Patents

Literature

32 results about "Cascade impactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

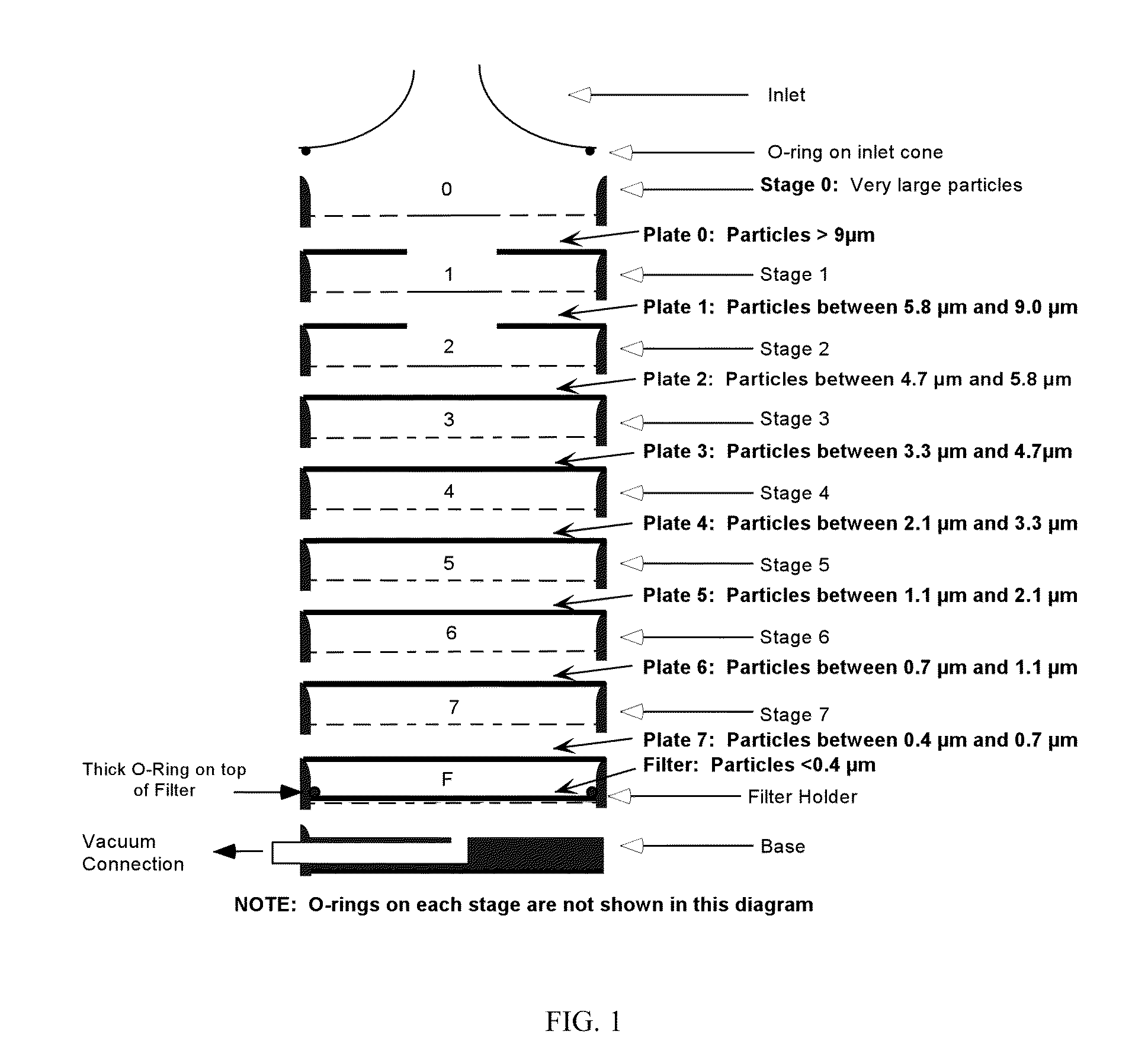

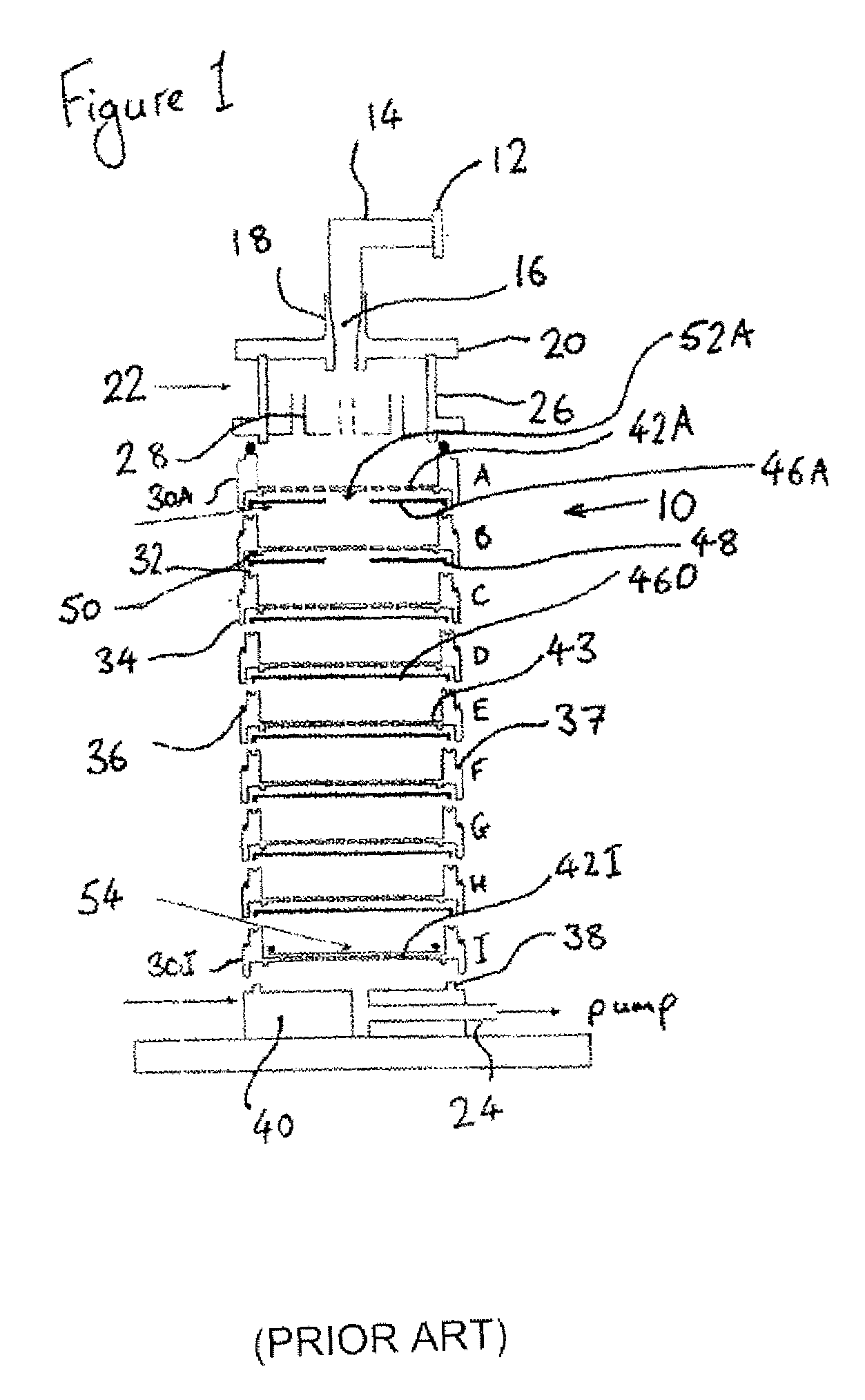

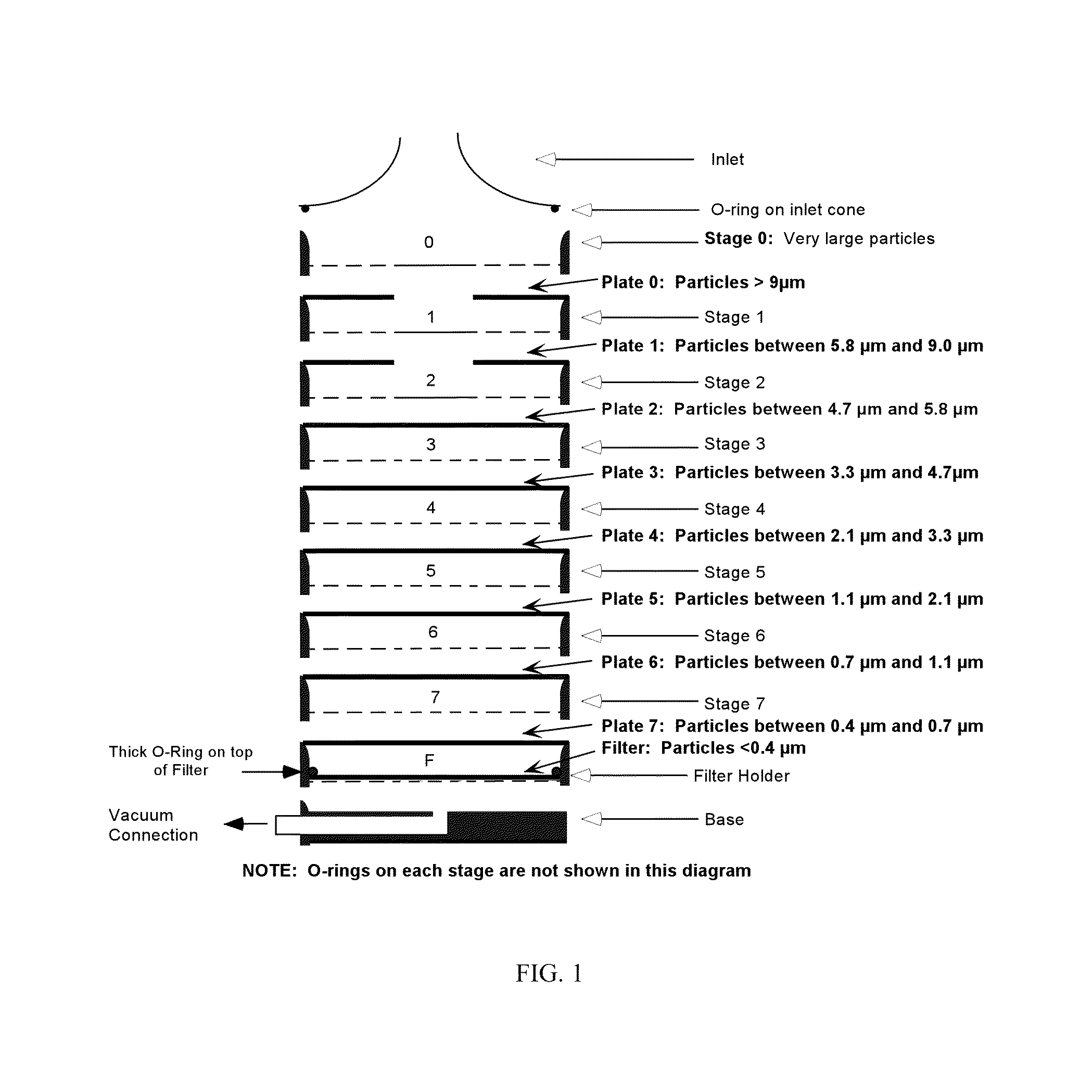

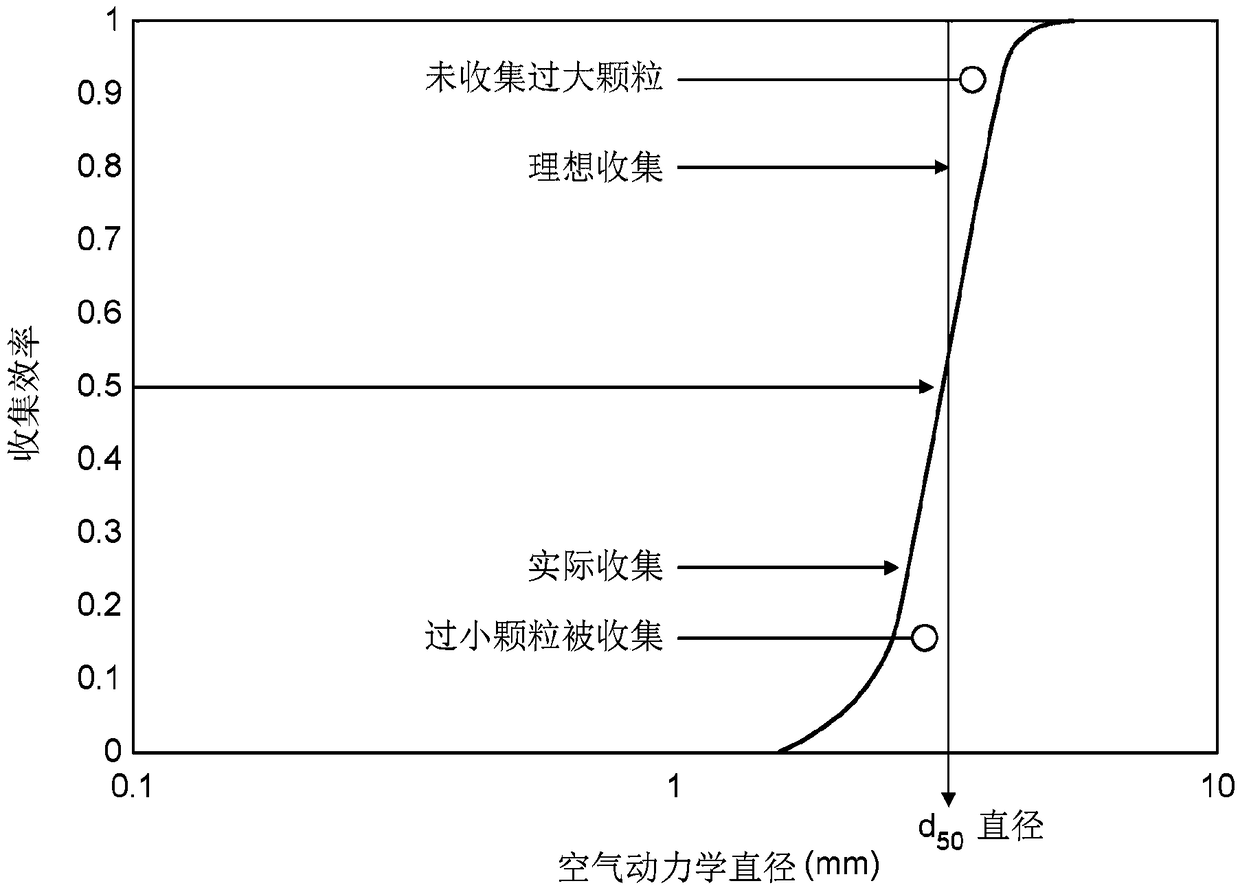

A cascade impactor measures the reach range of a particulate substance as it moves through an opening with the use of aerosol. Cascade impactors are strictly measurement-related devices. In addition to measuring the range of substances moved through an opening by aerosol, the impactor can also be used to determine the particle size of the distributed substance. A cascade impactor collects its samples in a graduated manner. This allows the user to identify the sizes of the substance particles as the particles are distributed from the propellant aerosol source.When the aerosol substance is distributed into the cascade impactor, the substance enters a series of discs designed to collect solids and different particulate matter. The substance is thus collected as it passes through the disc series. Each disc is set in sequence with both the prior and the previous disc. The size of the discs is graduated as well, to properly determine the size of the particulate matter at each stage of the impactor.

Maskless direct write of copper using an annular aerosol jet

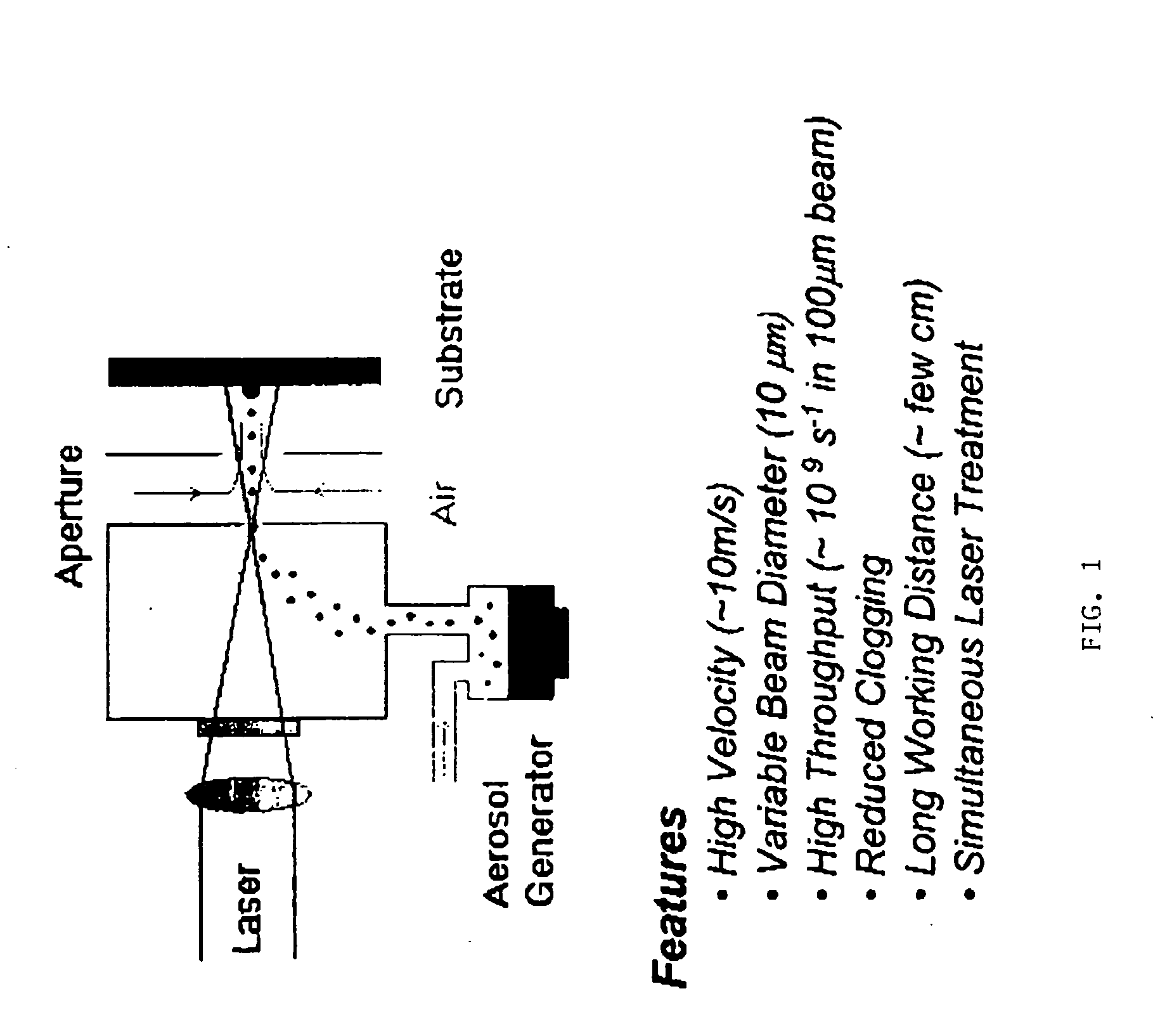

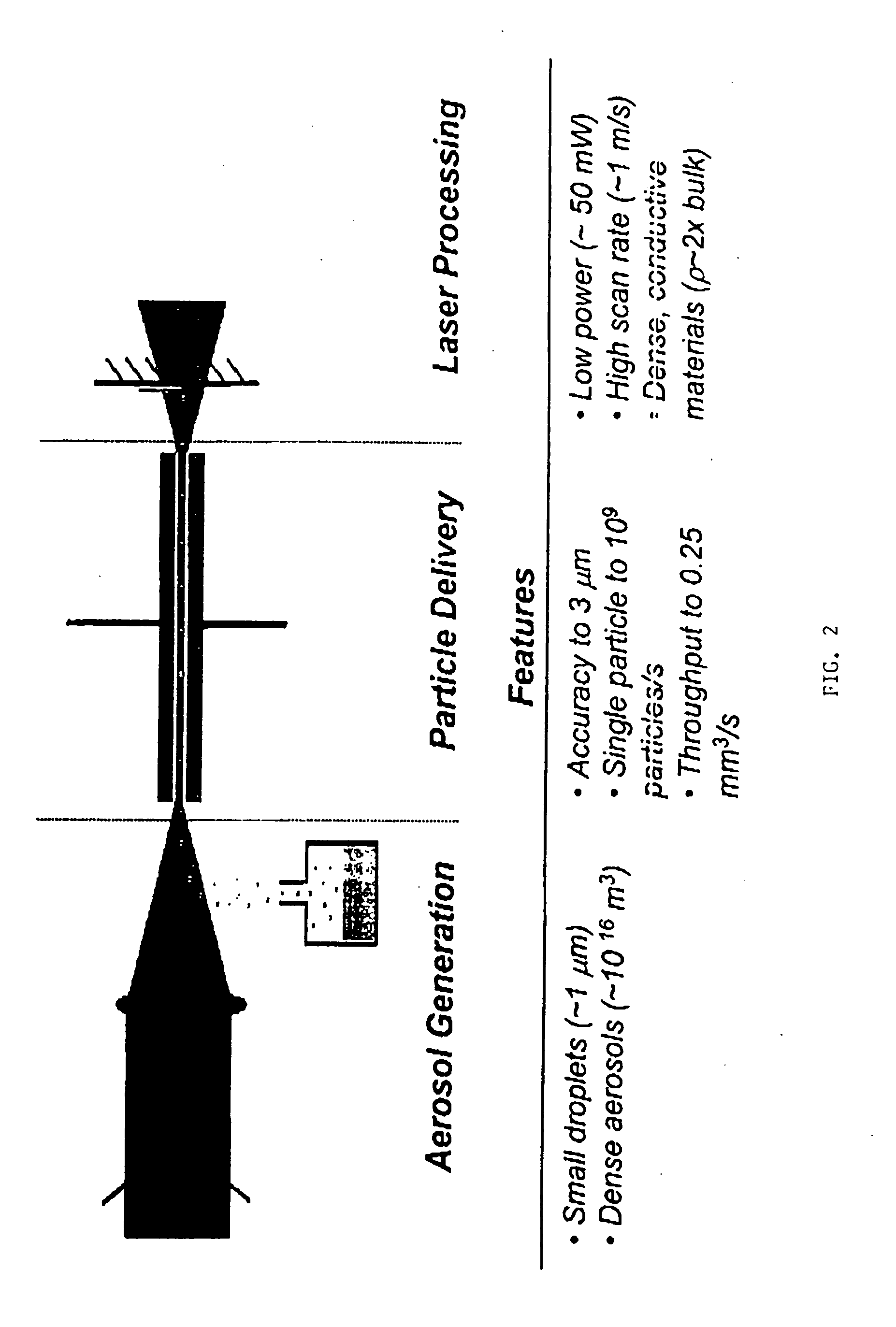

InactiveUS20050156991A1Prevent crystallizationLower decomposition temperatureSolid-state devicesLiquid/solution decomposition chemical coatingLaser processingSource material

