Polyborate binder as well as preparation method and application thereof

A technology of polyborate and binder, which is applied in the direction of structural parts, active material electrodes, electrical components, etc., can solve the problems of low bonding strength, poor conductivity and high preparation cost of binders, and achieve strong bonding Intensity, the effect of great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

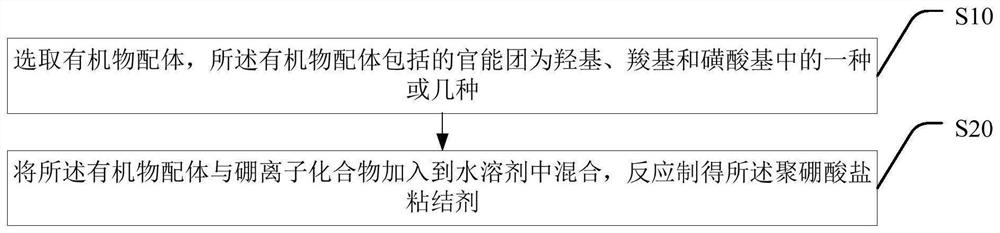

Method used

Image

Examples

Embodiment 1

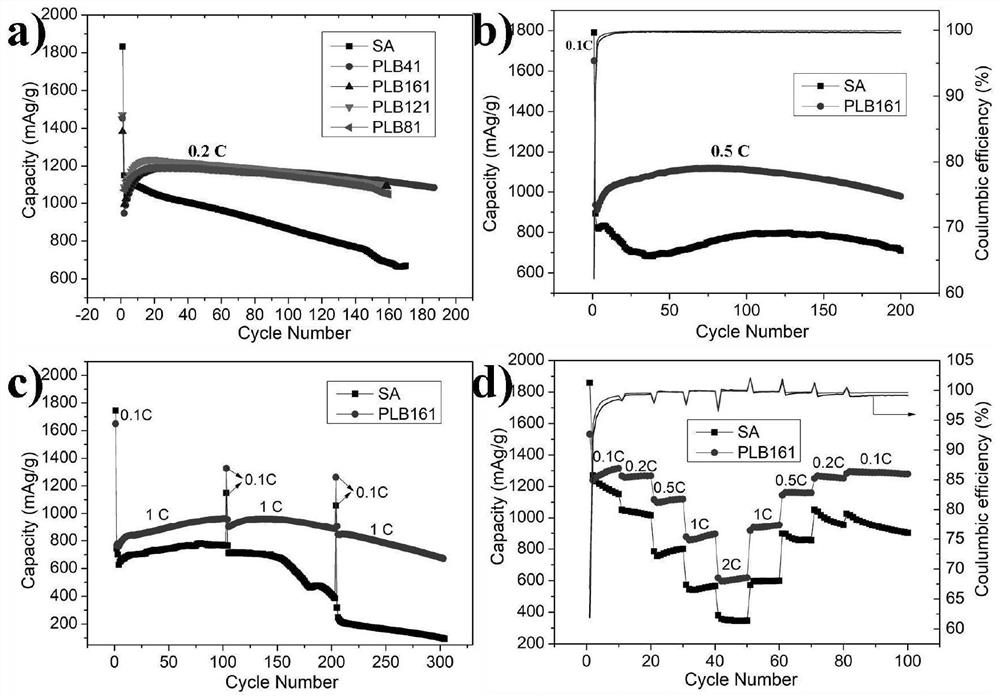

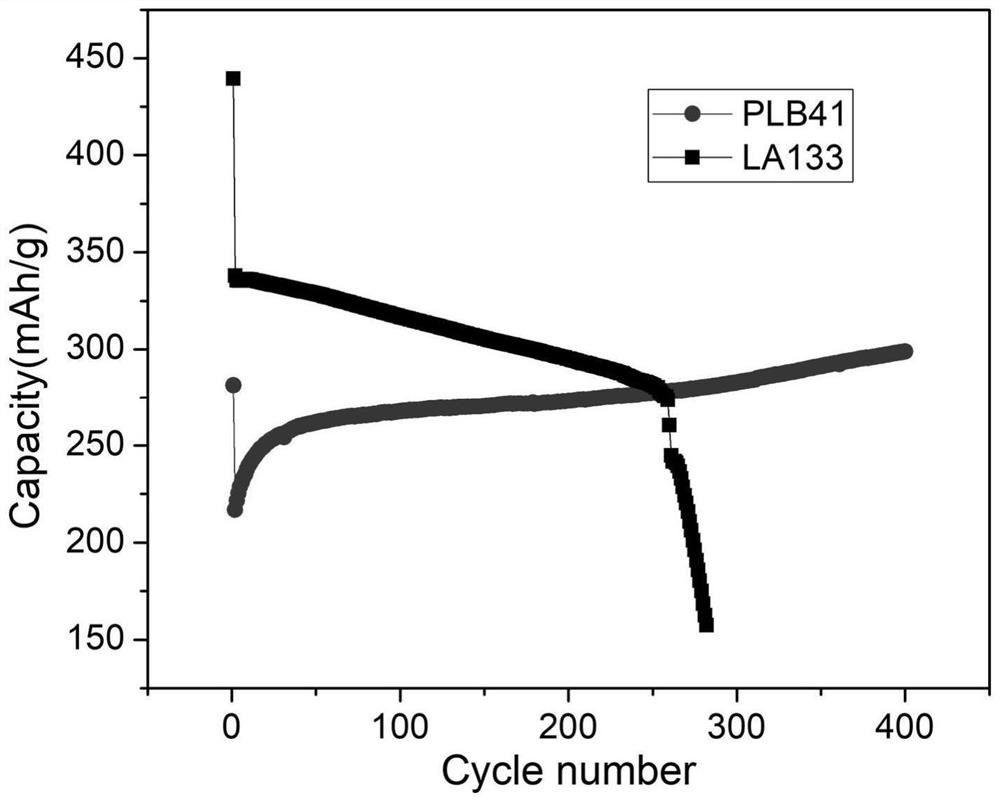

[0035] 1. Synthesis of polyborate binder: Add 22.70 grams of cyclodextrin and 4.228 grams of lithium tetraborate to 200 grams of water, stir and react at room temperature for 6 hours to obtain a colorless solution, which is diluted to a solid content of 2%. The solution.

[0036] 2. Battery production: Weigh 0.225 g of carbon-coated SiO negative electrode material, add 0.045 g of Ketjen black conductive agent, mix evenly in an agate mortar, add 1.50 g of the above-mentioned polyborate binder solution, and grind it into a uniform The slurry is scraped onto the copper foil, dried at 80 degrees, punched into a pole piece with a diameter of 12mm, dried overnight at 70 degrees under vacuum, and then assembled into a button battery in a glove box, wherein the negative electrode is a metal lithium sheet, and the electrolyte is 1mol / L LiPF6 solution (the solvent is ethylene carbonate and diethyl carbonate with a volume ratio of 1:1, and 2% vinylene carbonate is added as a film-forming...

Embodiment 2

[0039] 1. Synthesis of binder: add 15.00 g of tartaric acid and 0.4975 g of metaboric acid in 200 g of water, stir and react at room temperature for 6 hours to obtain a colorless solution, which is diluted to a solution with a solid content of 2%.

