Roof exhaust system

An exhaust system and exhaust pipe technology, applied in the direction of roof, ventilation system, roof covering, etc., can solve the problems of inconvenient construction, inability to effectively prevent rainwater from entering the interior of the roof, and inability to discharge gas quickly and timely, etc., to achieve Convenient construction, prevent rainwater from entering the interior of the roof, and good exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

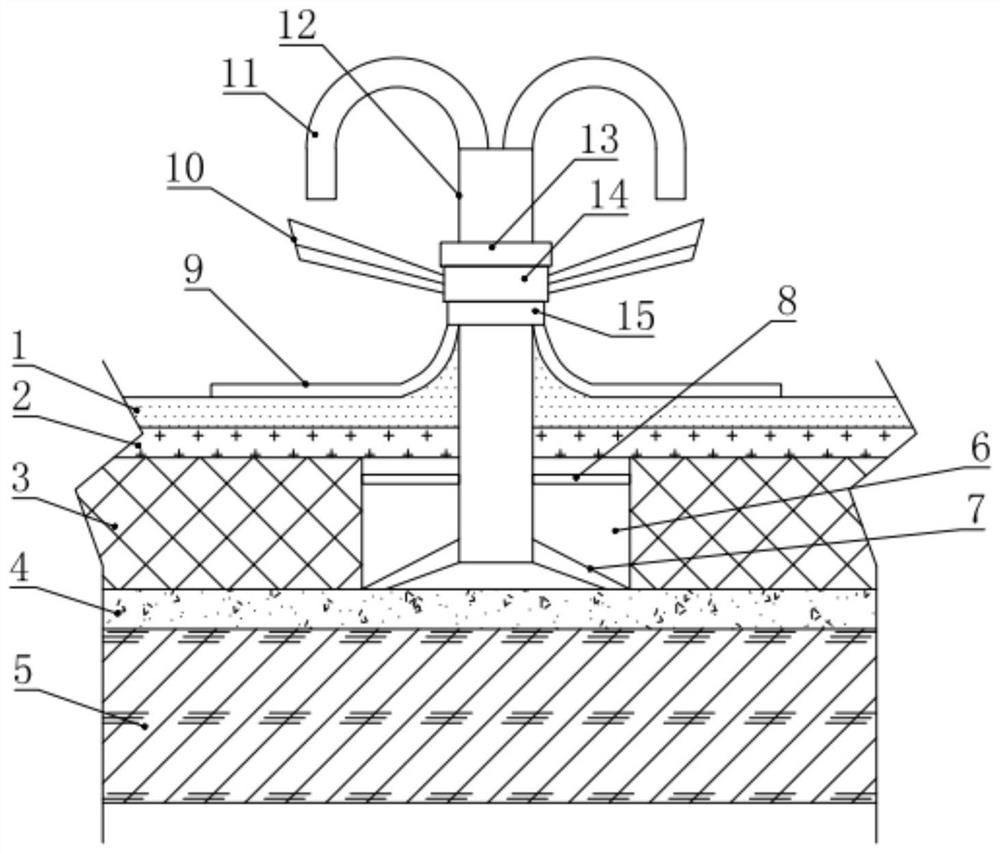

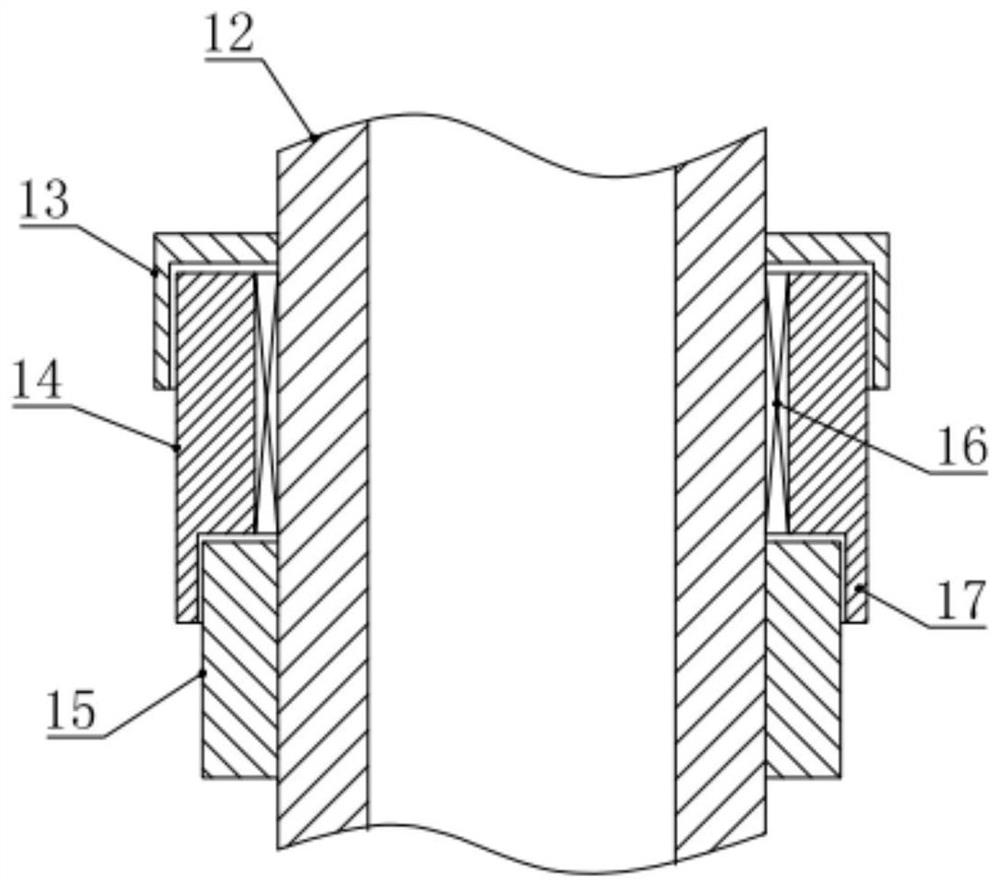

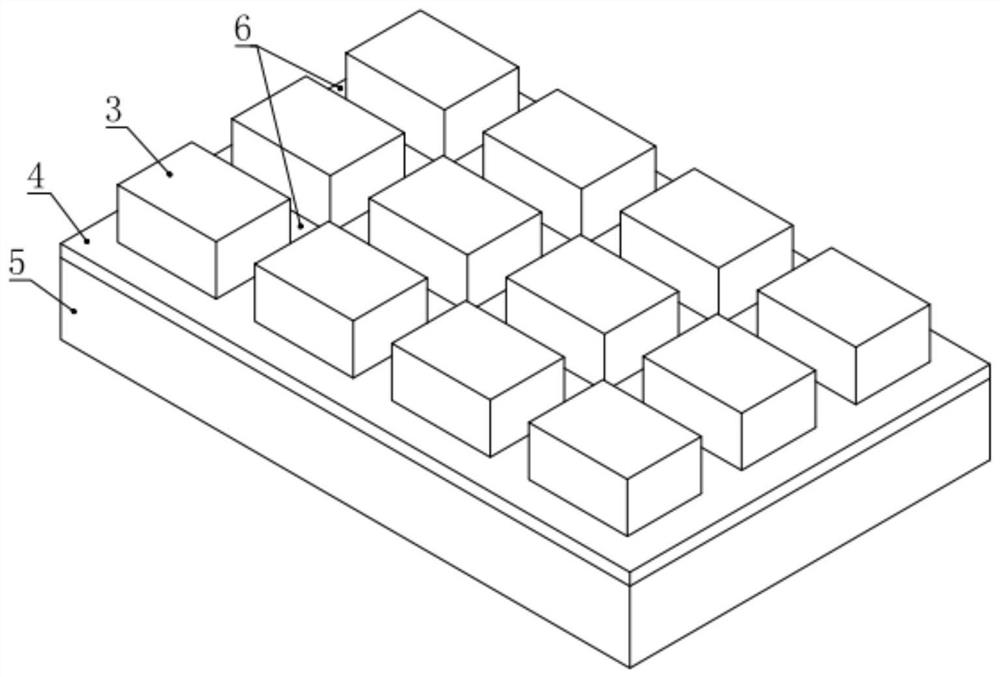

[0020] see figure 1 , 3 And 4, in an embodiment of the present invention, a roof exhaust system includes a roof, and the roof includes a waterproof layer 1, a first leveling layer 2, a thermal insulation layer 3, and a second leveling layer 4 arranged sequentially from outside to inside and the reinforced concrete structure layer 5, the thermal insulation layer 3 is provided with an exhaust channel 6 that runs vertically and horizontally, and the exhaust channel 6 is connected with a plurality of main pipes 12 protruding from the roof. A plurality of exhaust pipes 11 are arranged in the circumferential distribution of one end, and a plurality of oblique supports 7 are arranged in the circumferential distribution of the main pipe 12 close to the insulation layer 3. The main pipe 12 on the outside of the roof is installed with a unidirectional rotation device for exhausting the air. The fan blade 10 from which air is extracted from the inner cavity of the pipe 11 , and an elast...

Embodiment 2

[0024] see Figure 1-5 , the difference between this embodiment and embodiment 1 is:

[0025] In this example, if figure 1 As shown, the main pipe 12 is arranged perpendicular to the roof, and the end of the diagonal support 7 away from the main pipe 12 is fixed against the second leveling layer 4. The distance between the end of the main pipe 12 and the second leveling layer 4 is greater than 1 cm. It has a better supporting effect on the main pipe 12.

[0026] In this example, if figure 1 As shown, the main pipe 12 in the exhaust passage 6 is also circumferentially distributed with a plurality of elastic fixing parts 8 horizontally. The elastic fixing parts 8 are springs, elastic ropes or elastic rods. It is connected and fixed on the thermal insulation layer 3 , and has further elastic support effect on the main pipe 12 through the elastic fixing member 8 .

[0027] In this example, if figure 1 , 4 As shown in and 5, the exhaust pipe 11 is an inverted "U"-shaped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com