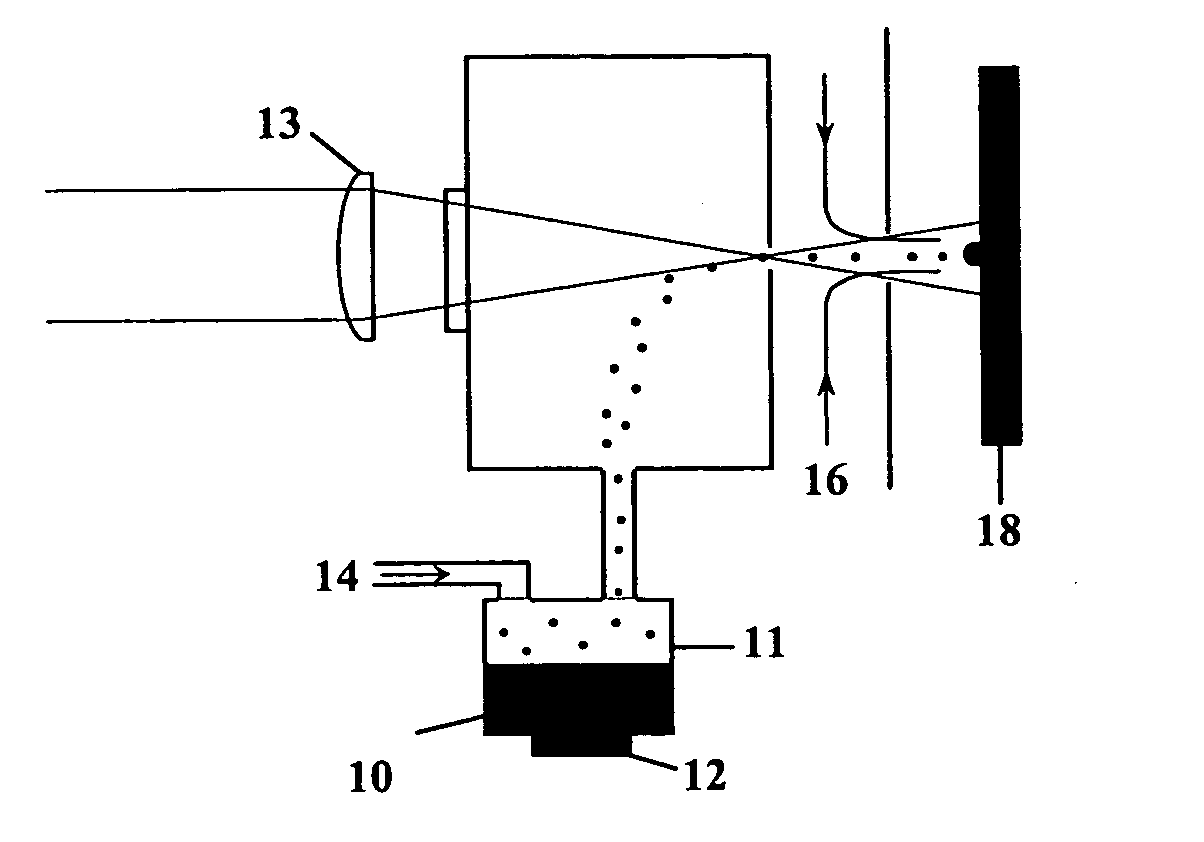

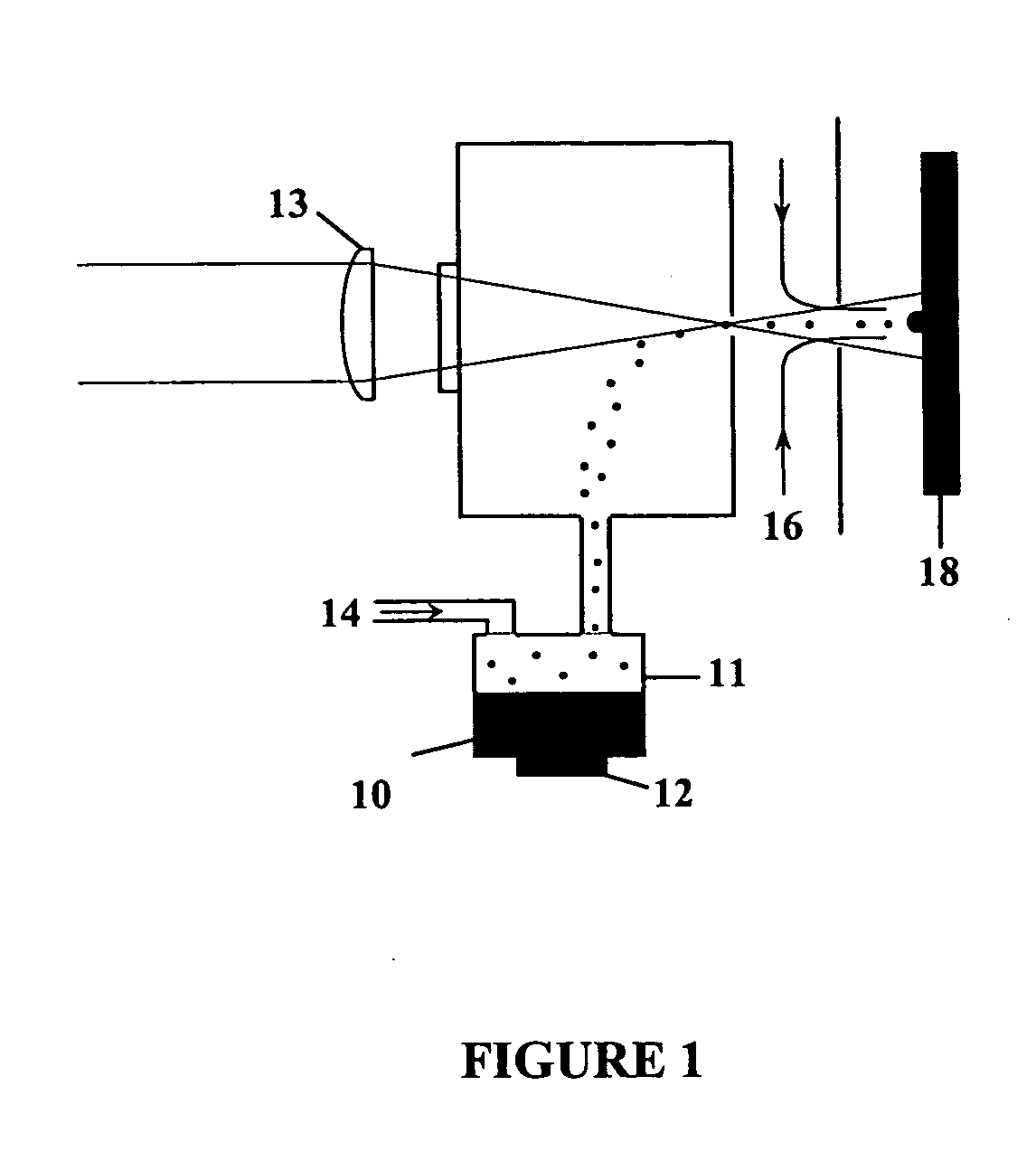

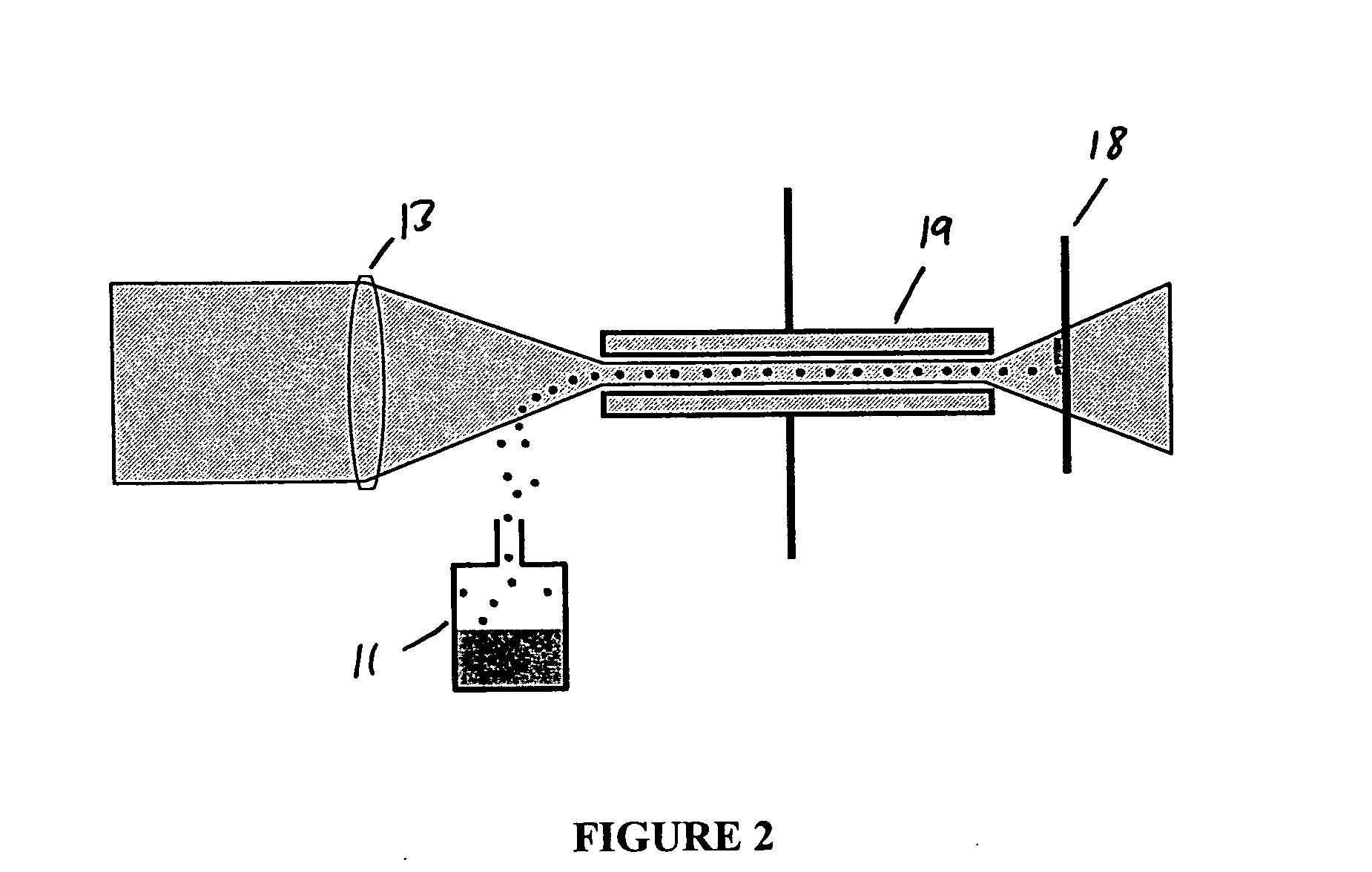

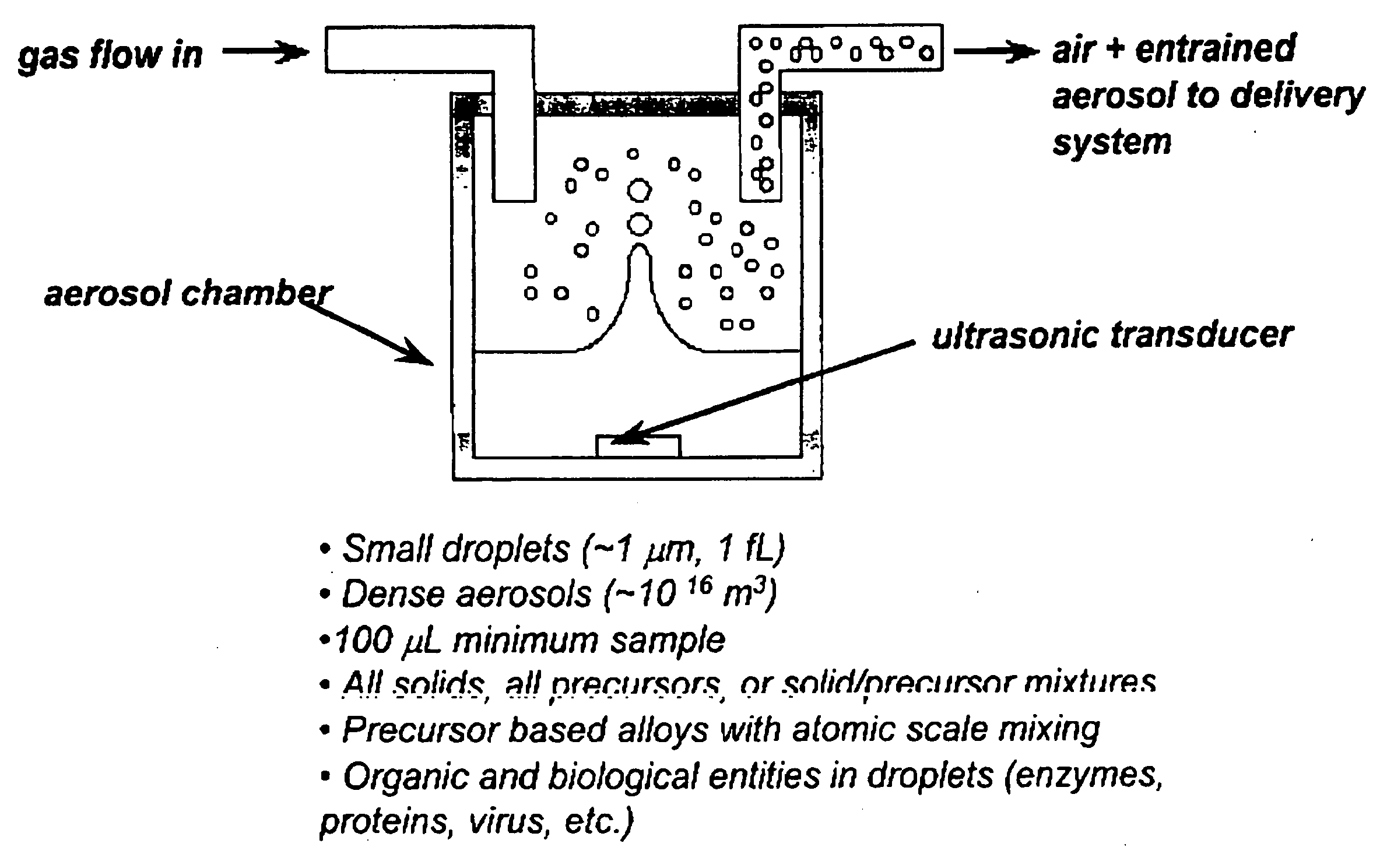

Methods and apparatus for the deposition of a source material (10) are disclosed. An atomizer (12) renders a supply of source material (10) into many discrete particles. A force applicator (14) propels the particles in continuous, parallel streams of discrete particles. A collimator (16) controls the direction of flight of the particles in the stream prior to their deposition on a substrate (18). In an alternative embodiment of the invention, the viscosity of the particles may be controlled to enable complex depositions of non-conformal or three-dimensional surfaces. The invention also includes a wide variety of substrate treatments which may occur before, during or after deposition. In yet another embodiment of the invention, a virtual or cascade impactor may be employed to remove selected particles from the deposition stream. Also a method and apparatus for maskless deposition of copper lines on a target, specifically relating to localized solution-based deposition of copper using an annular aerosol jet and subsequent material processing using conventional thermal techniques or laser processing.

Owner:OPTOMEC DESIGN CO

Direct writeTM system

InactiveUS20050046664A1Increase depositionMolten spray coatingVacuum evaporation coatingSource materialCascade impactor

Methods and apparatus for the deposition of a source material (10) are disclosed. An atomizer (12) renders a supply of source material (10) into many discrete particles. A force applicator (14) propels the particles in continuous, parallel streams of discrete particles. A collimator (16) controls the direction of flight of the particles in the stream prior to their deposition on a substrate (18). In an alternative embodiment of the invention, the viscosity of the particles may be controlled to enable complex depositions of non-conformal or three-dimensional surfaces. The invention also includes a wide variety of substrate treatments which may occur before, during or after deposition. In yet another embodiment of the invention, a virtual or cascade impactor may be employed to remove selected particles from the deposition stream.

