Prefabricated pier column reinforced roadway support method

A technology for roadway support and prefabricated piers, which is used in pillars/supports, earthwork drilling, mining equipment, etc., can solve the problems of high construction cost, many procedures, and long concrete hardening period, and achieves reduced equipment investment, simple process, Good top effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The fully mechanized mining face is inclined to the goblin, the height of the roadway is 2.0m, and the width is 5.4m. 3m.

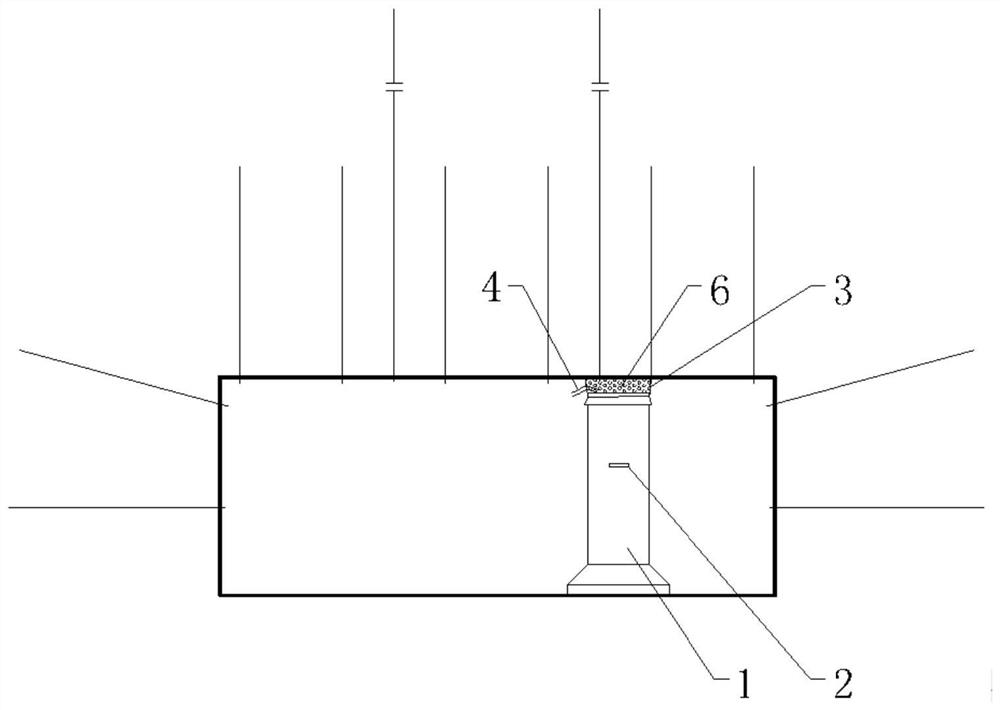

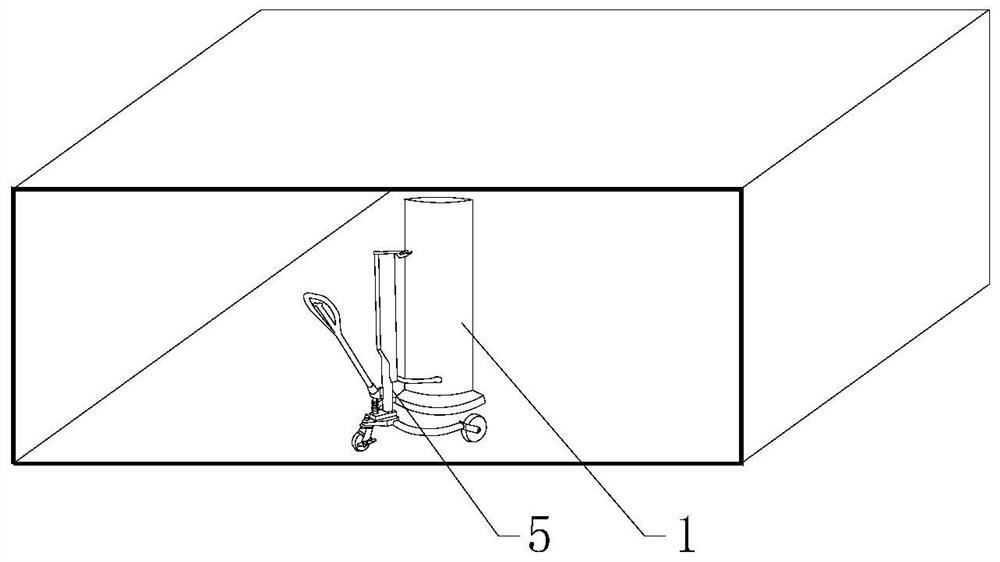

[0053] according to figure 1 , figure 2 and image 3 Shown, the prefabricated pier column provided by the present invention strengthens roadway support method as follows:

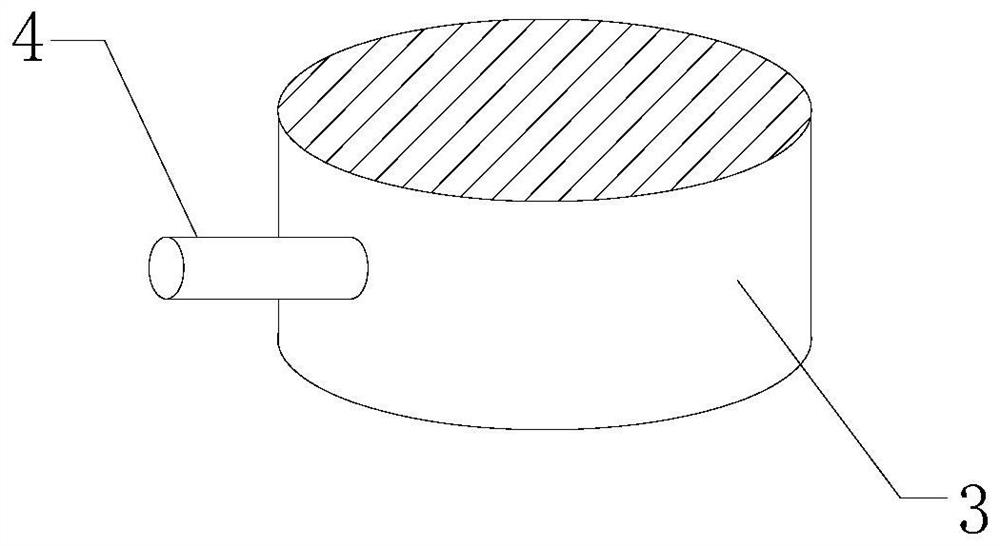

[0054]Step 1, prefabricated reinforced concrete on the ground to form prefabricated pier column 1 and top pocket 3, pier column label C30, diameter 0.6m, pier body pre-embedded lifting ring 2, prefabricated pier column 1 height 1.85m, bottom diameter 1m, top connection The bag 3 is a cylindrical structure, one end is closed, the other end is open, the side is provided with a grouting port 4, the diameter of the top bag is 0.7m, and the height is 0.6m;

[0055] Step 2, using a trackless rubber-tyred vehicle to transport the prefabricated pier column 1 from the ground to the underground, and the transport destination is the trough near the gob in the fully mechanized mining f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap