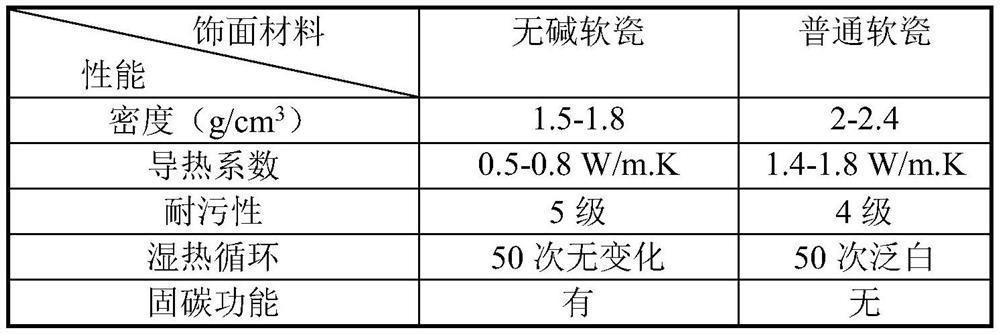

Alkali-free soft porcelain capable of fixing carbon and preparation method of alkali-free soft porcelain

A technology of soft porcelain and base layer, which is applied in the direction of solid waste management, climate sustainability, and sustainable waste treatment. Effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method of preparation of alkali -free porcelain with solid carbon, steps::

[0035] Step 1: Mix 10 parts of water -based acrylic emulsion, 10 parts of water, and 5 partial membranes in the mixer at 1500R / min speed at 1500r / min, and then add 50 parts of quartz sand and 25 parts of calcium powder, 800R / 800R / MIN mix for 20min to mix the slurry 1, spray the pulp 1 evenly on the surface of the flat soft porcelain mold, 6mm thick, and dry 6h in the 120 ° C oven to get the base layer;

[0036] Step 2: Mix 10 parts of water, 10 parts of sodium alginate, 8 parts of collapse enzyme activible agent (APMA), 8 parts of glucose oxidase (God), and 1 part of nano oxide mixing, in accordance with the quality portion Stir at 1500R / min at a speed of 30 minutes in the mixer, reduce the speed to 300R / min, then add 20 parts of seaweed extraction solution and 30 porridge powder, stir for 1h to get mixed pulp 2, dissolve 3 parts of calcium chloride in 10 parts of water Obtain calcium chloride s...

Embodiment 2

[0040] A method of preparation of alkali -free porcelain with solid carbon, steps::

[0041] Step 1: Mixing 13 parts of acrylic lotion, 13 parts of water and 4 film -forming aids 1500R / min is mixed for 5 minutes, and 50 parts of quartz sand and 20 portion of calcium powder are mixed with 800R / min 20min. Spray the slurry 1 evenly on the surface of the flat soft porcelain mold, with a thickness of 5mm, and dry the mold layer in 5H in a 100 ° C oven;

[0042] Step 2: Mixing 13 parts of water, sodium alginate, 6.2 parts of collazan enzyme potentase APMA, 6 parts of glucose oxidase God and 0.8 nano oxide 1500R / min are mixed with 1500R / min in the mixer 1500R / min After the speed is stirred for 30 minutes, the speed is reduced to 300R / min, and then 20 parts of seaweed extract and 35 sake powder are added. Stir for 1h for 1h to get a mixed pulp 2. Drip in the calcium chloride solution in the mixed pulp 2 to obtain gel spheres, filter through 40 mesh sieve nets, and dry 20 ° C to obtain chl...

Embodiment 3

[0046] A method of preparation of alkali -free porcelain with solid carbon, steps::

[0047] Step 1: Mix 12 parts of polyurethane lotion, 15 parts of water, and 3 film -forming aids 1500R / min to mix for 5 minutes, add 50 quartz sand, 20 part of calcium powder to mix with 800R / min to mix for 20min, and mix the pulp 1. The slurry 1 is sprayed evenly on the surface of the flat soft porcelain mold, with a thickness of 4mm. Dry 4h demolished in a 100 ℃ oven to obtain the base layer;

[0048] Step 2: Mix 10 parts of water, 6 parts of sodium alginate, 4.3 parts of collazan enzyme potentase APMA, 6 parts of glucose oxidase God and 0.7 nano oxide 1500r / min, and in the mixer 1500R / min 1500R / min After the speed is stirred for 30 minutes, the speed is reduced to 300R / min, and then 21 parts of seaweed extract and 40 pile powder are added. Stir for 1h to get a mixed pulp 2. Drip in the calcium chloride solution in the mixed pulp 2 to obtain gel spheres, filter through 50 mesh sieve nets, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com