Owner:OPTOMEC DESIGN CO

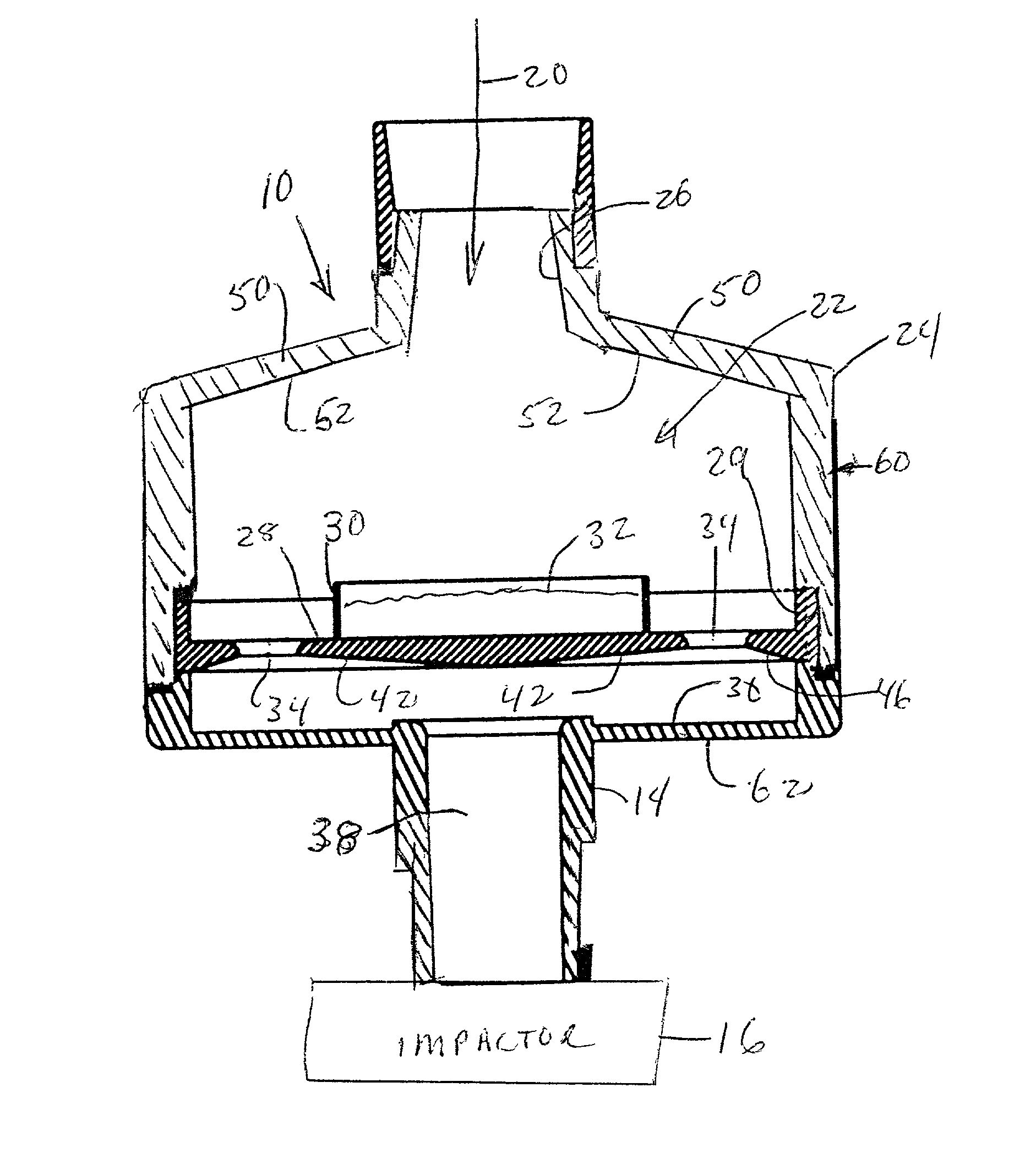

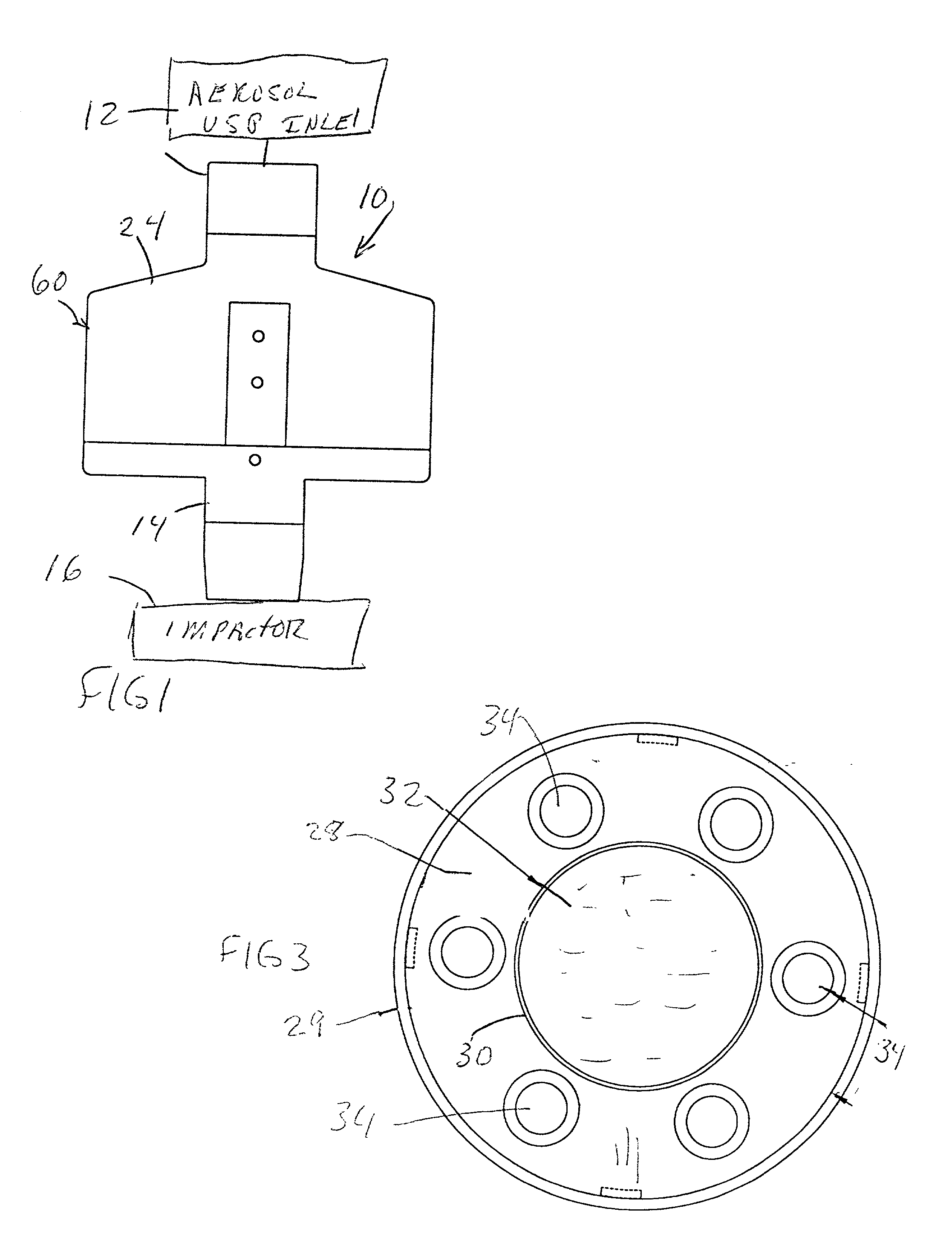

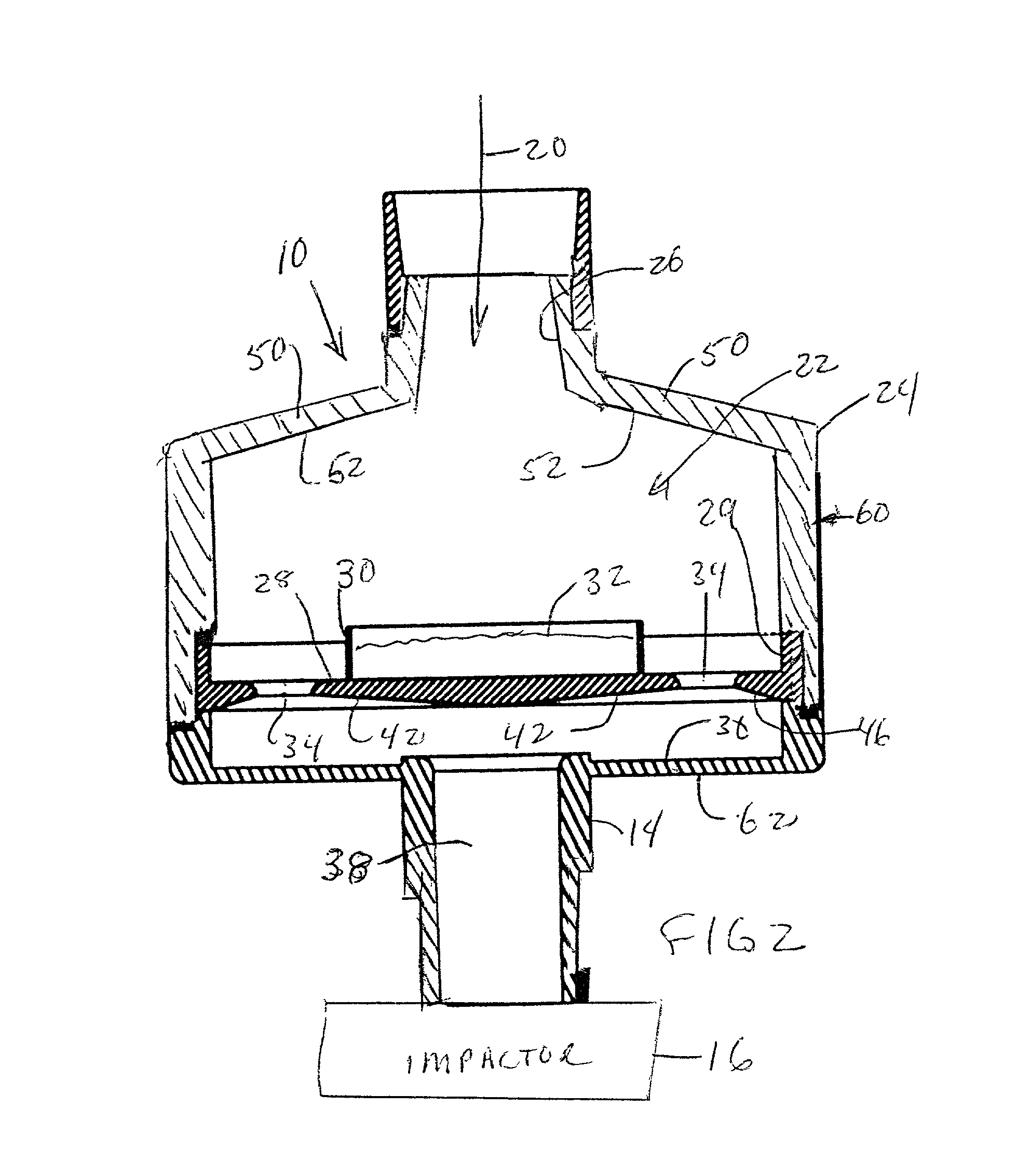

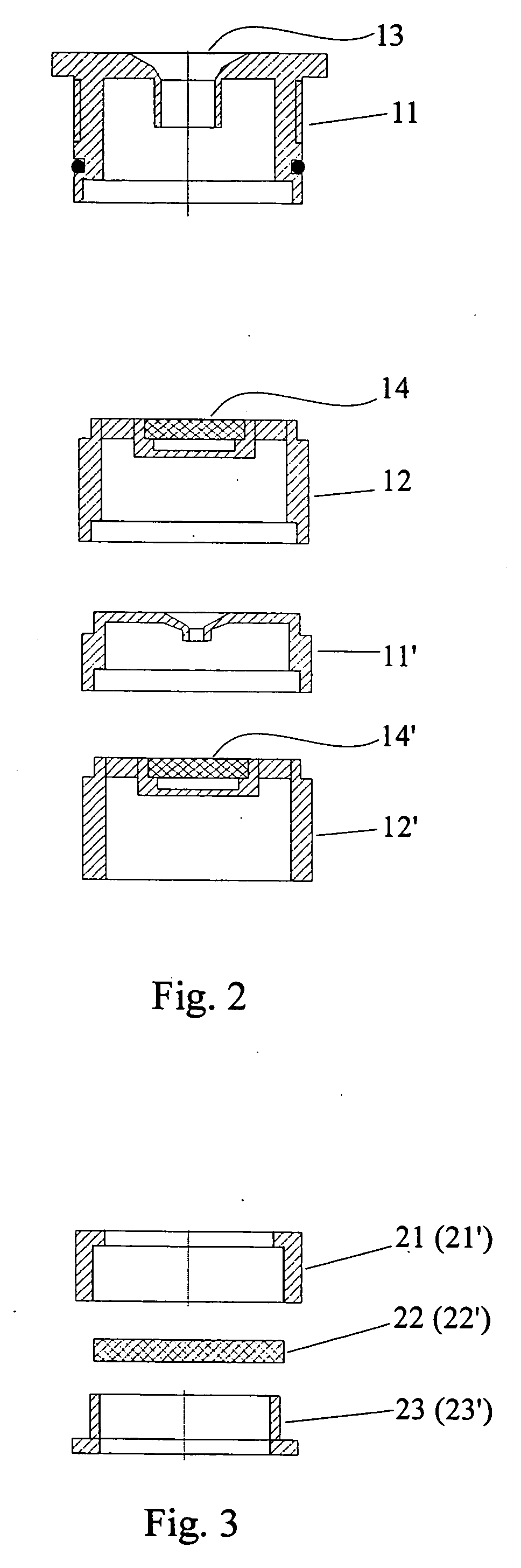

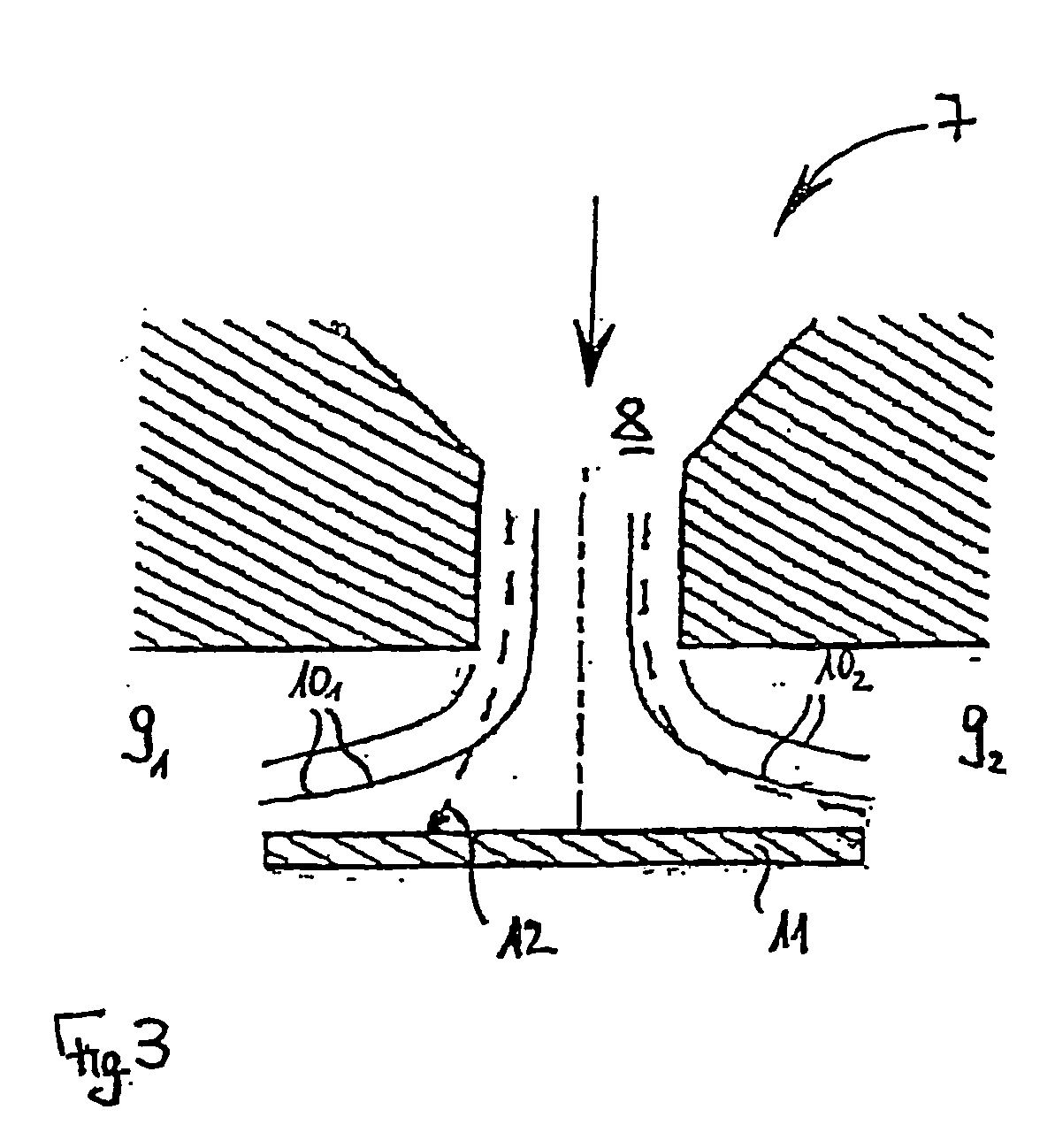

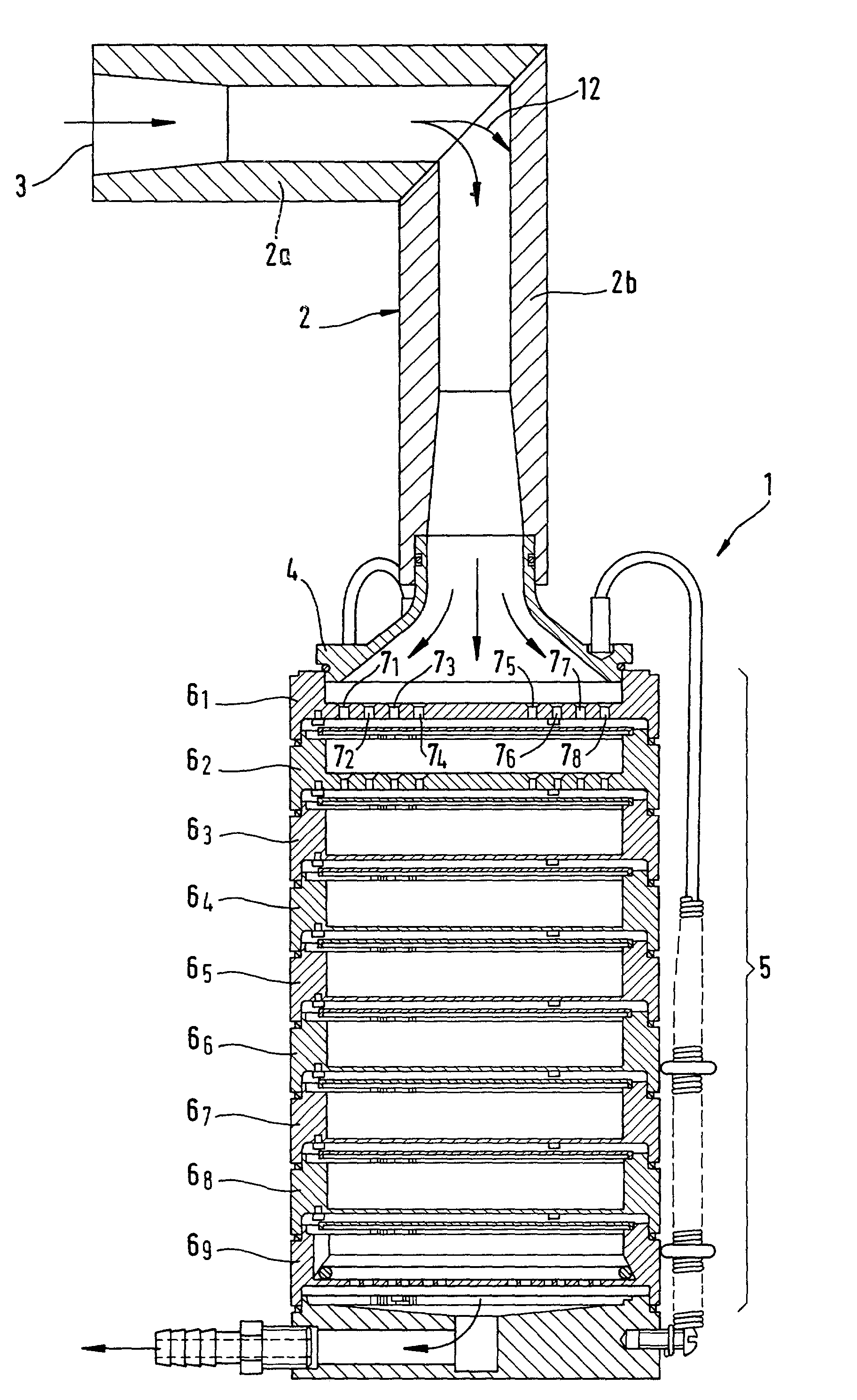

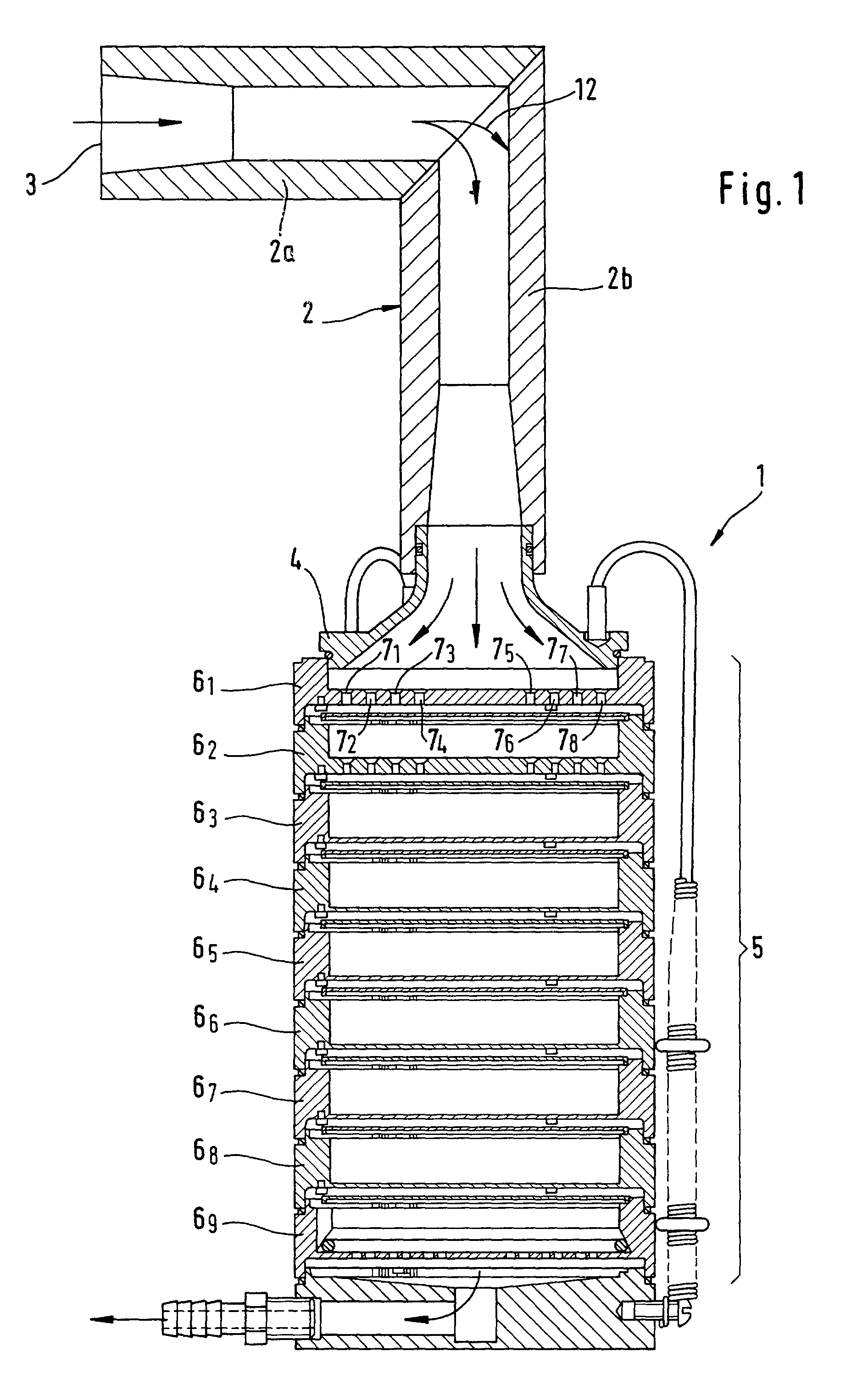

Cascade Impactor

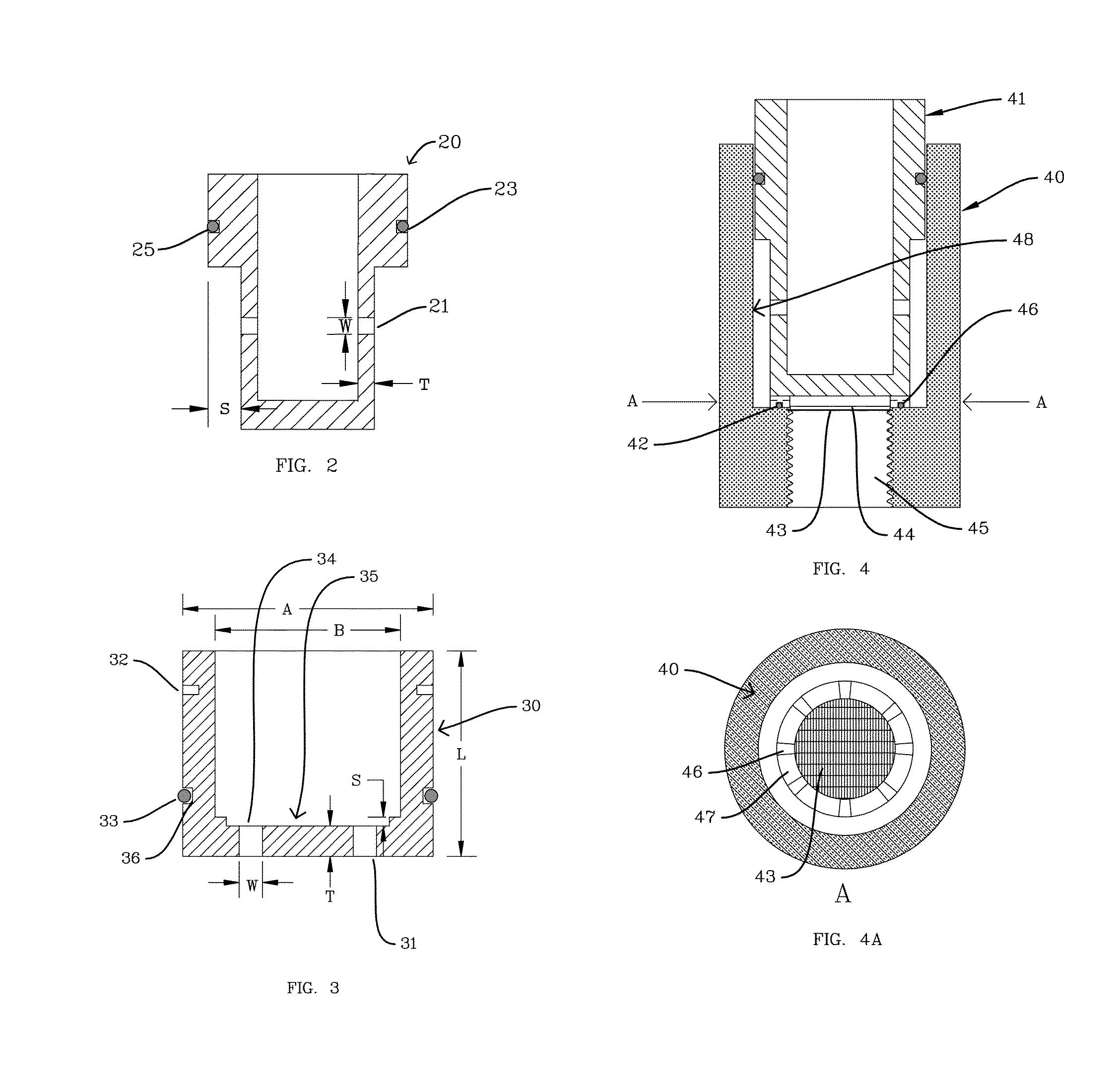

InactiveUS20100288057A1Improve collection efficiencyFew applicationCombination devicesDispersed particle filtrationVena contracta diameterInspiratory flow

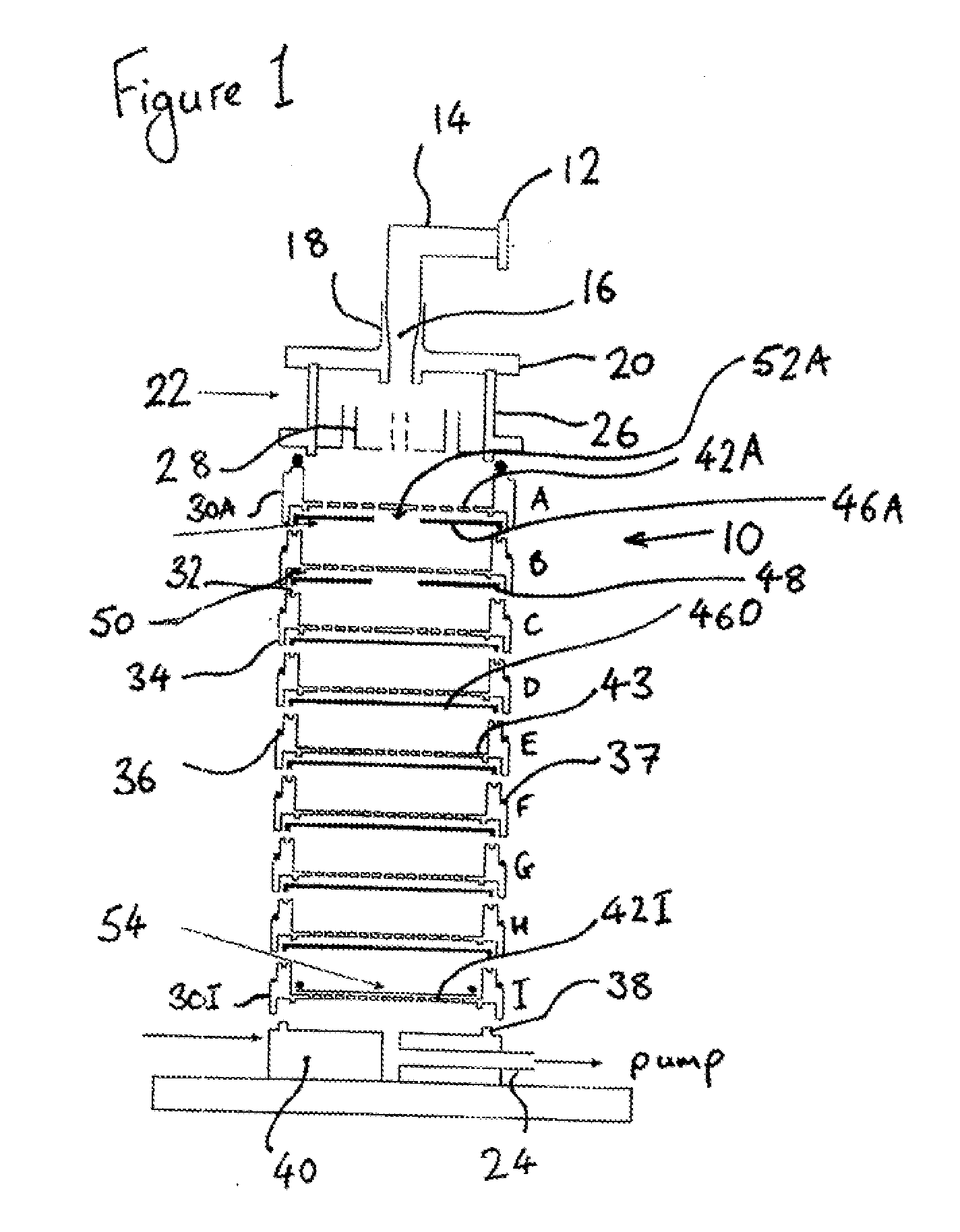

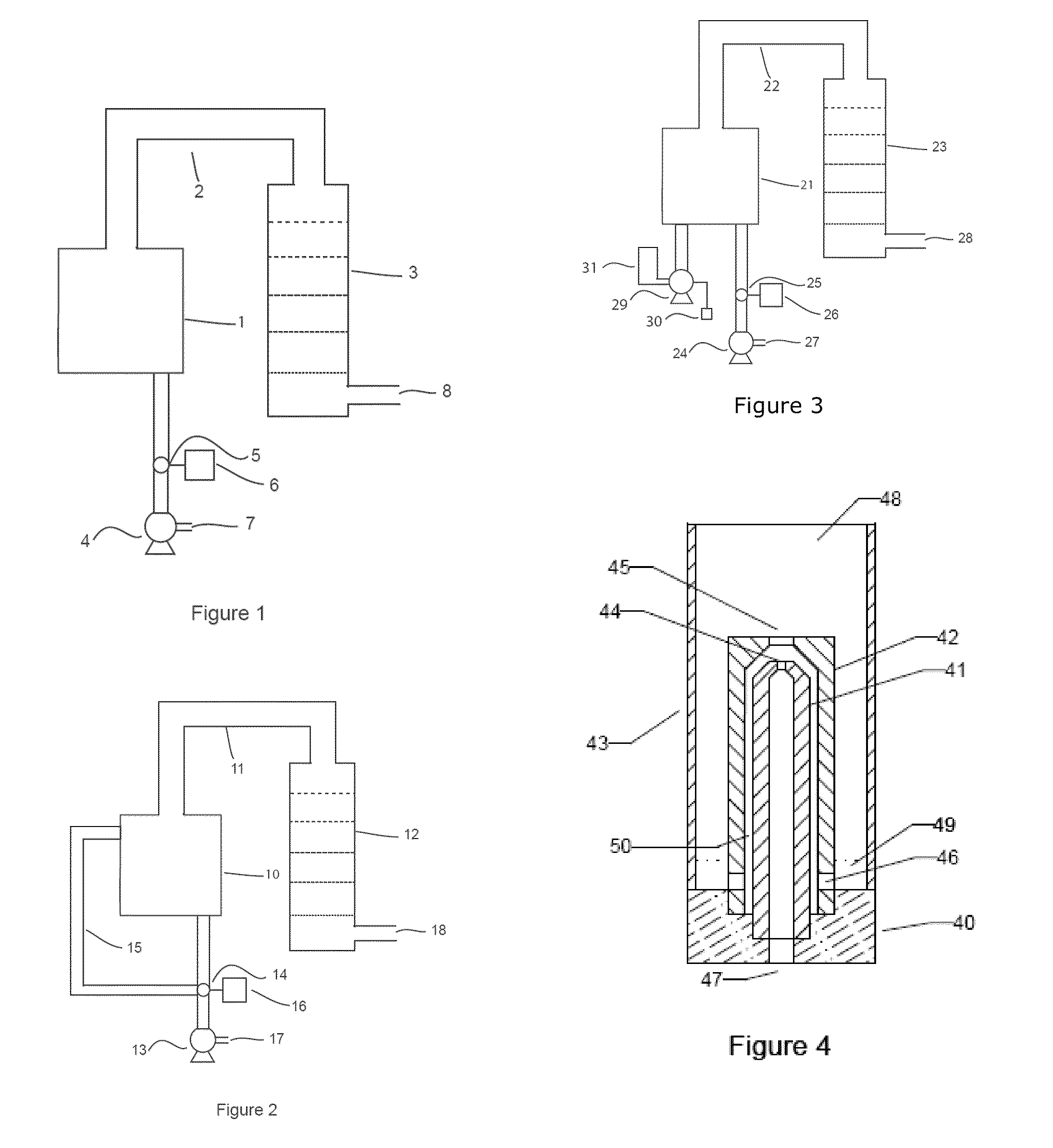

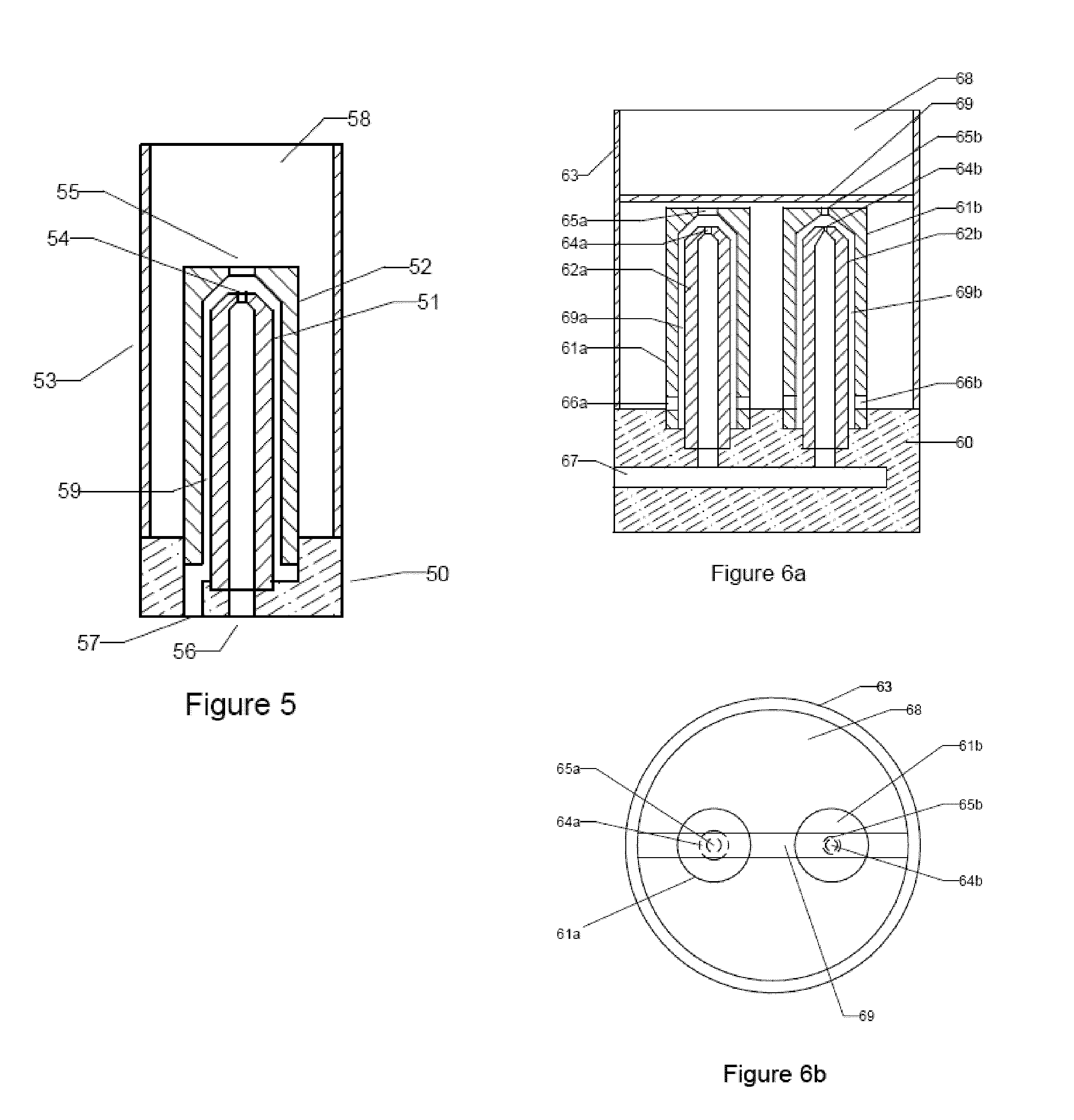

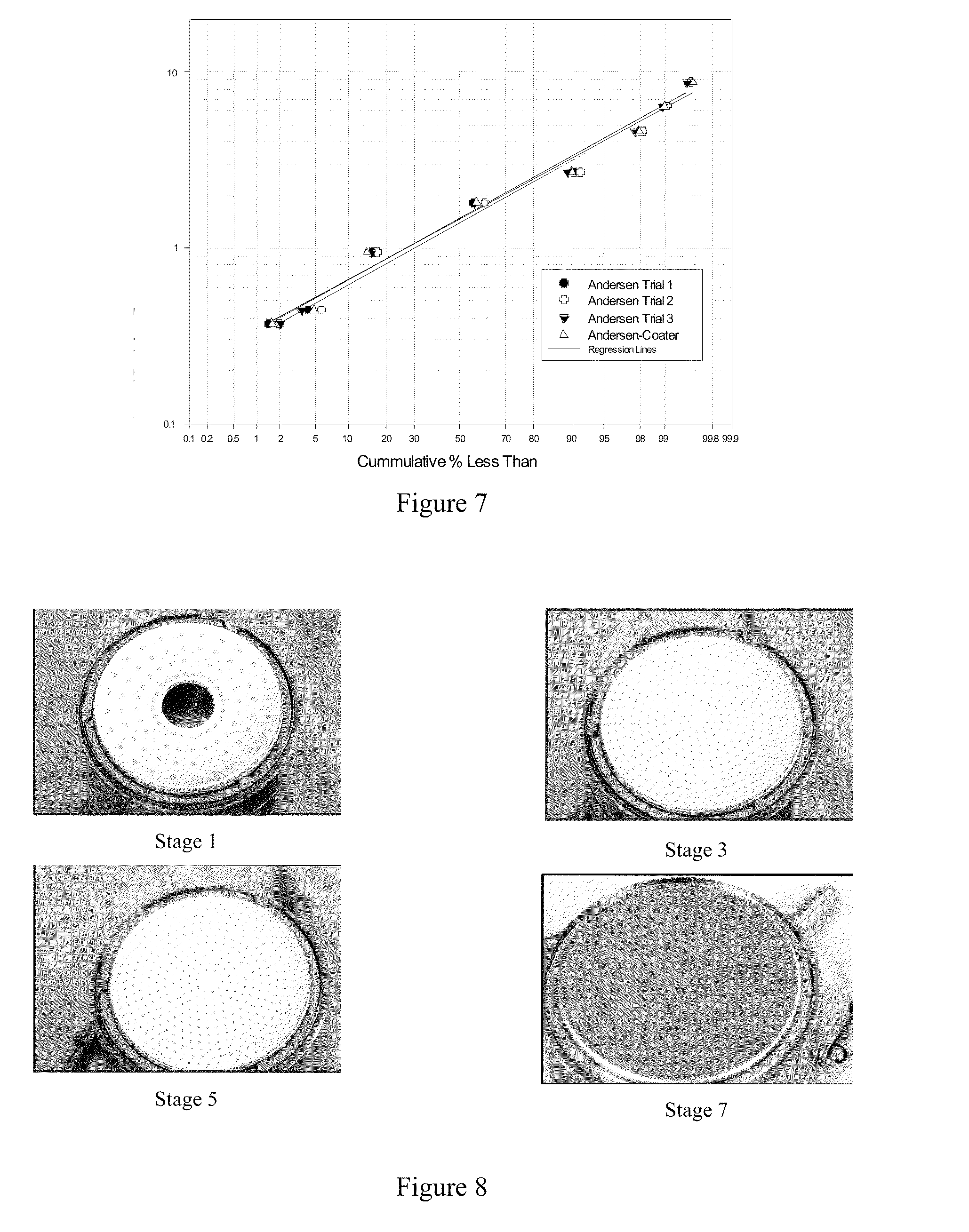

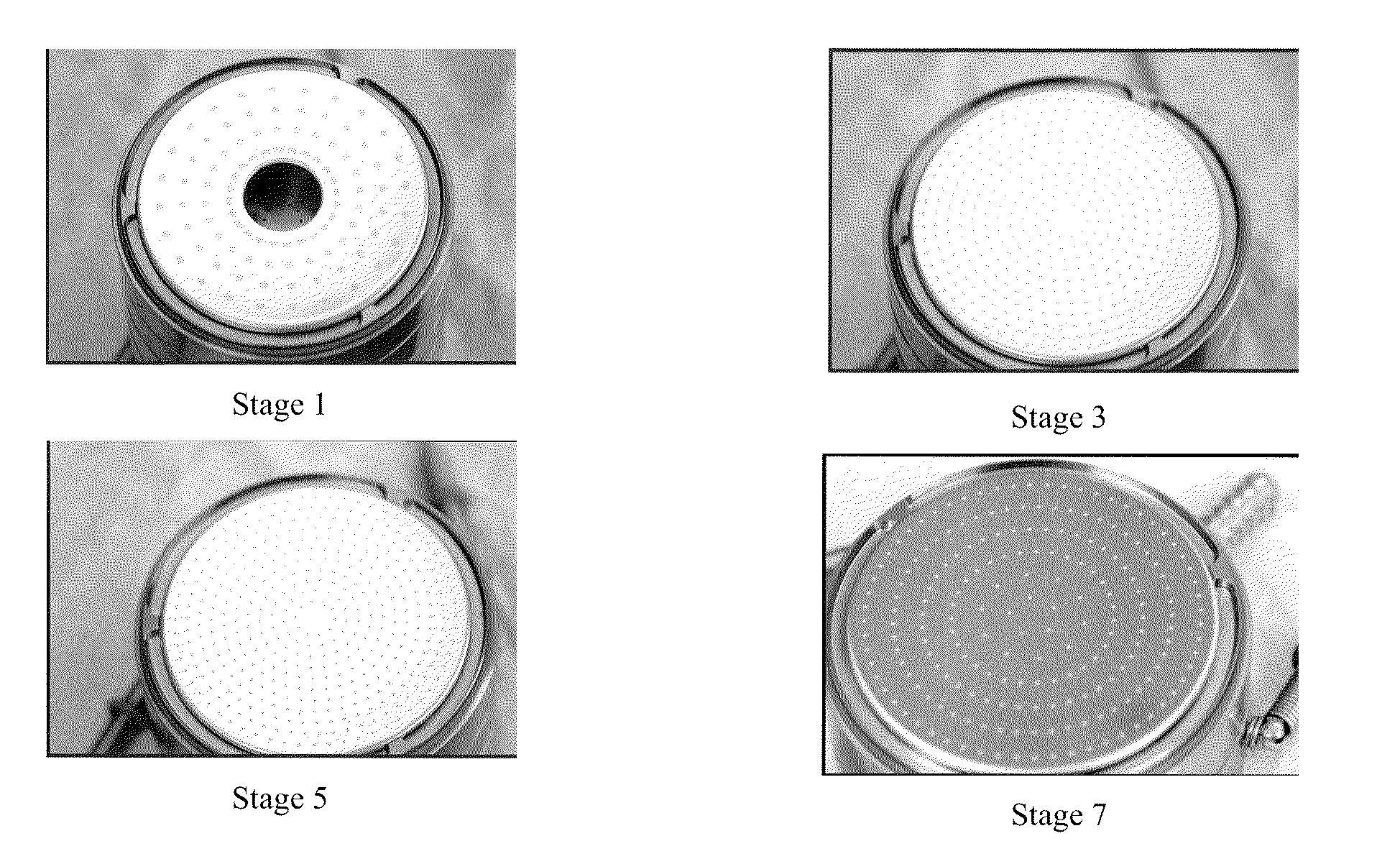

The invention relates to low flow rate cascade impactors for sampling aerosols, notably but not limited to pharmaceutical aerosols. The impactor stages serve as both orifice plate and collecting cup, simplifying collection and analysis. The impactor is designed to operate at flow rates approximating the inspiratory flow rates of young children and infants. Also presented is a method of and apparatus for applying a coating material to the collection surface of the stages after an impactor is assembled for use. The method entails generation of a polydisperse aerosol and sampling into the impactor. The coating substance