Wharf ship impact simulation test box capable of avoiding simultaneous vibration

A simulation test and ship technology, which is applied in the field of wharf collision test equipment, can solve problems such as water vibration, equipment shake, and test result influence, and achieve the effect of ensuring accuracy and avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

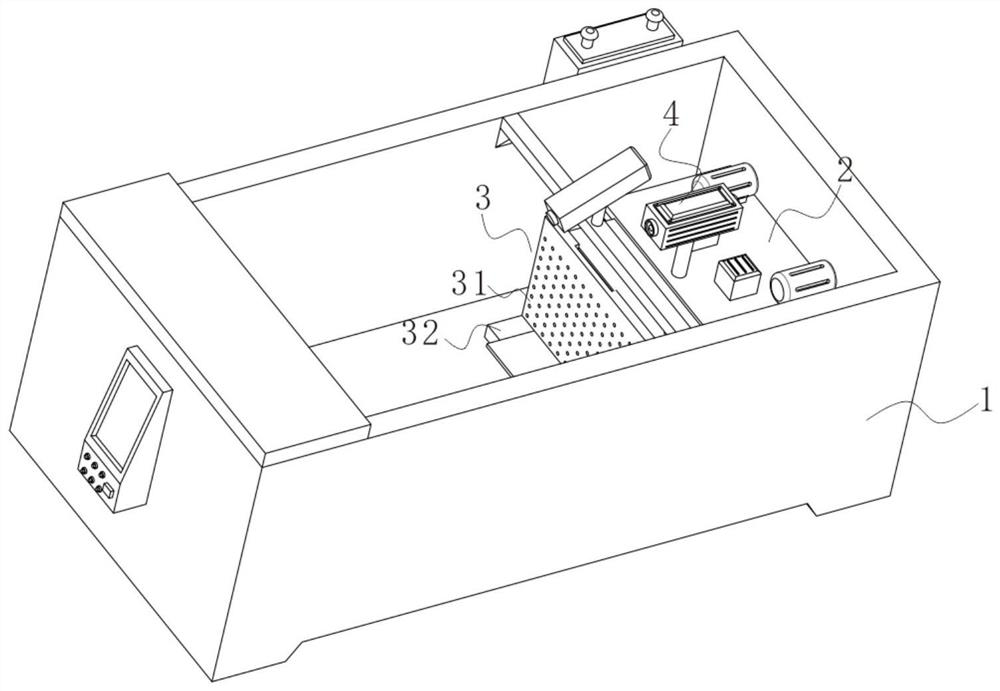

[0022] The present invention provides a technical solution: a wharf ship impact simulation test box that can avoid simultaneous vibration, please refer to figure 1 , including the simulation box 1;

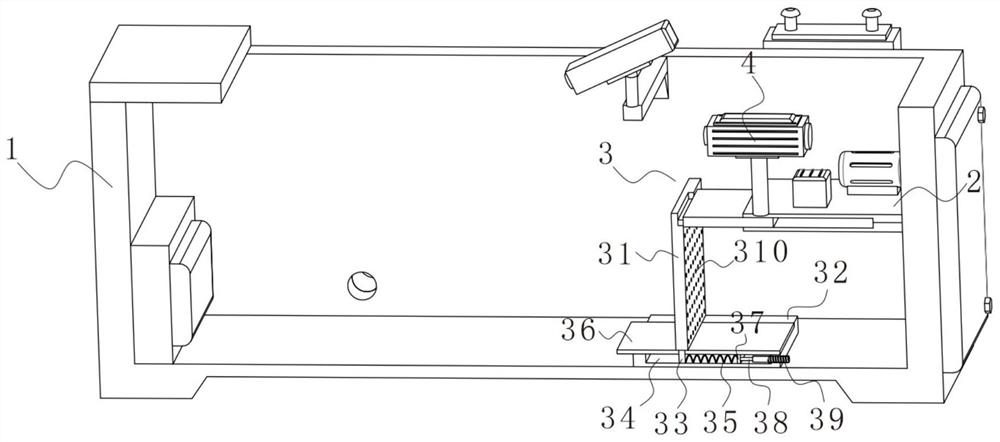

[0023] see figure 1 and figure 2 A mounting plate 2 is fixedly installed on the inner wall on the right side of the simulation box body 1, and a detection device 4 is fixedly mounted on the outer wall of the top of the mounting plate 2. The detection device 4 refers to equipment such as a camera, a laser rangefinder, and a sensor, and is used to detect the position of the simulation device 3. The magnitude of force and movement of the simulated baffle 31 is consistent with the detection equipment in the public document of a wharf ship impact simulation test box with the application number CN201920348543.0, and the working method is the same. Water will be added to the inside of the simulated box 1, and the The wave maker works to generate water waves inside the simulation box 1...

