Filterability detection process for epidemic prevention mask produced based on melt-blown cloth

A technology of filterability and melt-blown cloth, which is applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., can solve the problem that the detection results of melt-blown cloth materials cannot be guaranteed to be accurate, and the materials of melt-blown cloths are easily shifted Or offset, inability to select materials for melt-blown cloth, seal protection, etc., to achieve the effect of increasing the stability and accuracy of use, increasing the efficiency and convenience of use, and increasing the diversity and convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

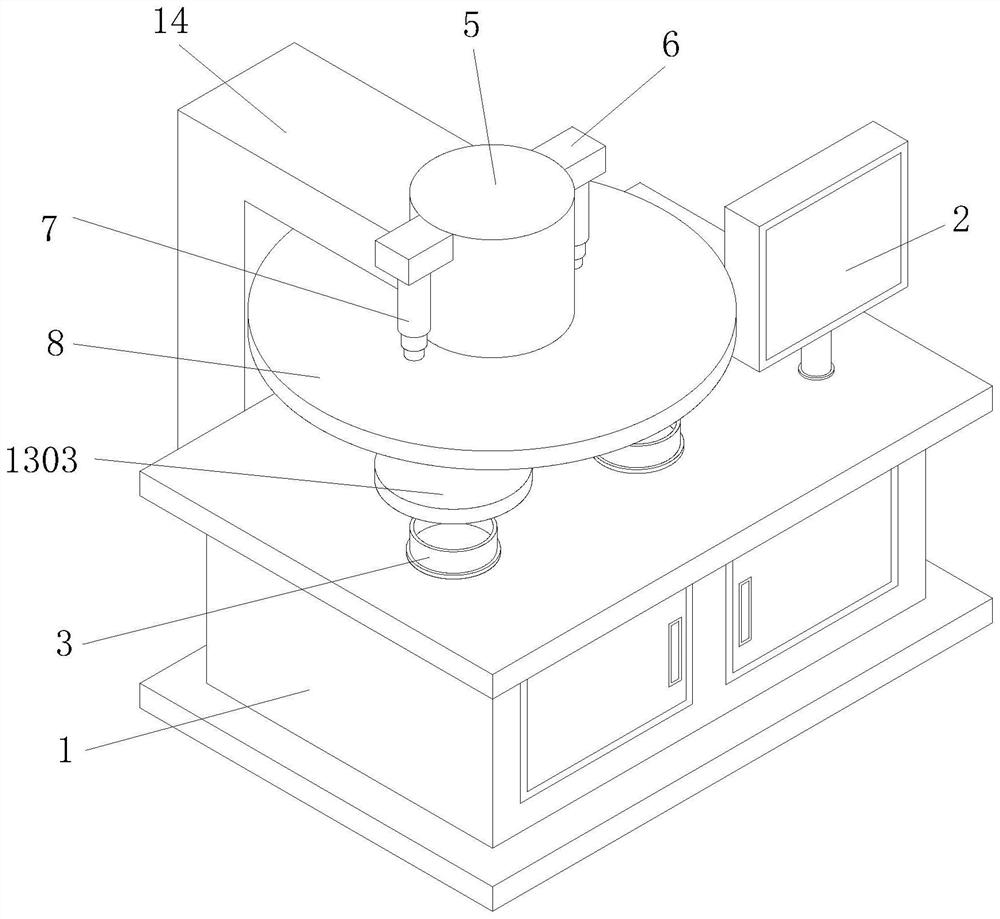

[0048] like figure 1 Shown is a schematic diagram of the overall structure of a filterability detection process for the production of epidemic prevention masks based on melt blown cloth according to the present invention.