improves the trapping of particles on the stages. The apparatus and method of application limit the amount of coating material applied and confines it to the regions of particle impact opposite the stage orifices.

Owner:WITHAM CLYDE L

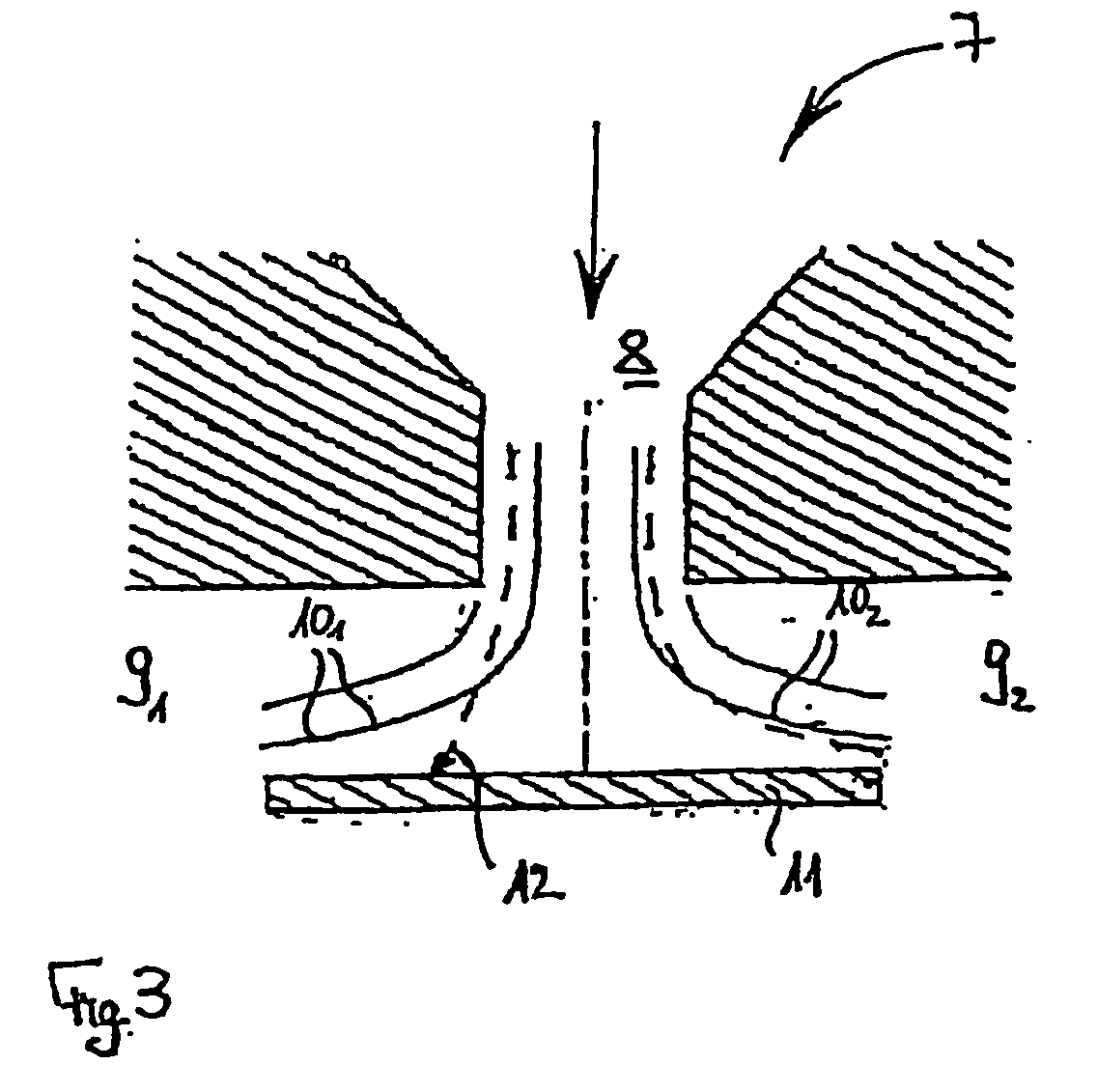

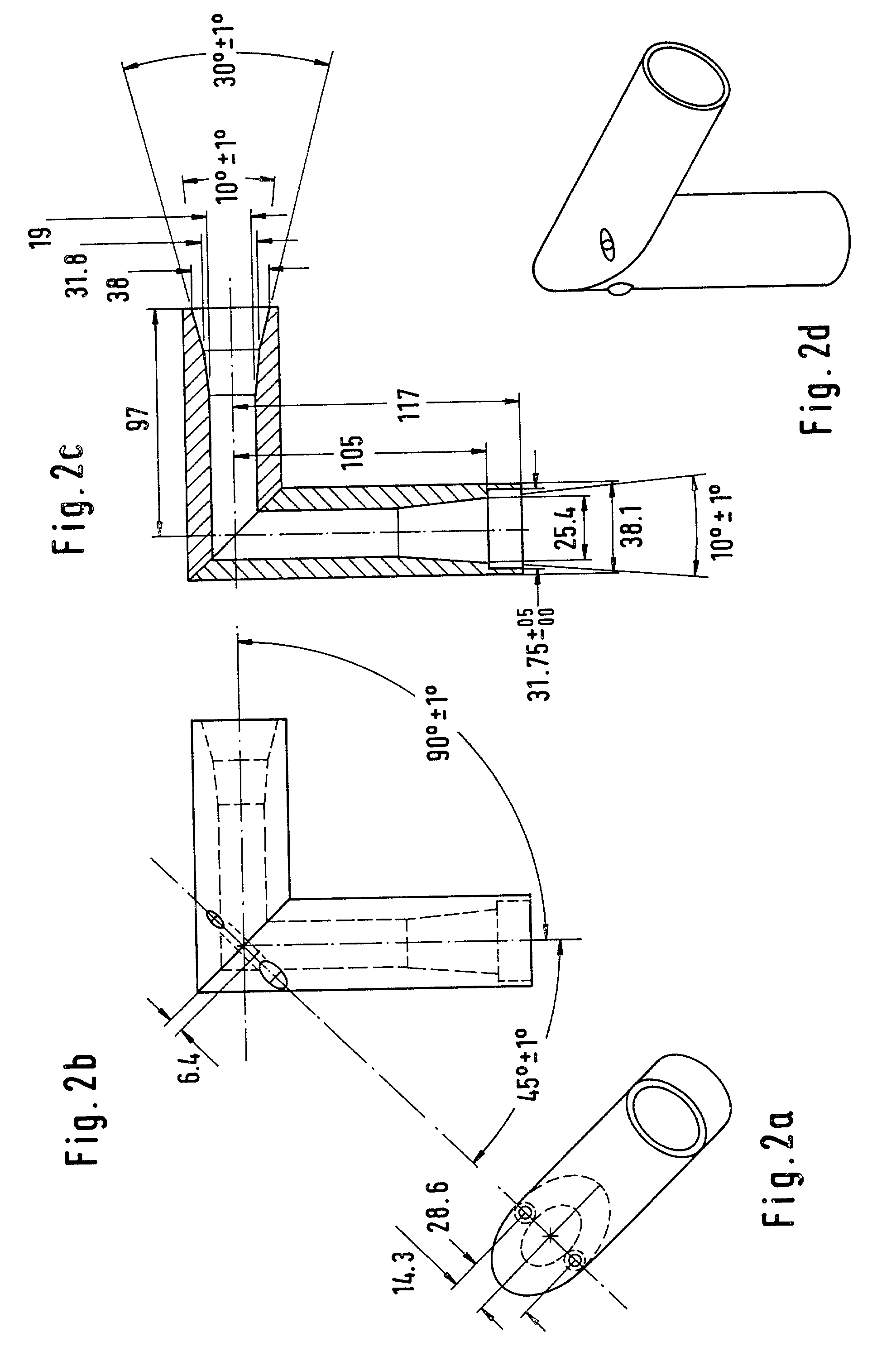

Pre-separator for inlets of cascade impactors

InactiveUS20020070148A1Wider flow rate rangeLow viscosityGas current separationDispersed particle separationCascade impactorEngineering

A pre-separator for separating out large particles from a fluid flow has a housing forming an interior chamber with an inlet and an outlet, and a separator plate in the chamber between the inlet and outlet. The separator plate has a surface facing the inlet that is provided with a liquid carrying tank into which the flow is directed when it enters the interior chamber through the inlet. The separator plate has a series of nozzle openings therethrough adjacent its periphery to the outside of the tank. The nozzle openings adjacent the periphery of the separator plate overlie a surface of the housing adjacent the outlet. The pre-separator thus has two impaction stages that permit use across a wide range of flows. The separator plate and the housing have surfaces which are tapered so that liquid in the housing can be drained out when the housing is inverted.

