discloses a uric acid reducing solid beverage and a preparation method thereof. The preparation method comprises the following operating steps of step S1, checking and accepting raw materials: performing inspection according to the acceptance criteria of each raw material, enabling qualified raw materials to enter a warehouse for warehousing, and controlling the quality of the raw materials during factory entry; step S2, removing coats: dismantling outer package of the materials after inspection completion in step S1 in an unpackaging room so that bacteria and grits carried in the transportation process of the materials are prevented from being carried into clean air workshops; step S3, performing disinfection; step S4, pretreating the raw materials; step S5, weighing the materials; step S6, performing granulation; step S7, performing drying; step S8, performing granule trimming; step S9, performing mixing and filling; step S10, performing packaging; step S11, performingthermal contraction; and step S12, performing metal detection. The uric acid reducing solid beverage and the preparation method thereof disclosed by the invention have the beneficial effects that dispersion effects and mixing quality are improved, the qualified rate of products is increased, massive materials are saved, the cost is reduced, the unit output value is increased, the qualified rate ofthe products is increased, and the molding cycle of the products is effectively reduced.

Owner:广东微纳生物科技有限公司

Formula of tablet candy with auxiliary uric acid reducing function

PendingCN113424895AHave a sense of enjoymentAchieve enjoymentConfectionerySweetmeatsBiotechnologyGrape seed

The invention discloses a formula of a tablet candy with an auxiliary uric acid reducing function. The formula comprises the following raw materials in parts by weight: 80-220 parts of sorbitol, 85-255 parts of marine fish oligopeptide powder (containing goose carnosine), 175-525 parts of acerola cherry powder, 15-45 parts of turmeric, 40-110 parts of chitosan oligosaccharide, 5-20 parts of a grape seed extract, 42-125 parts of poria cocos powder, 80-180 parts of microcrystalline cellulose and 2-7 parts of magnesium stearate. Most of existing medicines (such as allopurinol, benzbromarone and febuxostat) for reducing uric acid have side effects and can cause harm to human bodies after being used for a long time. The tablet candy adopts natural and healthy animal and plant components, and the marine fish oligopeptide powder containing goose carnosine, turmeric, chitosan oligosaccharide, the grape seed extract and poria cocos powder are combined for use to achieve the effect of reducing uric acid, so that the safety is high; and through a reasonable formula proportion, the product achieves a good taste, and meanwhile, on the premise of ensuring the effects, consumers can enjoy the tablet candy better and the compliance is high.

