Preparation method of acetic acid

A technology of acetic acid and acetaldehyde, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of loss of activity and short service life, so as to improve the efficiency, prolong the service life and improve the catalytic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

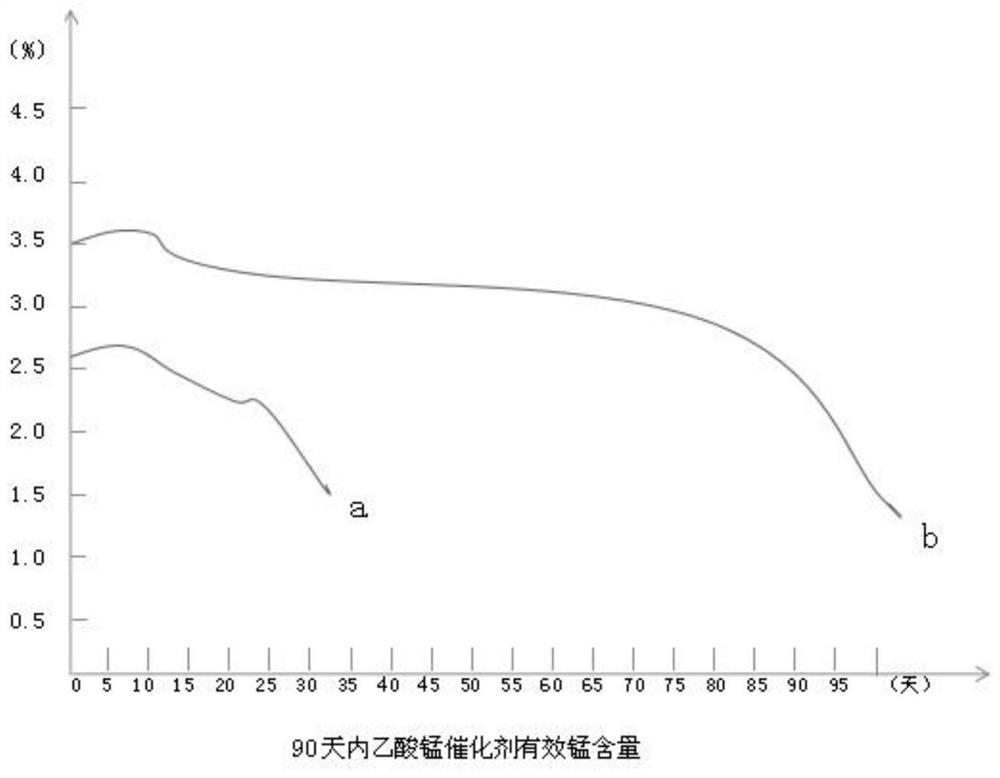

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of acetic acid, comprises the following steps:

[0025] Manganese acetate is mixed with demineralized water to obtain manganese acetate solution;

[0026] Preheating acetic acid to obtain preheating acetic acid;

[0027] The preheated acetic acid and manganese acetate solution are mixed and then heated to obtain a manganese circulating fluid;

[0028] The manganese circulating fluid is mixed with acetaldehyde to carry out oxidation reaction to obtain acetic acid.

[0029] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in this field.

[0030] The invention mixes manganese acetate and demineralized water to obtain manganese acetate solution.

[0031] In the present invention, the pH value of the demineralized water is preferably >7, the total hardness is preferably ≤0.03, and the suspended matter is preferably ≤5mg / L.

[0032] In the present invent...

Embodiment 1

[0052] 1. Prepare the project

[0053] 1.1 Prepare 7 bags of manganese acetate (25kg / bag);

[0054] 1.2 50Kg demineralized water, demineralized water needs to be tested, standard: pH value > 7, total hardness ≤ 0.03, suspended solids ≤ 5mg / L;

[0055] 1.3 One electronic scale, two stainless steel barrels, two stirrers, thermometer (range ≥ 120 ℃), gloves and gas mask labor protection supplies.

[0056] 2. Preparation process

[0057]2.1 Check whether the pipes connected to the manganese preparation kettle are well connected and whether the valves are in normal condition.

[0058] 2.2 Add a small amount of finished acetic acid (50kg / time) to the manganese preparation kettle from the metering tank, and wash it twice until the blowdown liquid is clean, transparent and colorless.

[0059] 2.3 Add the finished acetic acid to the manganese preparation kettle until the liquid level reaches 90cm (corresponding to the liquid level of the finished product metering tank 15cm, 900kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com