Owner:MSP

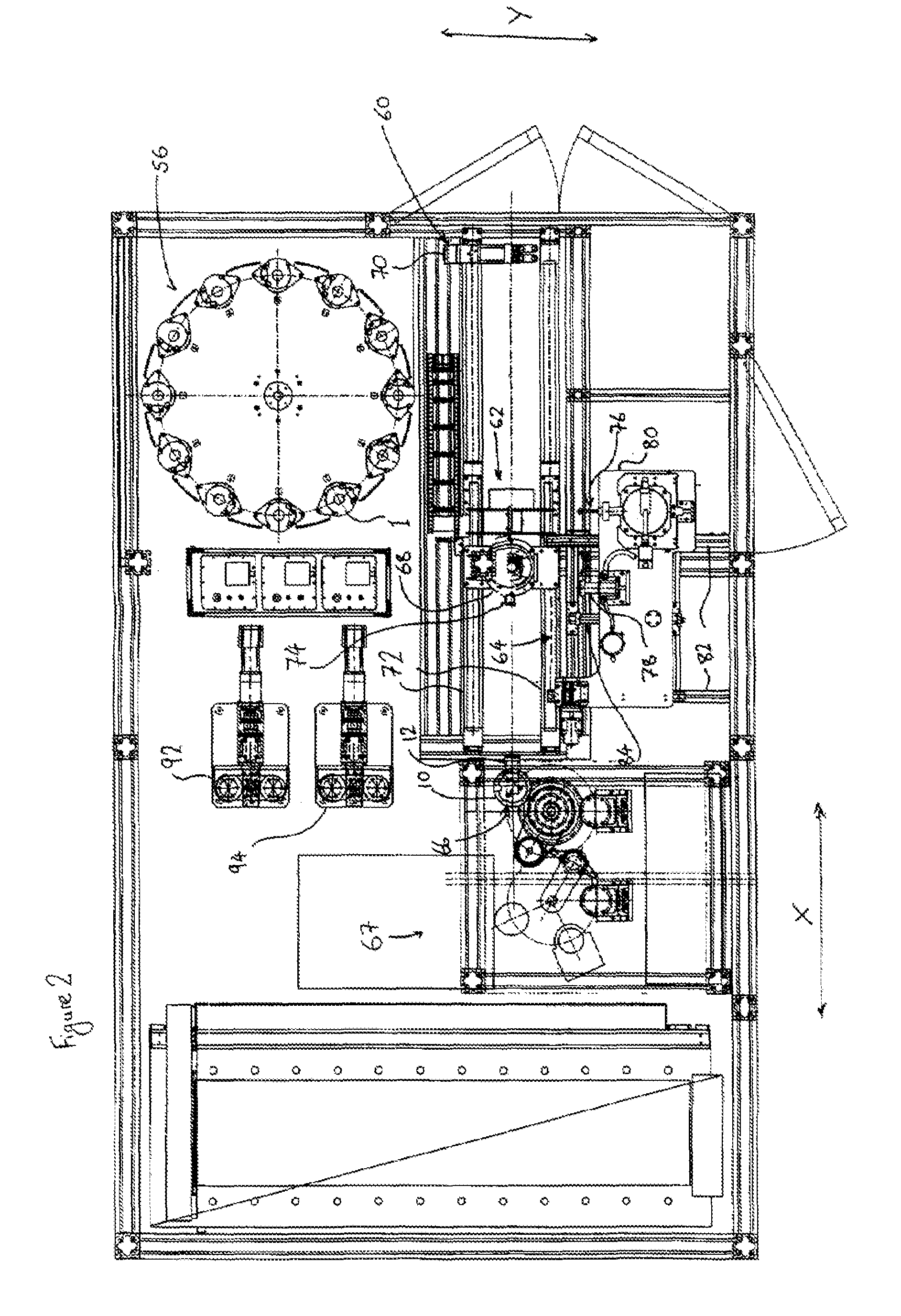

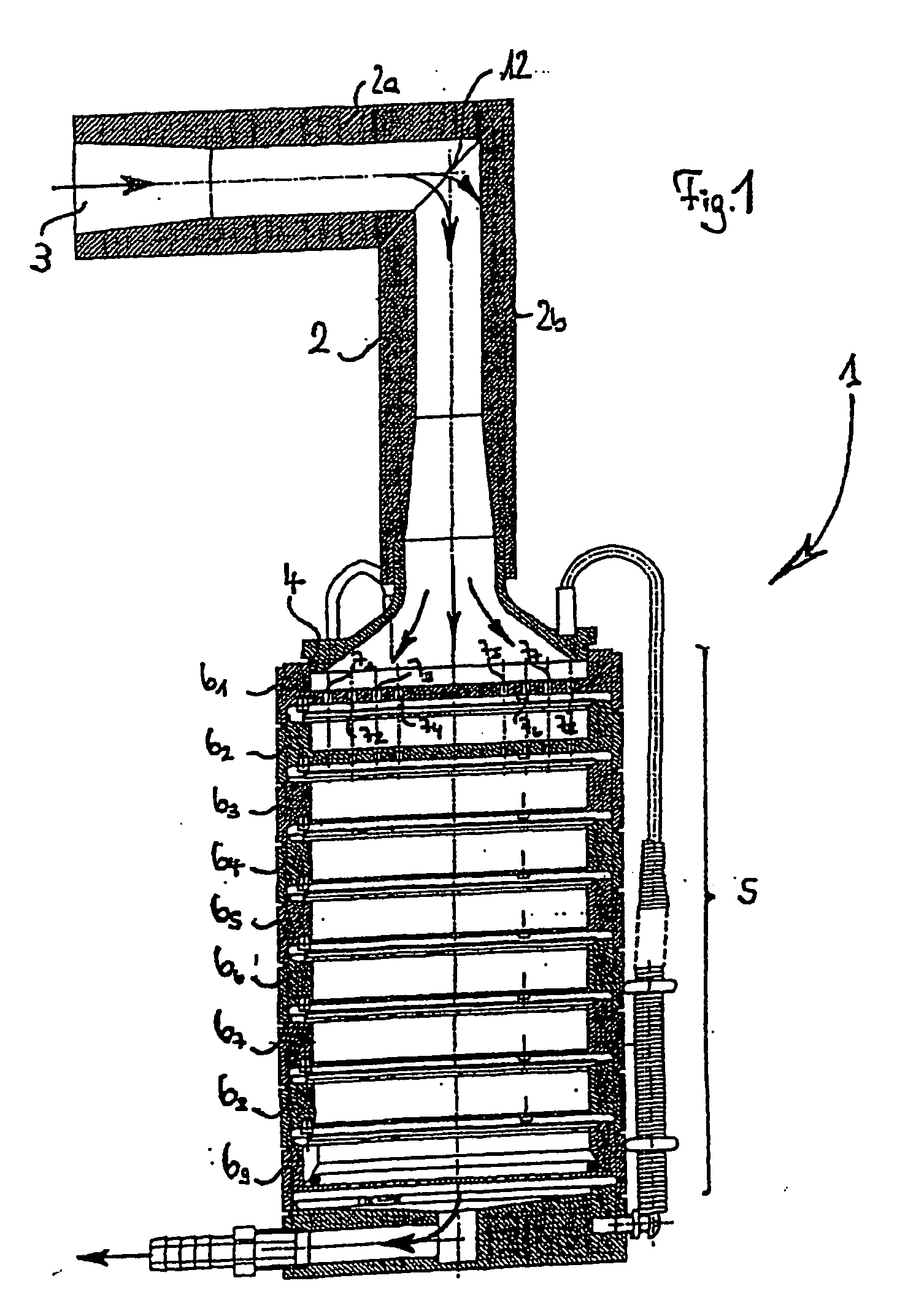

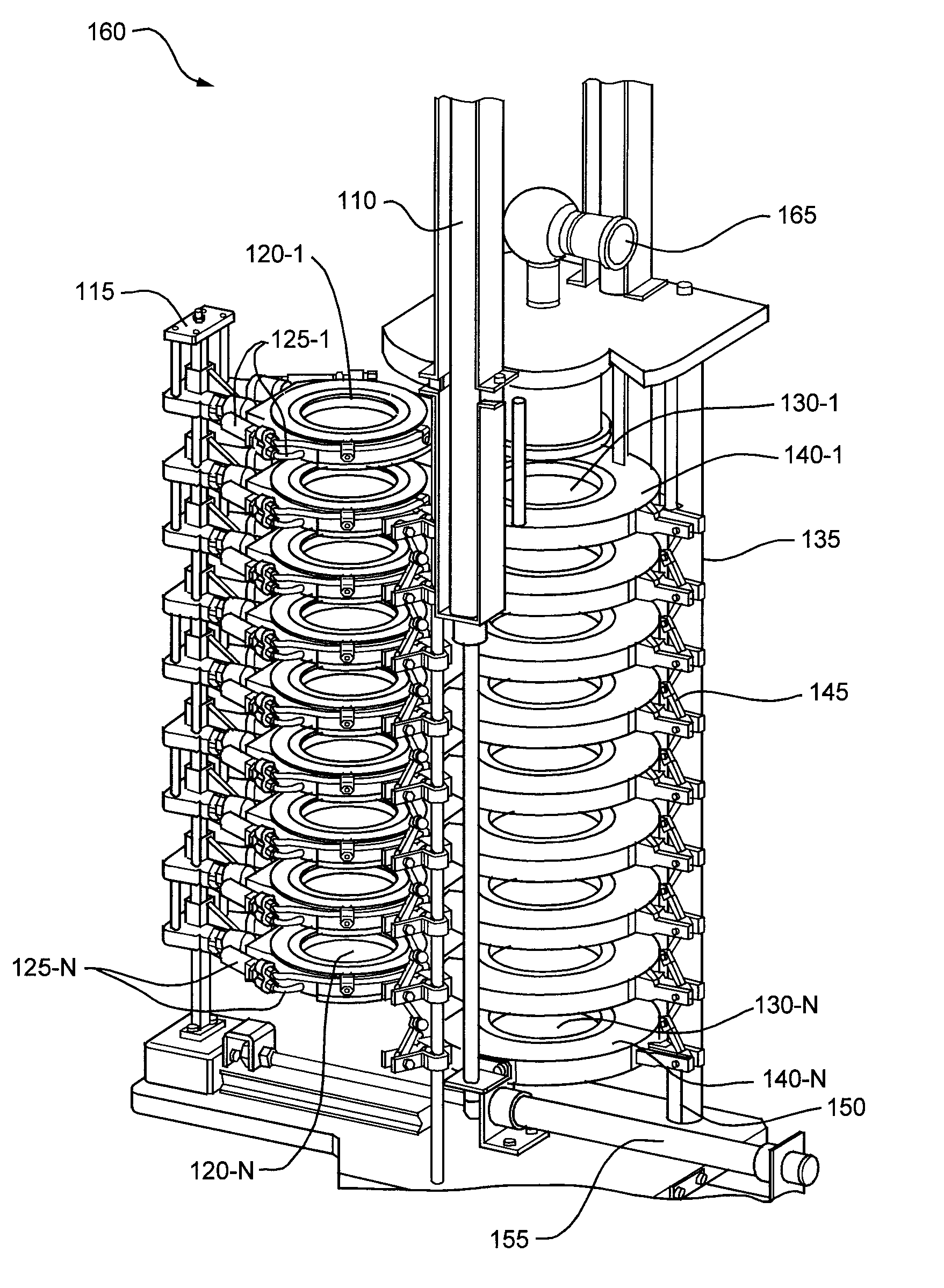

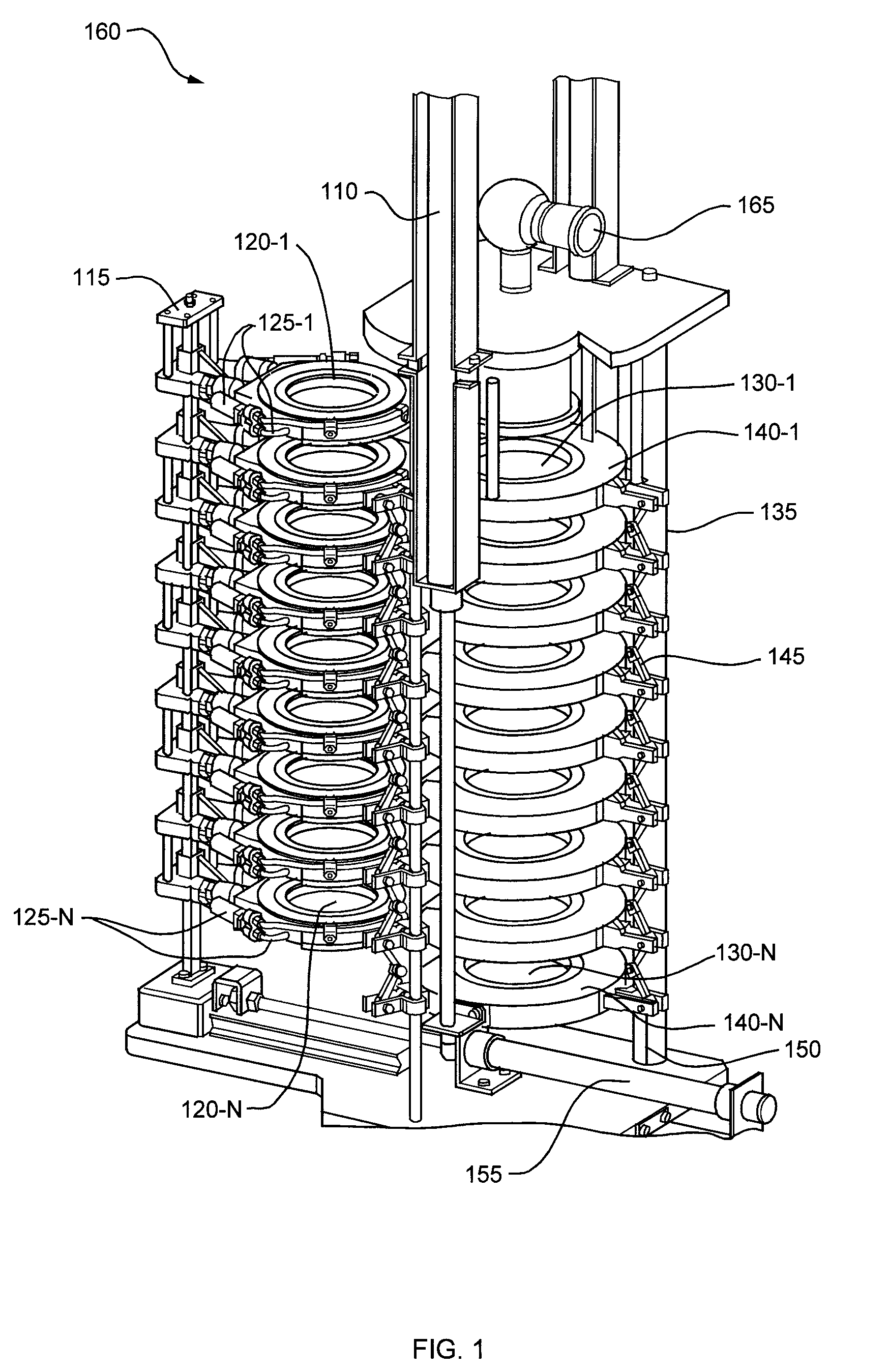

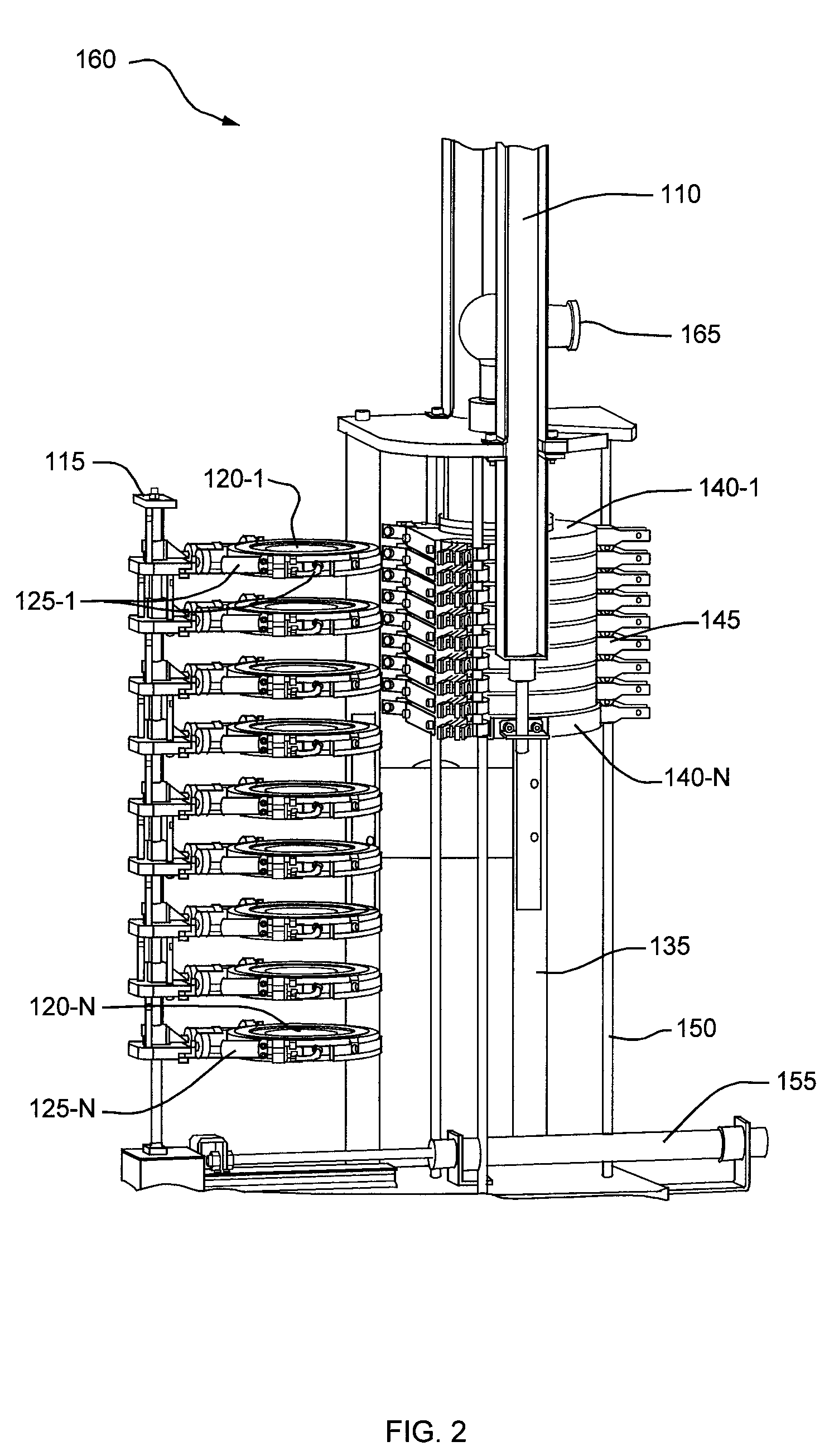

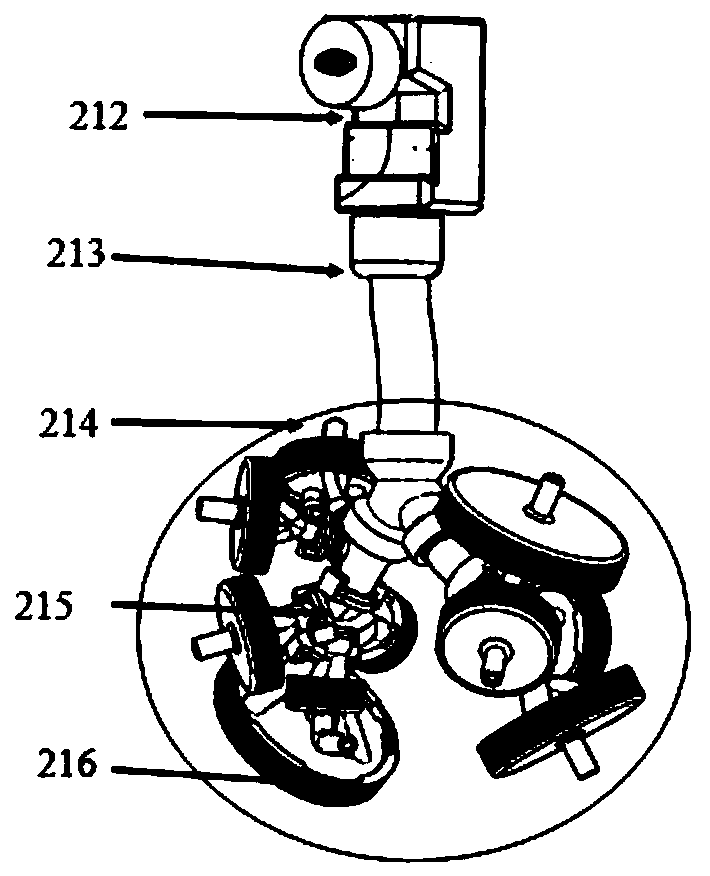

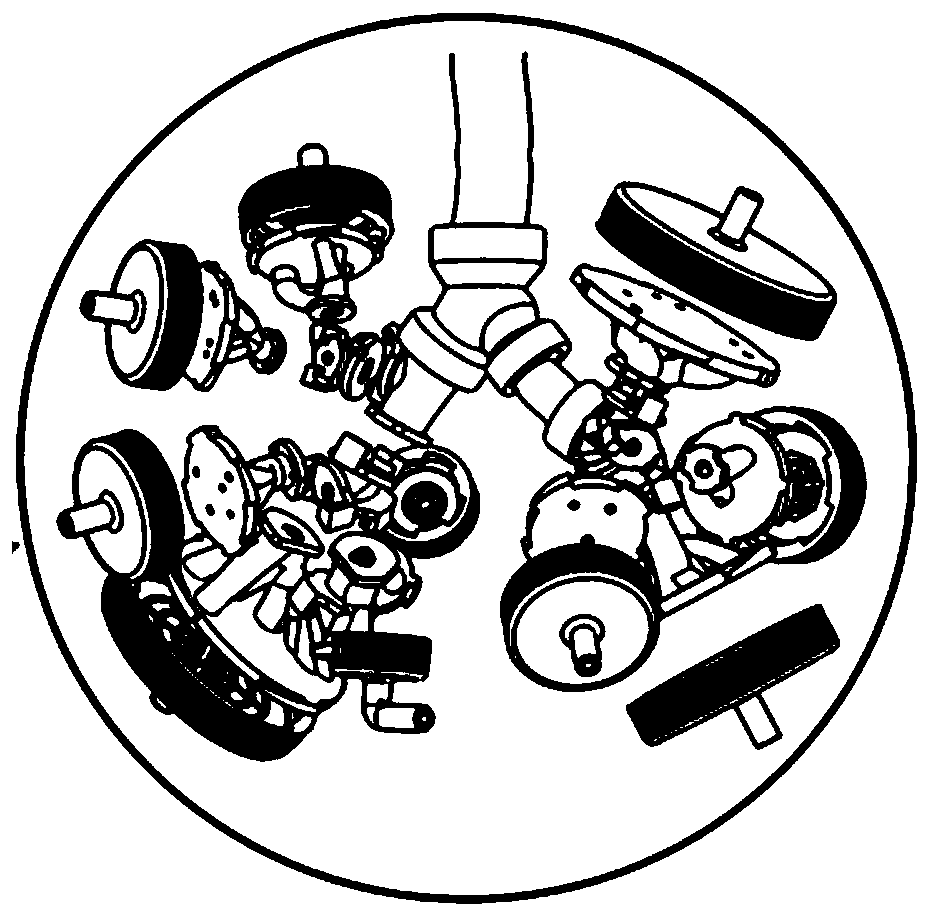

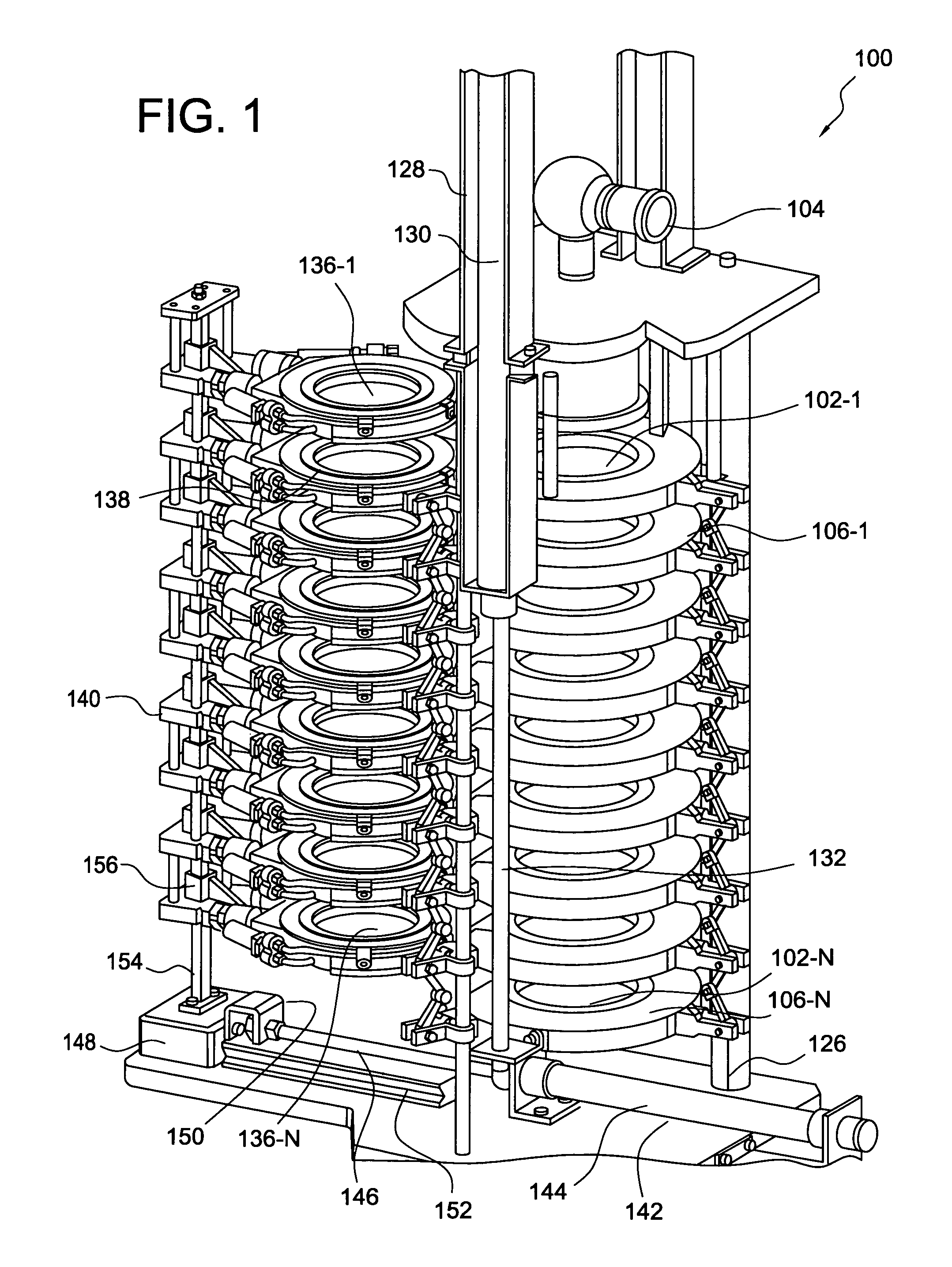

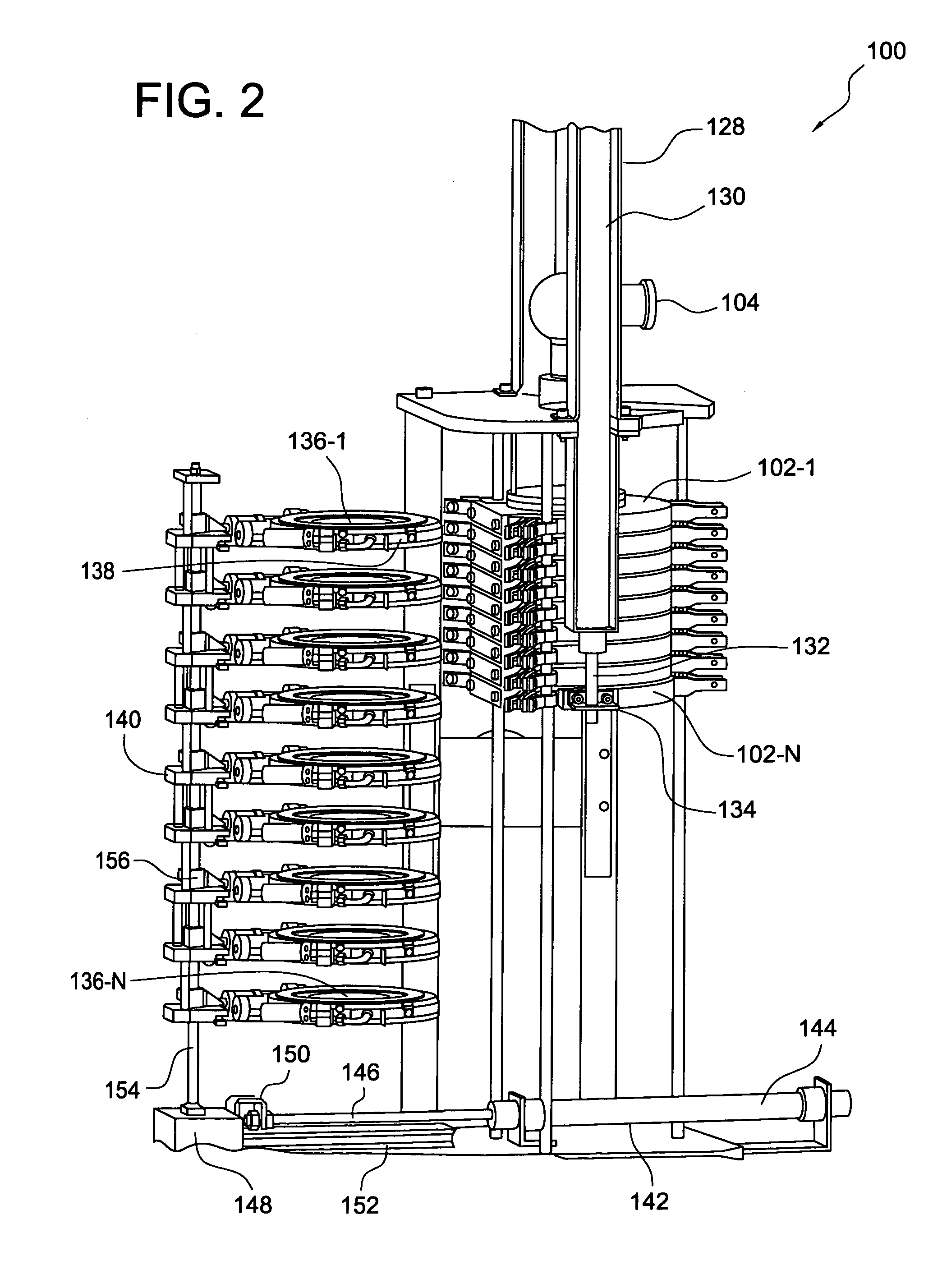

Impactor automation

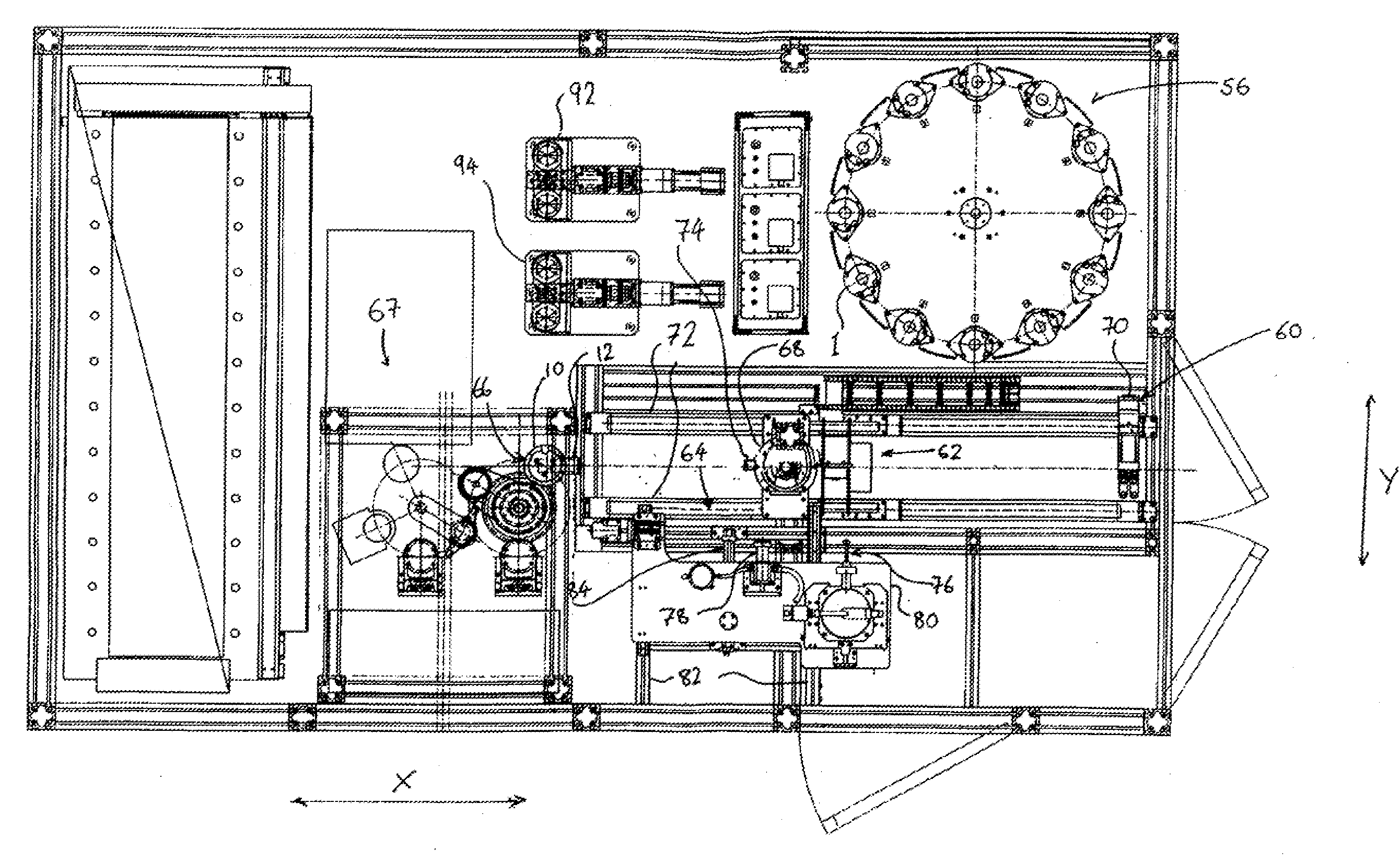

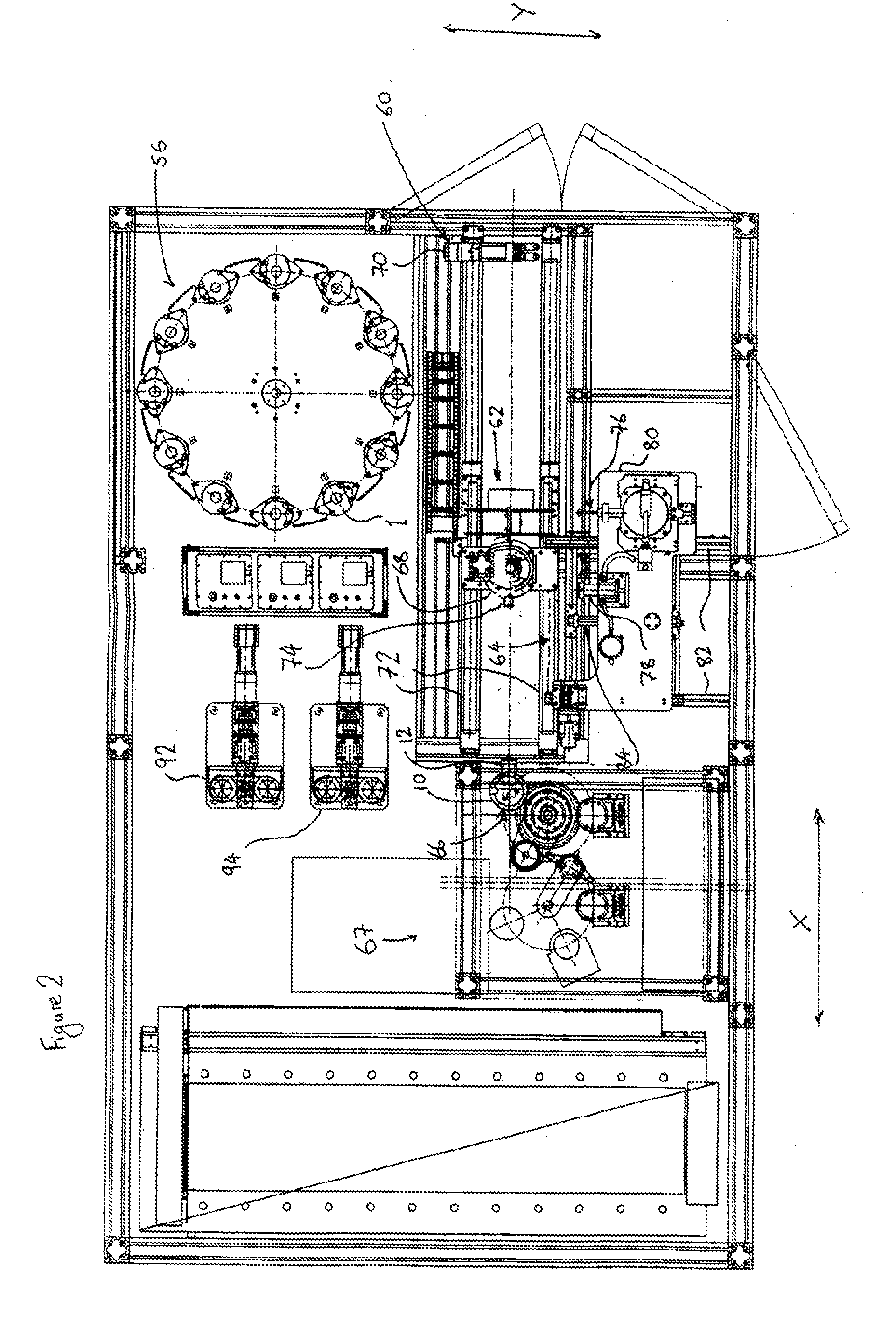

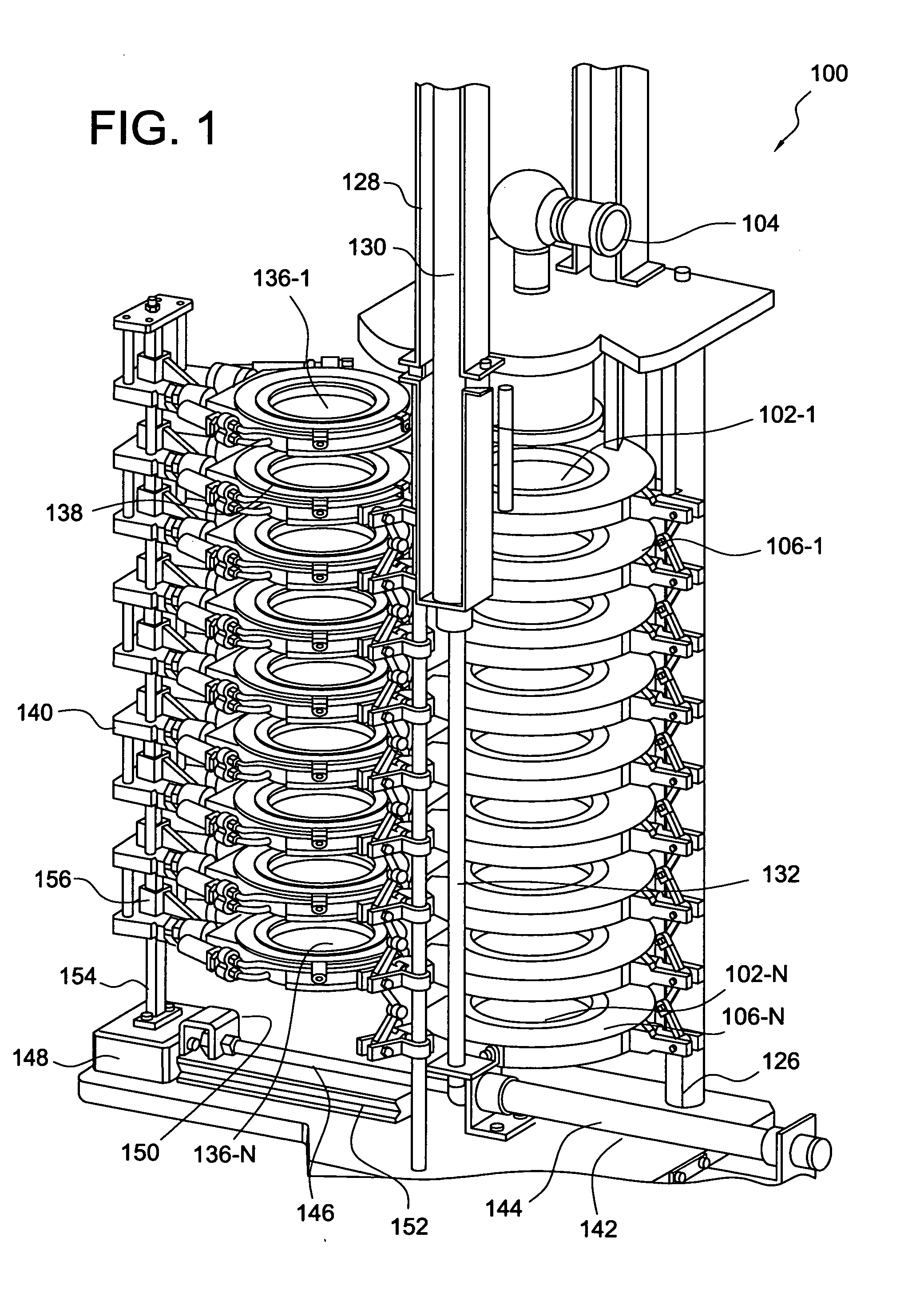

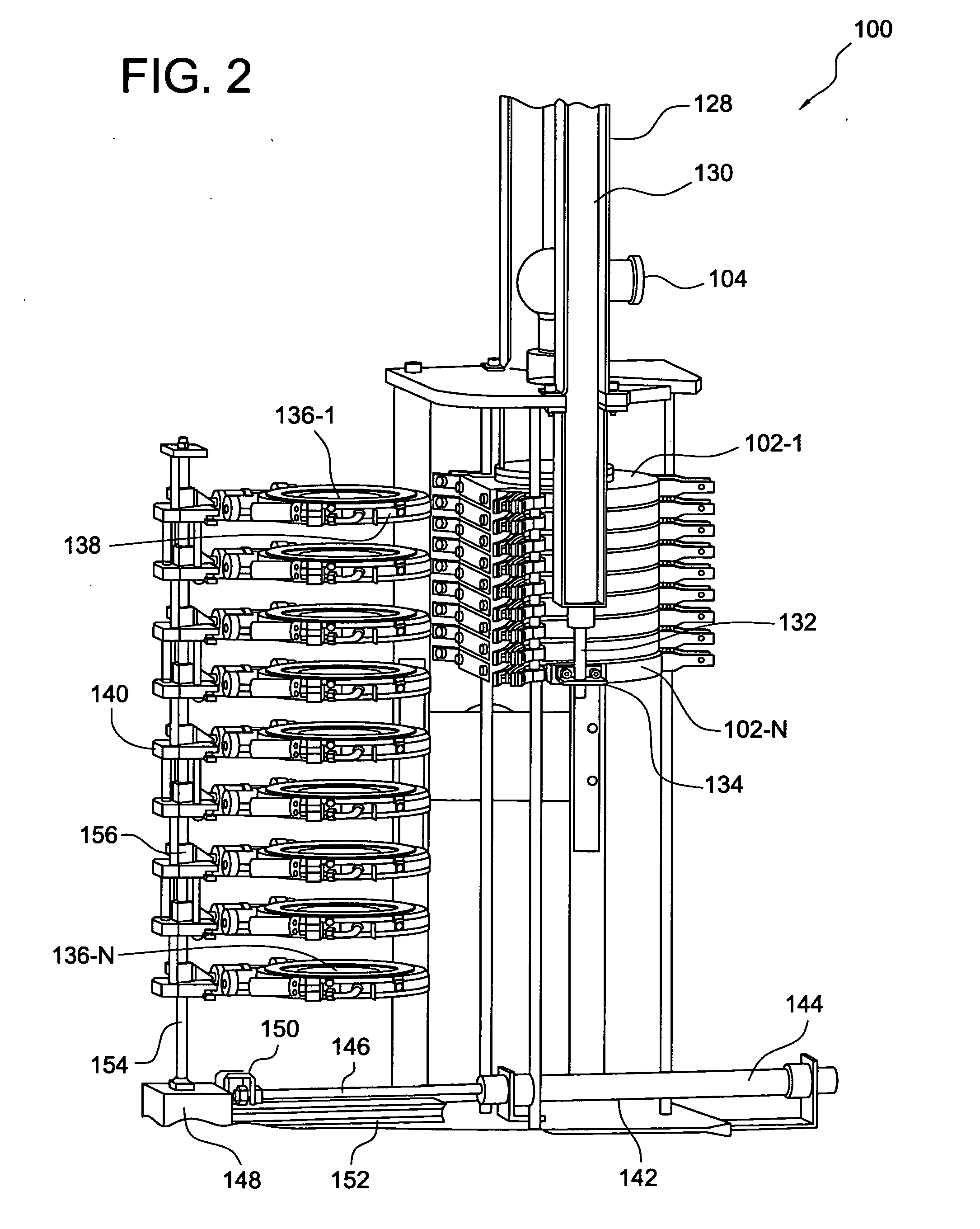

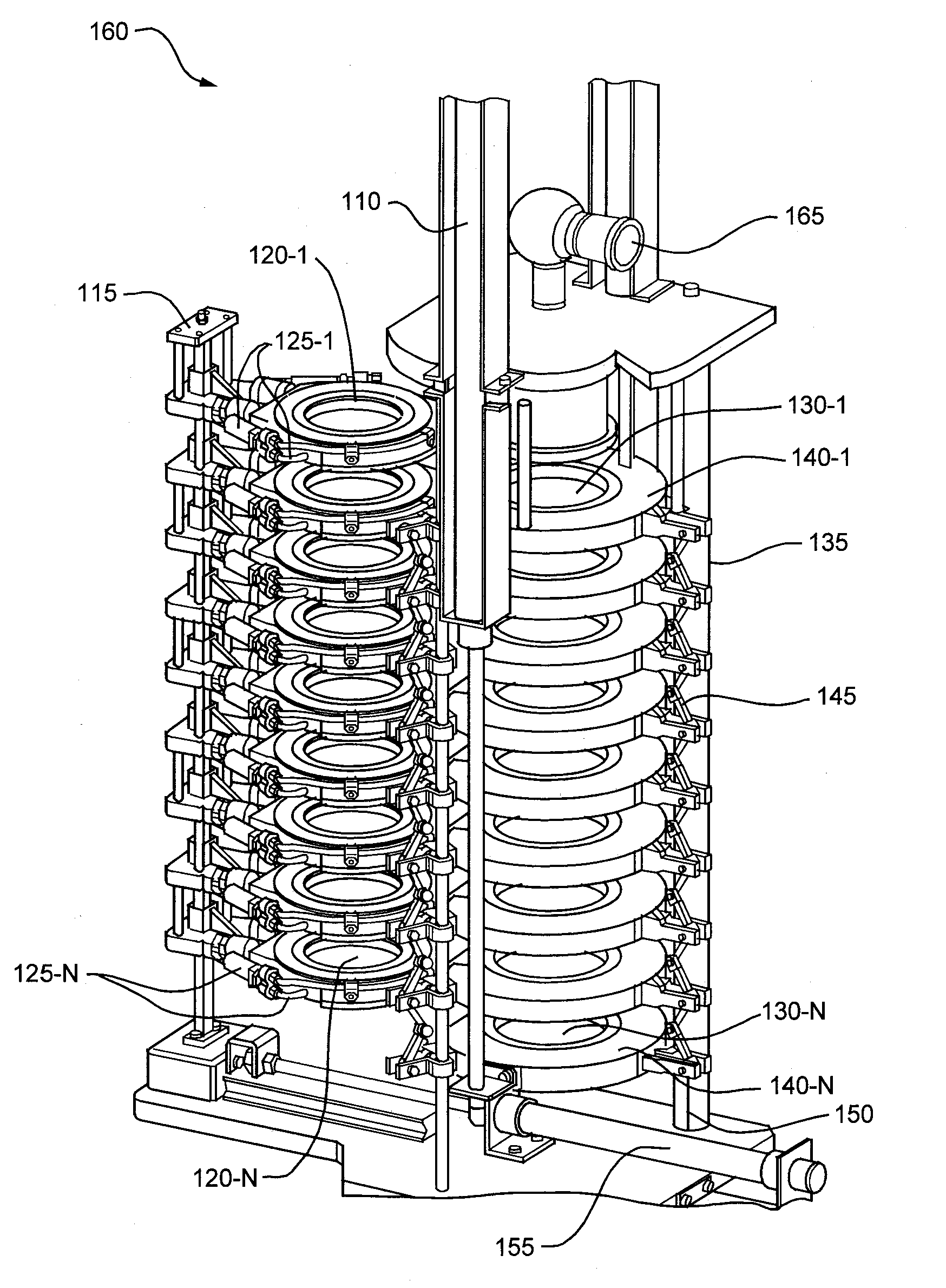

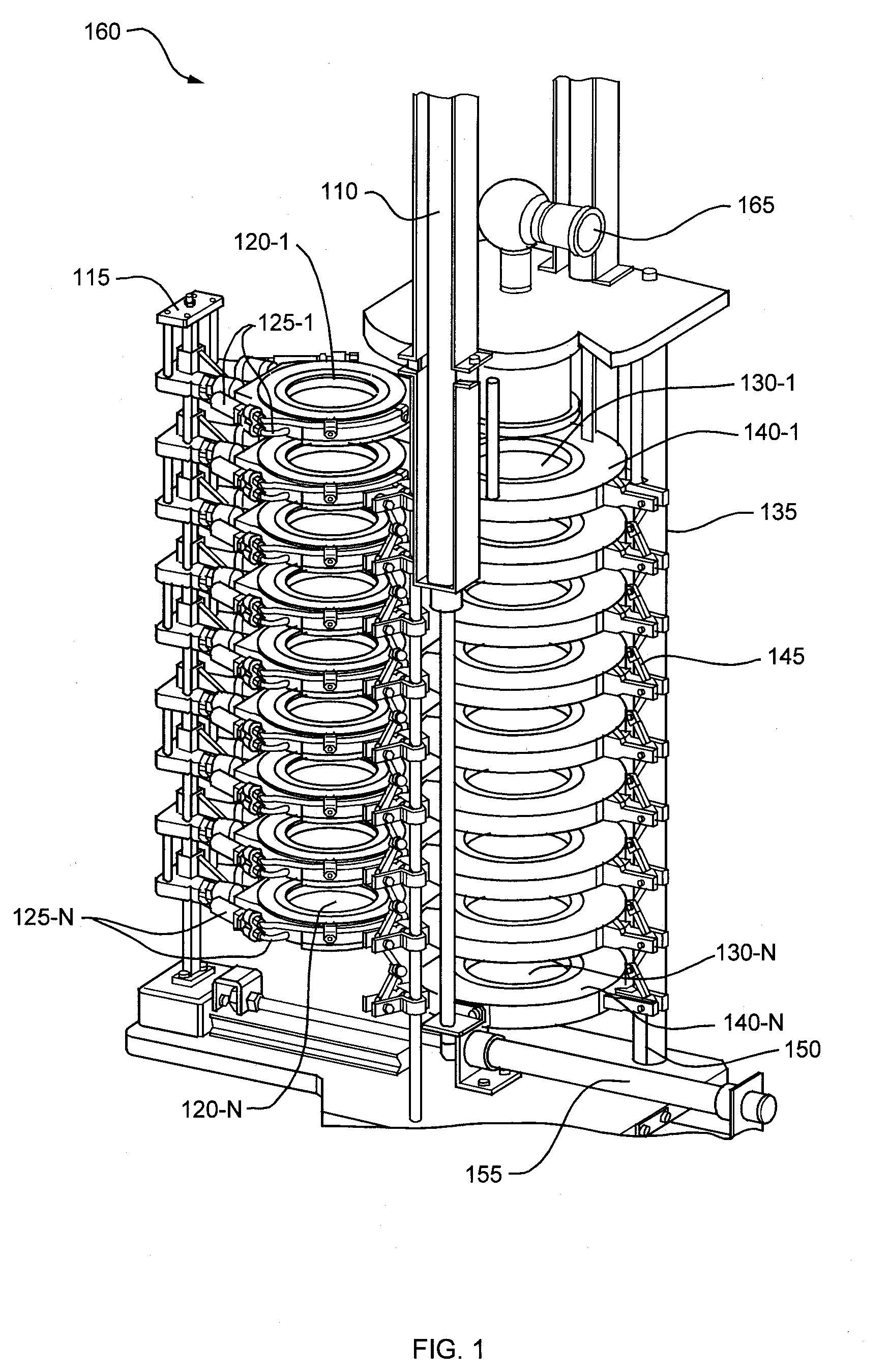

InactiveUS20080047372A1Promote withdrawalMaximize throughputWithdrawing sample devicesMaterial analysis by optical meansCascade impactorEngineering