Owner:安徽天凯生物科技有限公司

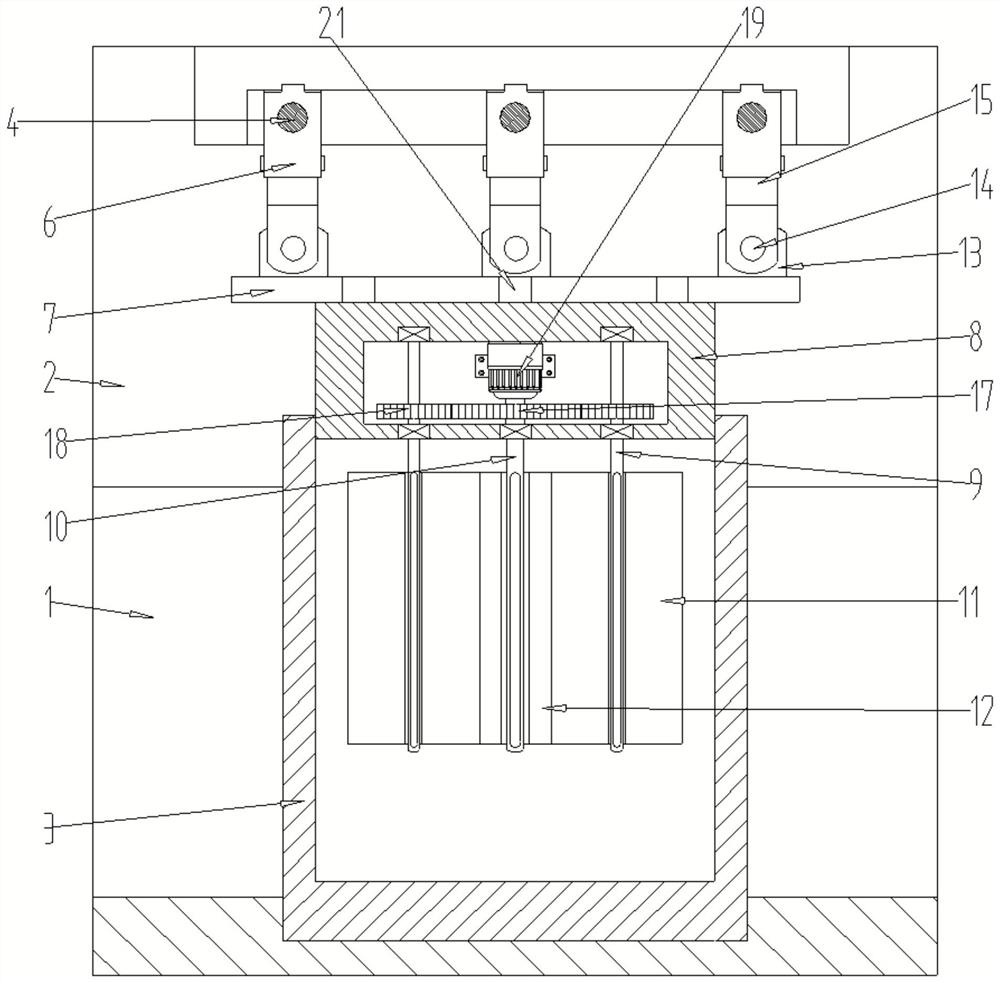

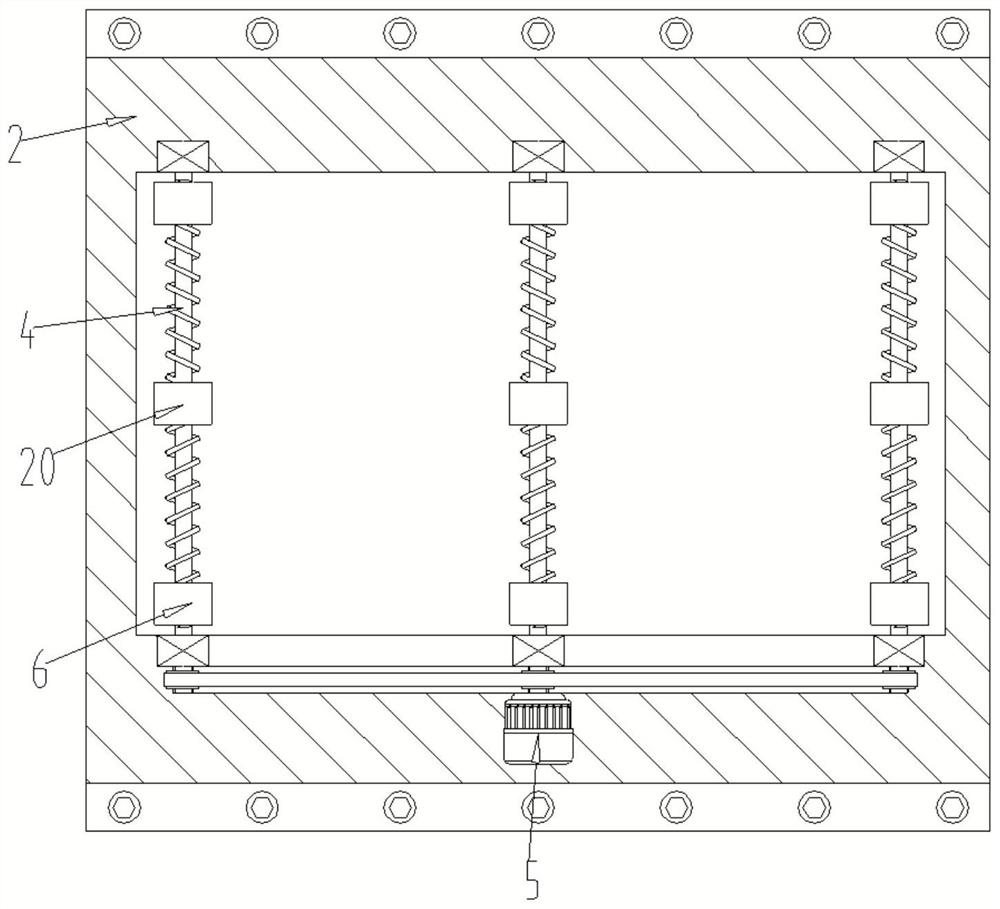

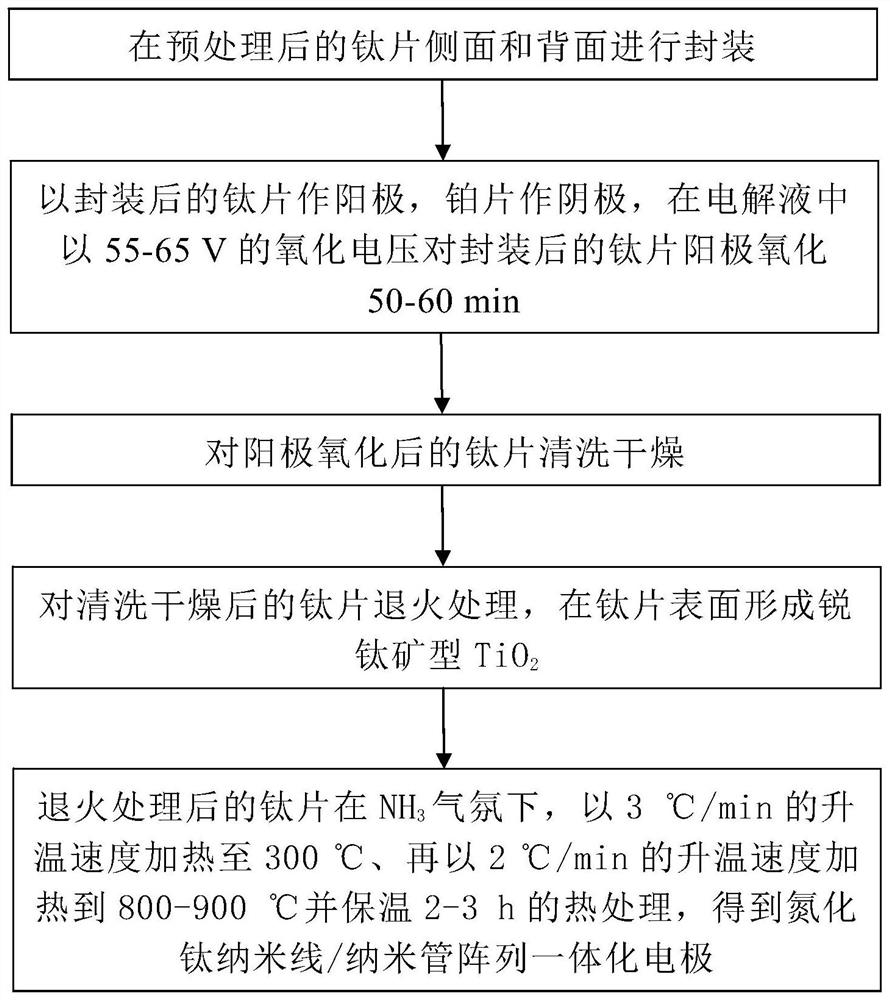

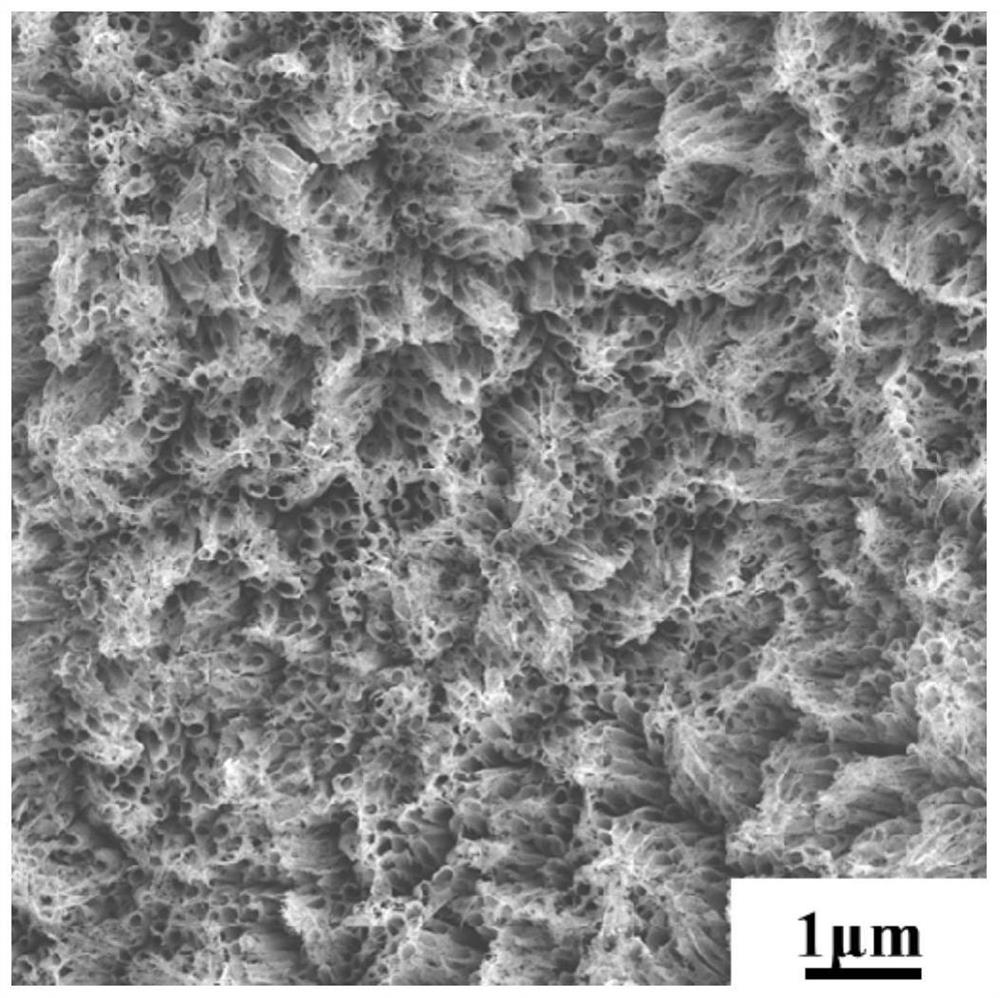

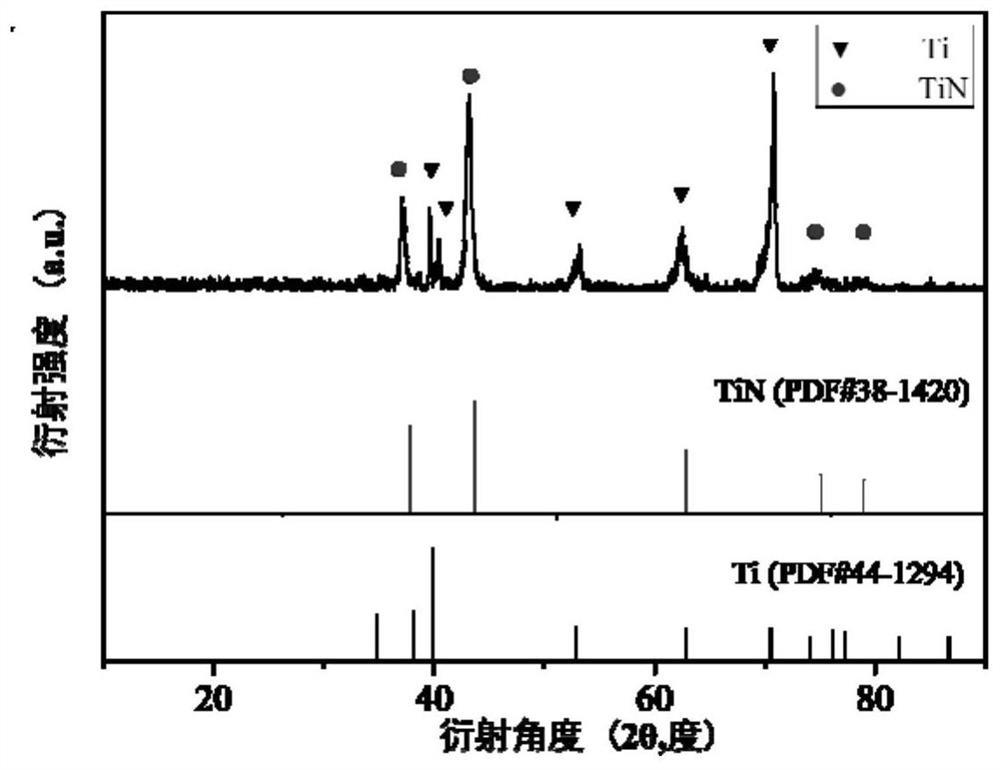

Preparation method of titanium nitride nanowire/nanotube array integrated electrode for simultaneously detecting dopamine, uric acid and ascorbic acid

InactiveCN112198203AImprove detection limitLow detection limitMaterial electrochemical variablesNanowireTitanium nitride

