Nitrogen cylinder structure capable of prolonging service lifetime

A technology of nitrogen cylinder and service life, which is applied in the field of stamping die manufacturing, can solve problems such as failure and leakage, reduce the service life of nitrogen cylinders, etc., and achieve the effect of increasing manufacturing costs and increasing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

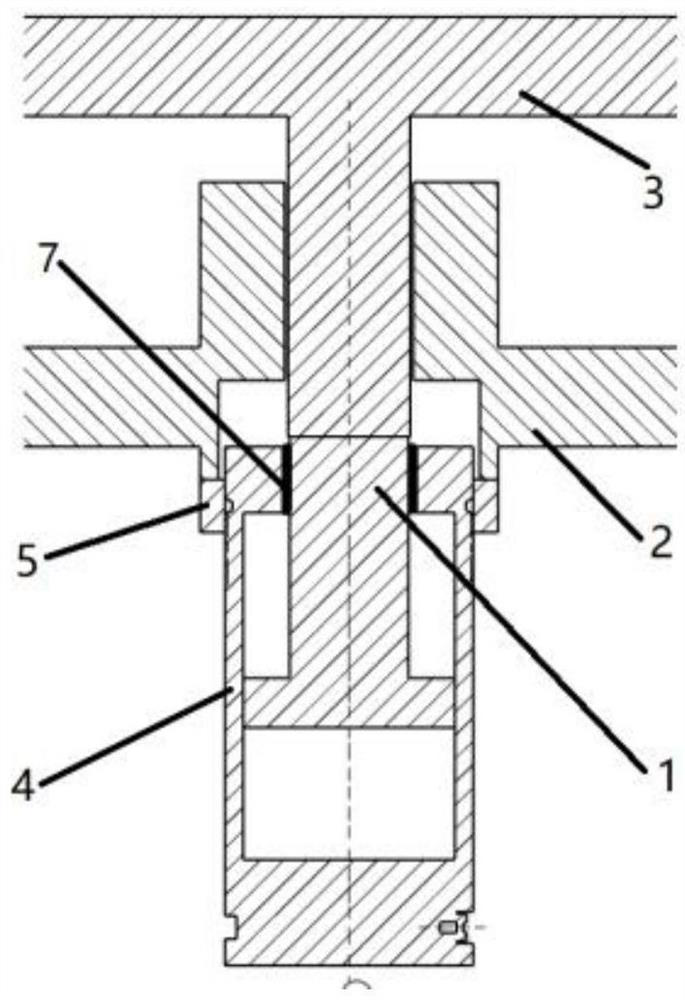

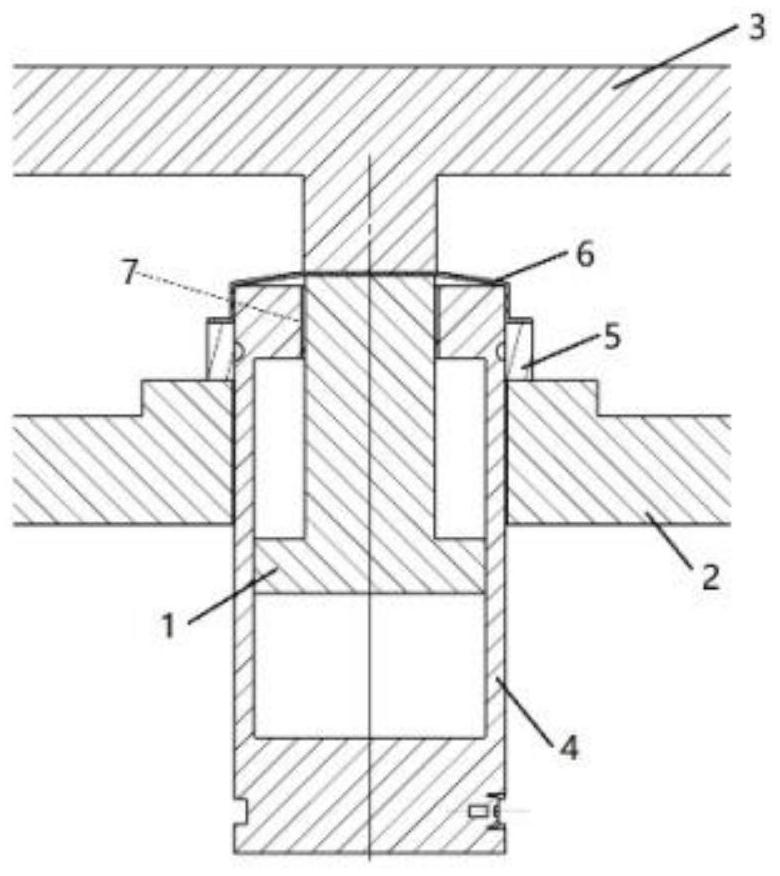

[0014] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 Shown, a kind of nitrogen cylinder structure that can prolong service life, wherein the present invention is realized by following technical scheme: A kind of nitrogen cylinder structure that can prolong service life, comprises piston rod, fixed part, moving part, nitrogen cylinder cylinder Body, isolation protection block, protective sleeve, sealing device; the upper end of the piston rod is provided with moving parts; the piston rod is provided with the inside of the nitrogen cylinder body; device; the outer side of the moving part is provided with a fixed part; the nitrogen cylinder block is connected with the fixed part through an isolation protection block. Dust protection is carried out through the protective cover as an isolation protection measure. The isolation protection block is independent of parts other than the fixed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com