Centering device for installing high-strain sensor and using method

A technology of strain sensor and centering device, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems that affect the accuracy of detection data and the difficulty of accurately controlling the measurement angle of steel tapes, and achieve convenient locking and measurement data errors. Small, the effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

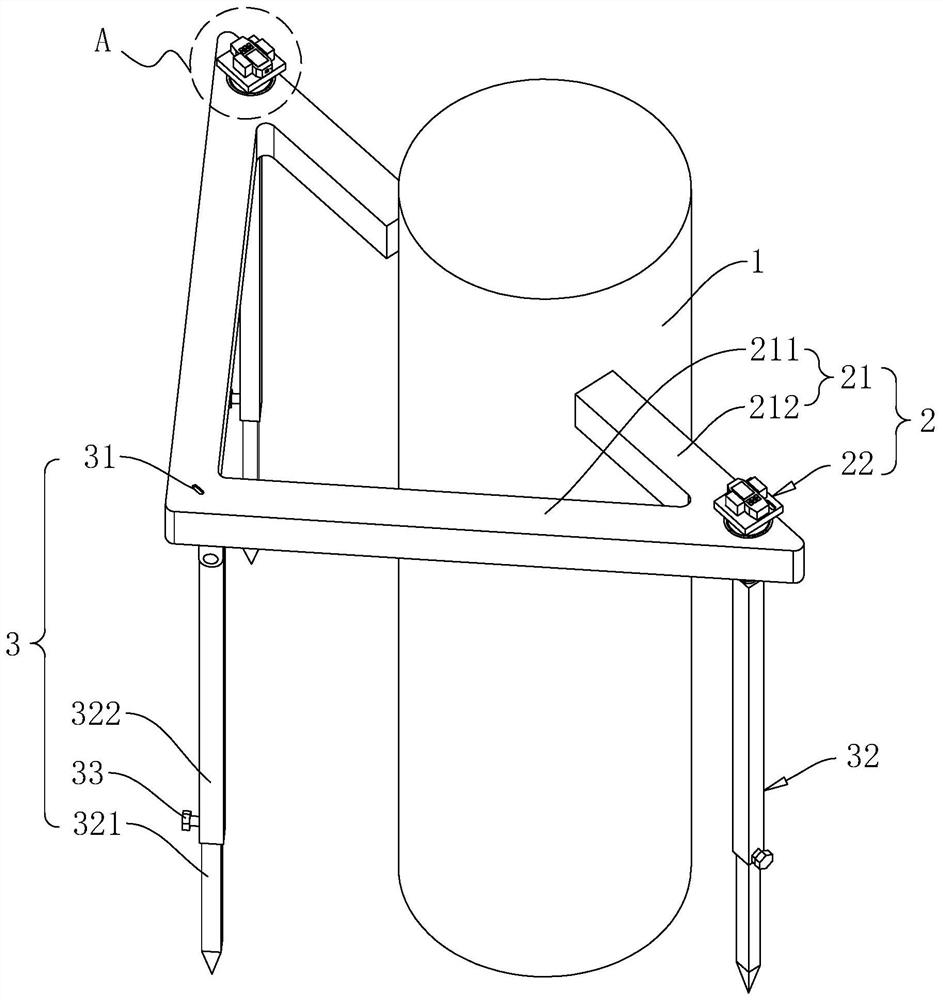

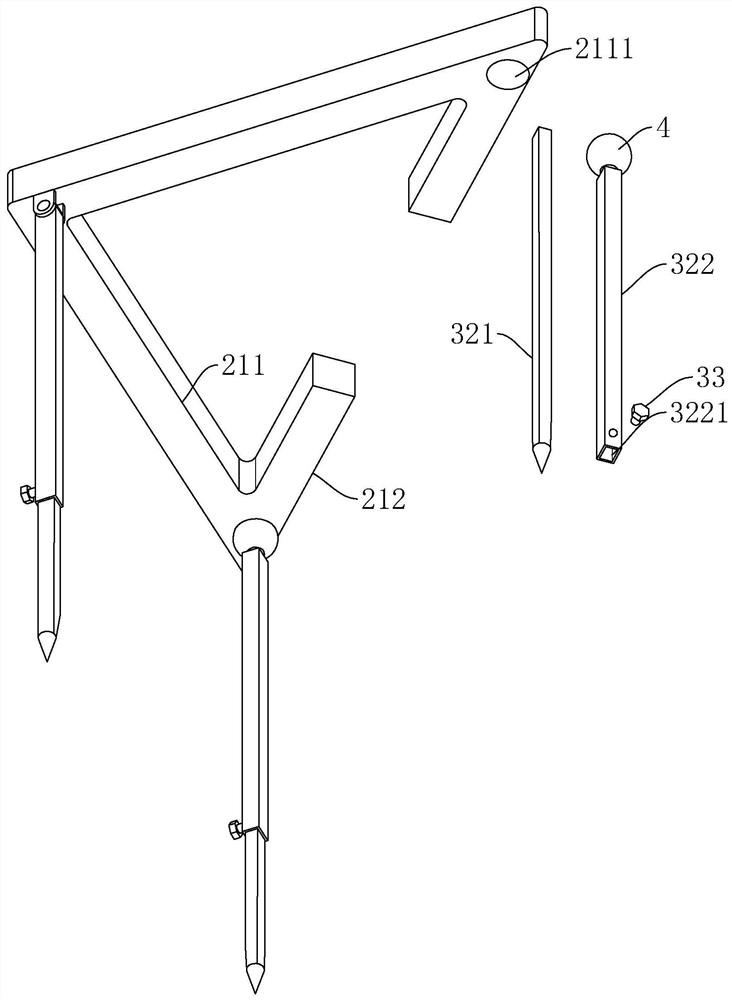

[0038] The following is attached Figure 1-3 The present invention is described in further detail.

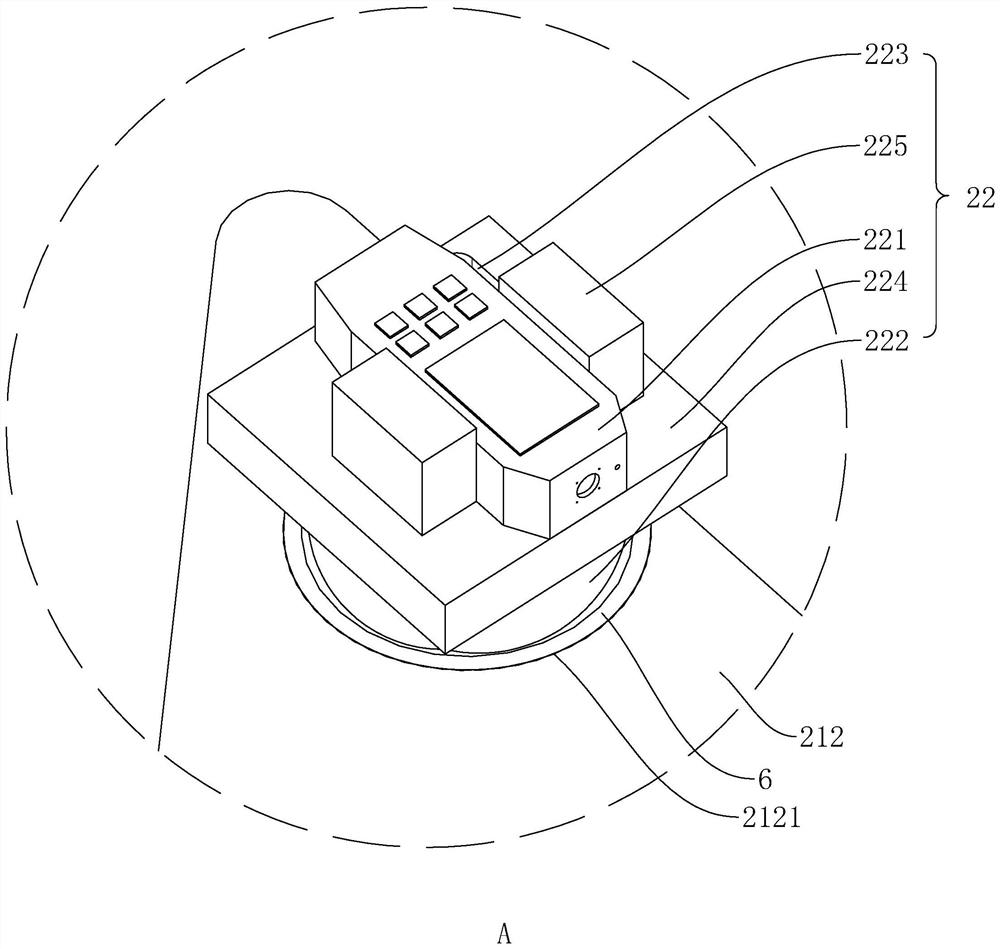

[0039] A centering device for installing a high-strain sensor disclosed in the embodiment of the present application is used to locate the installation position of the strain sensor and the acceleration sensor in the circumferential direction of the pile foundation 1, such as figure 1 , 2As shown, it includes a centering assembly 2 and a leveling assembly 3 for leveling the centering assembly 2. The centering assembly 2 includes a centering plate 21 and two measuring pieces 22 installed on the centering plate 21. The centering plate 21 includes two receiving plates 212 and a connecting plate 211. The shape of the connecting plate 211 can be arbitrary. In the embodiment of this application, one is used as an example. The middle part of the connecting plate 211 is bent into a right angle, and the two receiving plates 212 Relatively located at both ends of the connecting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com