The invention provides a preparation method of a titanium nitride nanowire / nanotube array integrated electrode capable of simultaneously detecting dopamine, uric acid and ascorbic acid. The preparation method comprises the following steps: packaging the side surface and the back surface of a pretreated titanium sheet; anodizing the packaged titanium sheet; cleaning and drying the titanium sheet subjected to anodic oxidation; annealing the cleaned and dried titanium sheet to form anatase TiO2 on the surface of the titanium sheet; and carrying out heat treatment on the annealed titanium sheet inan NH3 atmosphere to obtain the titanium nitride nanowire / nanotube array integrated electrode. According to the preparation method of the titanium nitride nanowire / nanotube array integrated electrodefor simultaneously detecting dopamine, uric acid and ascorbic acid provided by the invention, materials are easy to obtain, the process is simple and controllable, lower detection limits can be respectively detected for dopamine and uric acid, and dopamine, uric acid and ascorbic acid can be detected at the same time, so that the good resolution capability is shown.

Owner:UNIV OF SCI & TECH BEIJING

A preparation method of uricase-modified titanium diboride composite paste electrode sensor

InactiveCN108896362BSelectivityImprove conductivityPreparing sample for investigationMaterial electrochemical variablesTetrafluoroborateCarbon nanotube

Owner:山东政和产业大数据技术研究院

Composition with uric acid reducing function and sacha inchi polypeptide biscuit

InactiveCN113287649APromote excretionEnhance the effect of lowering uric acidDough treatmentPeptide/protein ingredientsBiotechnologyFood grade

