Deep foundation pit bottom plate concrete pouring system with multiple supporting beams and construction method thereof

A deep foundation pit and multi-support technology, applied in infrastructure engineering, construction, etc., can solve the problems of poor pouring quality, unfavorable traffic, and low pouring efficiency, so as to save later maintenance costs and reduce the possibility of cracks and water leakage , to overcome the adverse effects of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

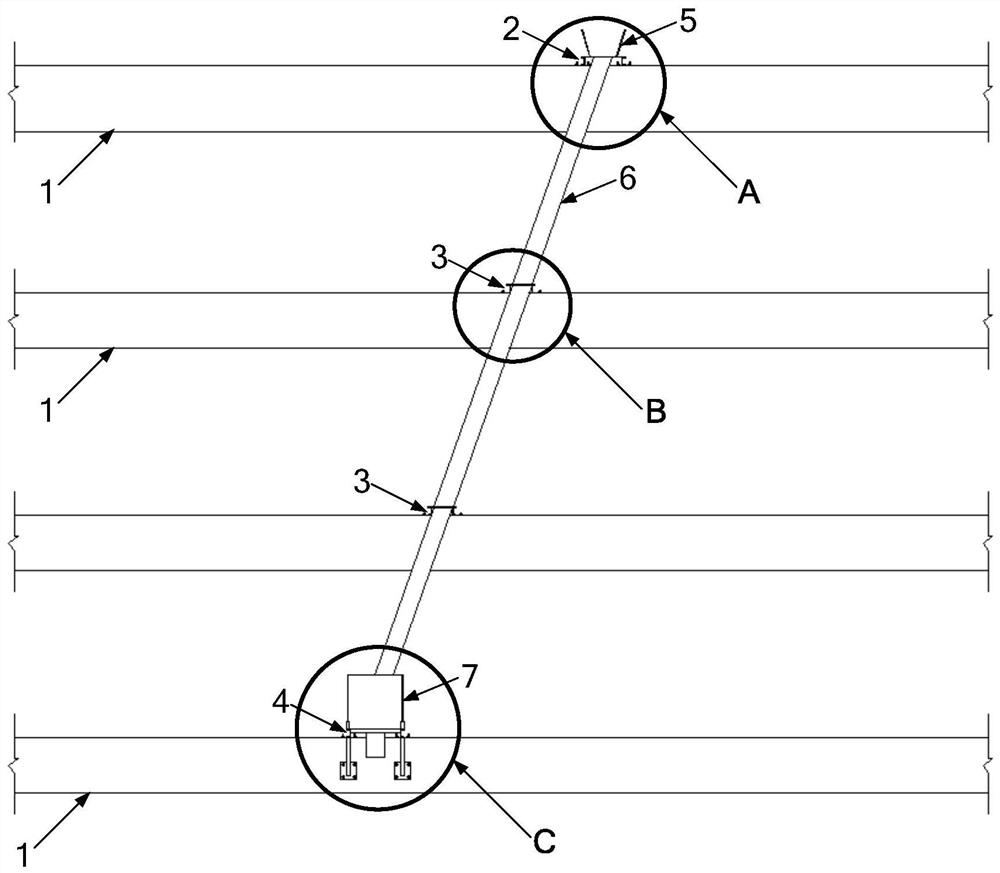

[0046] In order to solve the problems of unfavorable traffic, low pouring efficiency and unqualified pouring quality caused by the narrow construction site when pouring the existing foundation pit floor, the present invention provides a multi-support beam deep foundation pit floor concrete pouring system and its construction Methods: The concrete pouring system adopts cantilevered concrete conveying channel and multi-channel supporting beams as supporting points, which reduces the occupation of the construction site and overcomes various problems caused by the narrow construction site.

[0047] The concrete pouring system and construction method of the deep foundation pit floor with multiple support beams will be further described below with specific embodiments in conjunction with the accompanying drawings.

