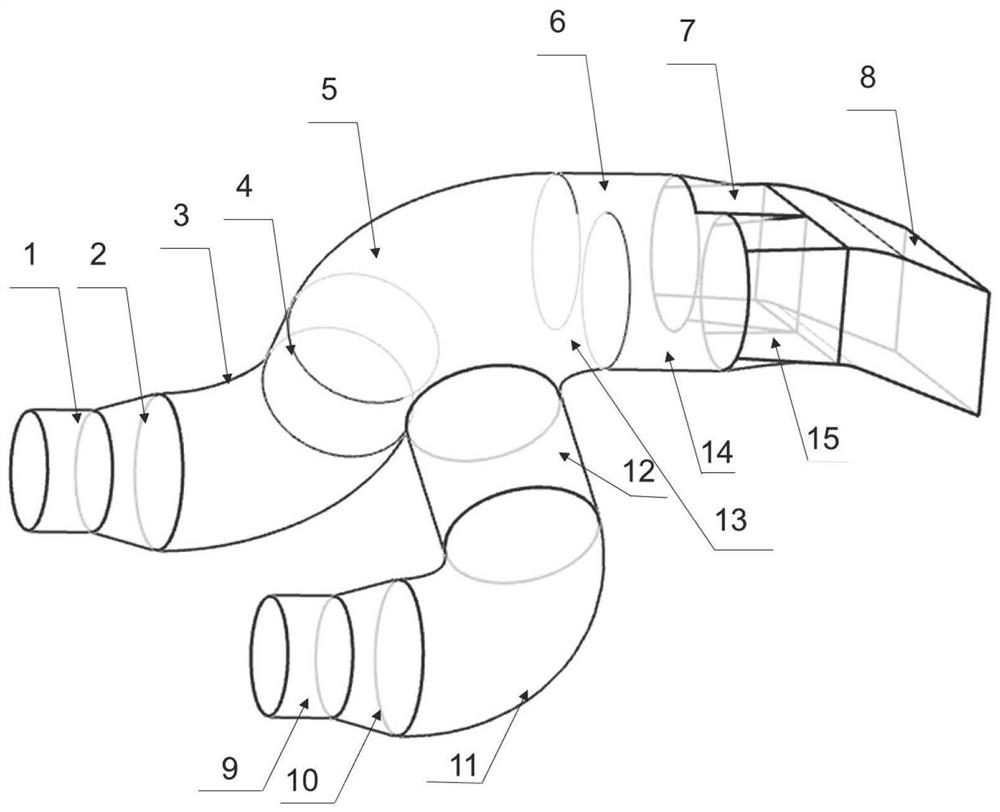

Inlet flue of coal-fired boiler desulfurization system

A technology of desulfurization system and inlet flue, which is applied in combustion method, combustion product treatment, lighting and heating equipment, etc. The effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the application more obvious and understandable, the application will be described in detail below in conjunction with the accompanying drawings. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0017] In each of the following embodiments or examples, if there is no specific functional component or structure, it means that it is a conventional component or conventional structure adopted in the art to realize the corresponding function.

[0018] In order to achieve a relatively uniform flue gas velocity at the outlet of the induced draft fan and a relatively small resistance loss, this application provides an inlet flue for the desulfurization system of a coal-fired boiler. For its structure, see figure 1 As shown, it includes the left flue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com