Regeneration column and dry apparatus for discharge gas treatment

A regeneration tower and exhaust gas technology, applied in gas treatment, chemical/physical process, membrane technology, etc., can solve the problem of activity reduction and achieve the effect of reducing dust, reducing the amount of dust, and uniform flow velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

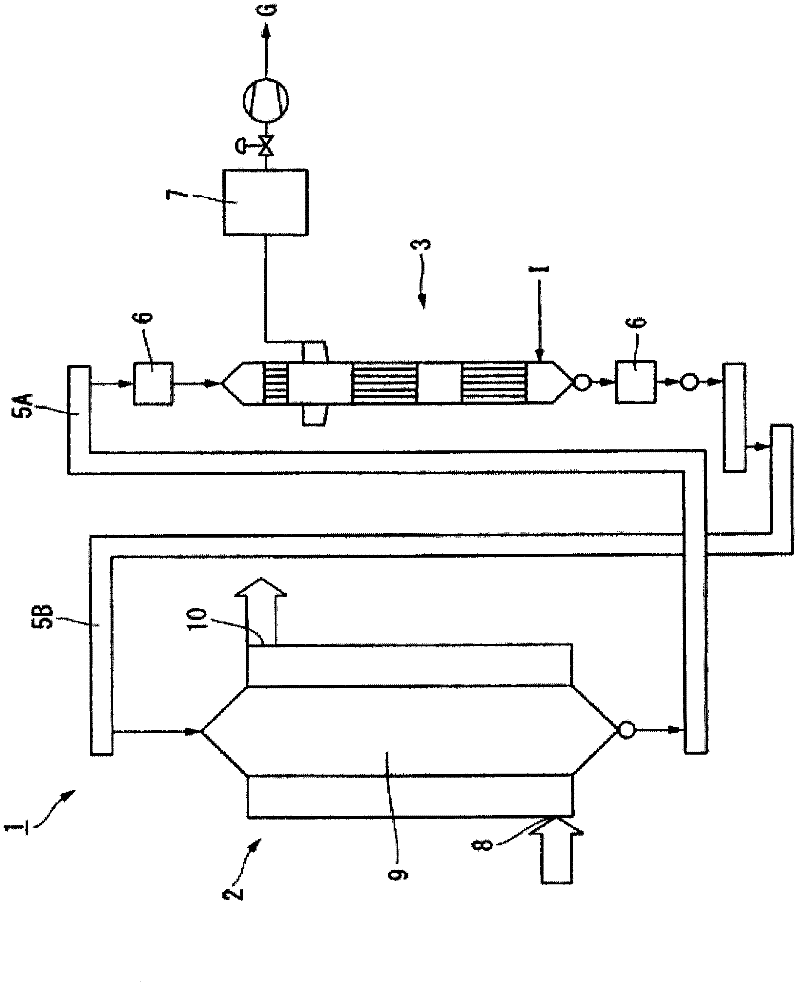

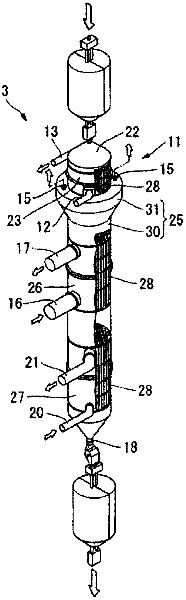

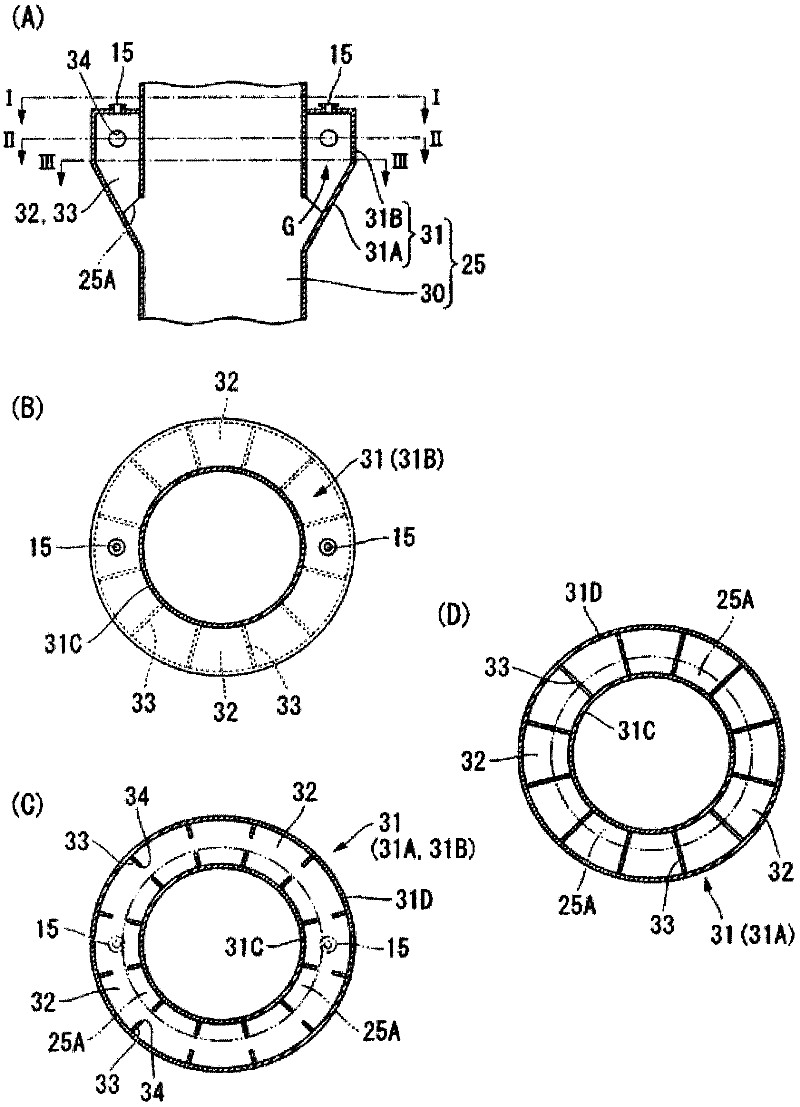

[0047] refer to Figure 1 to Figure 4 An example of the present invention will be described.

[0048] The dry exhaust gas treatment device 1 of this embodiment, such as figure 1 As shown, it has an adsorption tower 2, a regeneration tower 3, a first conveying channel 5A and a second conveying channel 5B connecting the adsorption tower 2 and the regeneration tower 3 and transporting the adsorbent, and a closed lock-type channel connected to the upper and lower ends of the regeneration tower 3. A hopper 6 and a cleaning tower 7 for cleaning the desorption gas G containing the desorbed product desorbed from the adsorbent.

[0049] The adsorption tower 2 is a device for adsorbing and removing various substances such as SOx (sulfur oxide) in gas using an adsorbent (for example, carbon adsorbent, alumina adsorbent, silica adsorbent, etc.). The adsorption tower 2 is provided with a waste gas inlet 8 for introducing waste gas, an adsorption tower body 9 in contact with the adsorbent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com