Novel multicolor bottle cap production line

A production line and bottle cap technology, applied in processing and manufacturing, conveyor objects, transportation and packaging, etc., can solve the problems of high energy consumption, low production efficiency, and inability to change multi-color content, etc., to achieve accurate printing position and good printing effect Beautiful appearance and low energy consumption of the whole line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

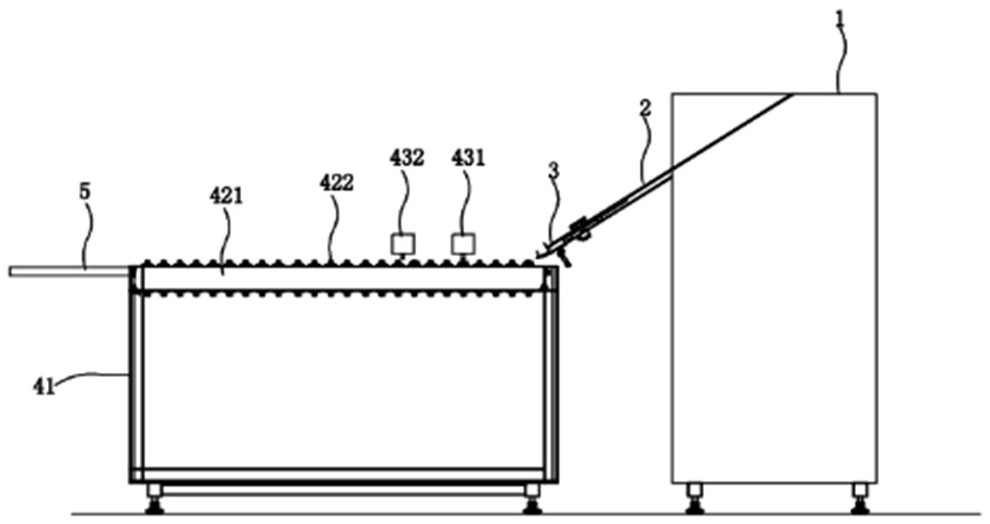

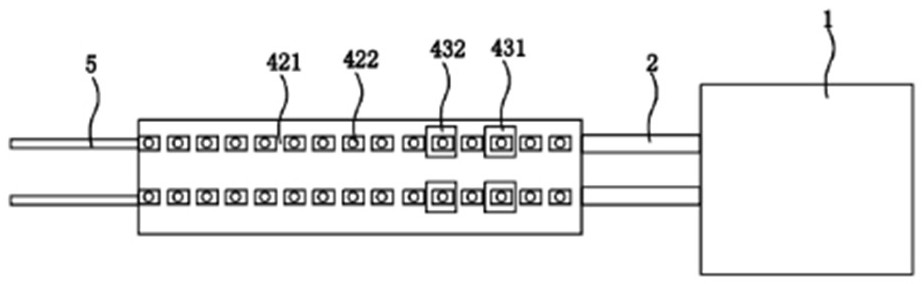

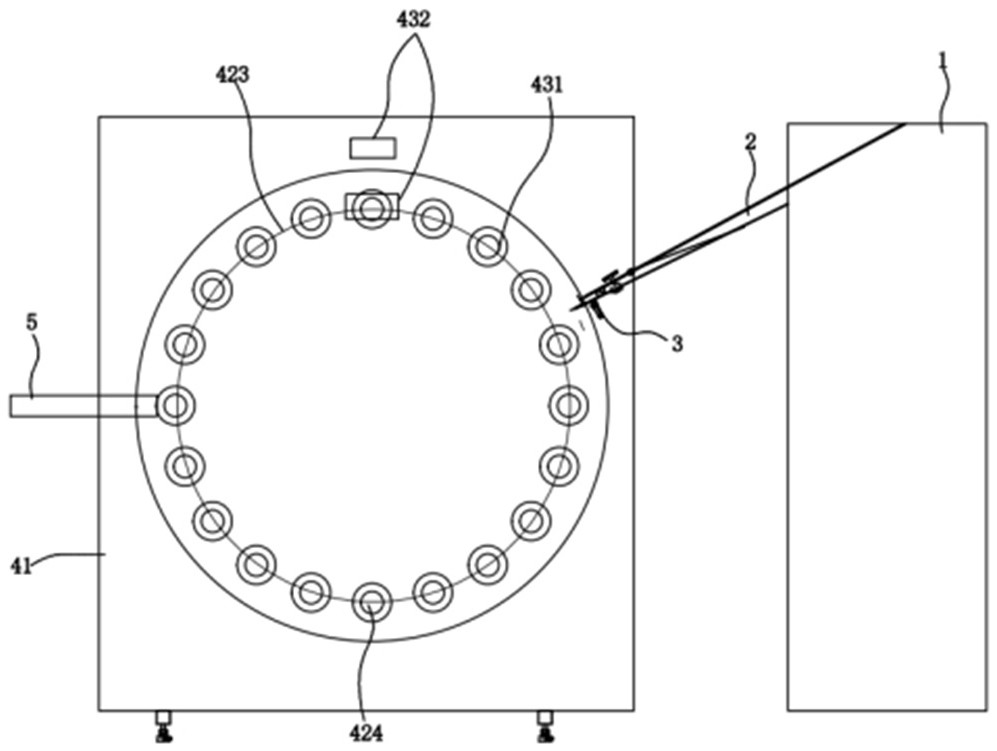

[0034] First, combine the Figure 1~5 Describe the new multi-color bottle cap production line according to the embodiment of the present invention, which is used for the production and manufacture of multi-color bottle caps, and its application scenarios are very wide.

[0035] Such as Figure 1~5 As shown, the new multi-color bottle cap production line of the embodiment of the present invention has a cap alignment device 1 , a feeding track 2 , a cap hanging mechanism 3 , a processing module and a discharging track 5 .

[0036] Specifically, as Figure 1~5 As shown, in this embodiment, the cover body alignment equipment 1 includes a storage feeder and a cover sorting machine, and the cover sorting machine can be used (disc cover sorting machine, waterfall cover sorting machine, vibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com