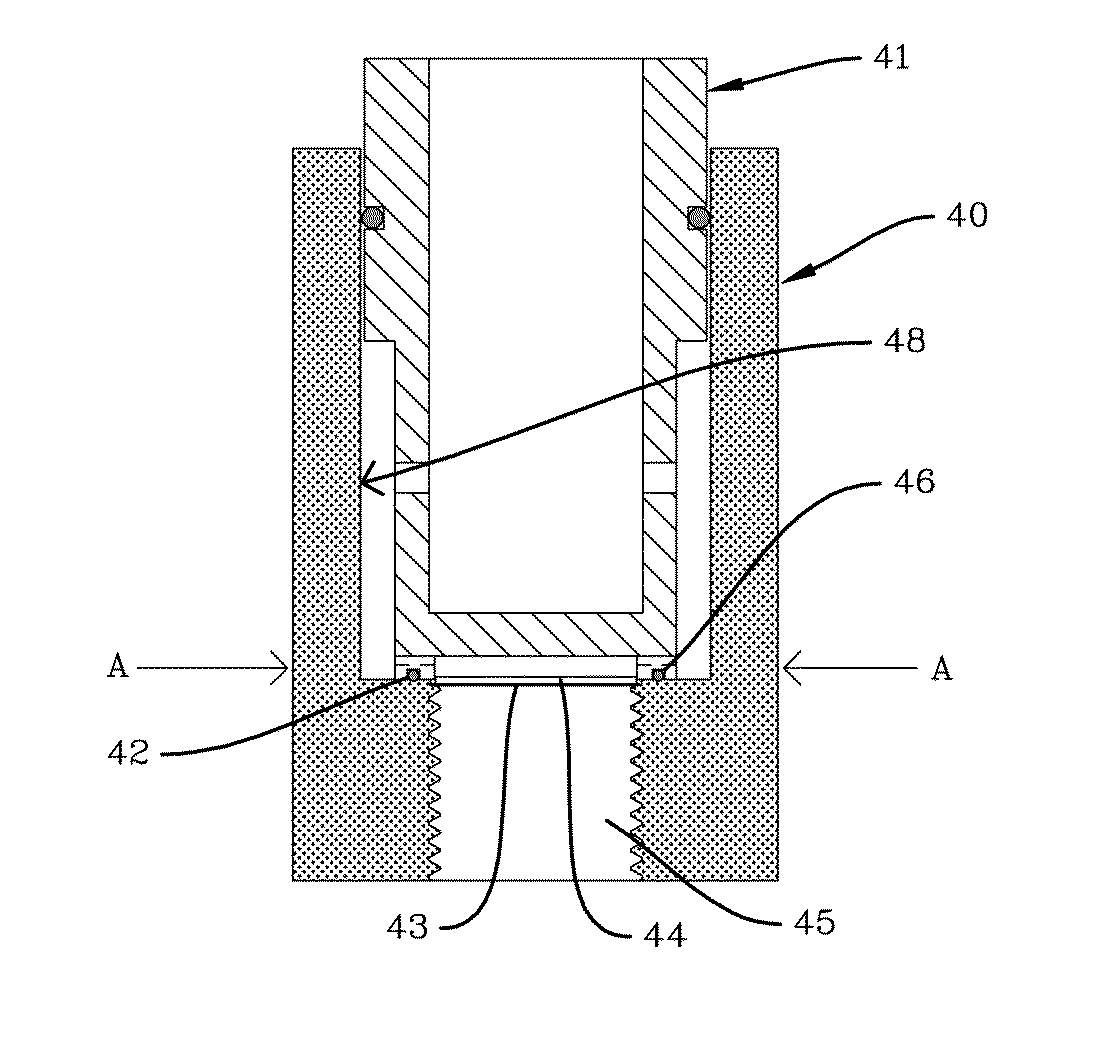

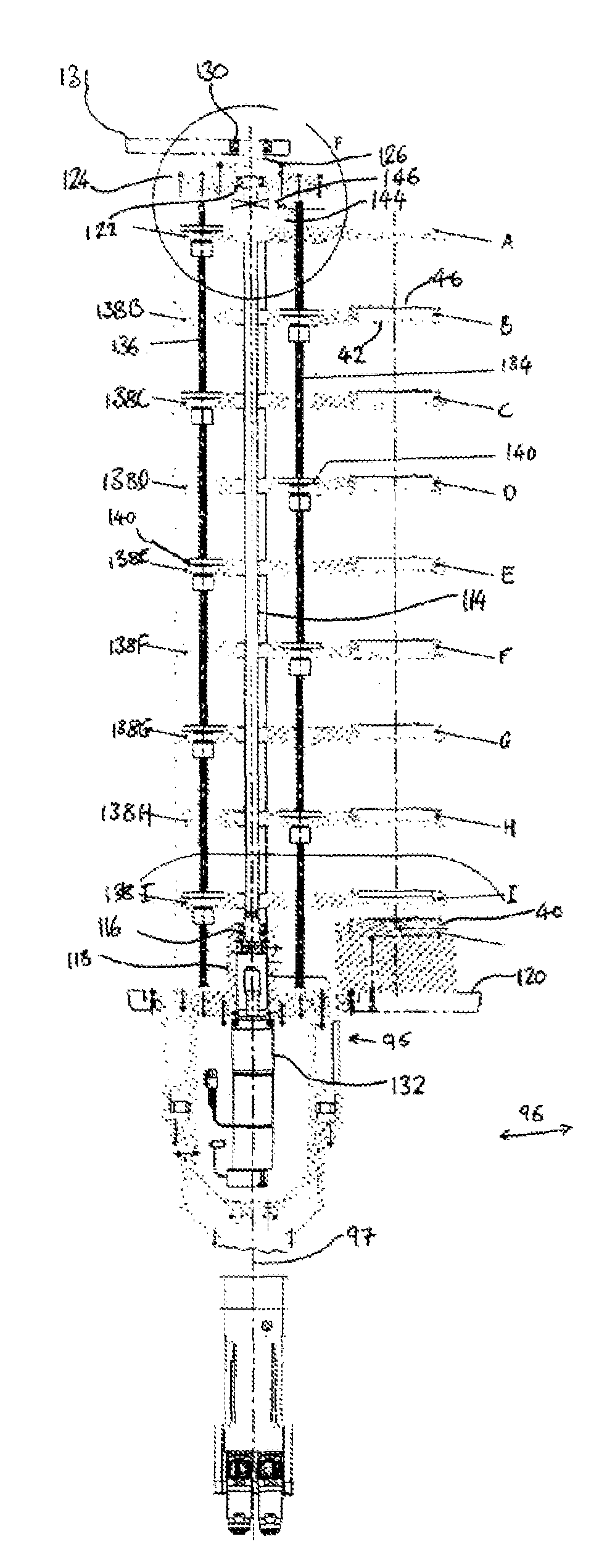

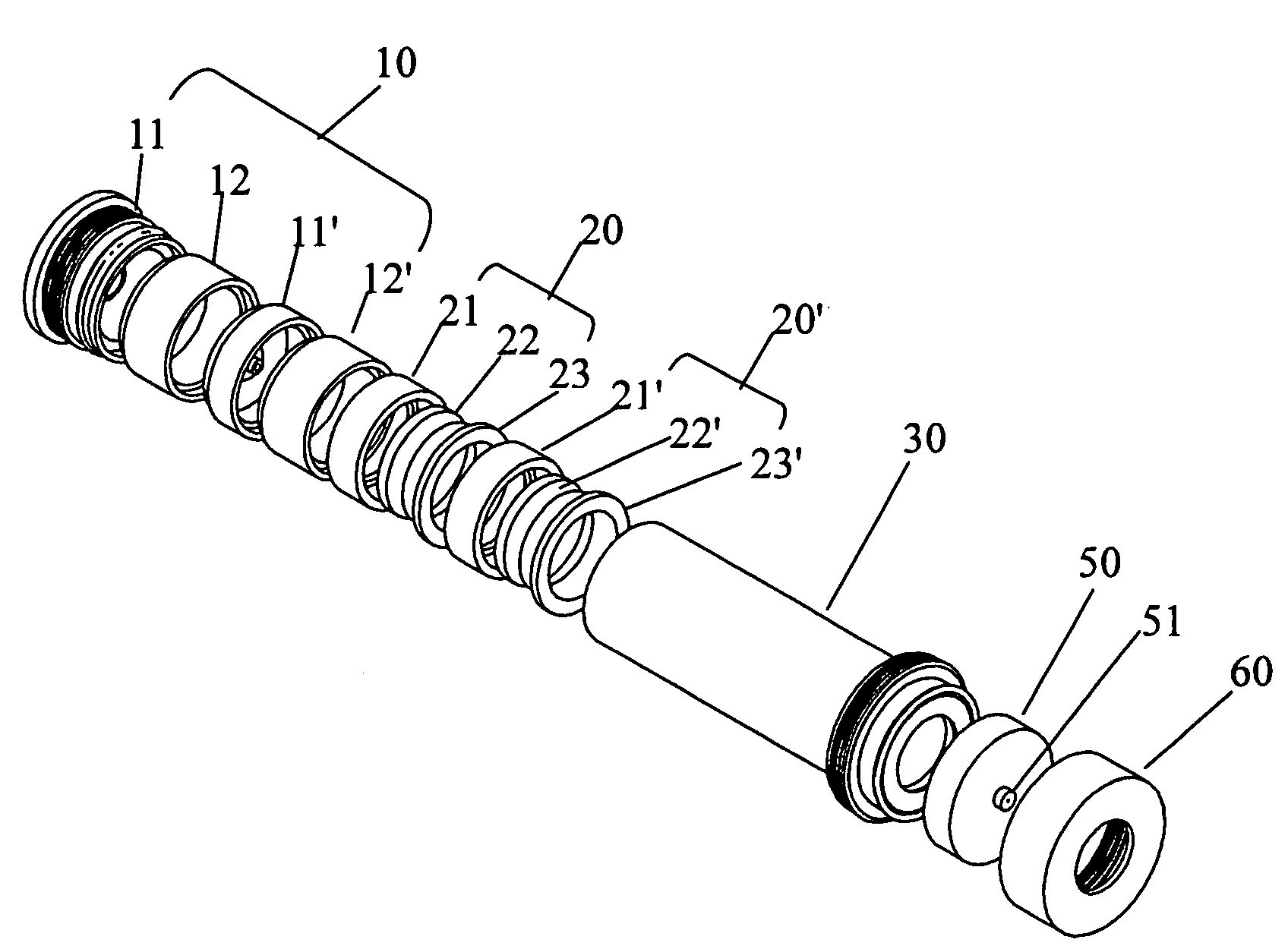

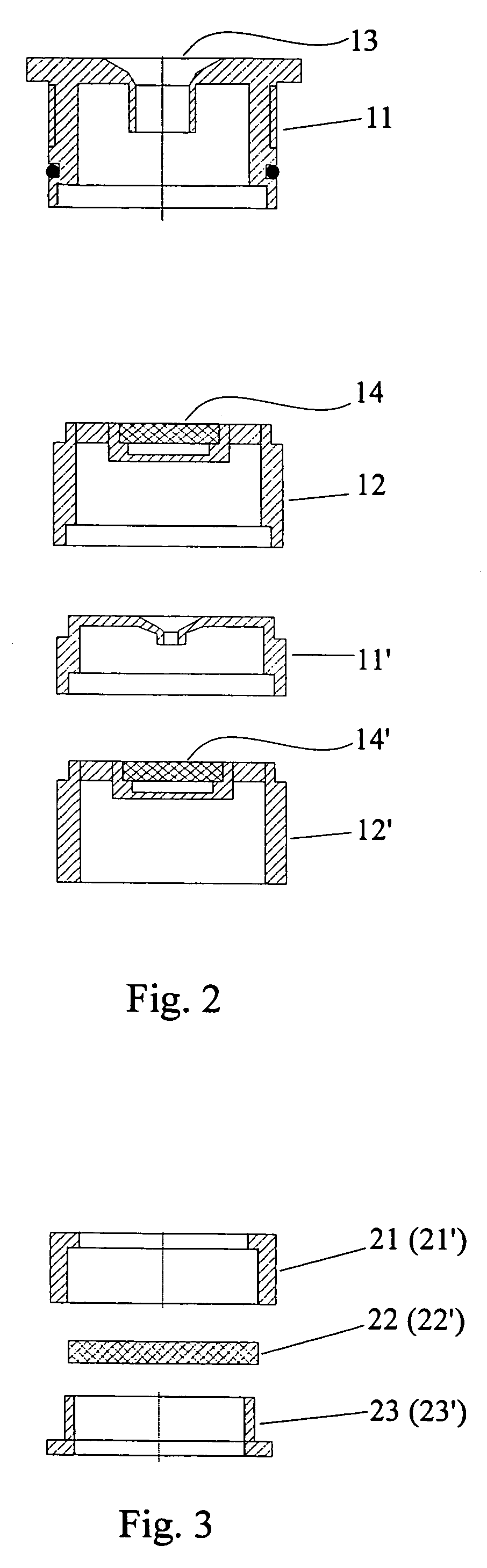

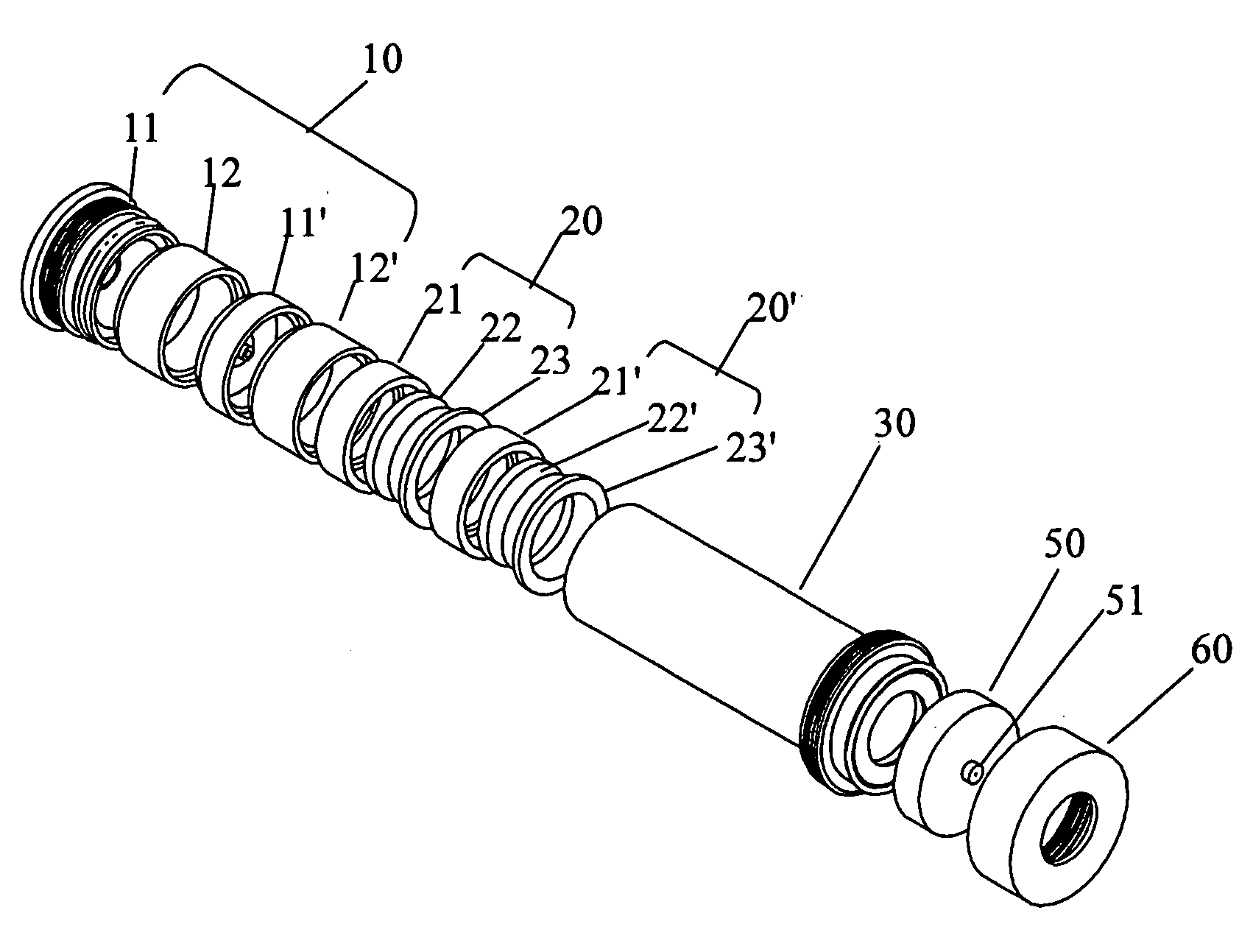

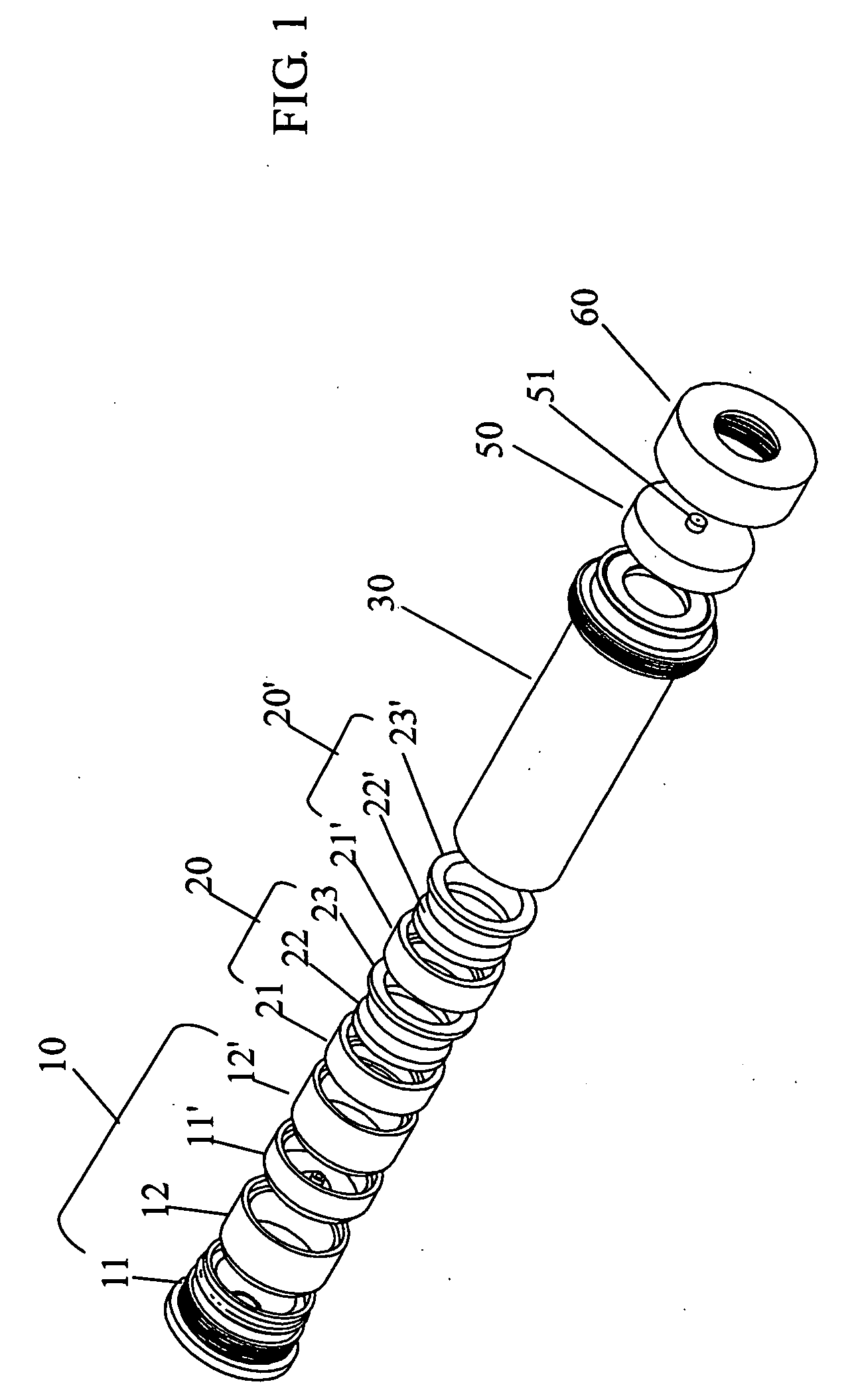

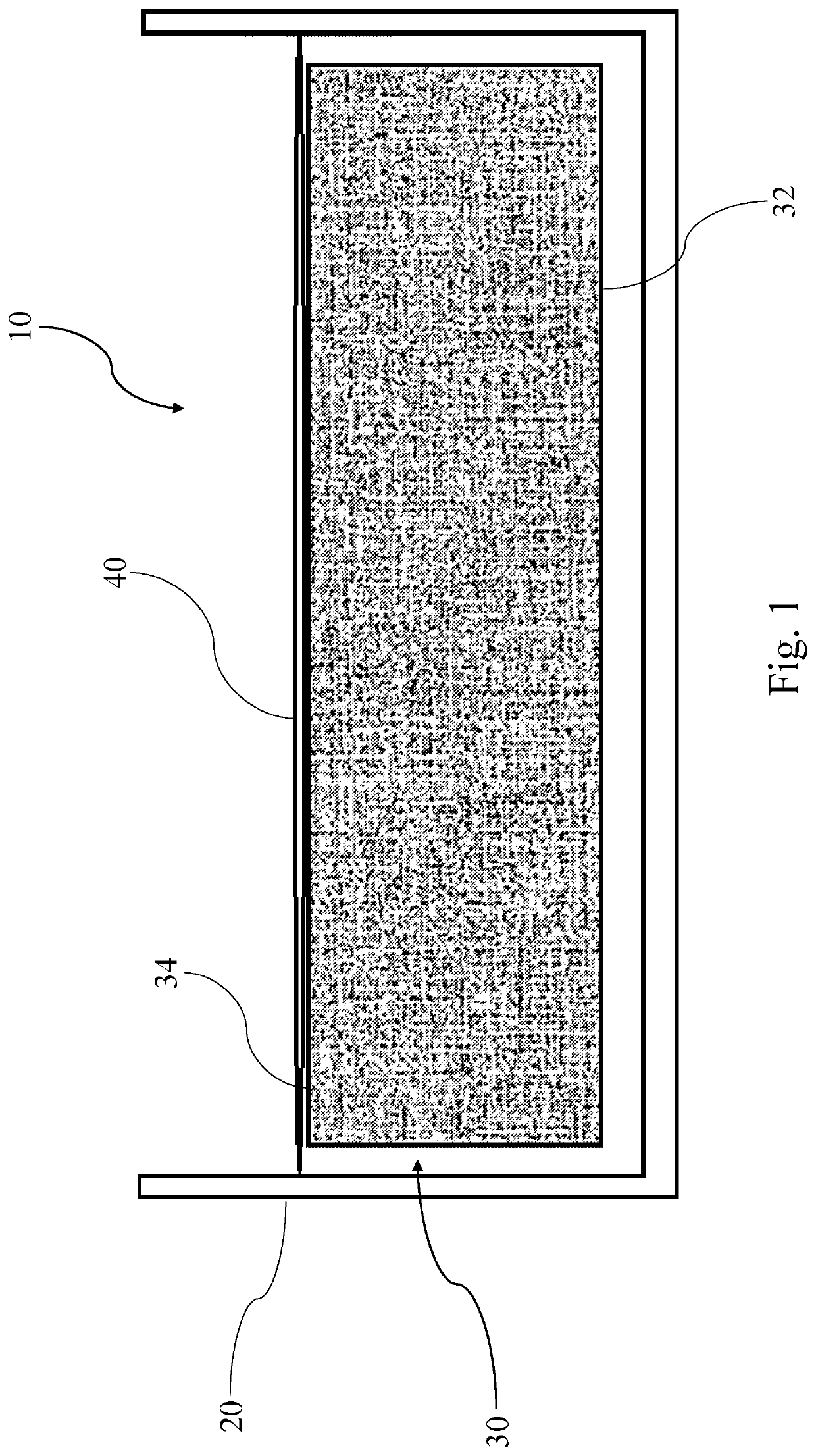

The application describes an automated system for carrying out tests using a cascade impactor 10 of the type having multiple impactor stages each comprising a respective stage body 30, the stage bodies being shaped to enable them to be assembled in a stack in which they locate one upon another. The system includes an expander device 90 having respective arms for supporting each of the stage bodies, and a mechanism for separating the arms along the axial direction to disassemble the impactor 10.

Owner:ASTECH PROJECTS

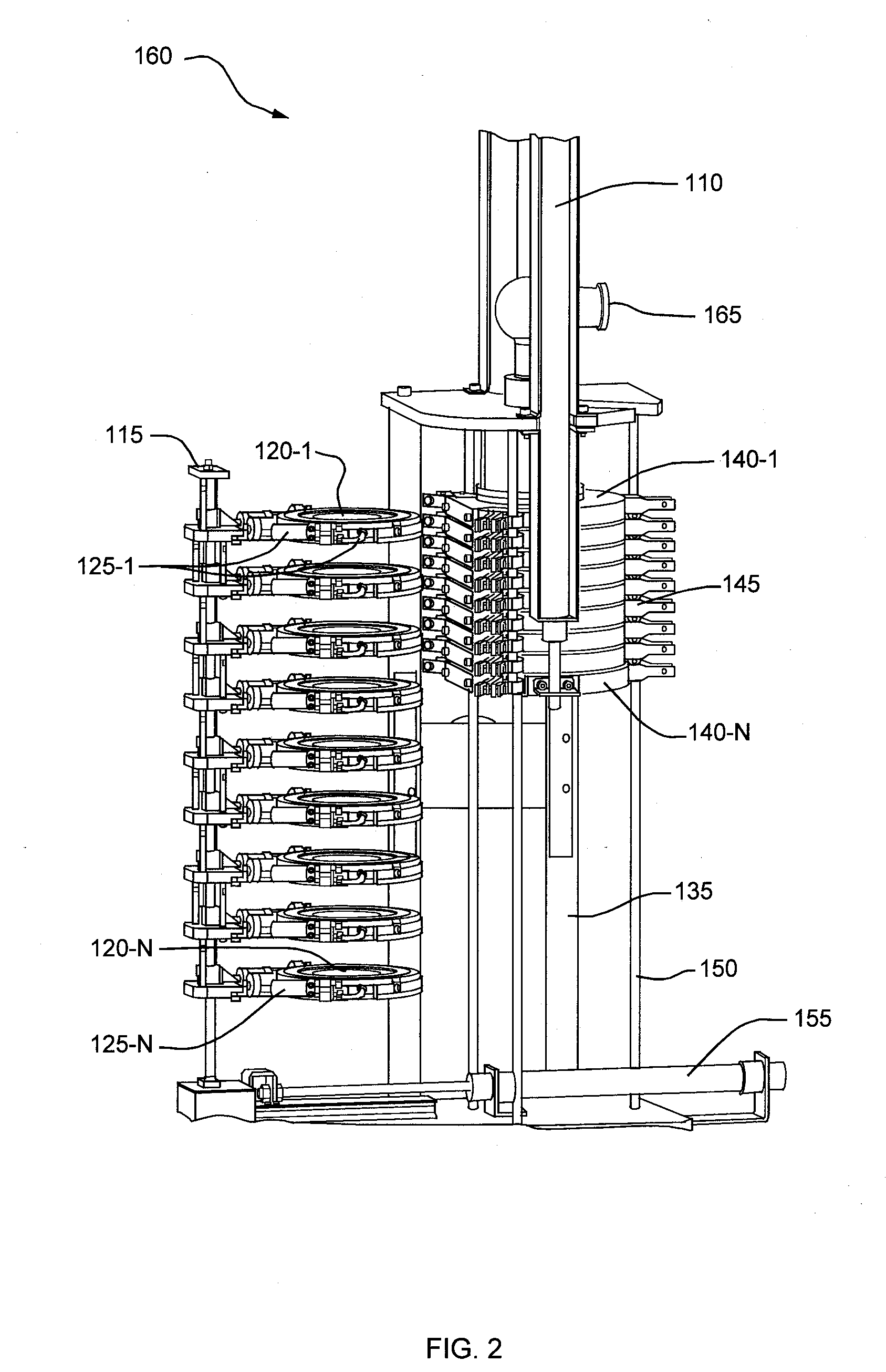

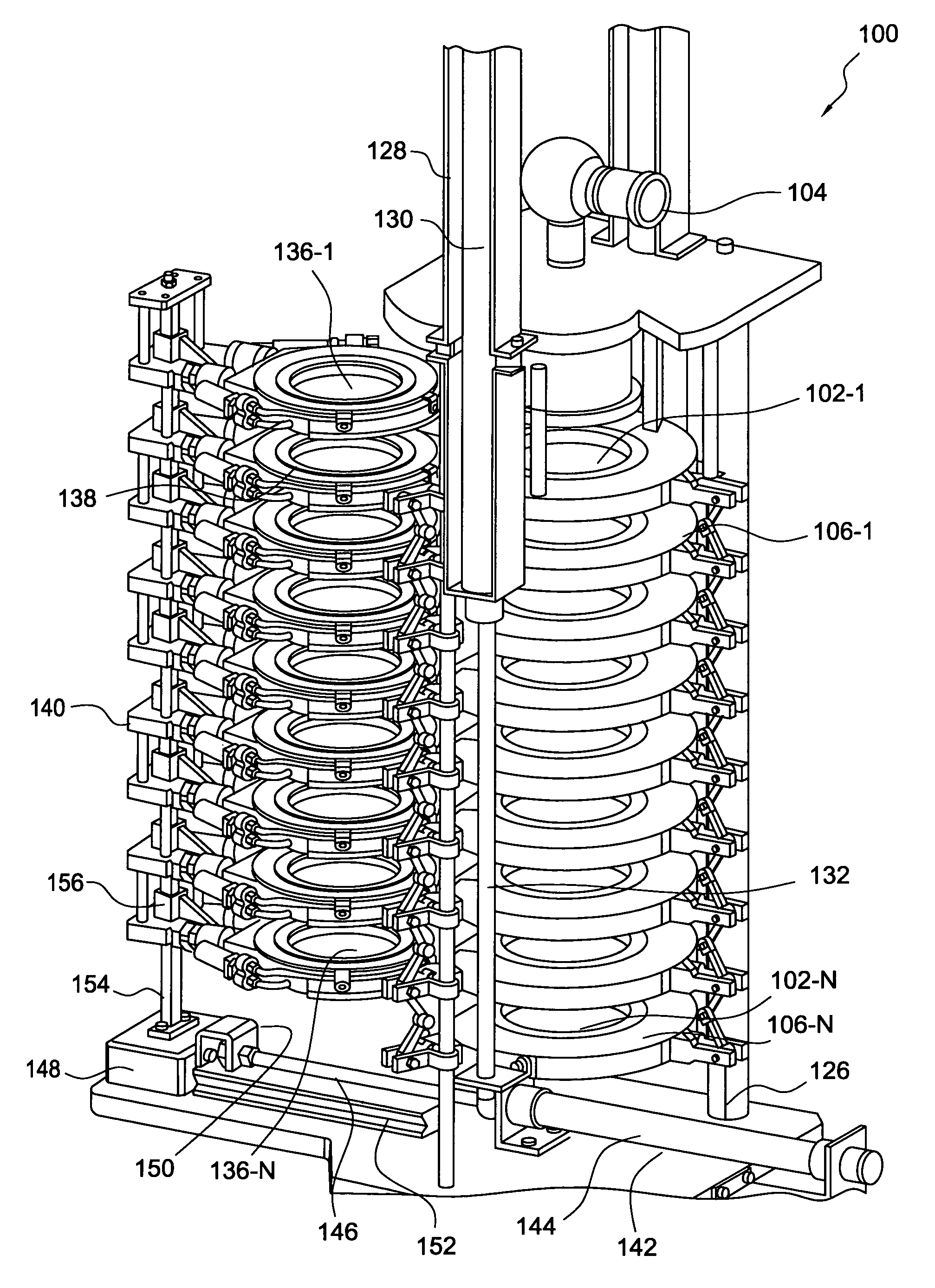

Automated cascade impactor

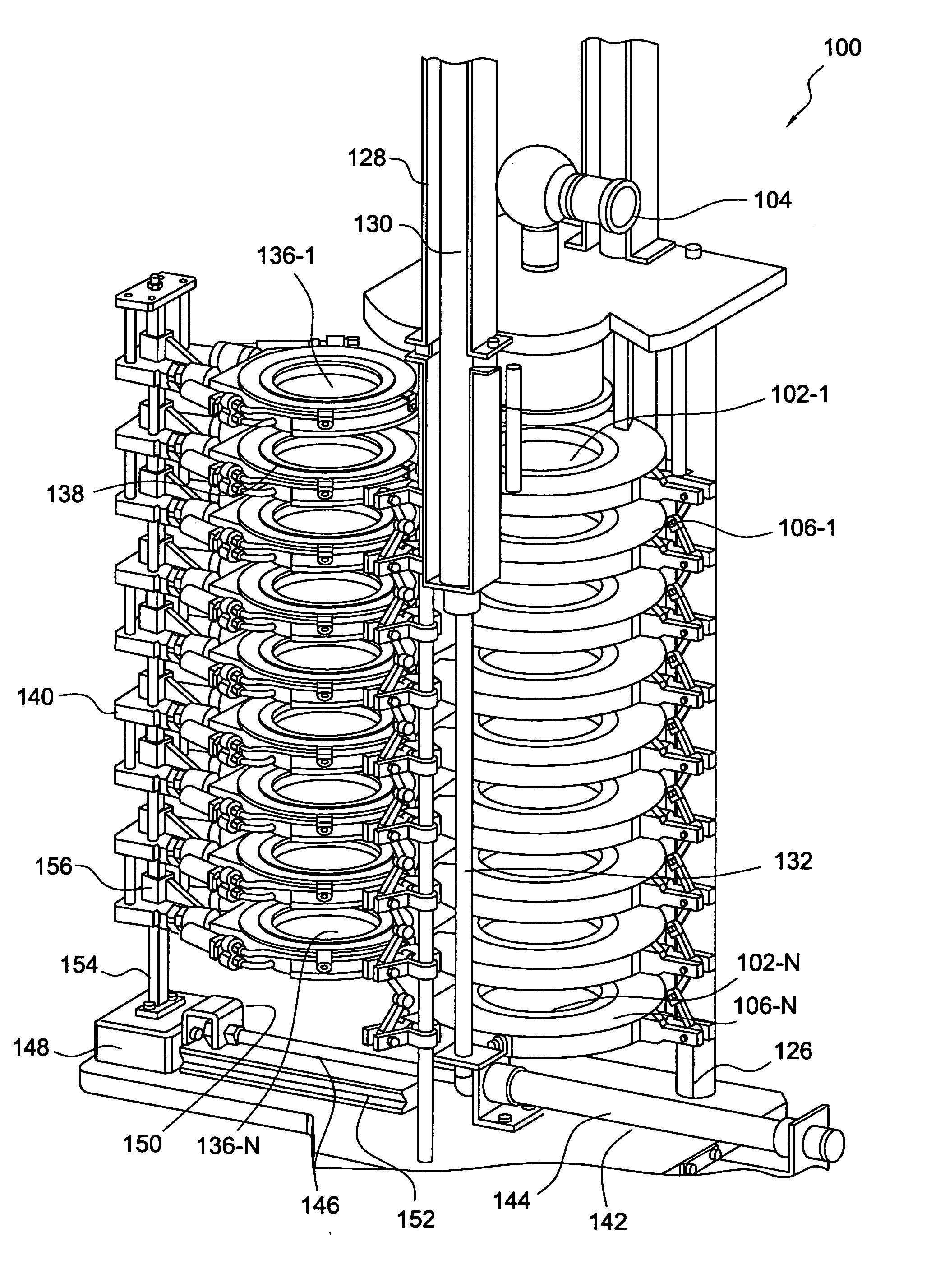

An automated cascade impactor is disclosed and comprises a vertical array of a plurality of impactor stages, and a vertical array of isolation stages, wherein the vertical array of the isolation stages comprises pairs of isolation stages between which impactor plates, removed from respective ones of the impactor stages are effectively sandwiched between each pair of isolation stages. Still further, each compactor stage is likewise sandwiched between and upper and a lower pair of the isolation stages.