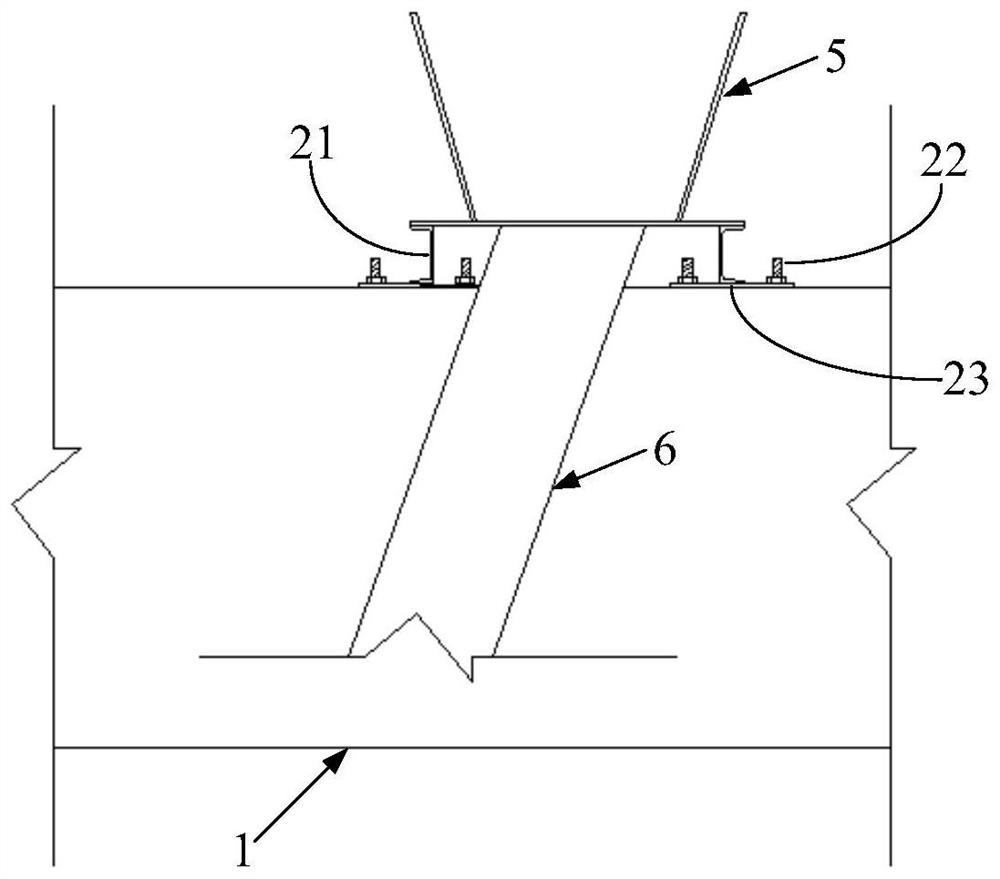

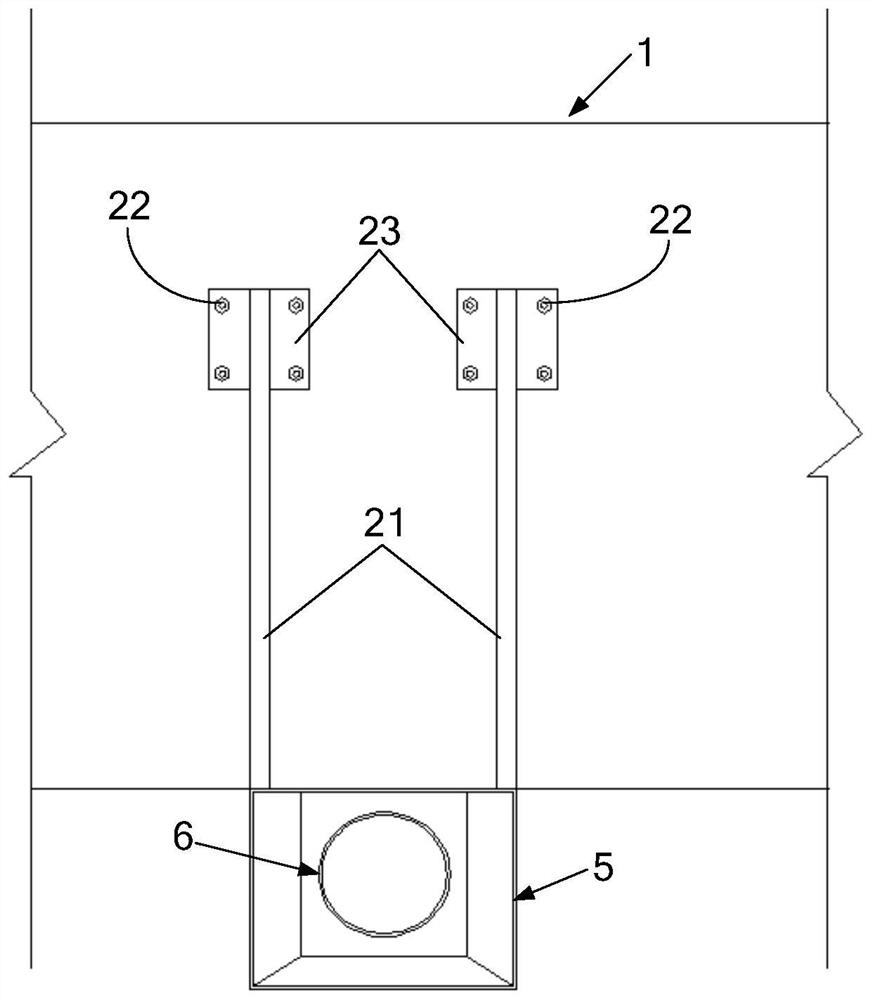

[0048] refer to Figure 11 Or as shown in 12, a deep foundation pit floor concrete pouring system with multiple support beams, including:

[0049] The first cantilever br...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap