Pseudo-color display method for high-gray-scale weld seam negative film image

A display method and high gray-scale technology, applied in the field of image processing, can solve problems such as loss of details, difficulty in obtaining required information for human eyes, etc., and achieve the effect of a simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments. These examples are for illustrating the present invention and do not limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the specific experimental environment, and the unspecified implementation conditions are usually the conditions in routine experiments.

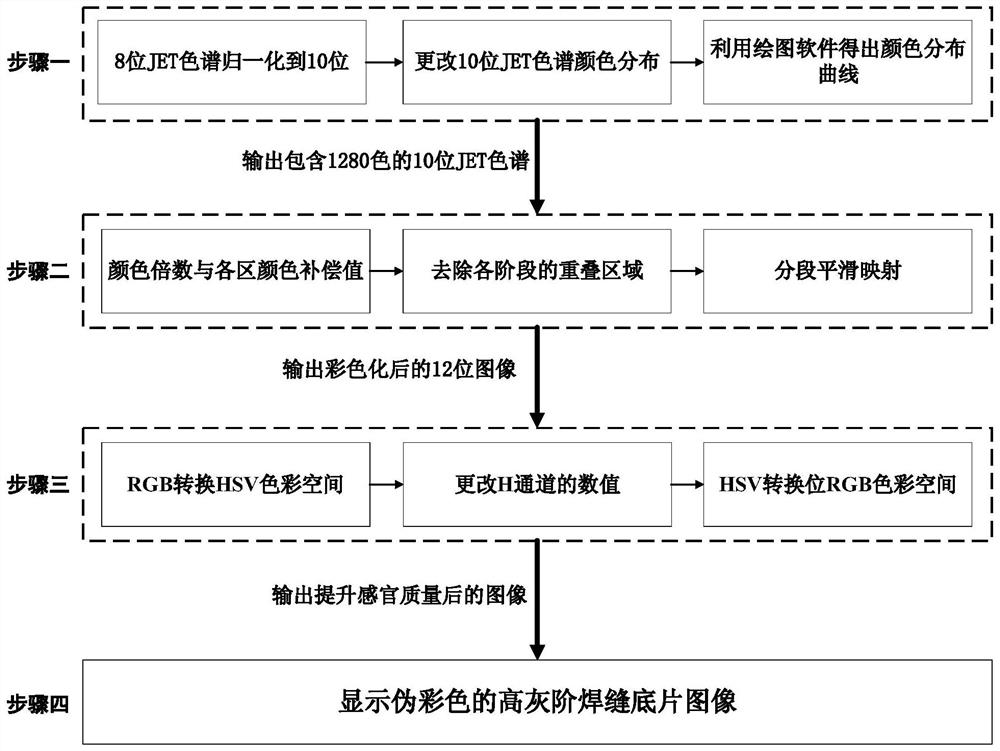

[0028] refer to figure 1 , the method of the present invention comprises the following steps: first normalize to JET chromatogram of 10 bit depths, the order of color arrangement is changed, utilize professional drawing software to obtain color distribution law; As the reference value, perform mathematical operations with the number of different shades of colors contained in the 12-bit high grayscale image to obtain the color multiplier relationship and color compensation value, and make changes based on the 10-bit deep JET spectrum color dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com