Anti-efflorescence floor and intelligent auxiliary construction method thereof

A construction method and ground technology, applied in the field of laying floor tiles, can solve the problems of affecting the service life of floor tiles, low levelness, affecting appearance, etc., and achieve the effect of avoiding water seepage and returning to alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

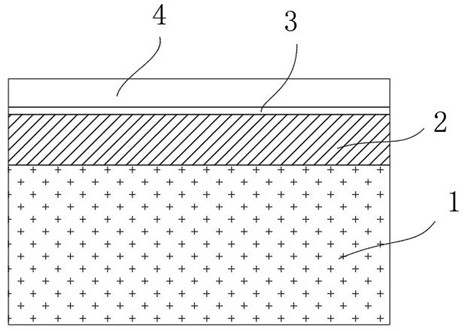

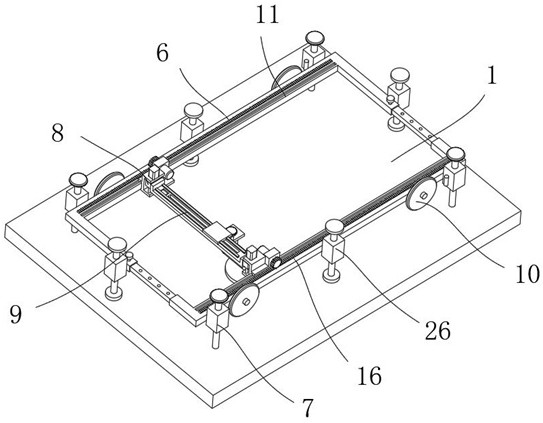

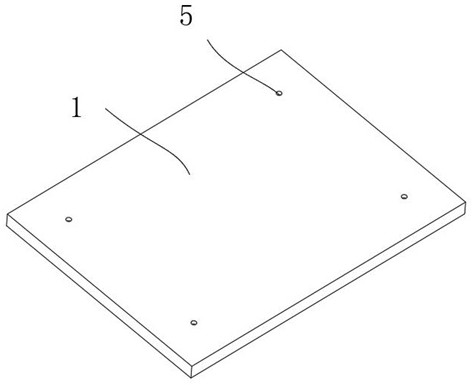

[0043] Please refer to Figure 1-11 ,in, figure 1 The schematic diagram of the sectional structure of the anti-alkali ground provided by the present invention; figure 2 A schematic diagram of the overall structure of the paving device provided by the present invention; image 3 Schematic diagram of the positioning groove structure provided for the present invention; Figure 4 Schematic diagram of the frame structure provided for the present invention; Figure 5 for Figure 4 Enlarged view of A in the figure; Image 6 Schematic diagram of the structure of the grinding disc provided by the present invention; Figure 7 Schematic diagram of the structure of the rotating plate provided by the present invention; Figure 8 Schematic diagram of the structure of the lifting mechanism provided by the present invention; Figure 9 One of the structural sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com