Owner:LAB AUTOMATE TECH

Automated cascade impactor

ActiveUS20090078062A1Low variabilityAutomatic collectionWithdrawing sample devicesCascade impactorAutomation

An automated cascade impactor comprises an extension mechanism operable to couple to a plurality of impactor stages. The extension mechanism is operable to compress and separate impactor stages of the plurality of impactor stages via automation. The system provides a plurality of isolation stages operable to be automatically inserted between respective impactor stages when the impactor stages are separated by the extension mechanism. The system provides the plurality of isolation stages to be automatically compressed between impactor stages to isolate each impactor stage from at least one adjacent impactor stage. The plurality of isolation stages is operable to be automatically uncompressed and removed from between the impactor stages. The isolation stages allow automated extraction of particulate matter, cleaning and drying of interior surfaces of each impactor stage.

Owner:LAB AUTOMATE TECH

Impactor Automation

InactiveUS7669488B2Maximize throughputPromote withdrawalWithdrawing sample devicesCascade impactorBiomedical engineering

The application describes an automated system for carrying out tests using a cascade impactor 10 of the type having multiple impactor stages each comprising a respective stage body 30, the stage bodies being shaped to enable them to be assembled in a stack in which they locate one upon another. The system includes an expander device 90 having respective arms for supporting each of the stage bodies, and a mechanism for separating the arms along the axial direction to disassemble the impactor 10.

Owner:ASTECH PROJECTS

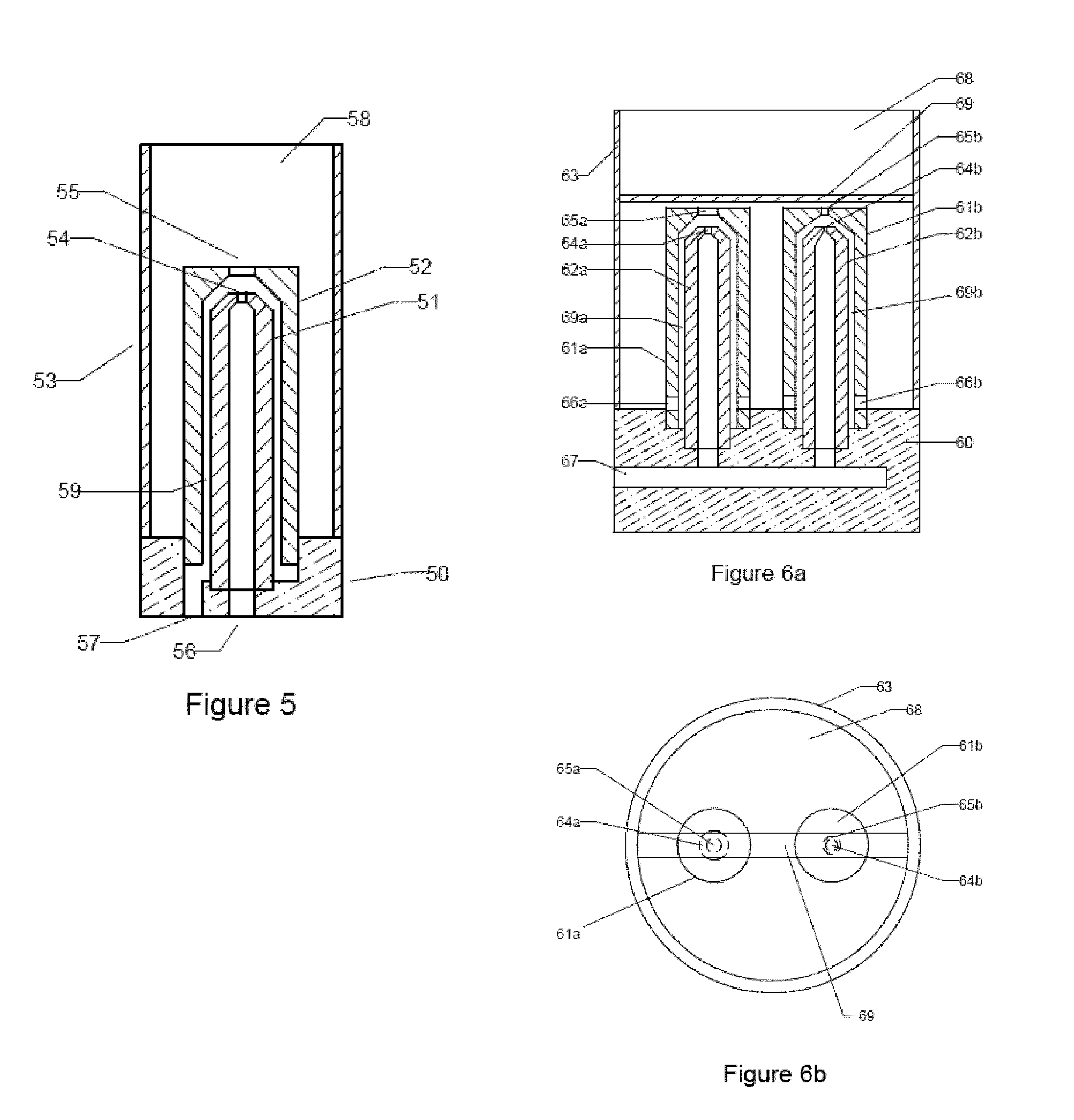

Porous metal denuder

InactiveUS7537629B2Increase load capacityCombination devicesWithdrawing sample devicesCircular discCascade impactor

A porous metal denuder has a cascade impactor to collect aerosol particles of different diameters, two porous metal discs downstream to collect basic and acidic gases, respectively, and a final filter to collect particles smaller than the cut diameter of the last stage of the cascade impactor which will penetrate the two porous metal discs.

Owner:INST OCCUPATIONAL SAFETY & HEALTH COUNCIL LABOR AFFAIRS EXECUTIVE YUAN

Porous metal denuder

InactiveUS20090095161A1Increase load capacityCombination devicesWithdrawing sample devicesCircular discCascade impactor

A porous metal denuder has a cascade impactor to collect aerosol particles of different diameters, two porous metal discs downstream to collect basic and acidic gases, respectively, and a final filter to collect particles smaller than the cut diameter of the last stage of the cascade impactor which will penetrate the two porous metal discs.

Owner:INST OCCUPATIONAL SAFETY & HEALTH COUNCIL LABOR AFFAIRS EXECUTIVE YUAN

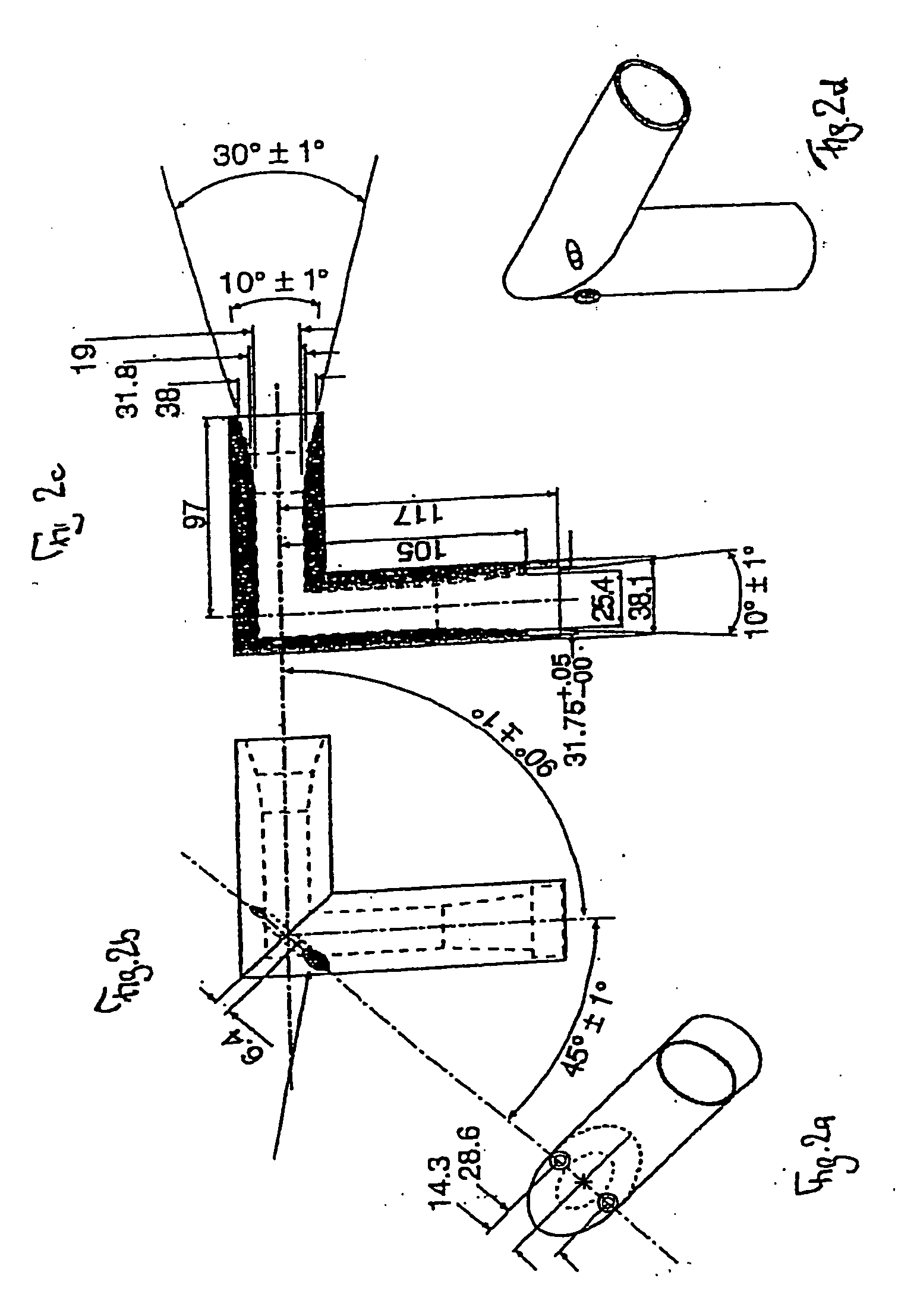

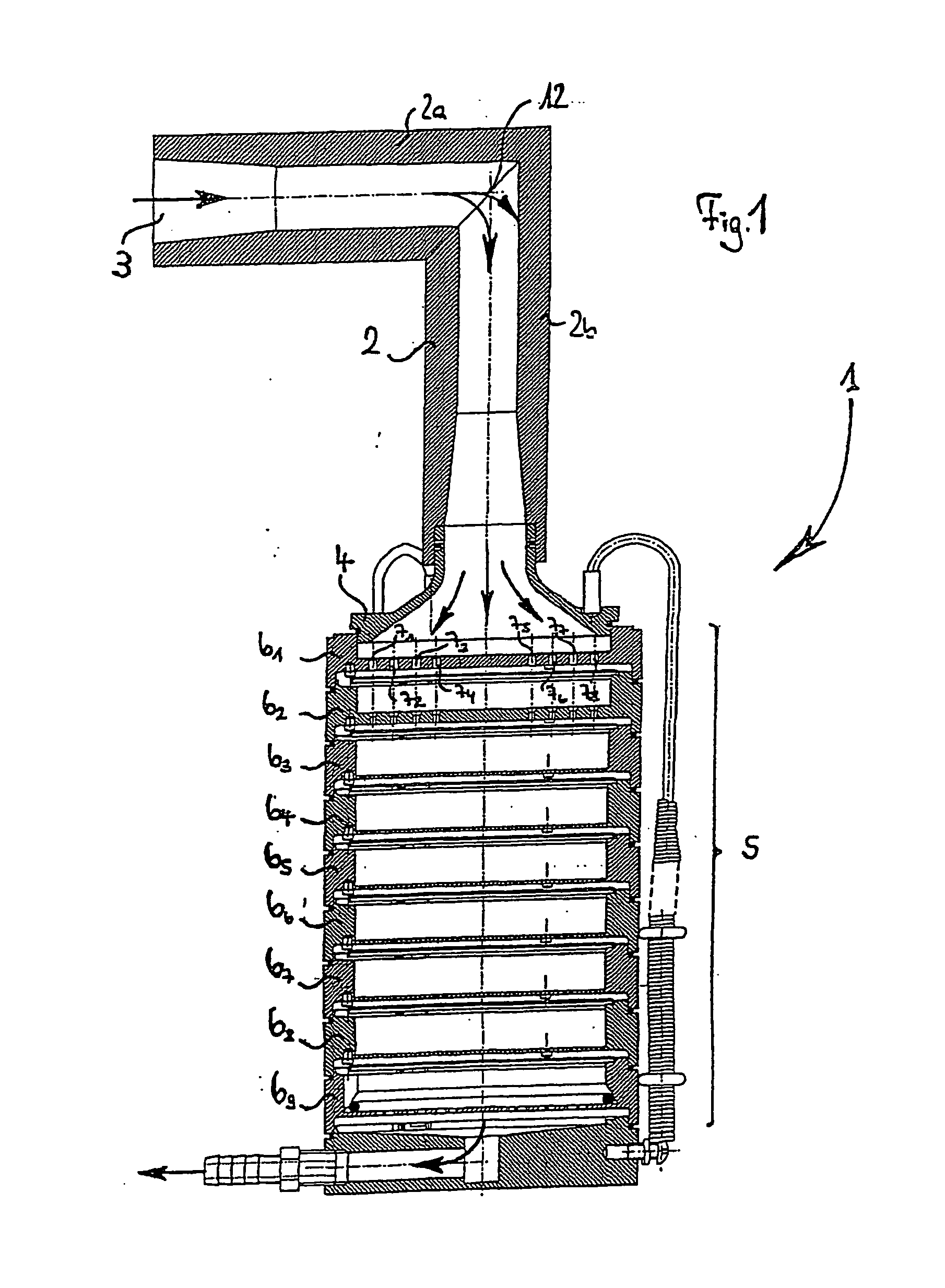

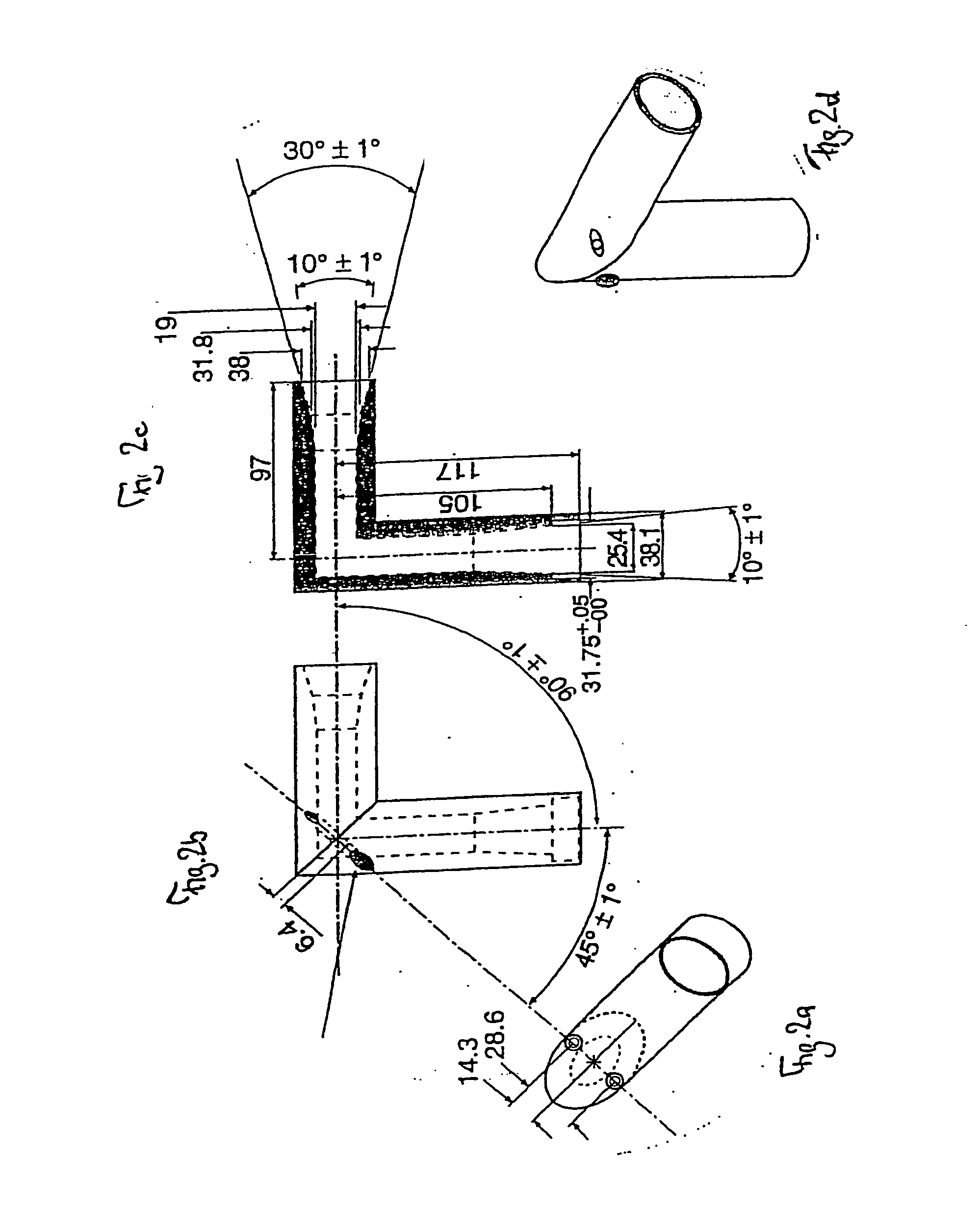

Process for Determining the particle size distribution of an aerosol and apparatus for carrying out such a process

InactiveUS20060246010A1Less-time-consuming and costlyPowder deliveryInvestigating moving fluids/granular solidsCascade impactorDrug industry

The present invention provides, for the first time, a process that meets the needs of the drug industry for measuring the particle size of nebulised aerosols simultaneously or one after another by the laser diffraction method and the cascade impactor method which is known in the art. In this way it is possible to bring the reliability of the results of the laser diffraction process according to the invention into conformity with that of the cascade impactor, and thereby obtain a process which combines the advantages of the rapid laser diffraction process with the accuracy of the otherwise time-consuming cascade impactor method. In addition to the process, apparatus for carrying out the process are also disclosed.

Owner:BOEHRINGER INGELHEIM INT GMBH

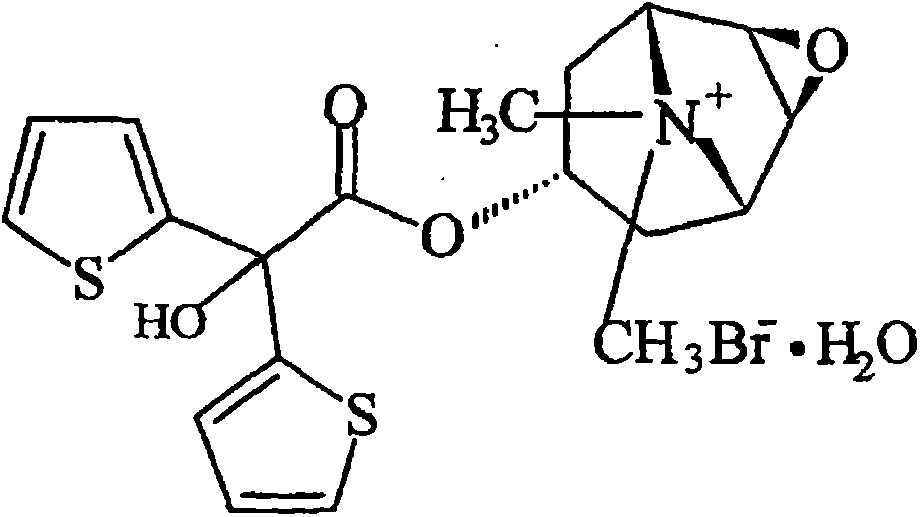

Tiotropium bromide powder inhalation and preparation method thereof

InactiveCN103110584ASignificant progressImprove medication safetyAerosol deliveryCapsule deliveryTiotropium bromideInhalation

The invention discloses a tiotropium bromide powder inhalation, which is obtained by carrying out micro powder treatment on a tiotropium bromide raw material, separating the raw material with the grain size in a range of 1-5 microns through a multistage cascade impactor NGI, mixing with inhalable lactose, and encapsulating. The grain size of the tiotropium bromide raw material of the tiotropium bromide powder inhalation provided by the invention is in the range of 1-5 microns, so that the security and the effectiveness in drug use can be improved.

Owner:QINGDAO UNIV

Process for determining the particle size distribution of an aerosol and apparatus for carrying out such a process

InactiveUS20050238588A1Less-time-consuming and costlyPowder deliveryMedical devicesCascade impactorDrug industry

The present invention provides, for the first time, a process that meets the needs of the drug industry for measuring the particle size of nebulised aerosols simultaneously or one after another by the laser diffraction method and the cascade impactor method which is known in the art. In this way it is possible to bring the reliability of the results of the laser diffraction process according to the invention into conformity with that of the cascade impactor, and thereby obtain a process which combines the advantages of the rapid laser diffraction process with the accuracy of the otherwise time-consuming cascade impactor method. In addition to the process, apparatus for carrying out the process are also disclosed.