Embodiment 2

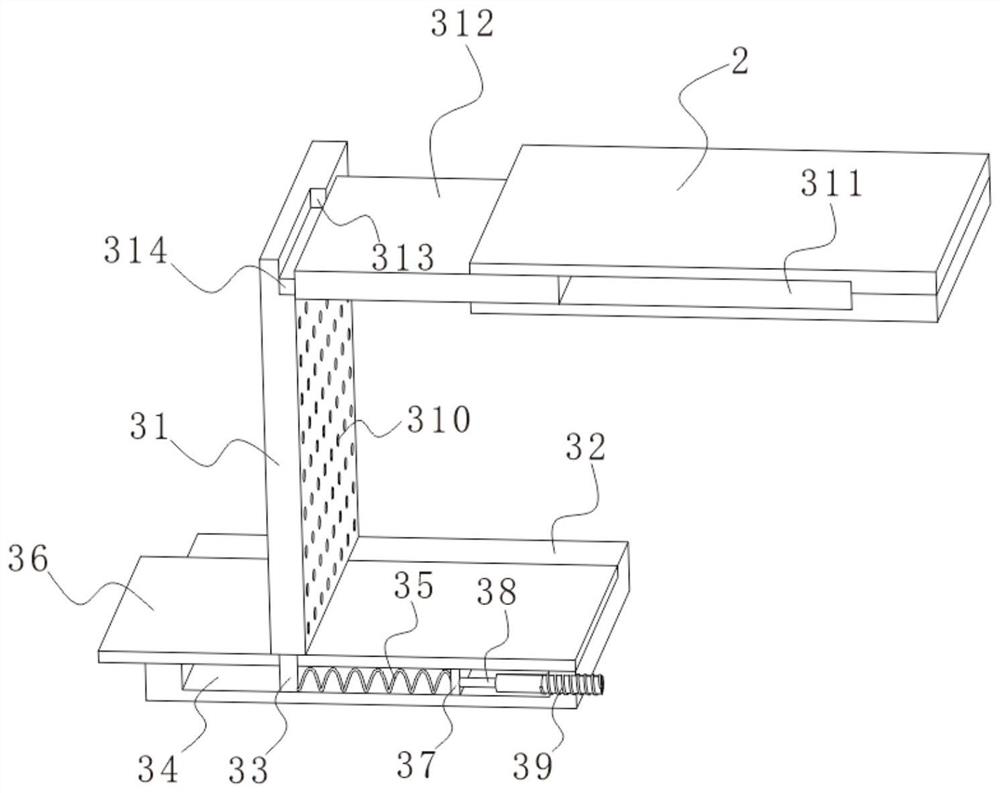

[0027] see figure 2 and image 3 , on the basis of Embodiment 1, a support block 37 is slidingly installed on the right side of the inner chamber of the chute 34, and the outer wall on the left side of the support block 37 is fixedly connected with the right end of the support spring 35, and the inner wall on the right side of the chute 34 is provided with a threaded hole, and the threaded hole The inner cavity is screwed with a threaded sleeve 39, and the outer wall on the left side of the threaded sleeve 39 is provided with a moving rod 38. Block 37 moves to the right, and the degree of compression of support spring 35 is changed, and the support force of support spring 35 to slide block 33 is increased, and the degree of difficulty that simulation baffle plate 31 moves to the right can be changed, thereby can according to ship and simulation The impact force of the baffle plate 31 is used to change the support force of the support spring 35, so that the right side of the ...

Embodiment 3

[0031] see figure 2 , image 3 and Figure 5 , on the basis of Embodiment 1, through holes 310 are evenly opened on the left outer wall of the simulated baffle 31, through the through holes 310, water can pass through the simulated baffle 31, so that when the simulated baffle 31 moves to the right when it collides, The blocking force of the simulated baffle 31 is reduced by water, the top outer wall on the right side of the simulated baffle 31 is provided with a guide block 312, the left outer wall of the mounting plate 2 is provided with a guide groove 311, and the right end of the guide block 312 slides and is inserted into the guide groove 311 In the cavity, the movement of the simulation baffle 31 is guided, and the simulation baffle 31 is supported. The outer wall on the left side of the guide block 312 is fixedly equipped with an insert 314, and the right outer wall of the top of the simulation baffle 31 is provided with a slot 313. 314 is inserted in the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com