Lawn trimmer for municipal engineering

A lawn trimmer and engineering technology, which is applied in the directions of lawn growth, application, and harvester, can solve the problems that the grass will rise, the lawn consumes a lot of effort, and it is difficult to trim the lawn into a uniform length. The effect of reducing labor burden and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

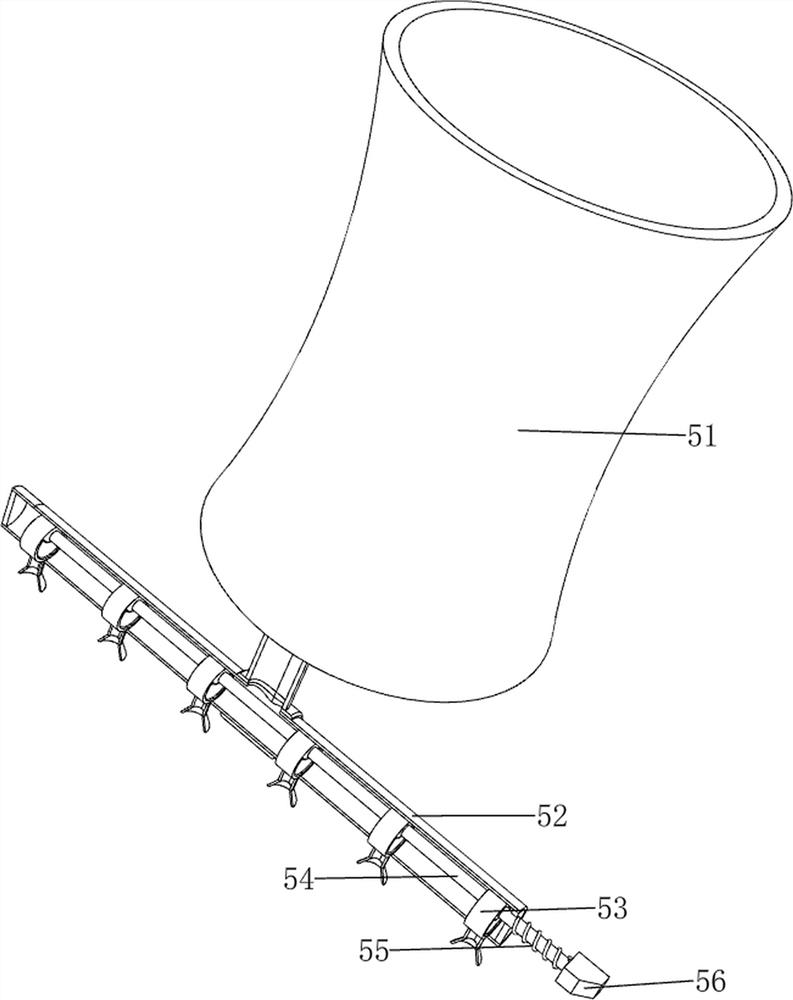

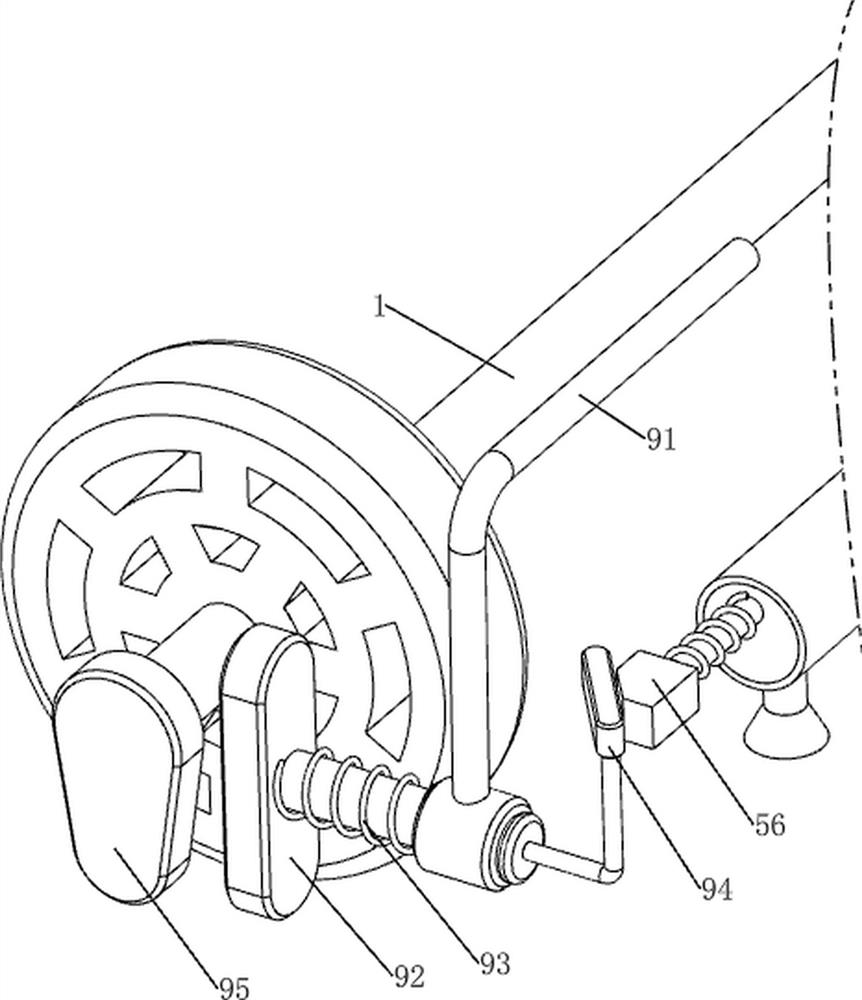

[0027] A lawn trimmer for municipal engineering, such as figure 1 As shown, it includes a first axle 1, a second axle 2, a vehicle frame 3, a cutter head 301, a first slide rail 302, a first slide bar 303, a first spring 304, a first fixed sleeve 305, and a mowing mechanism 4 And sprinkler mechanism 5, vehicle frame 3 rear sides left and right sides are all rotatable to be provided with the first axle 1, vehicle frame 3 front sides are all rotatable to be provided with the second axle 2, the first axle 1 and the second axle 2 All are in contact with the ground, and the left and right sides of the front side of the vehicle frame 3 are symmetrically welded with first slide rails 302, and the first slide bars 303 are slidingly arranged in the two first slide rails 302, and the first slide bars 303 are arranged inside the two first slide bars 303. A first fixed sleeve 305 is connected between the ends, and a cutter head 301 is rotatably arranged in the first fixed sleeve 305, and ...

