Uric acid reducing solid beverage and preparation method and processing equipment thereof

A solid beverage and processing equipment technology, applied in chemical instruments and methods, transportation and packaging, mixers with rotating stirring devices, etc., can solve the problems of too simple structure, resources affect processing, increase production costs, etc., and achieve simple structure , Low production cost and reduced molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

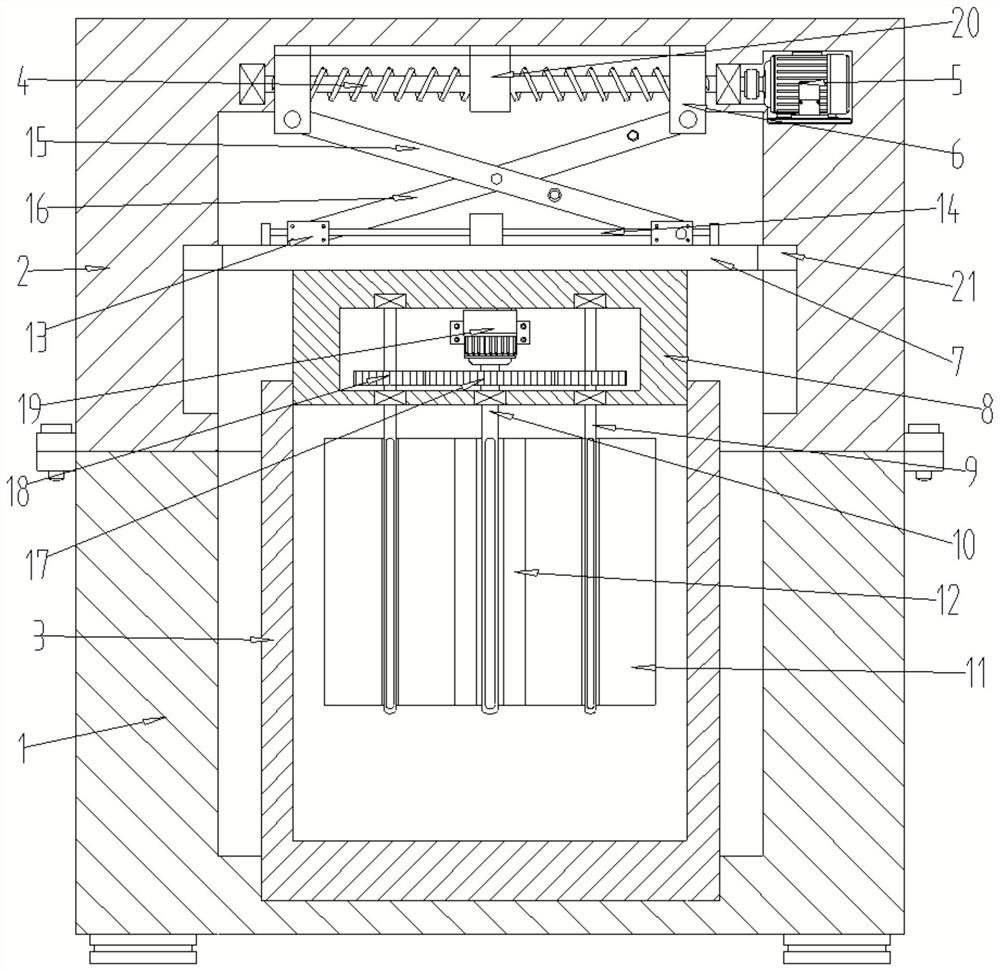

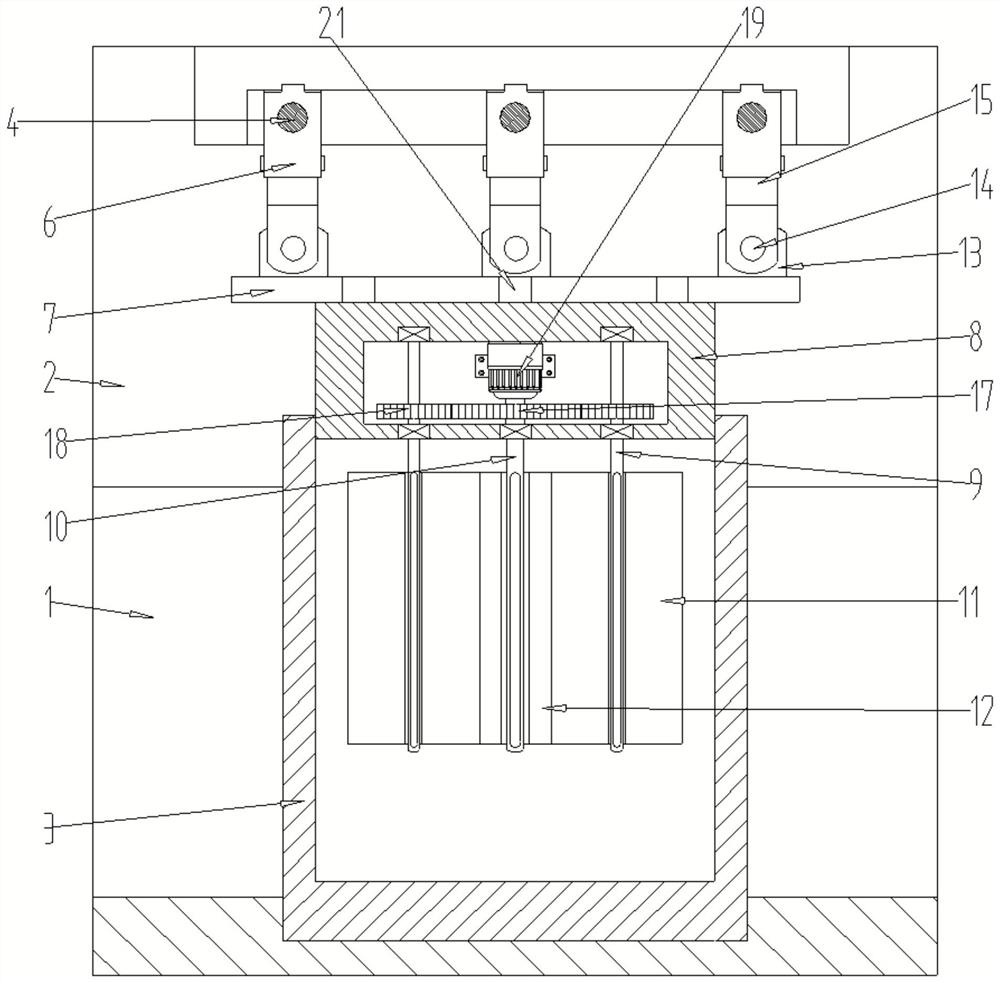

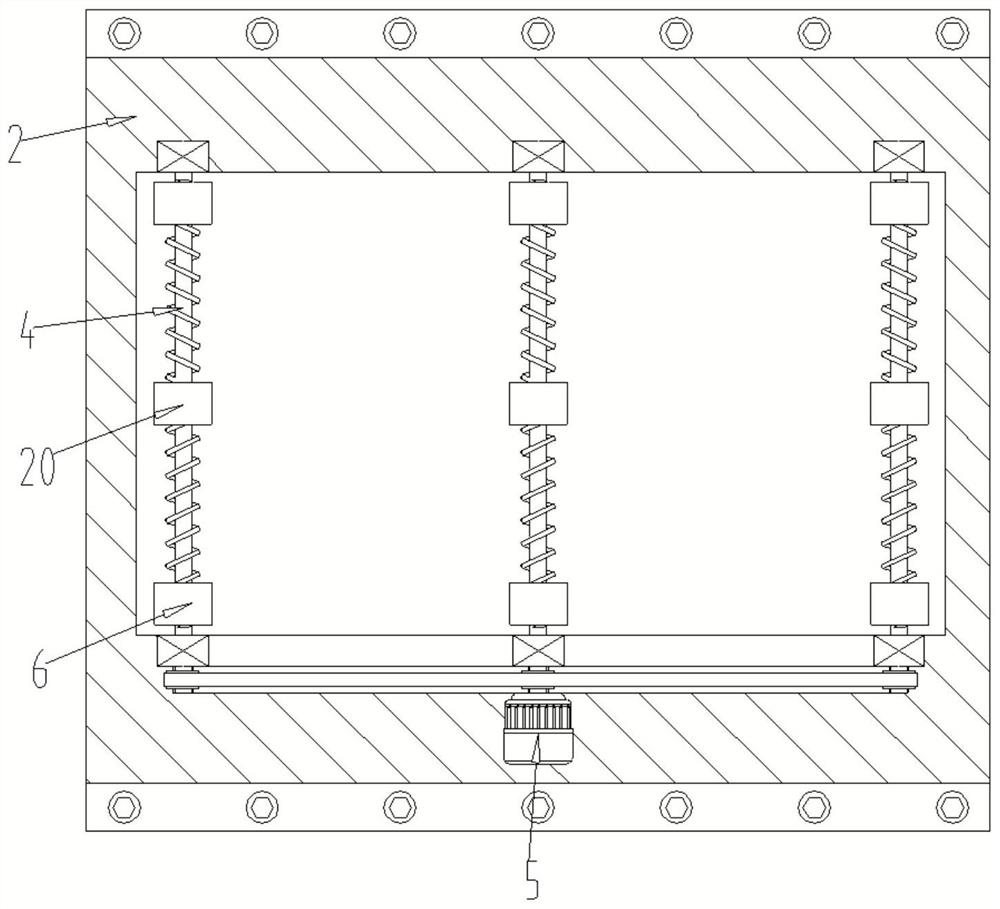

[0041] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a uric acid-reducing solid beverage and its preparation method include the following steps: step S1, raw material acceptance; step S2, coat removal; step S3, disinfection; step S4, raw material pretreatment; step S5, weighing; S6, granulation; step S7, drying; step S8, granulation; step S9, mixing and filling; step S10, packaging; step S11, heat shrinking; step S12, metal detection; step S1: according to the acceptance criteria of each raw material After the inspection, the raw materials can be put into the warehouse after passing the inspection, and the raw materials are put into the factory; Step S2: Remove the outer packaging of the materials after the inspection of the step S1 in the unpacking room to prevent bacterial sand from being carried during transportation Bring into the clean air workshop; step S3: remove the material from the outer packag...

Embodiment

[0054] Example: Example: A uric acid-reducing solid beverage and its preparation method, comprising the following steps: step S1, raw material acceptance; step S2, coat removal; step S3, disinfection; step S4, raw material pretreatment; step S5, weighing material; step S6, granulation; step S7, drying; step S8, granulation; step S9, mixing and filling; step S10, packaging; step S11, heat shrinking; step S12, metal detection; step S1: Acceptance standards are inspected, and only after passing the standard can they be put into the warehouse, and good raw materials are put into the factory; Step S2: Remove the outer packaging of the materials after the inspection in Step S1 in the unpacking room to prevent bacteria from being carried during transportation The sand is brought into the clean air workshop. The clean air workshop in step S2 must have at least 300,000 grades for production; step S3: the materials removed from the outer packaging in step S2 must be placed in the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com