Crane counterweight structure and stabilizing method

A crane and counterweight technology, used in cranes, load hanging elements, transportation and packaging, etc., can solve the problems of falling off surrounding people and buildings, crane counterweights, fixed cranes, etc., to reduce weight and reduce oil. Loss and shedding prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

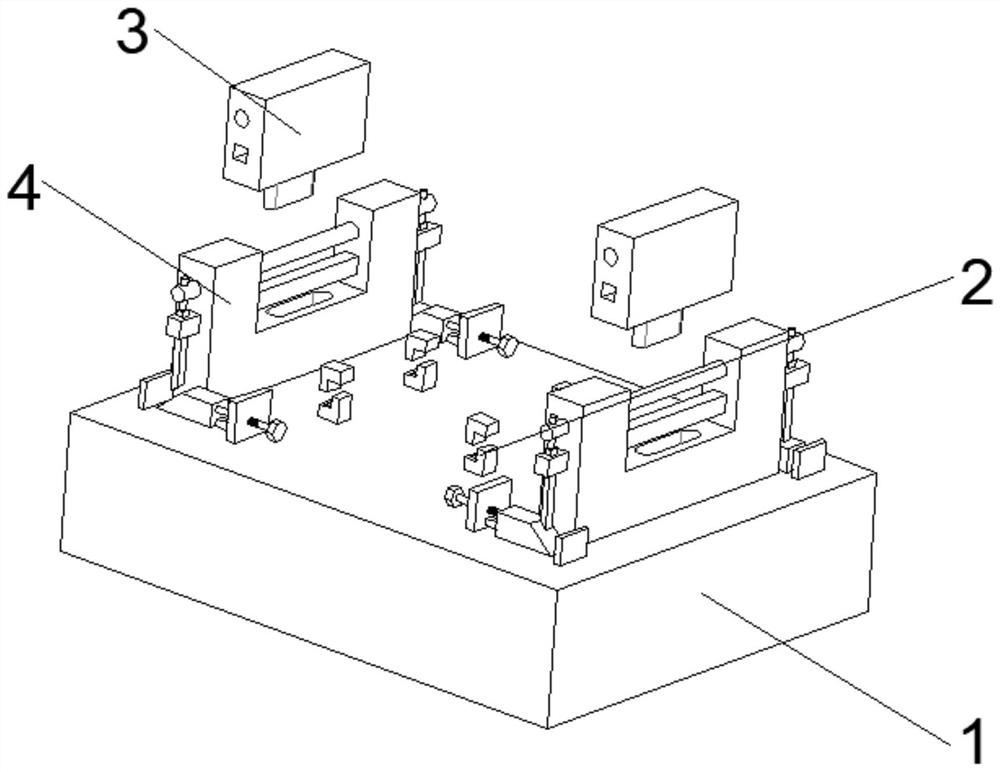

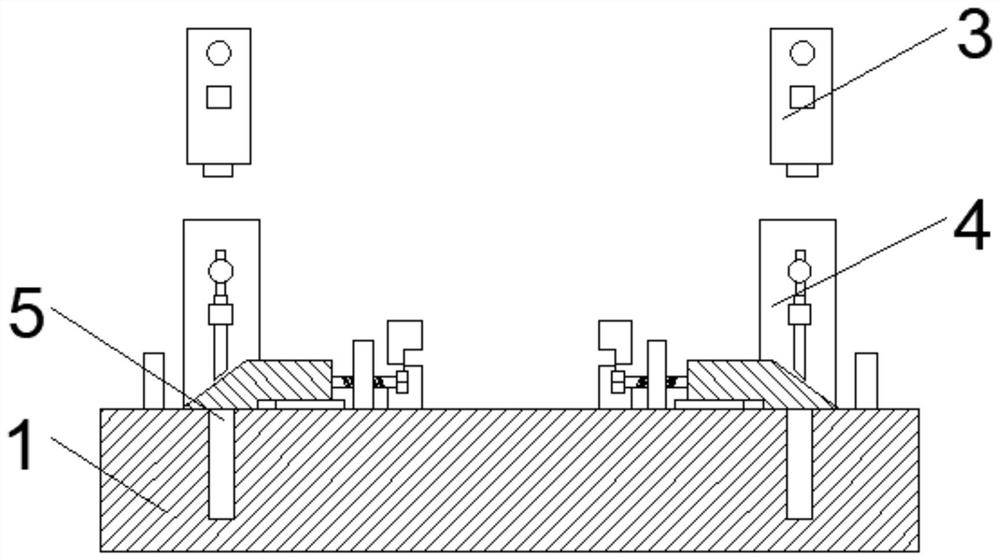

Embodiment 1

[0033] The above-mentioned fixing mechanism 4 includes a mounting plate 402 fixedly connected with the counterweight 1, the top surface of the mounting plate 402 is provided with a mounting groove 401, the bottom of the groove wall of the mounting groove 401 is provided with a limiting groove 405, and the inside of the mounting groove 401 is provided with The first connecting rod 403 with a circular longitudinal section and the second connecting rod 404 with a rectangular longitudinal section, both ends of the first connecting rod 403 and the second connecting rod 404 move through the mounting plate 402, and the Limiting mechanisms 406 are provided on both sides.