Embodiment 2

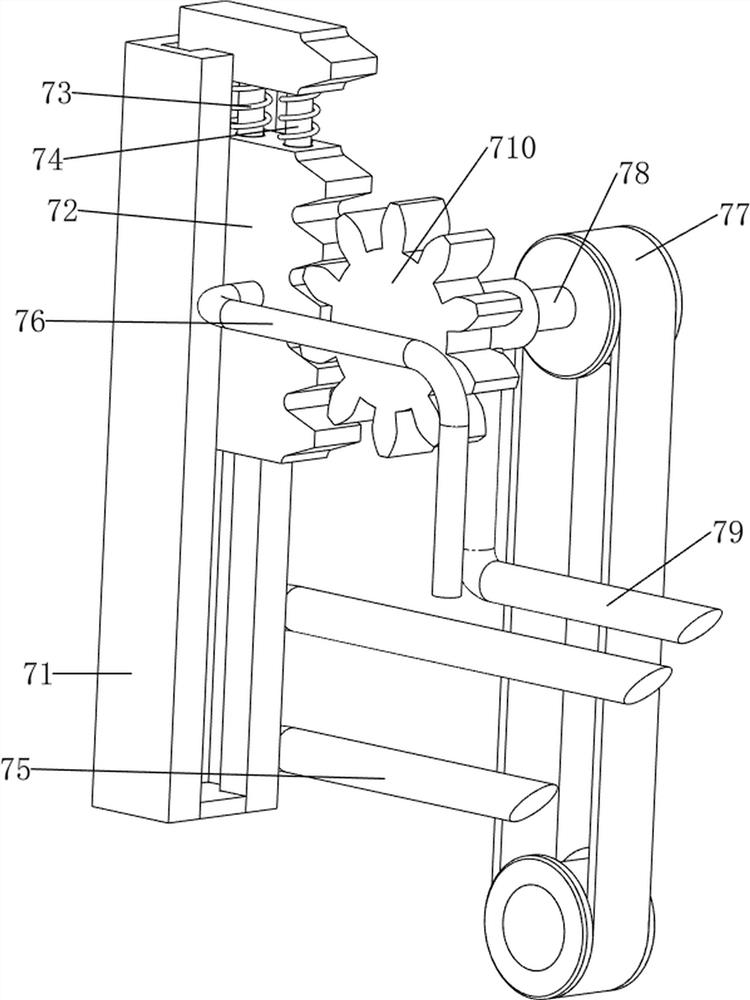

[0030] In a preferred embodiment of the present invention, as Figure 2-7As shown, the mowing mechanism 4 includes a first fixed mount 41, a protective cover 42, a second fixed mount 43 and a motor 44, and the left and right sides of the front side of the vehicle frame 3 are symmetrically welded with the first fixed mount 41. A protective cover 42 is connected between the inner sides of the frames 41, the cutter head 301 is located in the protective cover 42, the tops of the two first slide bars 303 are fixedly connected with the second fixed frame 43, and the tops of the two second fixed frames 43 are connected with a Motor 44, the output shaft of motor 44 is connected with cutter head 301 top.

[0031] When the vehicle frame 3 was positioned above the lawn, the worker could rotate the motor 44, the rotation of the output shaft of the motor 44 would cause the cutter head 301 to rotate in the first fixed sleeve 305, and the protective cover 42 and the first fixed mount 41 coul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com