Extraction method for improving content of cannabidiol in China-hemp essential oil

A technology of cannabidiol and extraction method, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problem of low CBD content of hemp essential oil, reduce the loss of active components of essential oil, facilitate long-term storage, and facilitate release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

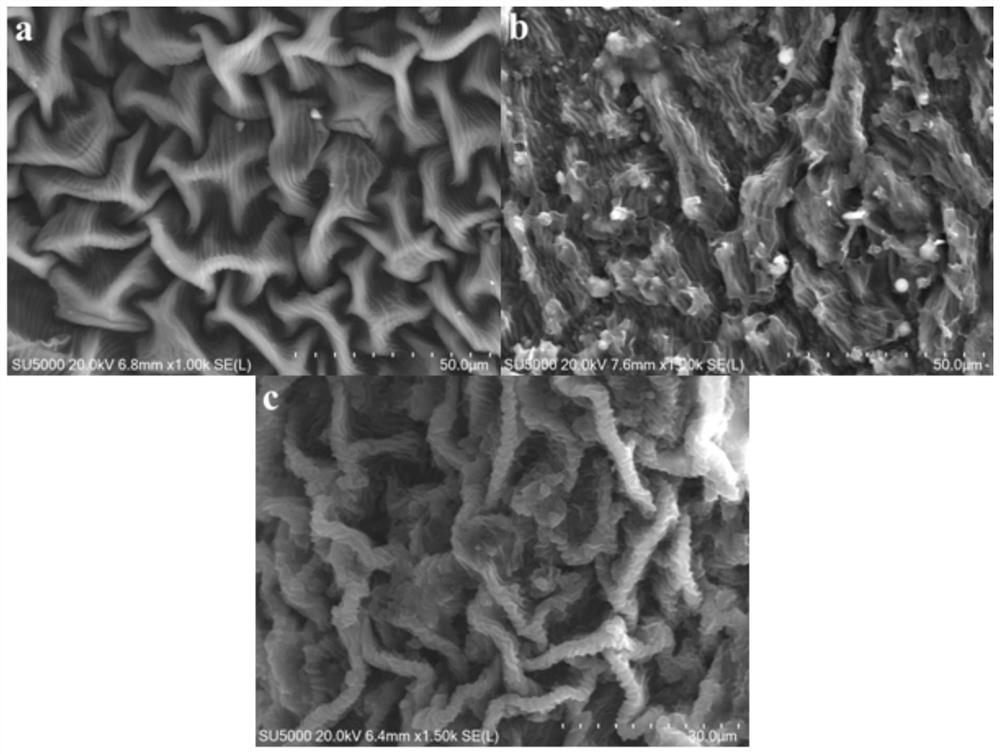

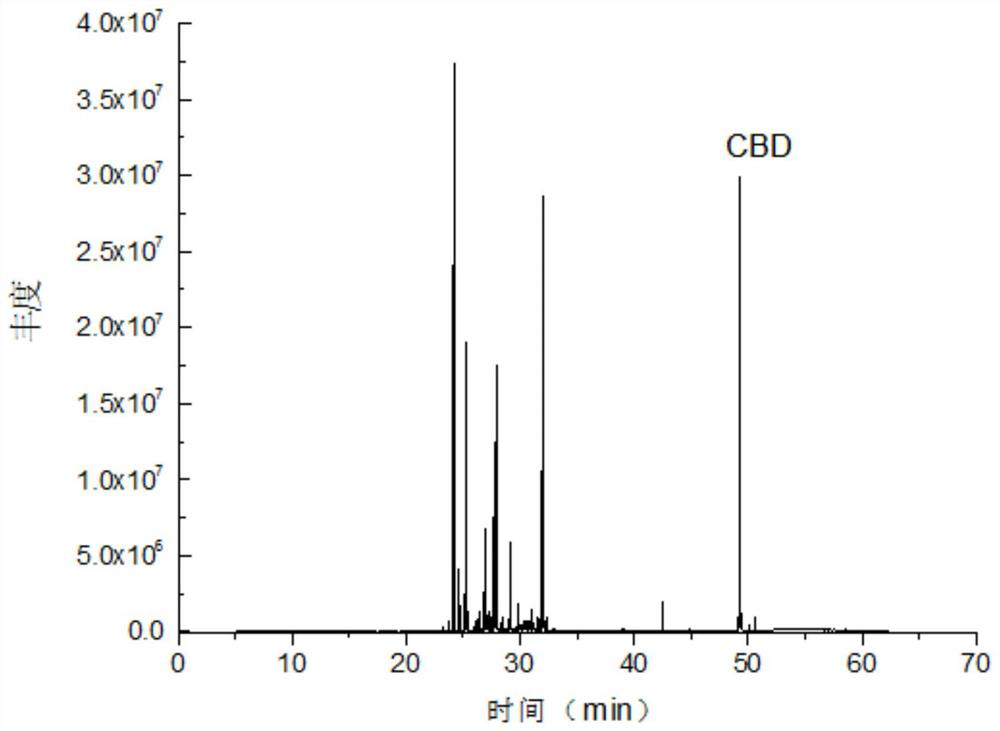

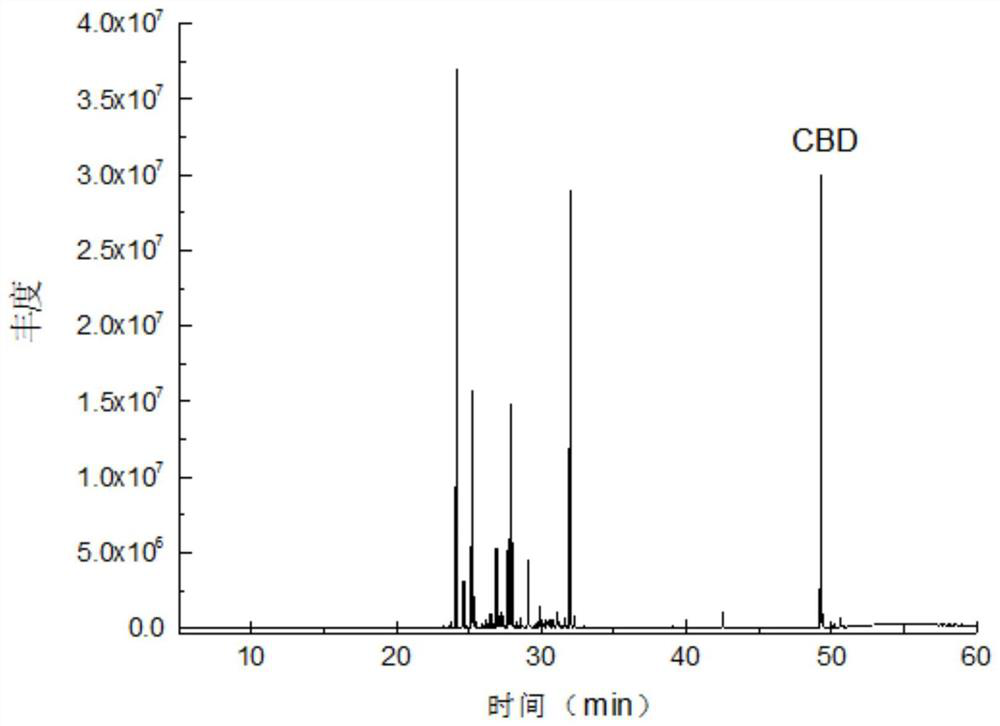

Image

Examples

specific Embodiment approach 1

[0041] Specific embodiment one: present embodiment a kind of extraction method that improves the content of cannabidiol in hemp essential oil, it is to carry out according to the following steps:

[0042] 1. Pretreatment:

[0043] Collect fresh hemp flowers and leaves as raw materials, put the raw materials in the freezer, freeze for 0 days to 60 days, take them out after freezing and let them stand naturally to warm up to room temperature, and then place them at a temperature of 120 ° C to 160 ° C to keep warm 0min to 8min, and finally let it stand naturally to room temperature to obtain the pretreated raw material;

[0044] Second, broken:

[0045] 1. Mix the pretreated raw material with distilled water and place it in a cooking machine; the mass ratio of the pretreated raw material to distilled water is 1:(1~5);

[0046] ②. Under the condition that the power of the cooking machine is 1000 watts to 1500 watts and the speed is 15000 rpm to 40000 rpm, stir and crush for 2 mi...

specific Embodiment approach 2

[0061] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the surfactant described in step three is one or more of anionic surfactants, cationic surfactants and nonionic surfactants mixture. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0062] Specific embodiment three: this embodiment is different from one of specific embodiment one or two: the surfactant described in step 3 is sodium lauryl sulfate, polyoxyethylene sorbitan monostearate and A mixture of lauroyl sarcosine, or a mixture of sodium lauryl sulfate, sodium dodecylbenzenesulfonate and polyoxyethylene sorbitan monostearate. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com