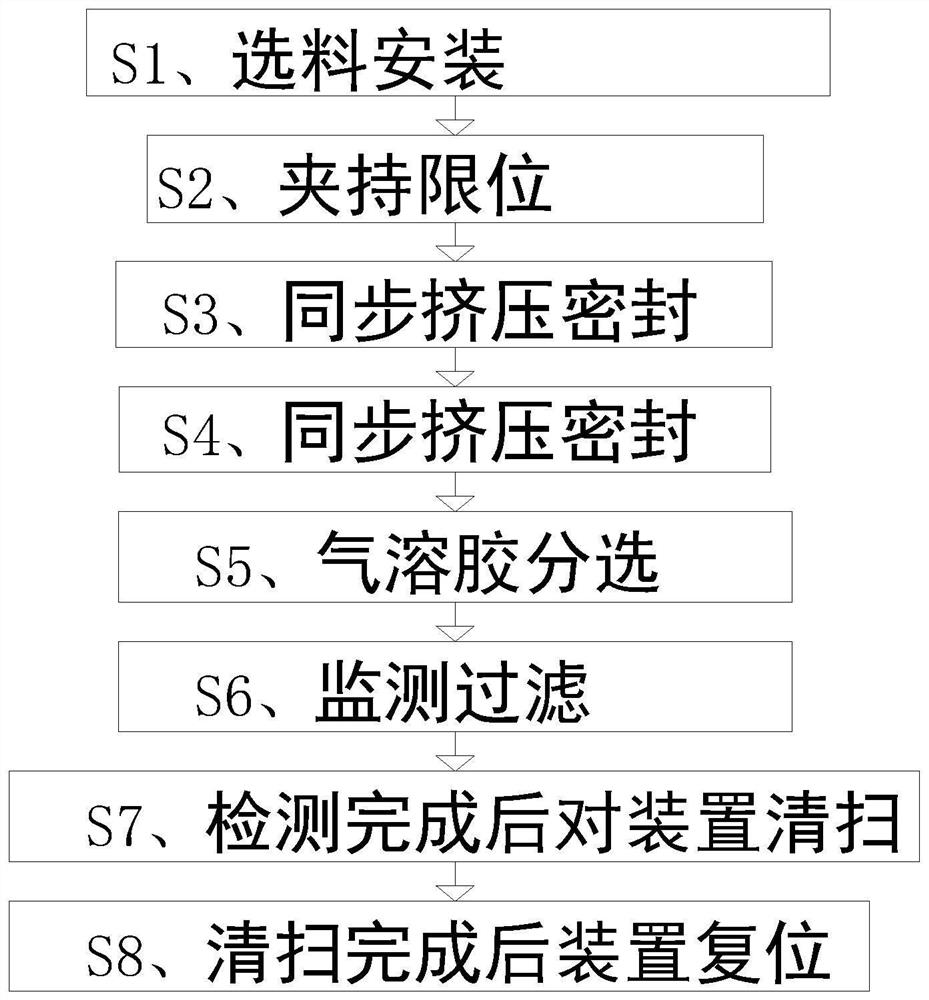

[0049] A filterability detection process based on melt-blown cloth to produce anti-epidemic masks, including the following steps:

[0050] S1. Material selection and installation: the staff will place the selected materials that need to be tested on each test base one by one;

[0051] S2. Clamping limit: carry out stable clamping limit on the selected materials placed on each test base in step S1, and open the small hydraulic cylinder 6 by controlling. At this time, under the working action of the small hydraulic cylinders 6 on both sides, combined The corresponding hydraulic rod 7 can push the mounting plate 8 to move downward on the cascade impactor 5 stably, and then under the action of the continuous movement of the mounting plate 8, it can drive each ...

Embodiment 2

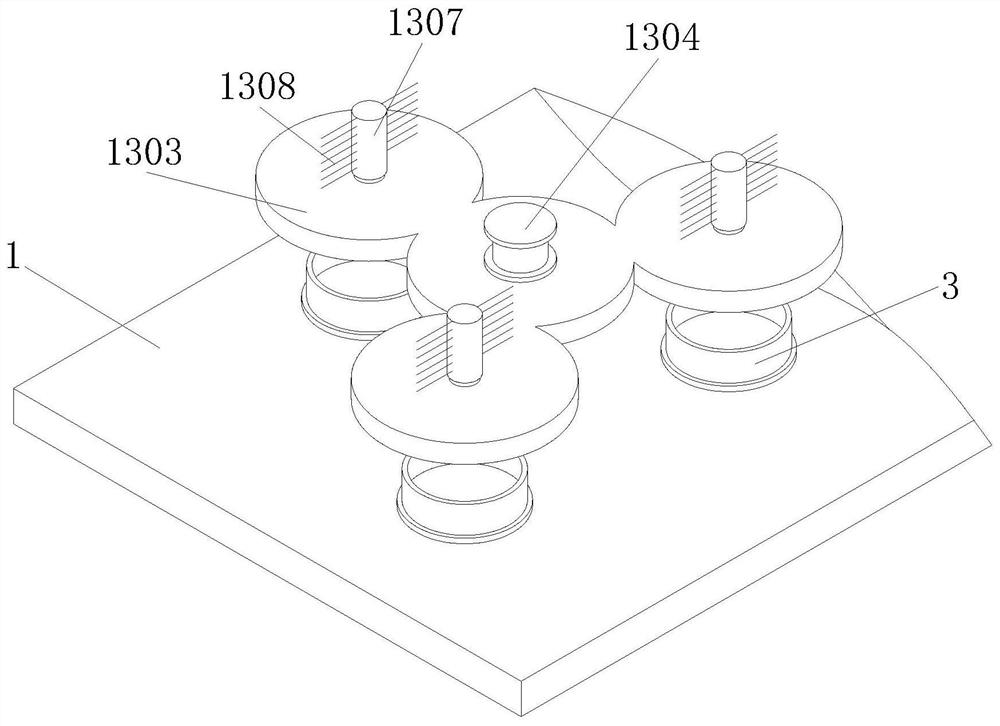

[0059] like Figure 2-Figure 13 As shown, it is a schematic diagram of the overall structure of a filterability detection device based on melt-blown cloth to produce anti-epidemic masks according to the present invention;

[0060]A filter detection device for producing anti-epidemic masks based on melt-blown cloth, including a fixed base 1, on which a control device 2 and a cleaning component 13 are installed, and the cleaning component 13 can ensure the subsequent cleaning of the test base 3 and the fixed cylinder 9 stability and convenience, the top surface of the fixed base 1 is welded and fixed with a test base 3, the inner bolt of the test base 3 is equipped with a first differential pressure sensor 4, and the fixed base 1 is equipped with an aerosol generator 14, an aerosol generator 14 is installed with a cascade striker 5, the top of the cascade striker 5 is welded and fixed with a small hydraulic cylinder 6, the output end of the small hydraulic cylinder 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com