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

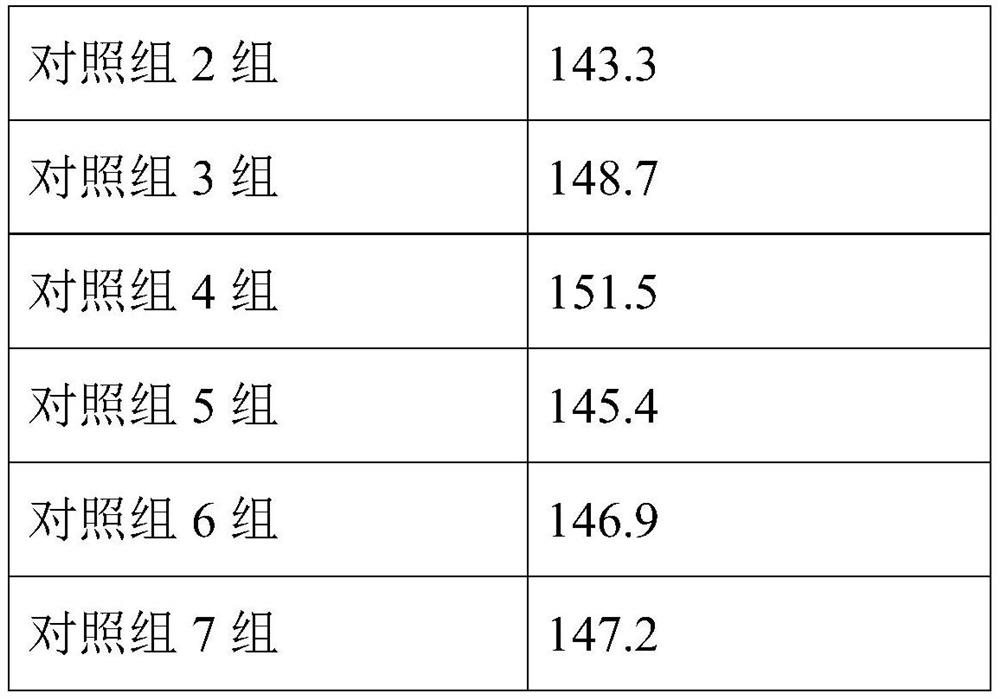

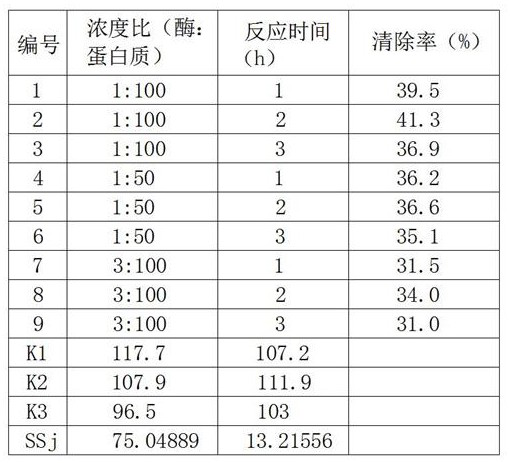

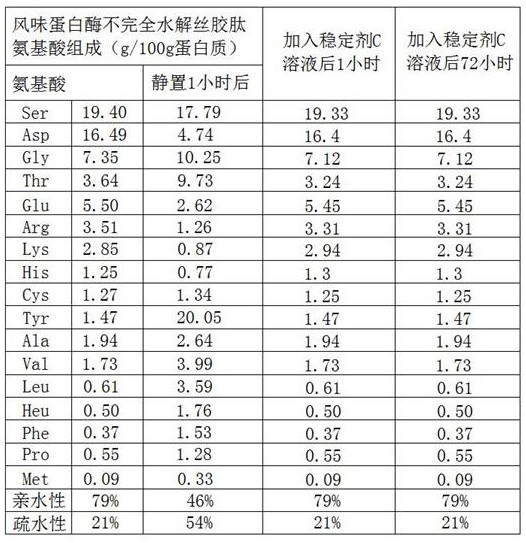

Preparation way of incompletely enzyme-digested sericin anti-oxidation and anti-initial-aging stock solution

PendingCN113633568AStable in natureStabilize and repair damageCosmetic preparationsToilet preparationsSILK SERICINDistilled water

