Dust removal equipment for cement manufacturing and processing

A technology of dust removal equipment and cement, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of dust falling on the ground, difficulty in cleaning, and low efficiency, and achieve simple operation, convenient use, and fast cementing The effect of absorbing and filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

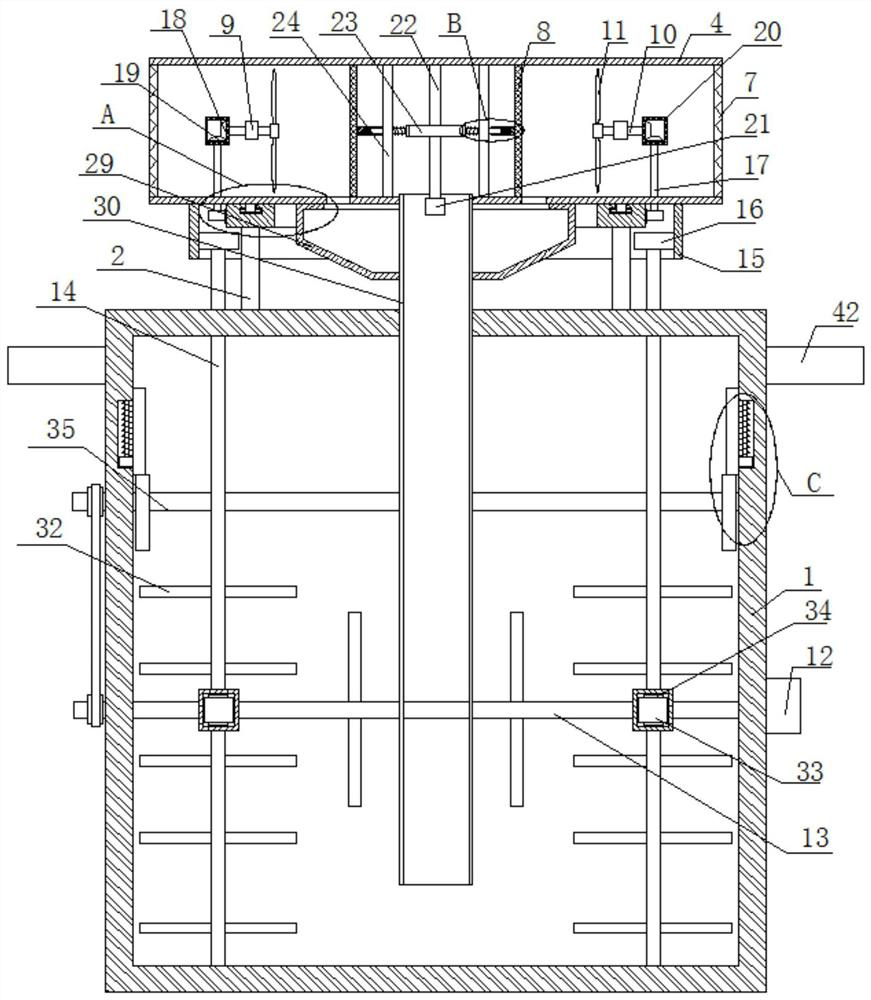

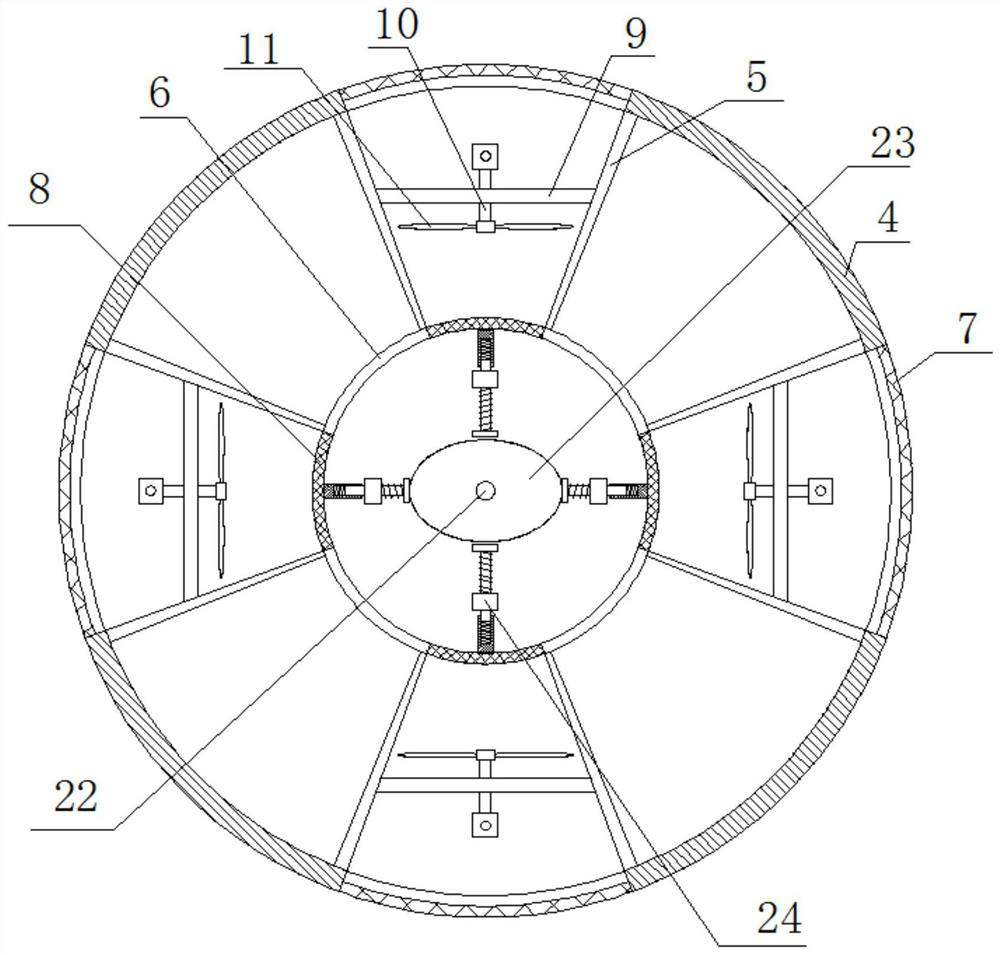

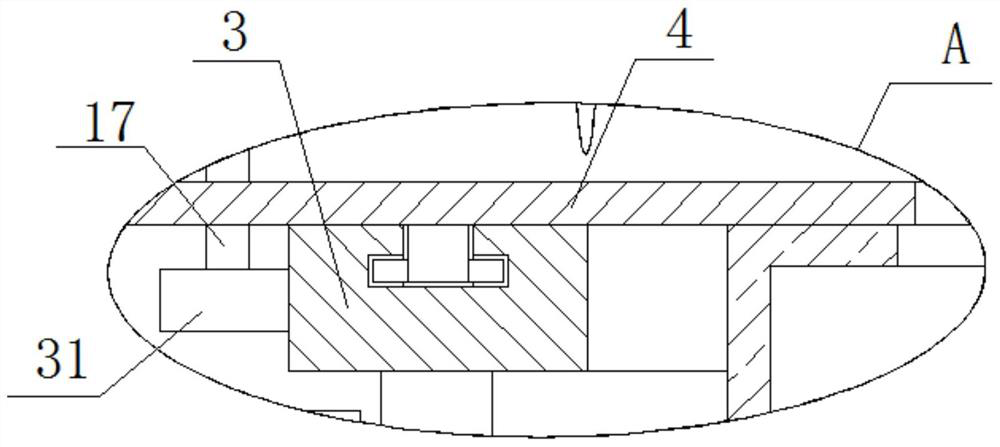

[0029] refer to Figure 1-5 , a dust removal device for cement manufacturing and processing, including a box body 1, four symmetrically arranged support rods 2 are fixedly installed on the top of the box body 1, and the same fixed ring 3 is fixedly installed on the top ends of the four support rods 2, The top of the fixed ring 3 is rotatably connected with the air intake box 4, and the inner wall of the air intake box 4 is fixedly equipped with an annular baffle plate 6, and a plurality of dividing plates 5 are fixedly installed between the annular baffle plate 6 and the air intake box 4, corresponding An isolation net 7 and a filter screen 8 are arranged between the two partitions 5, and the same fixed rod 9 is fixedly installed between the corresponding two partitions 5, and the fixed rod 9 is rotatably connected with a positioning shaft 10, and on the positioning shaft 10 The fan blade 11 is fixedly installed, and the top of the box body 1 is fixedly equipped with an air in...

Embodiment 2

[0040] refer to Figure 1-5 , a dust removal device for cement manufacturing and processing, including a box body 1, four symmetrically arranged support rods 2 are welded on the top of the box body 1, and the same fixed ring 3 is welded on the top ends of the four support rods 2, and the fixed ring The top of 3 is rotatably connected with an air intake box 4, and an annular baffle 6 is welded on the inner wall of the air intake box 4, and a plurality of baffles 5 are welded between the annular baffle 6 and the air intake box 4, and the corresponding two baffles 5 is provided with an isolation net 7 and a filter net 8, and the same fixed rod 9 is welded between the corresponding two partitions 5, and the fixed rod 9 is rotatably connected with a positioning shaft 10, and a fan blade 11 is welded on the positioning shaft 10. , the top of the box body 1 is welded with an air inlet pipe 30, the air inlet pipe 30 is rotationally connected with the air inlet box 4, and the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com