Aviation steel cable tension accurate measurement device

A technology of precise measurement and wire rope, applied in the direction of tension measurement, etc., can solve the problem of insufficient accuracy of wire tension measurement, and achieve the effect of reducing measurement workload, high measurement repeatability, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

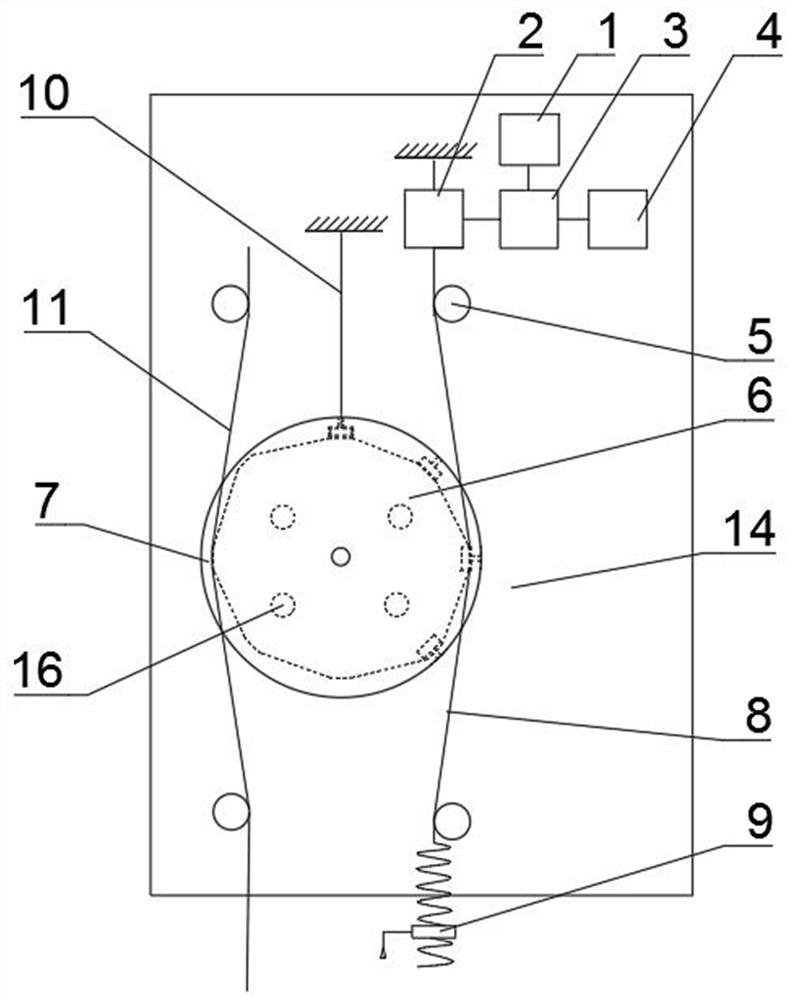

[0059] Such as Figure 1-Figure 4 Shown:

[0060] The present invention provides an accurate measurement device for aviation cable tension, which includes a pulley 5, an upper block 6, a lower block 7, a force-measuring cable 8, a connecting plate 10, a steel cable 11 to be tested and a bottom plate 14, wherein:

[0061] The upper block 6 is installed and fixed above the lower block 7;

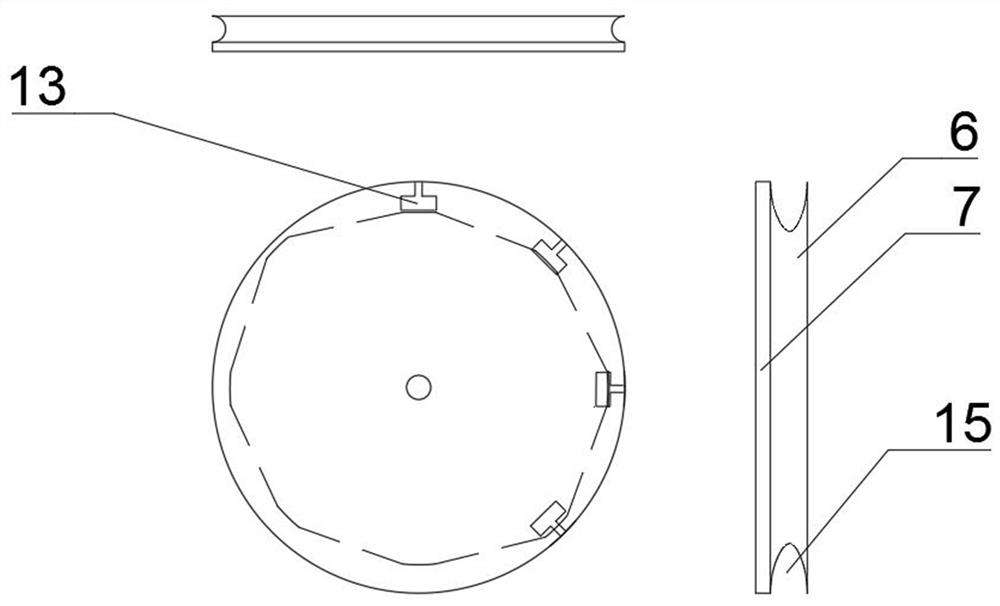

[0062] The upper pad 6 is a circular plate structure, and the side of the pad 6 is provided with a side groove 15;