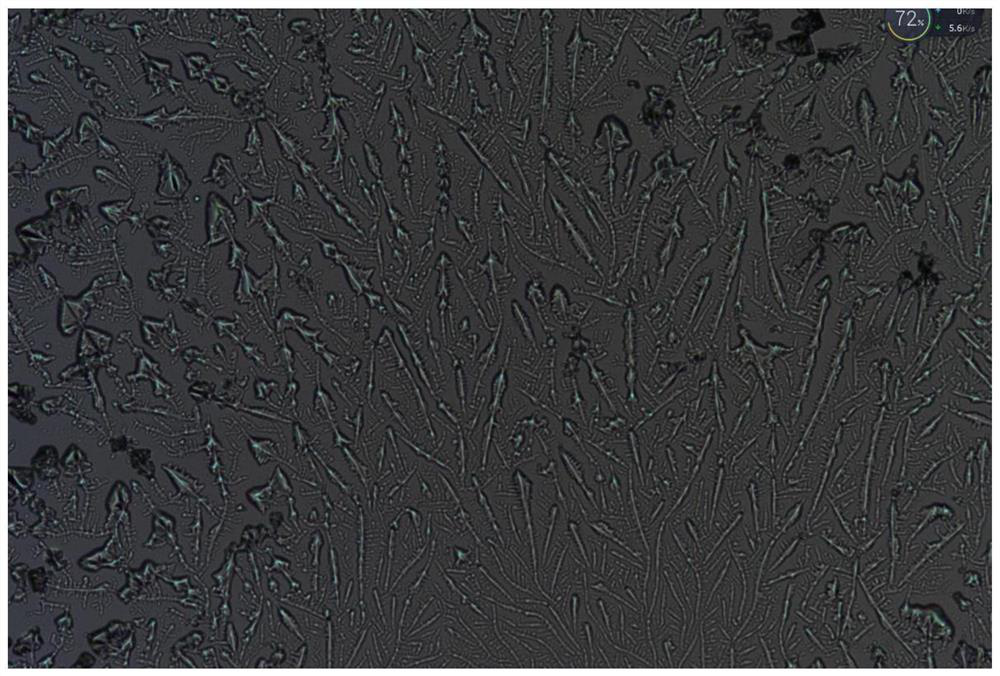

The invention discloses a preparation way of an incompletely enzyme-digested sericin anti-oxidation and anti-initial-aging stock solution. The preparation way comprises the following steps of: dissolving 100g of sericin powder in 1L of distilled water to prepare a solution A with the concentration of 0.1 g / ml; dissolving 100g of protease into 1L of distilled water to prepare a solution B with the pH value of 7.0 and the concentration of 0.1 g / ml; dissolving 10g of trehalose powder and 10g of hyaluronic acid in 1L of distilled water according to the ratio of 1: 1 to prepare a solution C with the concentration of 0.01 g / ml; heating the solution A to 50 DEG C, adding a solution B (the ratio of enzyme to protein is 1: 100) according to the proportion of 1 / 100 of the solution A, maintaining the temperature, testing the PH value to be 7, and if conditions change, regulating the PH value to be maintained to be 7 through NAHO; and after reacting for two hours, heating the solution to 80-100 DEG C to destroy the protease, terminating the hydrolysis reaction of enzyme, cooling to the room temperature, and adding 1 / 10 of the solution C for stabilizing. According to the preparation way, protein components which are not completely hydrolyzed can be kept stable, so that the optimal stable state of scavenging free radicals can be achieved.

