Reflective material mold with flat-topped microprism arrays and preparation method thereof

A technology of reflective materials and micro-prisms, applied in optics, optical components, household appliances, etc., can solve the problems of cumbersome preparation process, achieve easy separation of film molds, solve the effect of sharp drop in retroreflection coefficient, and reduce wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the specification and specific implementation manners.

[0043] A method for preparing a flat-top positive-angle microprism reflective material mold, comprising the steps of:

[0044] Step (1): Calculate the planing distance, first design the flat-top micro-prism unit, and then calculate the data of the flat-top micro-prism unit based on the pointed-top micro-prism unit, as follows

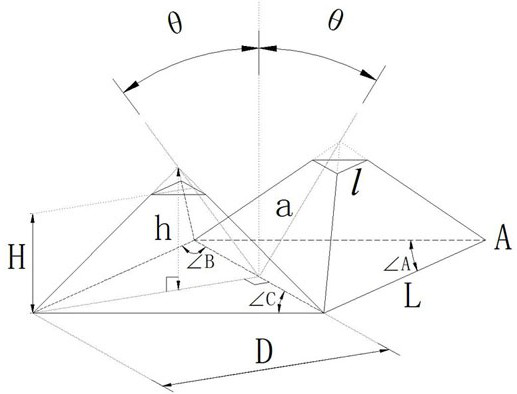

[0045] Please refer to figure 1 , the included angles of the triangles at the bottom of the right-angled pyramid are designed to be 60°, that is, ∠A=∠B=∠C=60°, the triangle at the bottom of the right-angled pyramid is an equilateral triangle, whose side length is L, and its height is D; The triangle on the side of the pyramid is an isosceles right triangle, and its edge length is L·sin45°; the height of the pointed pyramid is h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com