A non-contact stratified flow field measurement method

A measurement method and non-contact technology, applied in fluid velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., can solve the problem that particle image velocity measurement cannot achieve multi-layer flow field measurement, and achieve high measurement efficiency and simple operation. , the result is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

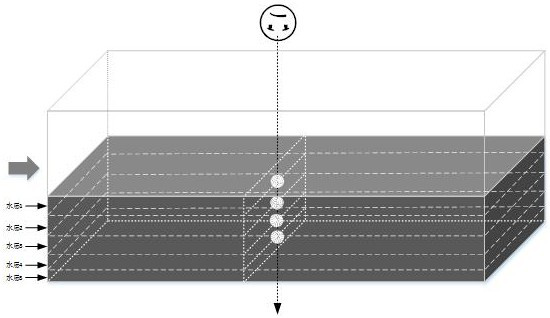

[0032] The invention discloses a method for measuring a non-contact stratified flow field. The method is used for measuring the flow velocity distribution of a water tank along the water depth direction. The method specifically includes the following steps:

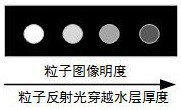

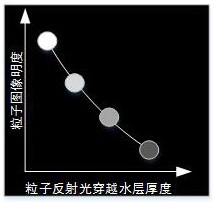

[0033] (1) Set the water flow of the tank as several water layers along the water depth direction, and the contact surface between adjacent water layers is the interface; place the tracer particles one by one on each interface, and fix them on the tank in the vertical and horizontal directions A camera, through which calibration images of tracer particles on various surfaces are taken

[0034] Determine the relationship between particle brightness and position: under the same conditions, the farther the object reflects light from the camera, the lower the brightness in the image; the farther the propagation distance in water, the lower the brightness in the image. According to the positional relationship, the step (1) is ...

Embodiment 2

[0050] Measure the flow velocity distribution in the cross-section direction of the tank (along the shooting direction), and the camera is placed on the side of the tank to shoot. The side wall of the tank near the camera is made of transparent material. In order to enhance the contrast between the particles and the shooting background, the side wall of the tank far away from the camera is made of low-light materials such as dark gray or black.

[0051] Subsequent steps are the same as in Embodiment 1.

Embodiment 3

[0053] To enhance the particle image contrast, the tracer particles are coated with a waterproof fluorescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com