Owner:伊深细胞生物技术上海有限公司

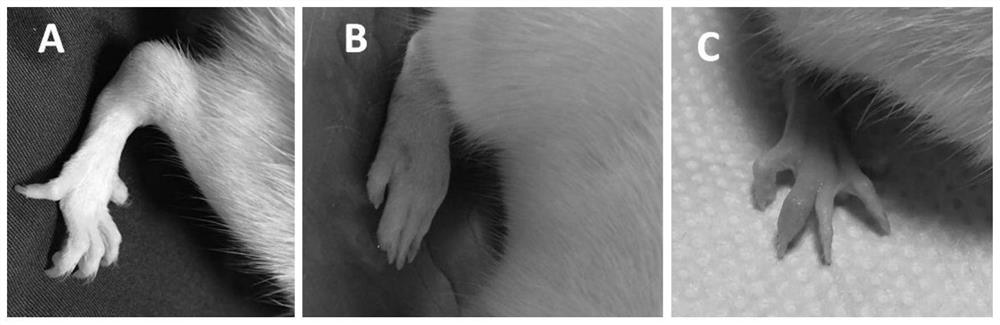

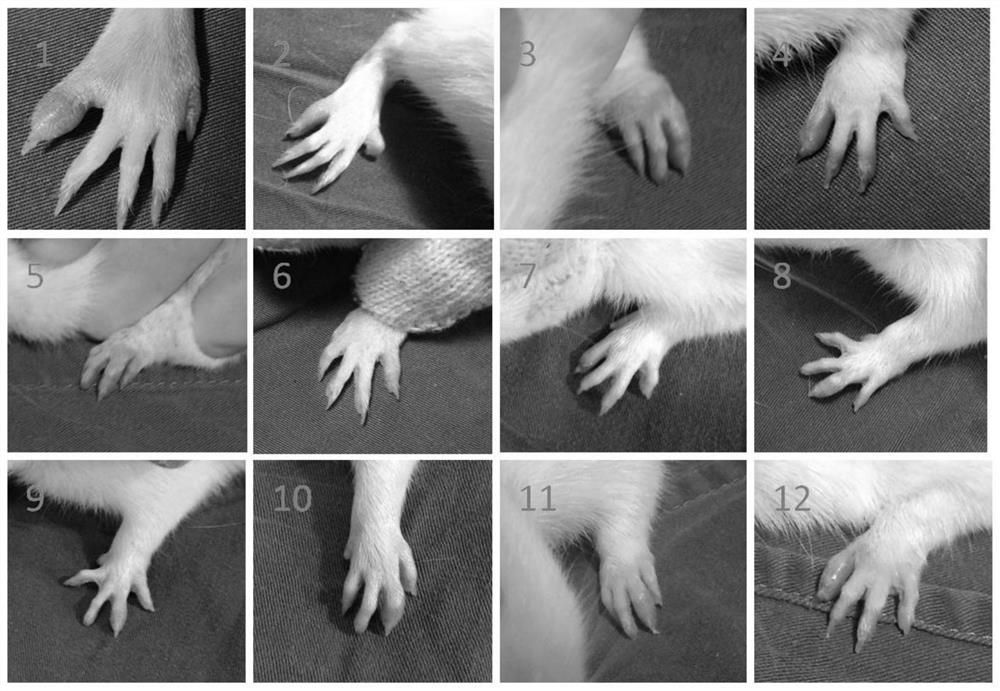

A construction method and application of a gout animal model

ActiveCN110338139BTypical gout symptomsCompounds screening/testingAnimal husbandryIntraperitoneal routeClinical manifestation

Owner:ANHUI PROVINCIAL HOSPITAL

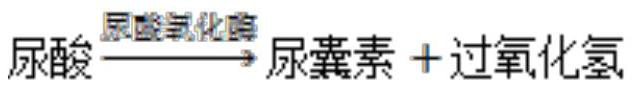

Preparation method of nanogold cluster and sensitization detection method of nanogold cluster in small biological molecules

PendingCN114324266AAvoid expensive pricesAvoid the problem of inconvenient storageNanoopticsFluorescence/phosphorescencePeroxidaseOxidative enzyme

The invention discloses a nanogold cluster preparation method and a biological small molecule sensitization detection method, uric acid generates hydrogen peroxide under the catalysis of urate oxidase, a substrate 3, 3 ', 5, 5'-tetramethyl benzidine is oxidized into ox-TMB by using peroxidase activity of the synthesized gold nanocluster and a catalytic product H2O2, at the moment, an emission spectrum of AuNCs is overlapped with an absorption spectrum of ox-TMB, and the concentration of the ox-TMB is determined. According to the method disclosed by the invention, fluorescence resonance energy transfer occurs between the strongly fluorescent AuNCs and ox-TMB, a BSA-AuNCs fluorescence signal achieves a quenching effect, and the method not only solves the problem that use conditions of a traditional enzyme method are restricted, but also reduces a detection line and realizes sensibilization detection of uric acid molecules. Due to the fact that the emission spectrum of the AuNCs is overlapped with the absorption spectrum of the ox-TMB, fluorescence resonance energy transfer occurs between the AuNCs with strong fluorescence and the ox-TMB, the fluorescence signal of the AuNCs is obviously reduced, and the purpose of sensitizing and detecting the content of the uric acid is achieved.

Owner:中检国研长春科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com