Preparation method of titanium nitride nanowire/nanotube array integrated electrode for simultaneously detecting dopamine, uric acid and ascorbic acid

A titanium nitride nanometer and nanotube array technology is applied in the field of electrochemistry to achieve the effects of easy material, good repeatability, and simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

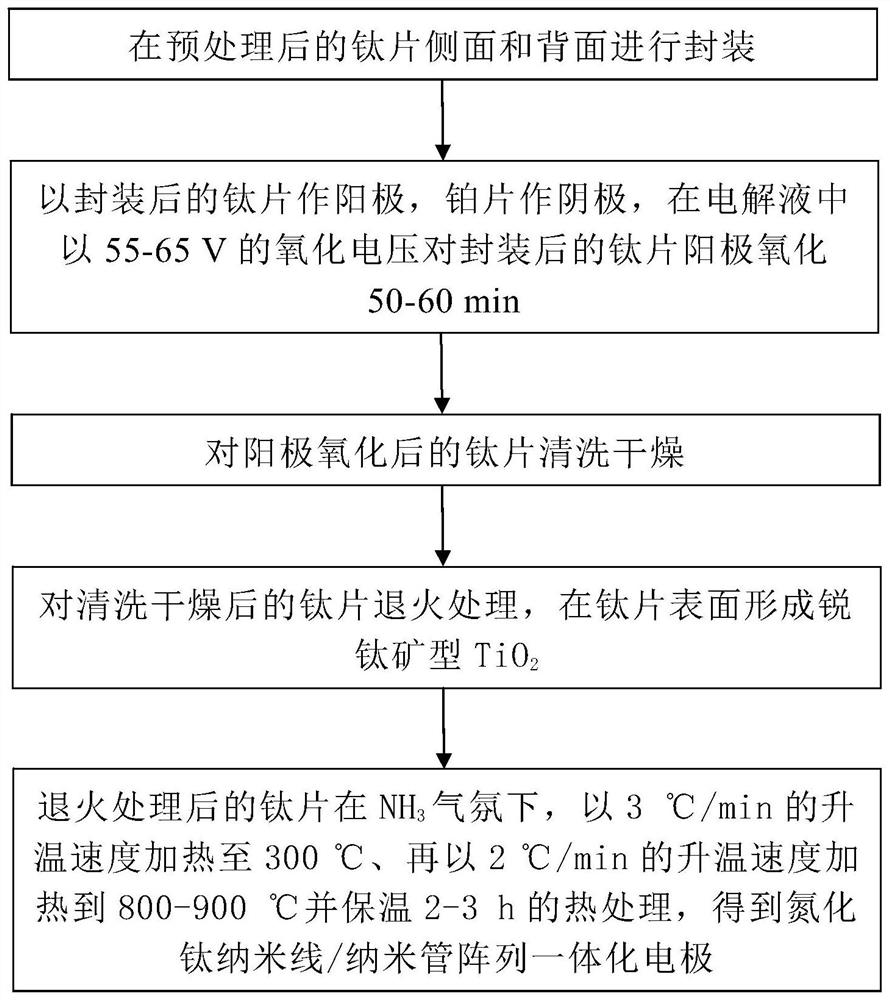

[0026] see figure 1 A method for preparing a titanium nitride nanowire / nanotube array integrated electrode for simultaneous detection of dopamine, uric acid and ascorbic acid provided by an embodiment of the present invention comprises the following steps:

[0027] Step 1) Polish the titanium sheet with sandpaper until there is no trace, ultrasonicate it in acetone, ethanol, and distilled water for 8-10 minutes, and dry it, wherein, in order to facilitate the final formation of titanium nitride on the surface of the titanium sheet into a nanowire / nanotube array Arrange, paste scotch tape on the side and back of the titanium sheet and package for use.

[0028] Step 2) The packaged titanium sheet is used as an anode, and the platinum sheet is used as a cathode, and the two are inserted in parallel and separated by 2-3 cm into the prepared electrolyte solution for anodic oxidation. The electrolyte is prepared from 90vol% ethylene glycol, 0.5wt% ammonium fluoride and distilled wa...

Embodiment 1

[0036] (1) Grind the titanium sheet with sandpaper until there is no trace, sonicate it in acetone, ethanol, and distilled water for 8 minutes, dry it, and stick transparent tape on the side and back of the titanium sheet for packaging.

[0037] (2) The titanium sheet is used as the anode, and the platinum sheet is used as the cathode, and the two are inserted into the prepared electrolyte (90vol% ethylene glycol, 0.5wt% ammonium fluoride and distilled water) for anodic oxidation in parallel at a distance of 2 cm, and the anodic oxidation voltage is 55V, the oxidation time is 60min. The titanium piece was taken out, rinsed with distilled water and ultrasonicated for 10 s to remove residual fluoride ions.

[0038] (3) Put the anodized titanium sheet in the air and anneal at 400°C for 2.5h to obtain anatase TiO 2 .

[0039] (4) Place the annealed titanium sheet in a chemical vapor deposition instrument, 3 Heat treatment under atmosphere, rising to 300°C at 3°C / min, then risin...

Embodiment 2

[0043] (1) Grind the titanium sheet with sandpaper until there is no trace, sonicate it in acetone, ethanol, and distilled water for 9 minutes, dry it, and stick scotch tape on the side and back of the titanium sheet for packaging.

[0044] (2) The titanium sheet is used as the anode, and the platinum sheet is used as the cathode, and the two are inserted into the prepared electrolyte (90vol% ethylene glycol, 0.5wt% ammonium fluoride and distilled water) for anodic oxidation in parallel and separated by 2.5cm, and the anodic oxidation voltage It is 60V, and the oxidation time is 55min. The titanium piece was taken out, rinsed with distilled water and ultrasonicated for 13 s to remove residual fluoride ions.

[0045] (3) Put the anodized titanium sheet in the air and anneal at 450°C for 2h to obtain anatase TiO 2 .

[0046] (4) Place the annealed titanium sheet in a chemical vapor deposition instrument, 3 Heat treatment under atmosphere, rising to 300°C at 3°C / min, then risi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com