Actuator

A technology of actuators and sliding parts, which can be used in transmission devices, bearings for linear motion, rotating parts that resist centrifugal force, etc., and can solve problems such as increased working resistance of balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

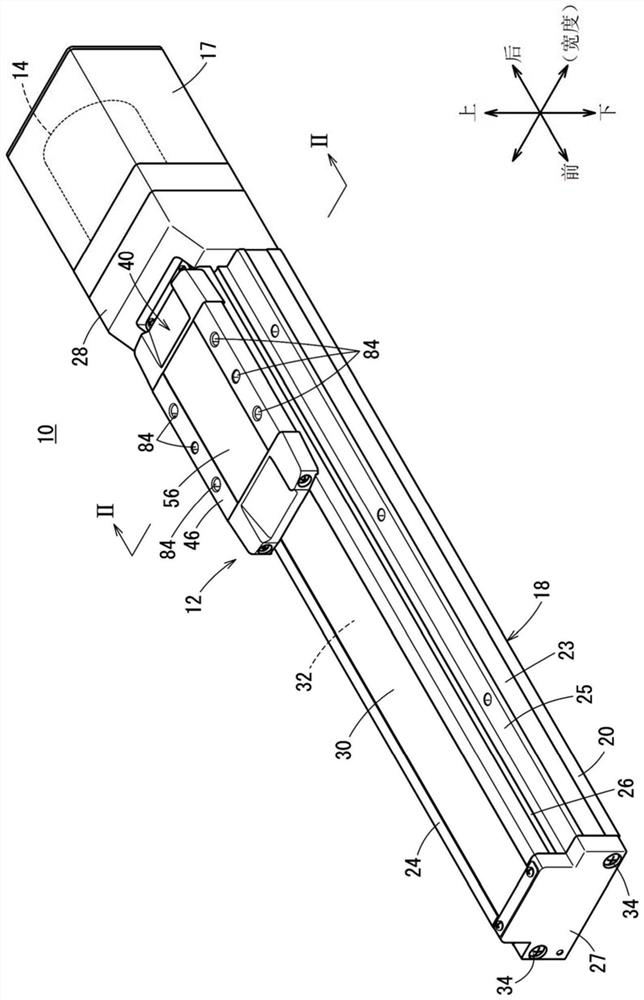

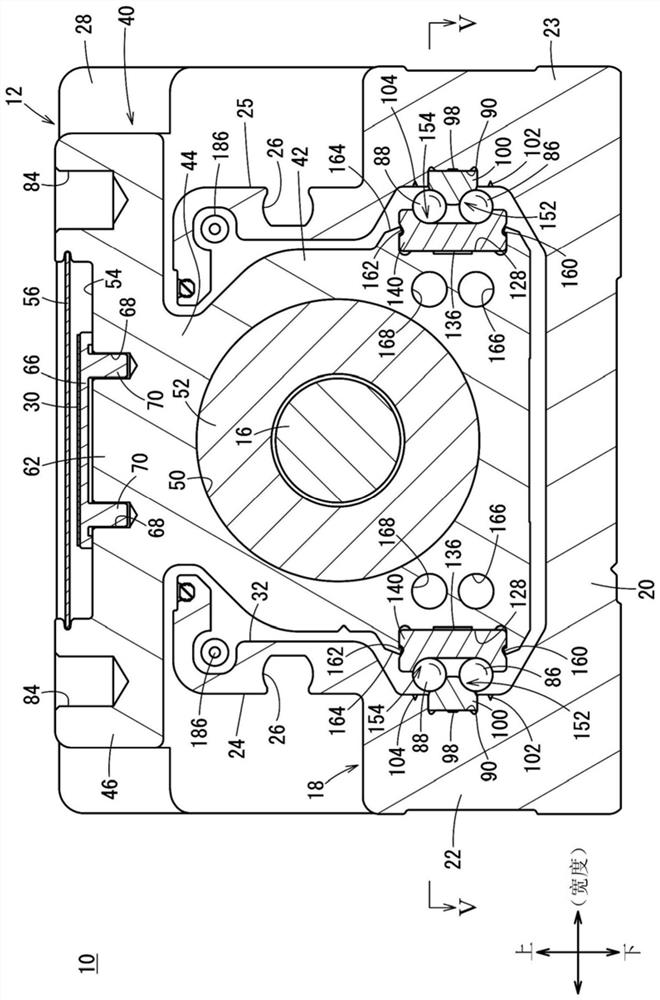

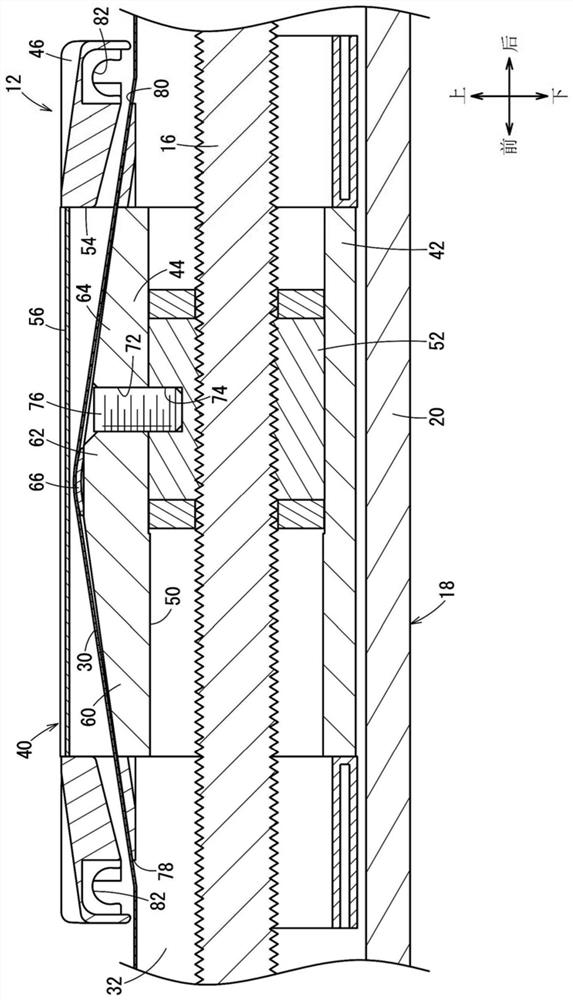

[0034] Hereinafter, preferred embodiments will be cited, and the actuator according to the present invention will be described in detail with reference to the drawings. Also, the following "front" is from figure 1 The direction away from the motor 14 is shown, and "rear" indicates the direction approaching the motor 14 . In addition, "down" and "up" are vertical directions perpendicular to the front-rear direction. Also, the "width direction" is a horizontal direction perpendicular to the front-back direction. Although the above directions are shown in each drawing, these directions are for the convenience of simplifying the description and facilitating understanding, and do not particularly designate the directions when the actuator is actually used.

[0035] figure 1 It is a schematic overall perspective view of the actuator 10 according to the first embodiment. The actuator 10 is configured as a linear actuator including a linear guide 12 extending in the front-rear dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com