[0034] The above-mentioned clamping block 3 includes a block body 301 located above the mounting plate 402, the top of the block body 301 is fixedly connected with the external crane, the bottom of the block body 301 is fixedly installed with a limit block 302, and the position of the limit block 302 and the limit gr...

Embodiment 2

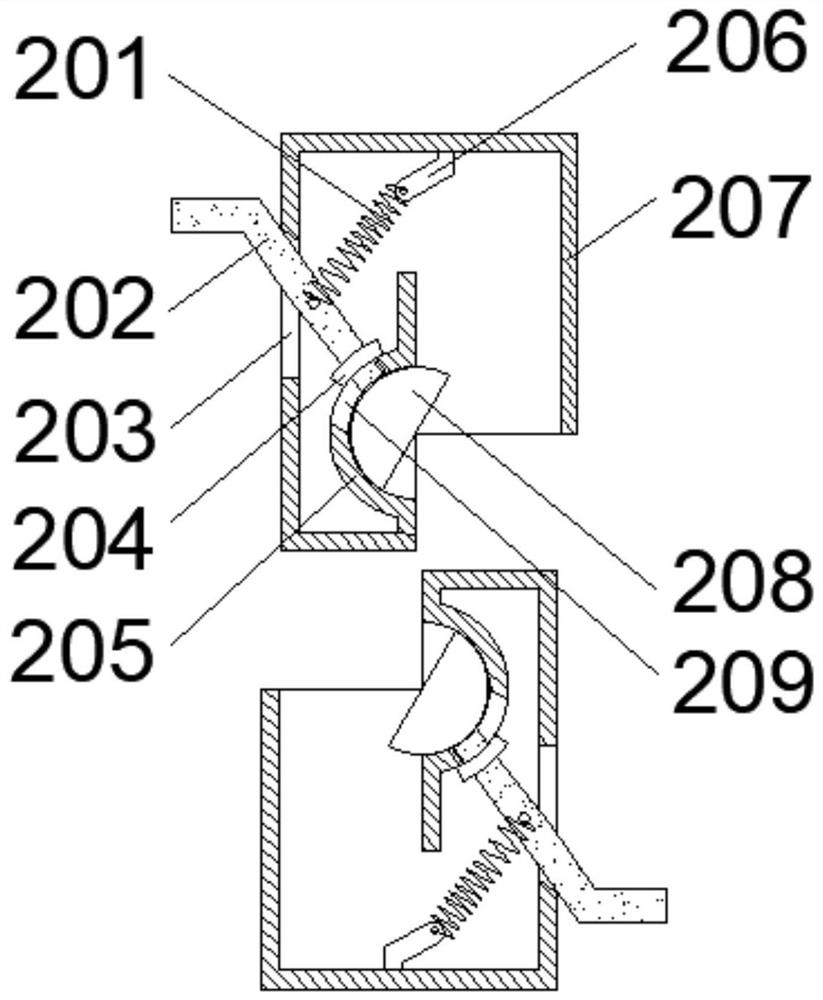

[0038] The above-mentioned connecting mechanism 2 includes a shell 207 fixedly connected to the counterweight 1 or one of the external cranes. One side of the shell 207 is provided with an opening, and a connecting plate 205 is fixedly installed at the opening. Circular rotating slot, the inside of the rotating slot is movably connected with a rotating block 208 with a semicircular section, the groove wall of the rotating slot is provided with a first limiting hole 209, and the inside of the first limiting hole 209 is provided with a rotating rod 202, the other side of the shell 207 is provided with a second limit hole 203, the inside of the shell 207 is provided with a moving cavity, the cavity wall of the moving cavity is fixedly installed with a connecting seat 206, and one end of the rotating rod 202 is fixedly connected with the rotating block 208, The other end of the rotating rod 202 moves through the second limiting hole 203, and the middle part of the rotating rod 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com