A 3D printed prefabricated reinforced concrete component and its manufacturing method

A technology of reinforced concrete and 3D printing, applied in building components, building structures, walls, etc., can solve the problems of not giving full play to the advantages of 3D printing, difficult calculation analysis and engineering applications, and low automation of reinforcement layout, saving Cost of material and labor consumption, avoidance of body shape constraints, the effect of high degree of freedom in body shape design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

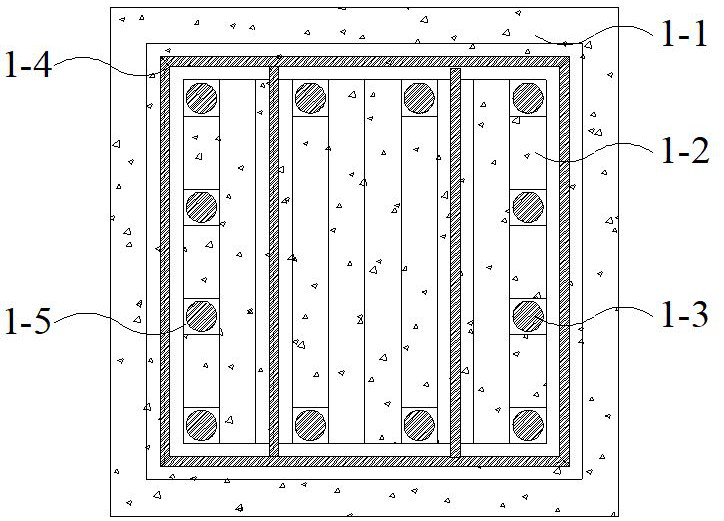

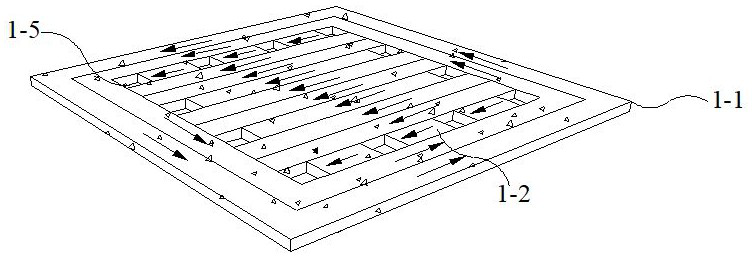

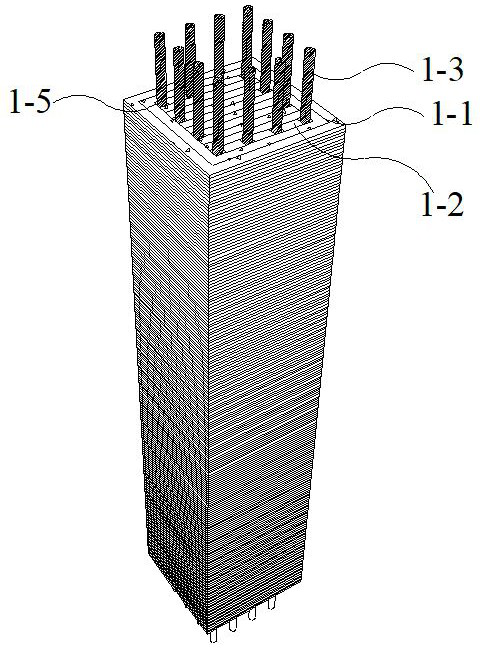

[0052] Such as Figure 1 ~ Figure 4 As shown, a 3D printed prefabricated reinforced concrete rectangular column, including: rectangular column 3D printed shell 1-1, rectangular column 3D printed internal structure 1-2, rectangular column stirrup 1-4, rectangular column longitudinally reserved Holes 1-5 and rectangular column longitudinal ribs 1-3; the rectangular column 3D printed shell 1-1 is printed around the component axis according to the shape of the component; the rectangular column 3D printed internal structure 1-2 is printed on the rectangular column 3D printed shell 1 -1, if figure 1 As shown; the stirrups are directly placed on the shell part of the printed concrete in the direction parallel to the printing plane at every fixed number of printing layers, and the longitudinal reserved holes are located in the internal structure of the concrete member; In the reserved holes, the grouting material is poured into the holes in the later stage to realize the fixation of ...

Embodiment 2

[0062] Such as Figure 5 ~ Figure 8 As shown, a 3D printed prefabricated reinforced concrete box girder, including: box girder 3D printed shell 2-1, box girder 3D printed internal structure 2-2, box girder longitudinally reserved holes 2-6 , box girder longitudinal reinforcement 2-4, box girder waist reinforcement 2-3 and box girder stirrup 2-5; the box girder 3D printing shell 2-1 is printed around the component axis according to the component shape; The box girder 3D printing internal structure 2-2 is printed in the box girder 3D printing shell 2-1, such as Figure 5 As shown; the longitudinally reserved hole 2-6 of the box girder is located in the internal structure of the concrete member; the longitudinal stress rib 2-4 of the box girder is directly penetrated in the longitudinally reserved hole 2-6 of the box girder, and in the later stage The grouting material is poured into the hole to realize the fixing of the longitudinal reinforcement 2-4 of the box girder; the stir...

Embodiment 3

[0075] like Figure 9 ~ Figure 12 As shown, a prefabricated 3D printed reinforced concrete rectangular column with variable cross-section includes: 3D printed outer shell 3-1 of variable cross-section rectangular column, 3D printed internal structure 3-2 of variable cross-section rectangular column, longitudinal reservation of variable cross-section rectangular column Holes 3-5, variable cross-section rectangular column longitudinal reinforcement 3-3 and variable cross-section rectangular column stirrup 3-4; the variable cross-section rectangular column 3D printing shell 3-1 is printed around the component axis according to the shape of the component; the variable cross-section rectangular The column 3D printing internal structure 3-2 structure is printed in the variable cross-section rectangular column 3D printing shell 3-1, such as Figure 9 As shown; the longitudinal reserved holes 3-5 of the variable cross-section rectangular column are located in the internal structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com