Driving device provided with piezoelectric element deterioration detection circuit and deterioration detection method

A piezoelectric element and driving device technology, which can be applied to piezoelectric or electrostrictive device parts, piezoelectric effect/electrostrictive or magnetostrictive motors, and electrical components, etc., can solve the problem of cost increase, Complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The experimental results are shown below, showing the effectiveness of the present invention.

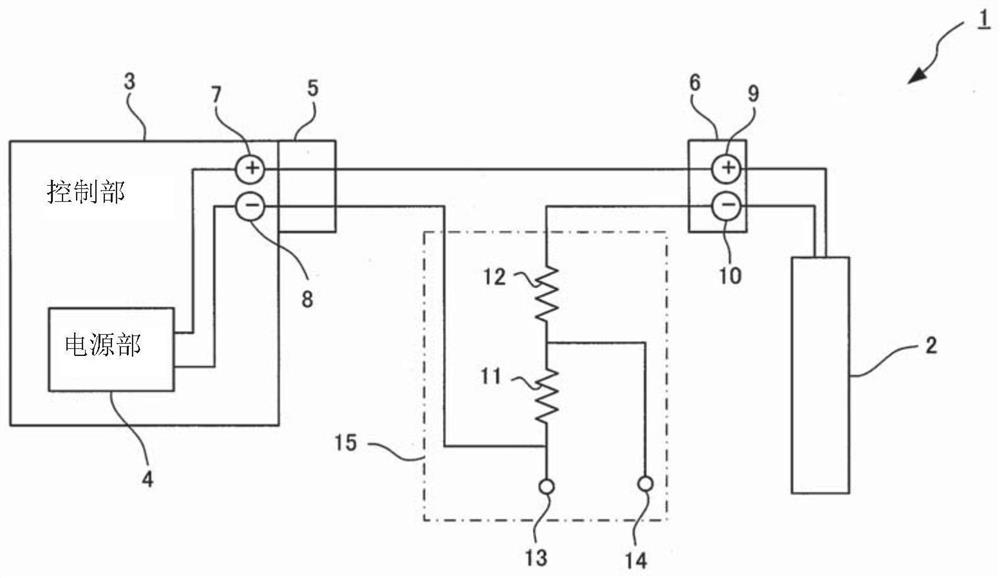

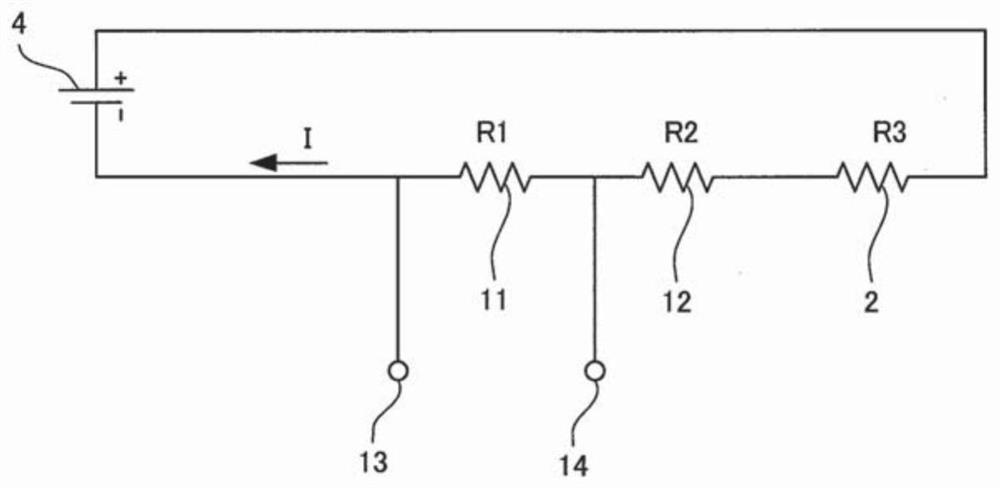

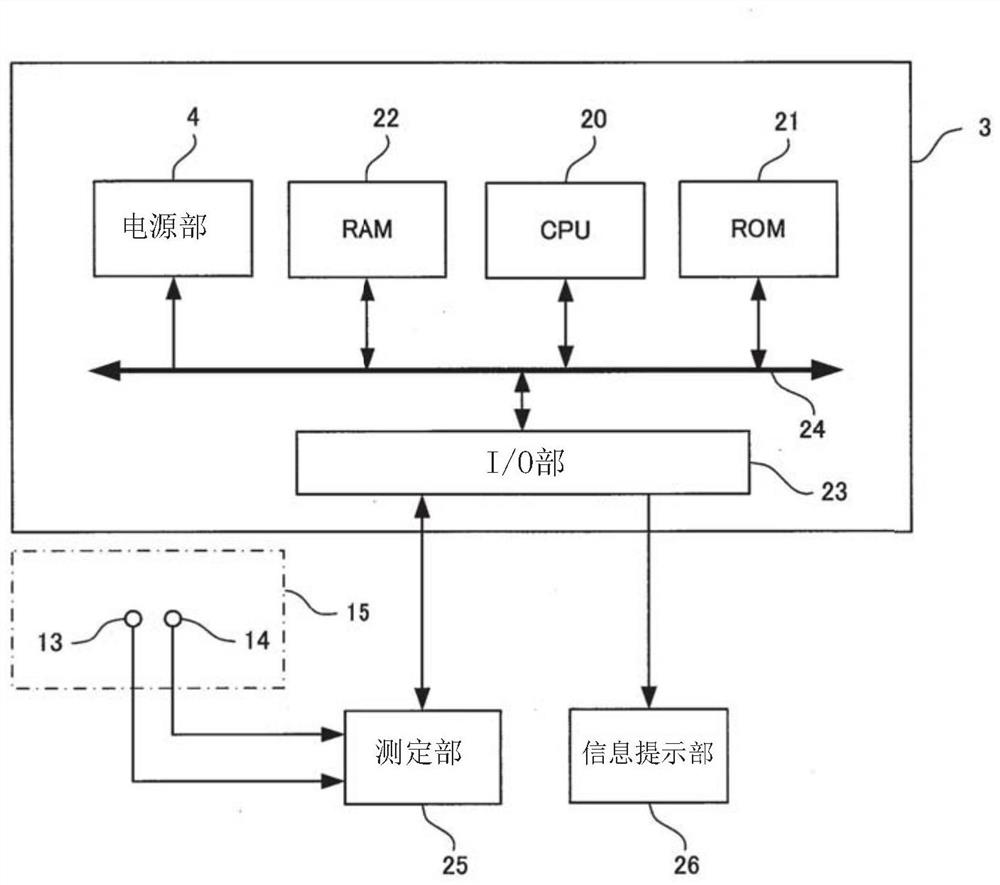

[0106] exist figure 1 In the pressure-type flow control device having the structure shown, the voltage across the first resistor 11 (the voltage between the first terminal 13 and the second terminal 14 ) is measured while a DC voltage of 140 V is supplied to the piezoelectric element 2 . , to calculate its average value. The resistance values of the first resistor 11 and the second resistor 12 are respectively set to 10 kΩ and 39 kΩ. For voltage measurement, a tester (Digital Multimeter 289, manufactured by Fluke Corporation) and a data recorder (Mobile recorder MV200, manufactured by Yokogawa Electric Corporation) were used.

[0107] In each of the three pressure-type flow control devices (ID1 to ID3) of the same type of piezoelectric element used, after opening and closing the control valve 3 million times, use the above two types of measuring devices to measure Measu...

Embodiment 2

[0112] For pressure type flow control devices using different types of piezoelectric elements, in the same manner as in Example 1, the voltage across the first resistor 11 was measured, and the resistance value of the piezoelectric element used in each pressure type flow control device was calculated. . The result is as Figure 7 shown.

[0113] Figure 7 Changes in resistance values calculated from measured values related to the respective piezoelectric elements are schematically shown. exist Figure 7 In , the vertical axis represents the resistance value (calculated value) of the piezoelectric element, and the horizontal axis represents the driving time of the control valve. As the driving time increases, the number of times the control valve is opened and closed (the number of voltage applications to the piezoelectric element) also increases. The solid line is the measurement result of the control valve provided with the moisture adsorbent, and the dotted line is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com