[0063] The lower pad 7 is a circular plate-shaped structure, and the lower pad 7 is provided with a plurality of T-shaped grooves 13;

[0064] The two centers of the upper pad 6 and the lower pad 7 coincide, and a through hole is provided at the center of the circle;

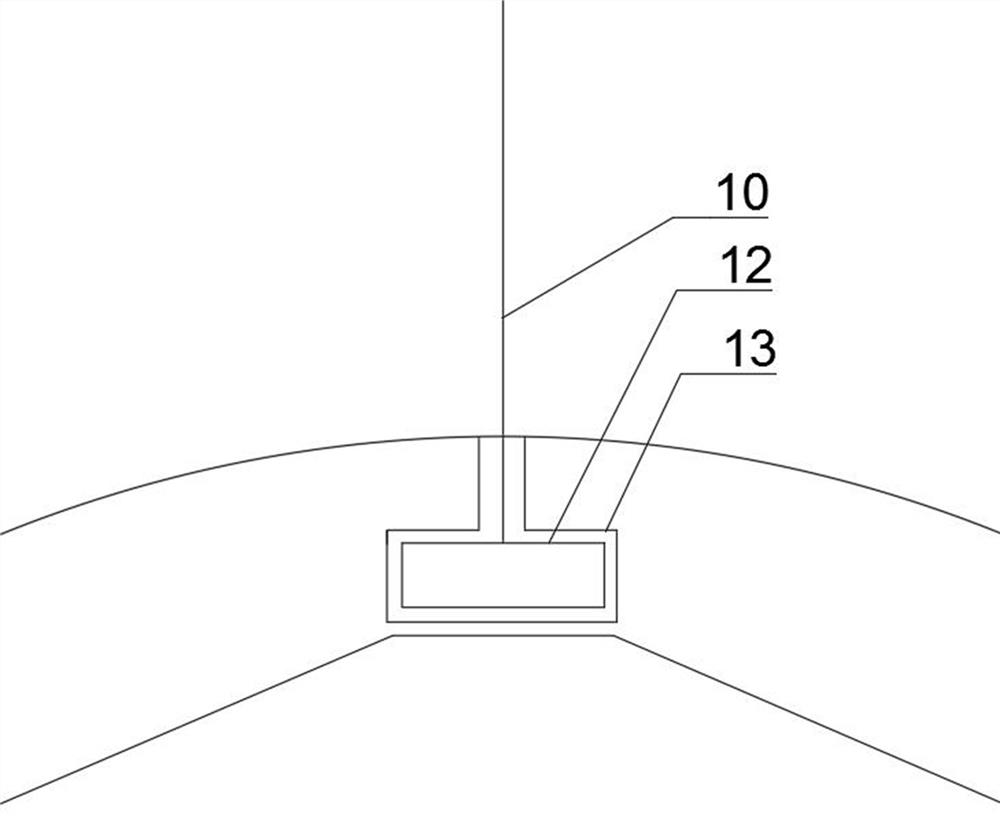

[0065] One end of the connecting plate 10 is fixed on the bottom plate 14, and the other end is provided with a T-shaped piece 12;

[0066] The T-shaped piece 12 is embedded in the T-shaped groove 13 and match...

Embodiment 2

[0086] The present invention provides an accurate measurement device for aviation cable tension, which includes a pulley 5, an upper block 6, a lower block 7, a force-measuring cable 8, a connecting plate 10, a steel cable 11 to be tested and a bottom plate 14, wherein:

[0087] The upper block 6 is installed and fixed above the lower block 7;

[0088] The upper pad 6 is a circular plate-shaped structure, and the side of the pad 6 is provided with a side groove 15, and the depth of the side groove 15 is uneven, and its depth value is about that of the upper pad 6. Symmetrical to the center of the circle;

[0089] The lower pad 7 is a circular plate-shaped structure, and the lower pad 7 is provided with a plurality of T-shaped grooves 13;

[0090] The two centers of the upper pad 6 and the lower pad 7 coincide, and a through hole is provided at the center of the circle;

[0091] One end of the connecting plate 10 is fixed on the bottom plate 14, and the other end is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com