[0040]2. Battery production: Weigh 0.225 g of carbon-coated SiO negative electrode material, add 0.045 g of Ketjen black conductive agent, mix evenly in an agate mortar, add 1.50 g of the above binder solution, grind into a uniform slurry, scrape Coated on copper foil, dried at 80 degrees, punched into a pole piece with a diameter of 12mm, dried overnight at 70 degrees in vacuum, assembled into a button battery in a glove box, in which the negative electrode is a lithium metal sheet, and the electrolyte is 1mol / L LiPF6 solution (the solvent is ethylene carbonate and diethyl carbonate with a volume ratio of 1:1, and 2% vinylene carbonate is added as a film-forming agent), and the diaphragm is cellgard2500.

[0041] 3. Performance te...

Embodiment 3

[0043] 1. Synthesis of binder: 18.20 grams of sorbitol and 0.8456 grams of lithium tetraborate were added to 200 grams of water, stirred and reacted at room temperature for 6 hours to obtain a colorless solution, which was diluted to a solution with a solid content of 2%.

[0044] 2. Battery production: Weigh 0.225 g of carbon-coated SiO negative electrode material, add 0.045 g of Ketjen black conductive agent, mix evenly in an agate mortar, add 1.50 g of the above binder solution, grind into a uniform slurry, scrape Coated on copper foil, dried at 80 degrees, punched into a pole piece with a diameter of 12mm, dried overnight at 70 degrees in vacuum, assembled into a button battery in a glove box, in which the negative electrode is a lithium metal sheet, and the electrolyte is 1mol / L LiPF6 solution (the solvent is ethylene carbonate and diethyl carbonate with a volume ratio of 1:1, and 2% vinylene carbonate is added as a film-forming agent), and the diaphragm is cellgard2500. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap