Urea granule dense-phase conveying method and system

A technology of dense phase conveying and urea granules, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as urea granule crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

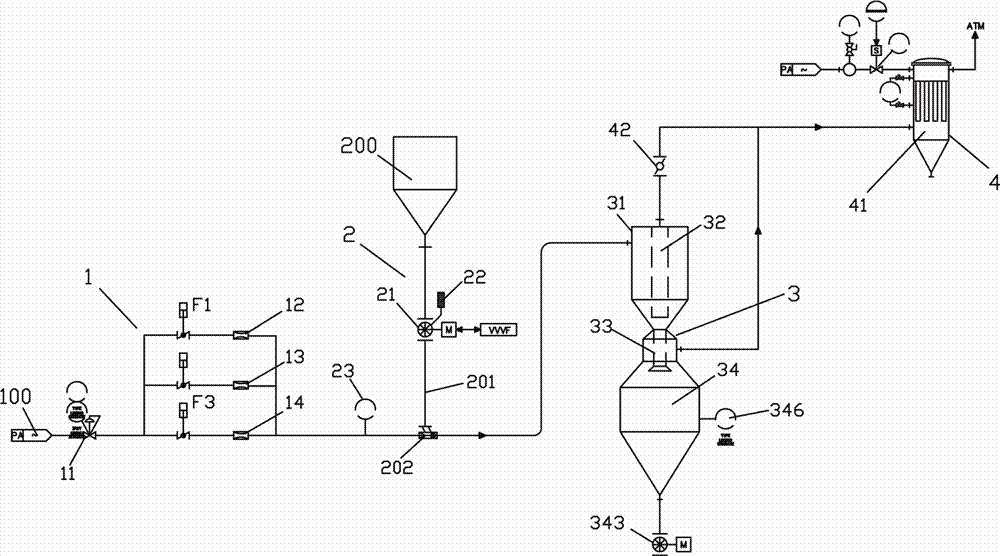

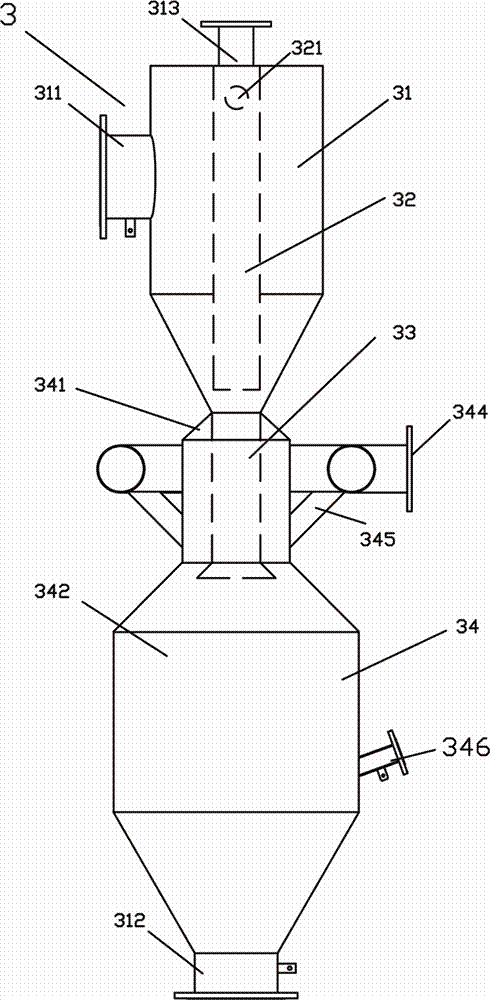

[0024] see figure 1 , figure 2 , a urea particle dense phase delivery system of the present invention, which comprises,

[0025] Dense-phase conveying air source control unit 1, including pressure reducing valve 11, three sets of laval tubes 12-14 and corresponding pneumatic butterfly valves F1-F3 arranged in sequence; wherein, pressure reducing valve 11 is set in the system air source pipeline 100 ;Three sets of laval tubes 12-14 and corresponding pneumatic butterfly valves F1-F3 connected in parallel are arranged in the outlet pipeline of the pressure reducing valve 11;

[0026] The rotary feeding valve unit 2 is arranged in the outlet pipeline 201 of the hopper 200, which includes a rotary feeding valve 21, a leakage gas filter 22, and a pressure sensor 23; wherein, the hopper outlet pipeline 201 is connected to the dense phase In the pipeline at the outlet end of the three groups of laval tubes in the delivery gas source control unit 1, the rotary feeding valve 21 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com