Universal torque sleeve

A sleeve and universal technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of eccentric vibration, steel needle deformation and damage, low construction efficiency, etc., and achieve the effect of avoiding vibration, not easy to deform, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

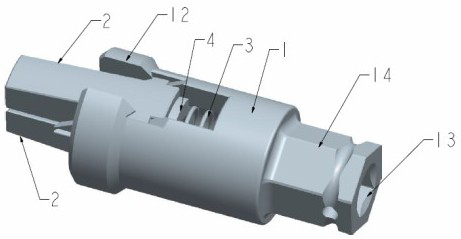

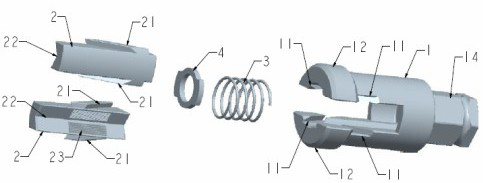

[0023] Example 1, such as figure 1 and figure 2 The shown universal torque sleeve of the present invention includes: a sleeve 1, a clamp block 2 and a spring 3, the end of the sleeve 1 has a notch, and the side wall of the notch has a sleeve inclined chute 11; the clamp block There is a clamp block inclined chute 21 on the 2, and the clamp block 2 and the sleeve 1 are connected through the sleeve inclined chute 11 and the clamp block inclined chute 21, and the clamp block 2 can slide obliquely in the notch; One end of the spring 3 tightens the bottom of the sleeve 1, and the other end tightens the tail of the clamp block 2; when the clamp block 2 is pushed against the nut, it can automatically open and automatically clamp the nut; the universal torque sleeve can be used for various specifications of nuts or special-shaped Continuous tightening of parts does not require frequent replacement of the sleeve head; when the torque reaches the design value, the clamp block 2 can be...

Embodiment 2

[0024] Example 2, such as figure 1 and figure 2 The torque adjustment principle of the universal torque sleeve of the present invention has three forces in the direction parallel to the axis of the inclined chute 11 of the sleeve. 1. Spring 3 pairs clamp block 2 in the parallel direction of the sleeve inclined chute 11 axis parallel component force of spring 3, the friction force between clamp block 2 and sleeve 1; the parallel component force of nut is greater than the parallel component force and friction of spring 3 When the force is summed, the clamping block 2 slides along the oblique slide groove 11 of the sleeve, the clamping block 2 opens, the fastening is completed, and the fastening torque reaches the design value.

[0025] When the clamp block 2 turns the nut, the nut produces a tangential reaction force on the clamp block 2 in the tangential direction of the rotation circle, and the nut produces an opening reaction force on the clamp block 2 in the radial directi...

Embodiment 3

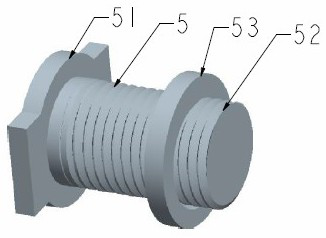

[0026] Example 3, such as figure 1 , figure 2 and image 3 As shown in the torque adjustment method of the universal torque sleeve of the present invention, the elastic force is changed by changing the length of the spring 3, and then the torque is adjusted; the length of the spring 3 is adjusted by increasing the gasket 4 or increasing the length adjustment mechanism 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com