Owner:BOEHRINGER INGELHEIM INT GMBH

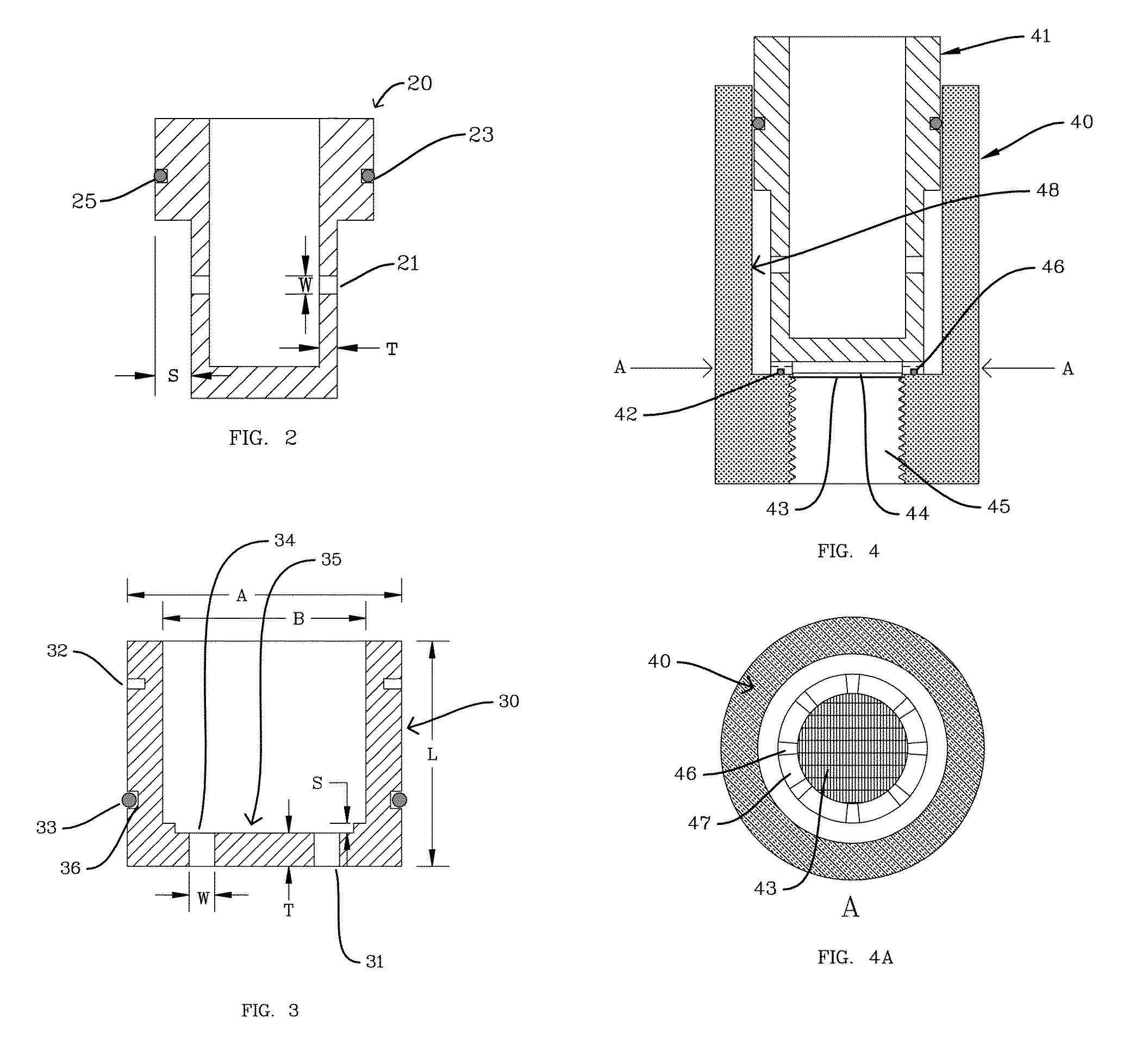

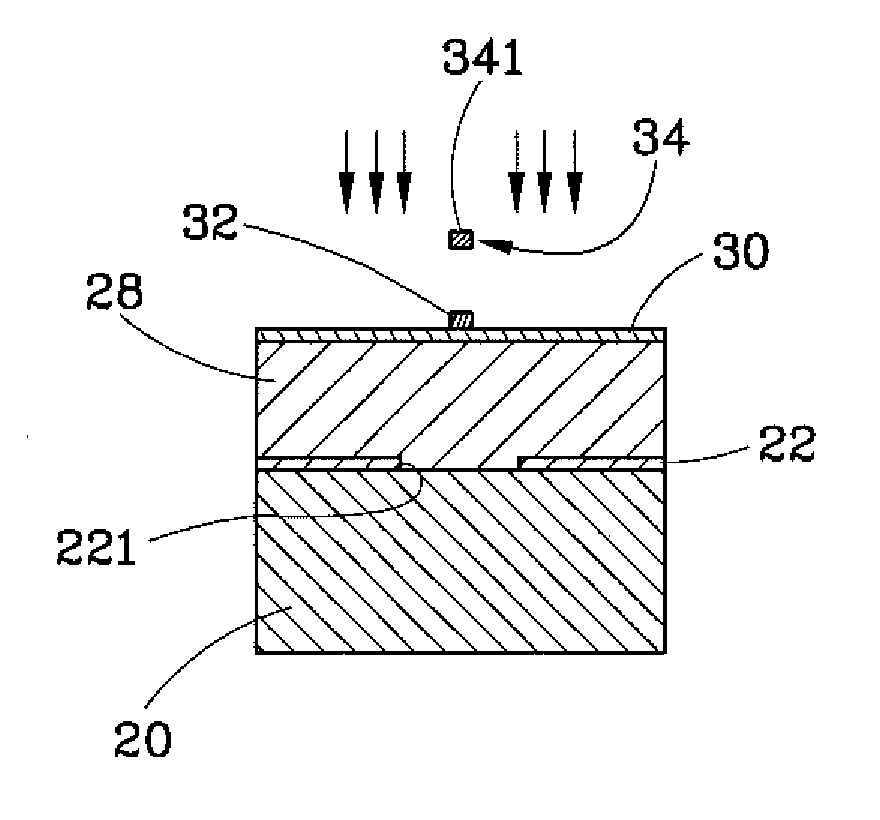

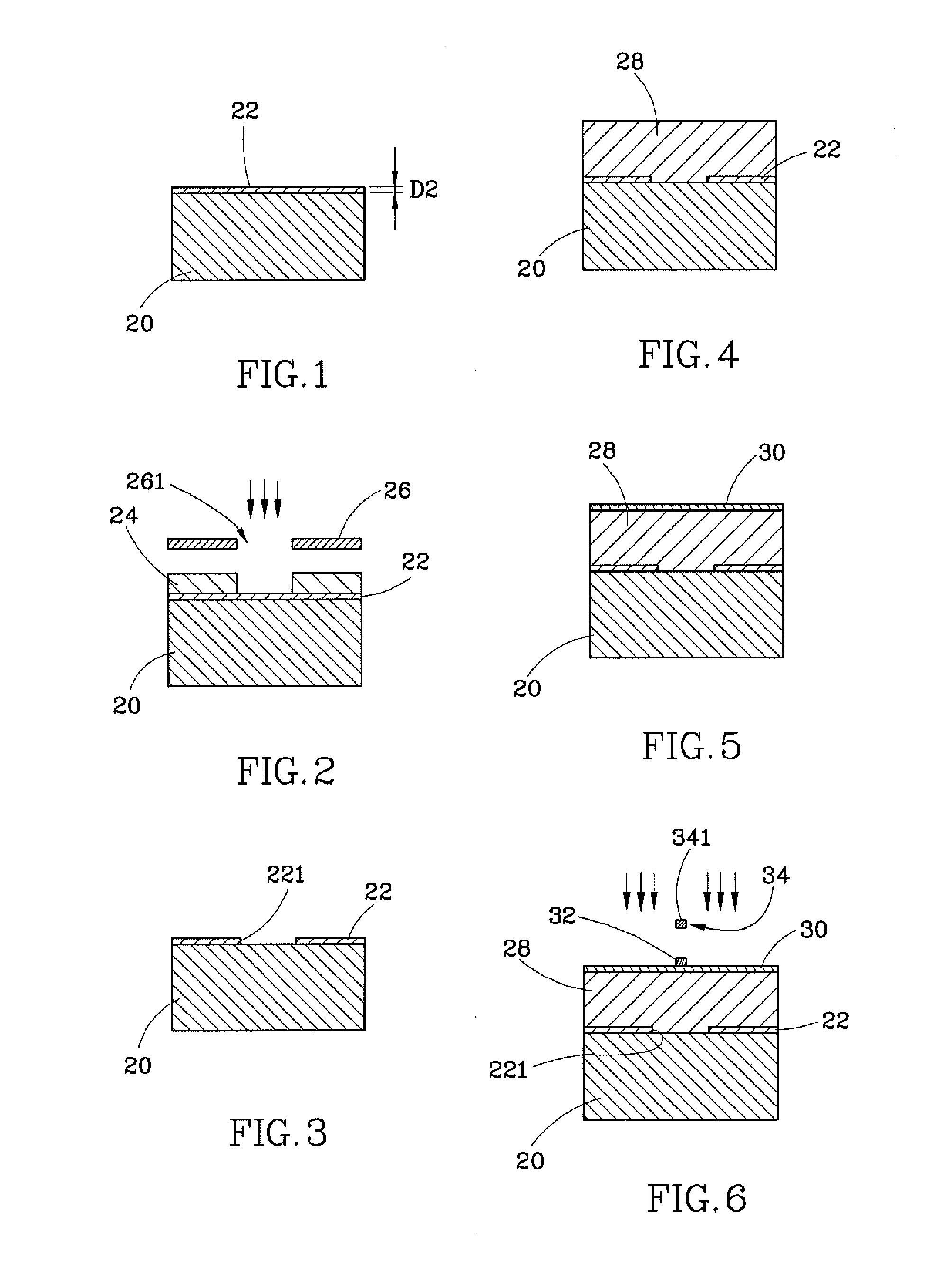

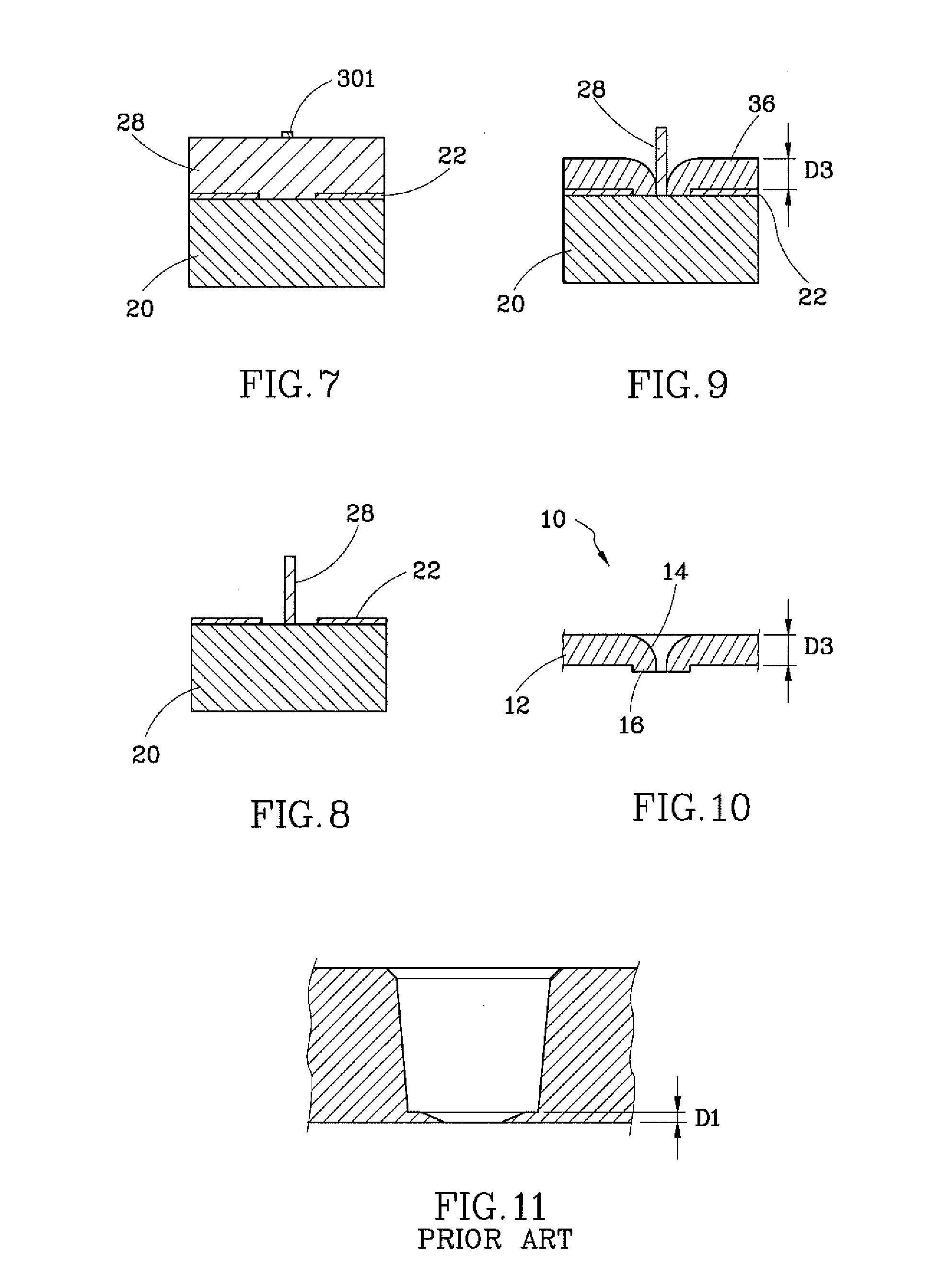

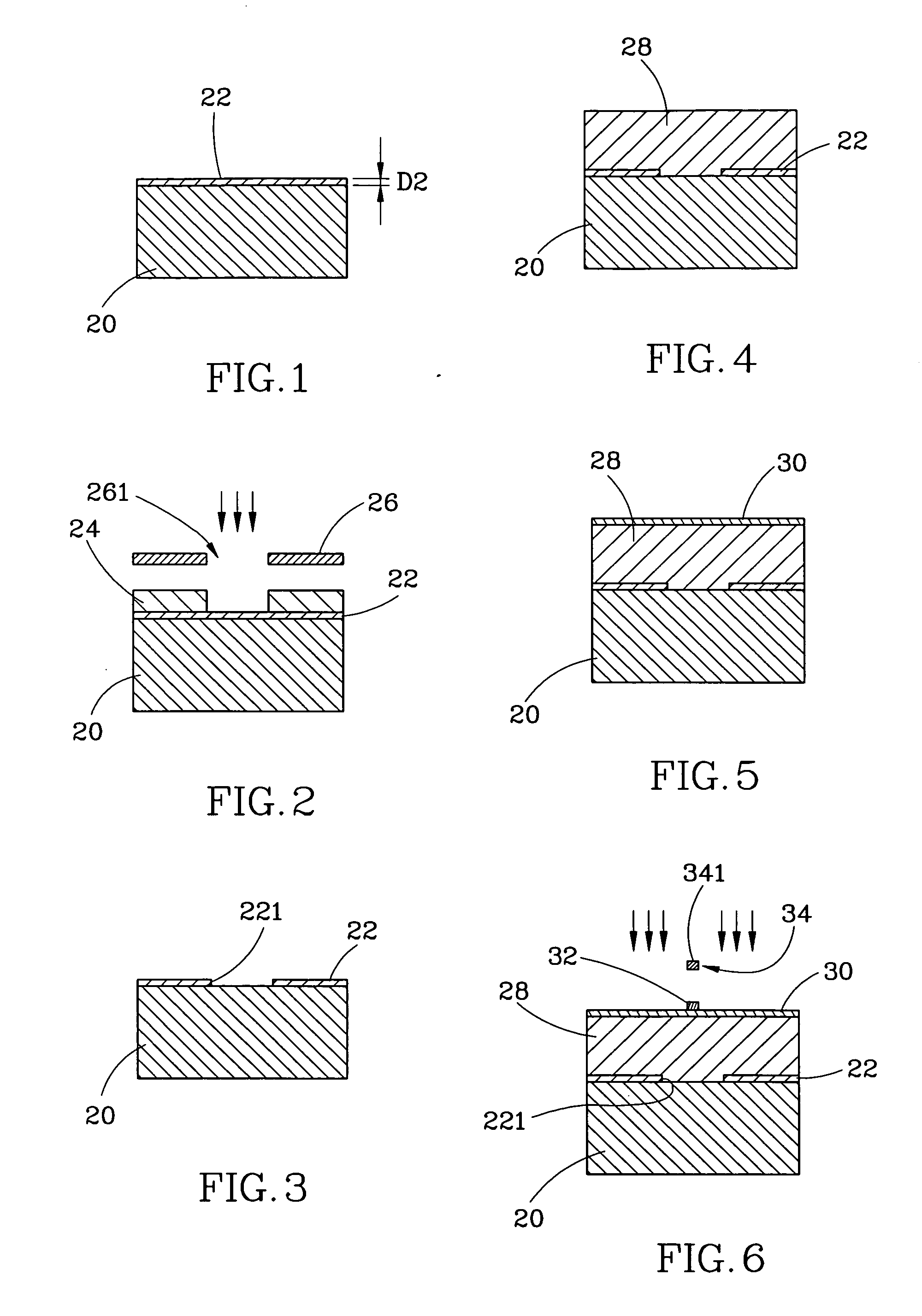

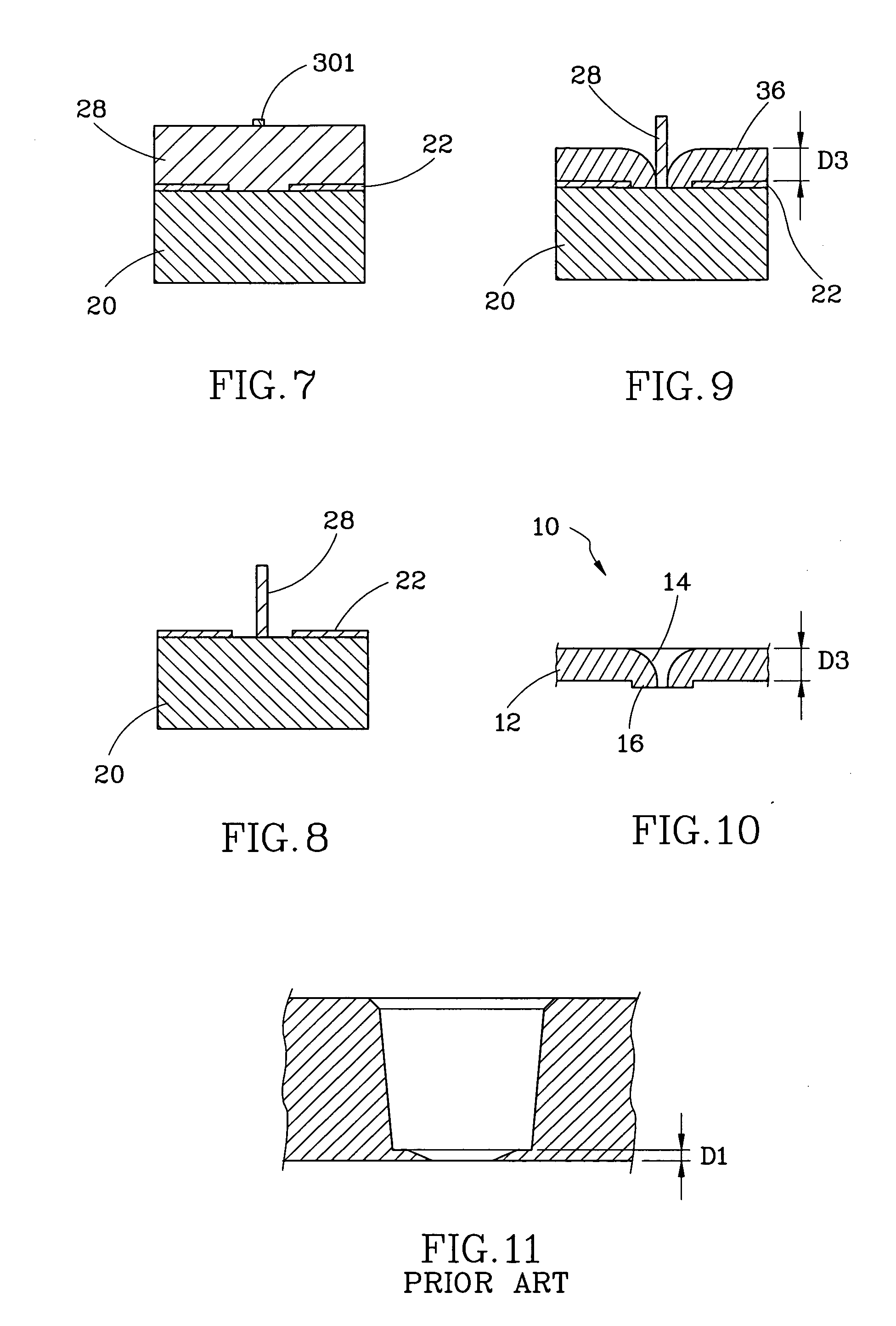

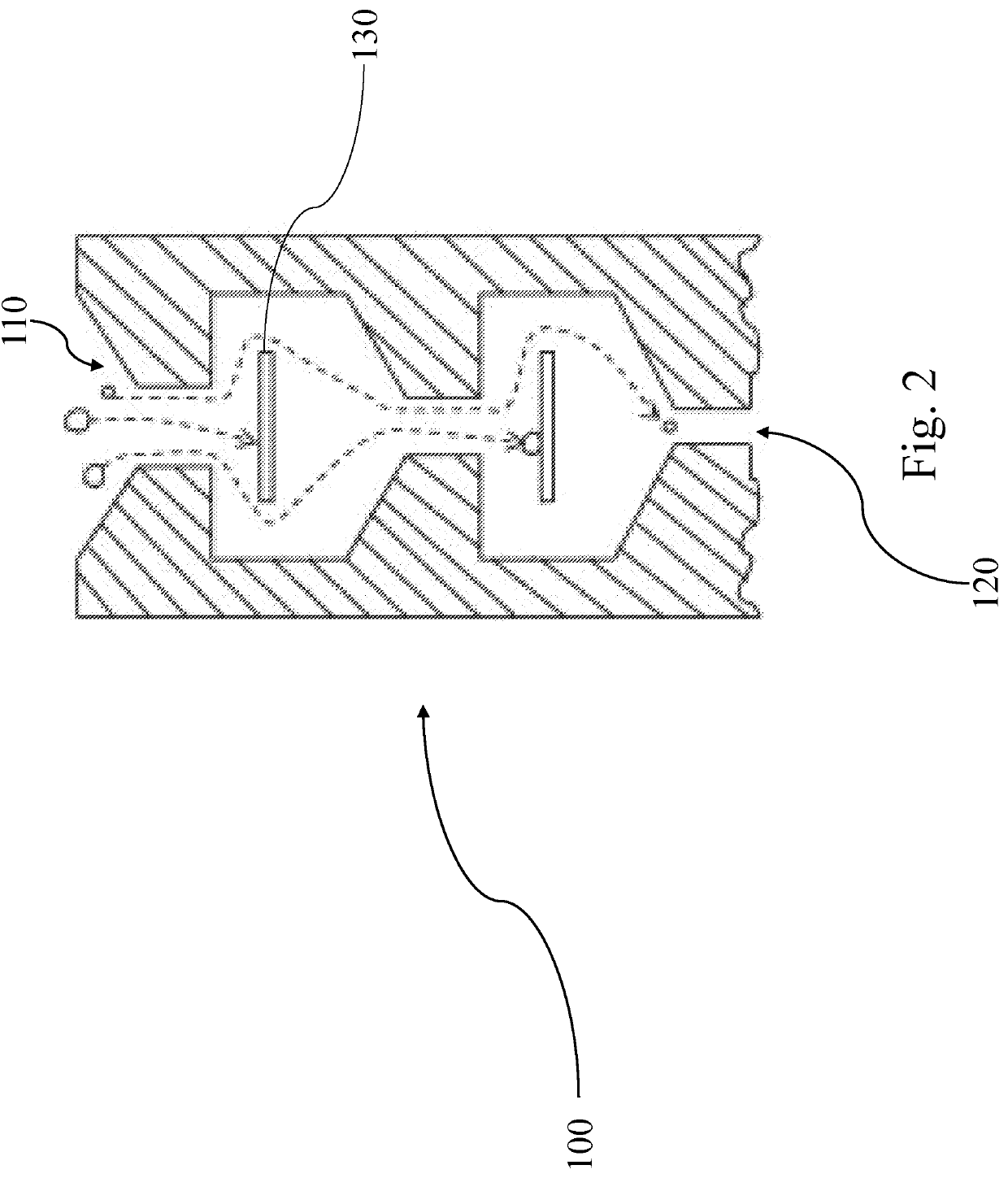

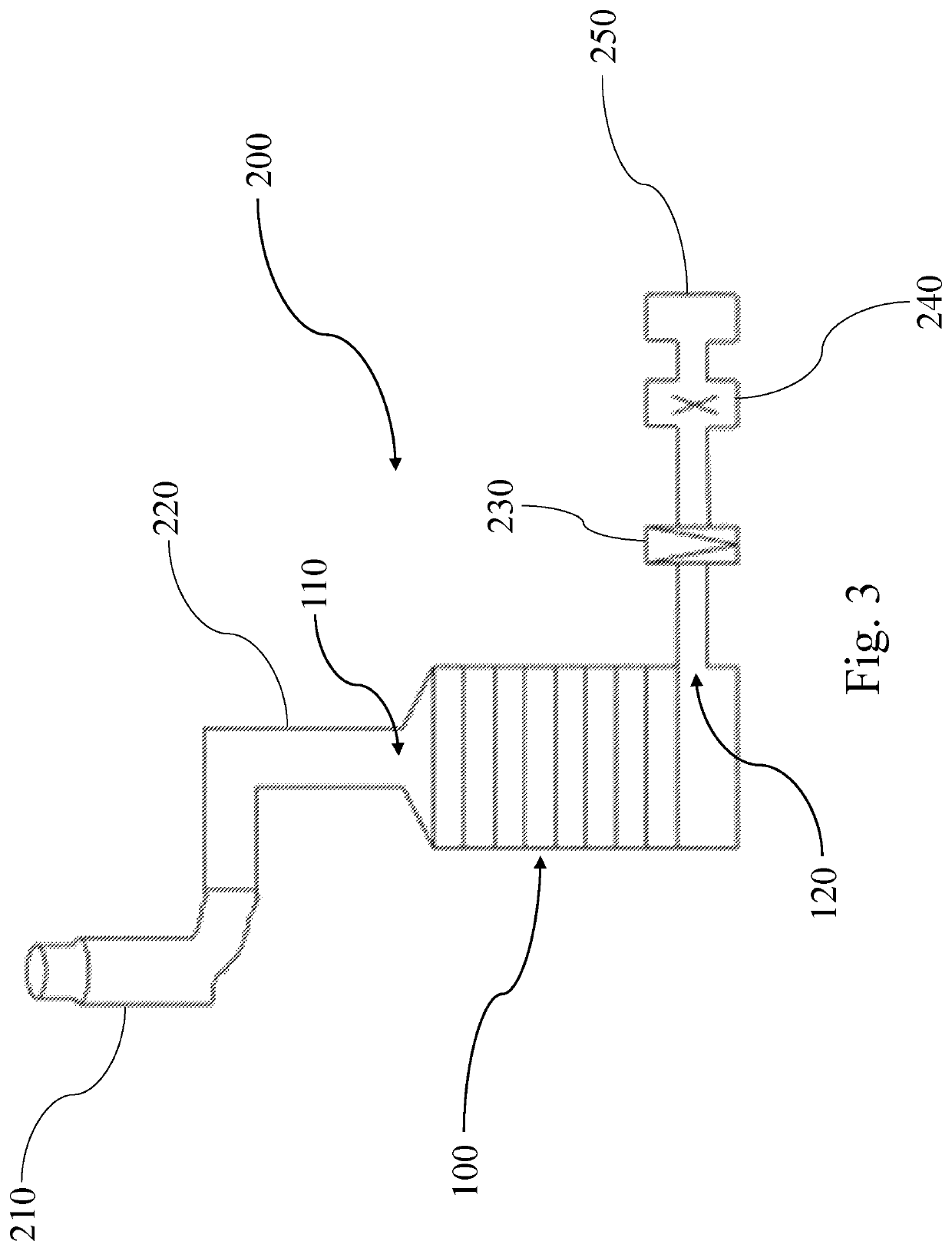

Method for manufacturing a nozzle plate containing multiple micro-orifices for cascade impactor

ActiveUS20140027406A1Avoid cloggingSmooth inner surfaceSamplingDecorative surface effectsCascade impactorElectroplating

A nozzle plate containing multiple micro-orifices for the cascade impactor and a method for manufacturing the same are disclosed. The nozzle plate is formed by a series of semiconductor processes, including lithography, etching and electroplating. The nozzle plate comprises a plate body and a plurality of micro-orifices formed on the plate body. The orifice has a diameter which gradually expands in the direction away from the bottom of the plate body to achieve a smooth inner surface, allowing particles to pass therethrough smoothly without being clogged in the nozzle plate.

Owner:NAT CHIAO TUNG UNIV

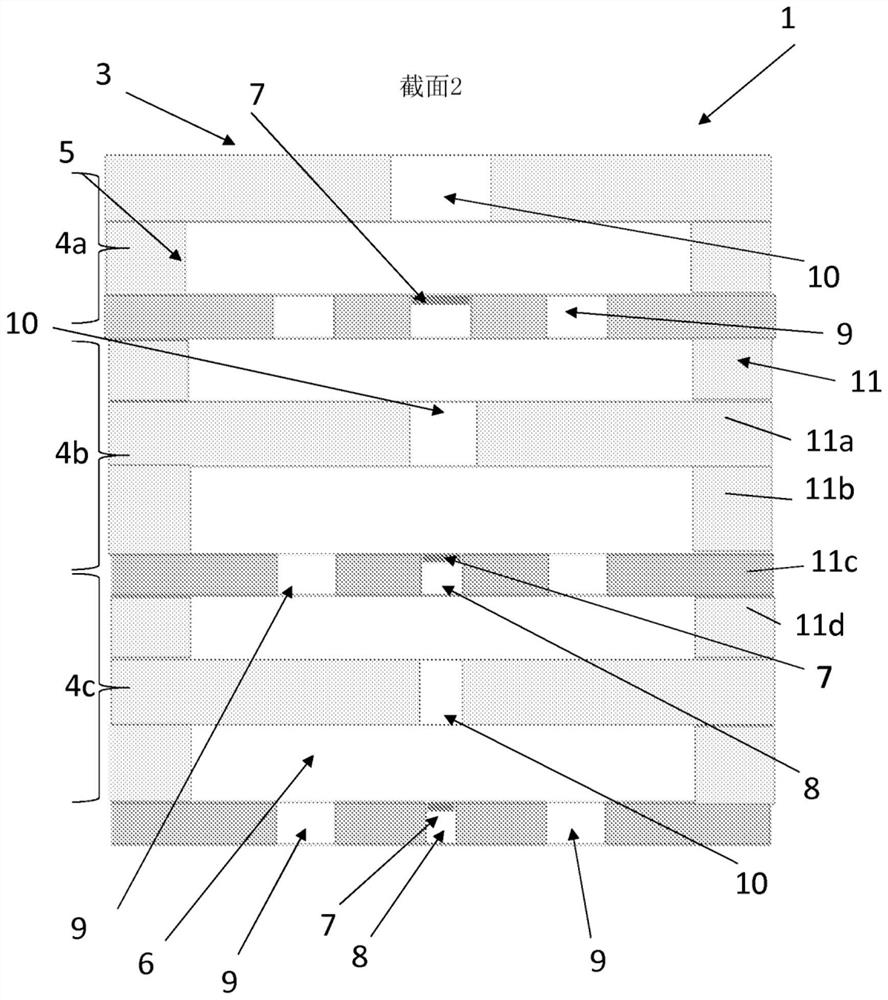

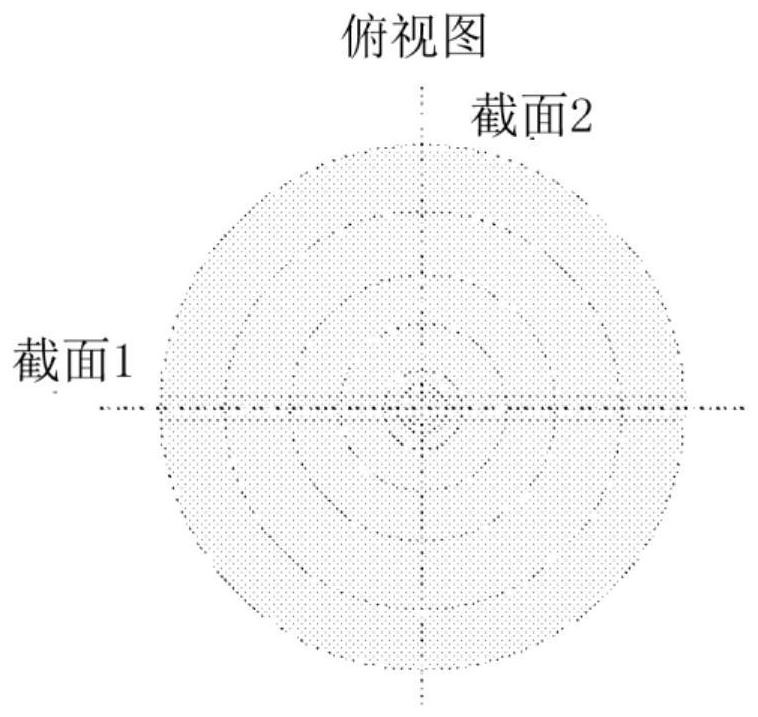

Cascade impactor

InactiveUS8671738B2Reduce in quantityEasy to disassembleCombination devicesDispersed particle filtrationVena contracta diameterInspiratory flow

Owner:WITHAM CLYDE L

Automated cascade impactor

ActiveUS7926367B2Low variabilityAutomatic collectionWithdrawing sample devicesCascade impactorAutomation

An automated cascade impactor comprises an extension mechanism operable to couple to a plurality of impactor stages. The extension mechanism is operable to compress and separate impactor stages of the plurality of impactor stages via automation. The system provides a plurality of isolation stages operable to be automatically inserted between respective impactor stages when the impactor stages are separated by the extension mechanism. The system provides the plurality of isolation stages to be automatically compressed between impactor stages to isolate each impactor stage from at least one adjacent impactor stage. The plurality of isolation stages is operable to be automatically uncompressed and removed from between the impactor stages. The isolation stages allow automated extraction of particulate matter, cleaning and drying of interior surfaces of each impactor stage.

Owner:LAB AUTOMATE TECH

Process for determining the particle size distribution of an aerosol and apparatus for carrying out such a process

InactiveUS7247496B2Withdrawing sample devicesMaterial analysis by electric/magnetic meansCascade impactorDrug development

The measurement of the particle size distribution of an aerosol is of crucial importance in pharmaceutical development. A prerequisite for this is a valid method, e.g. the cascade impactor method described in the pharmacopoeias. It requires measurement of the active substance concentration in order to determine the particle size distribution. The invention provides a process which makes it possible to measure the size of aerosol droplets containing pharmaceutical substances which are unstable in the event of changes in the pH.

Owner:BOEHRINGER INGELHEIM INT GMBH

Nozzle plate containing multiple micro-orifices for cascade impactor and method for manufacturing the same

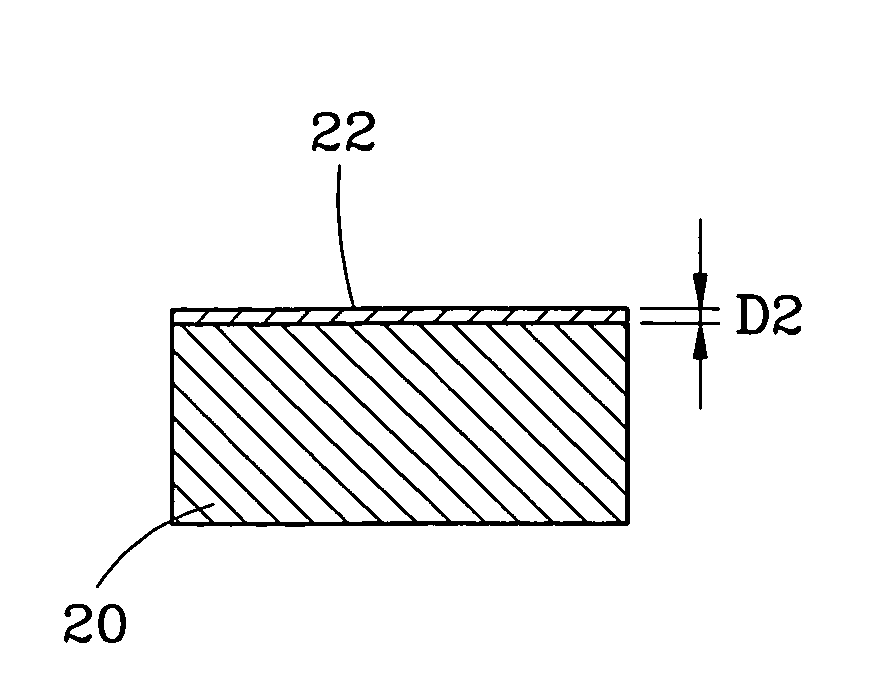

InactiveUS20110209528A1Avoid cloggingSmooth inner surfaceDecorative surface effectsWithdrawing sample devicesLithographic artistCascade impactor

A nozzle plate containing multiple micro-orifices for the cascade impactor and a method for manufacturing the same are disclosed. The nozzle plate is formed by a series of semiconductor processes, including lithography, etching and electroplating. The nozzle plate comprises a plate body and a plurality of micro-orifices formed on the plate body. The orifice has a diameter which gradually expands in the direction away from the bottom of the plate body to achieve a smooth inner surface, allowing particles to pass therethrough smoothly without being clogged in the nozzle plate.

Owner:NAT CHIAO TUNG UNIV

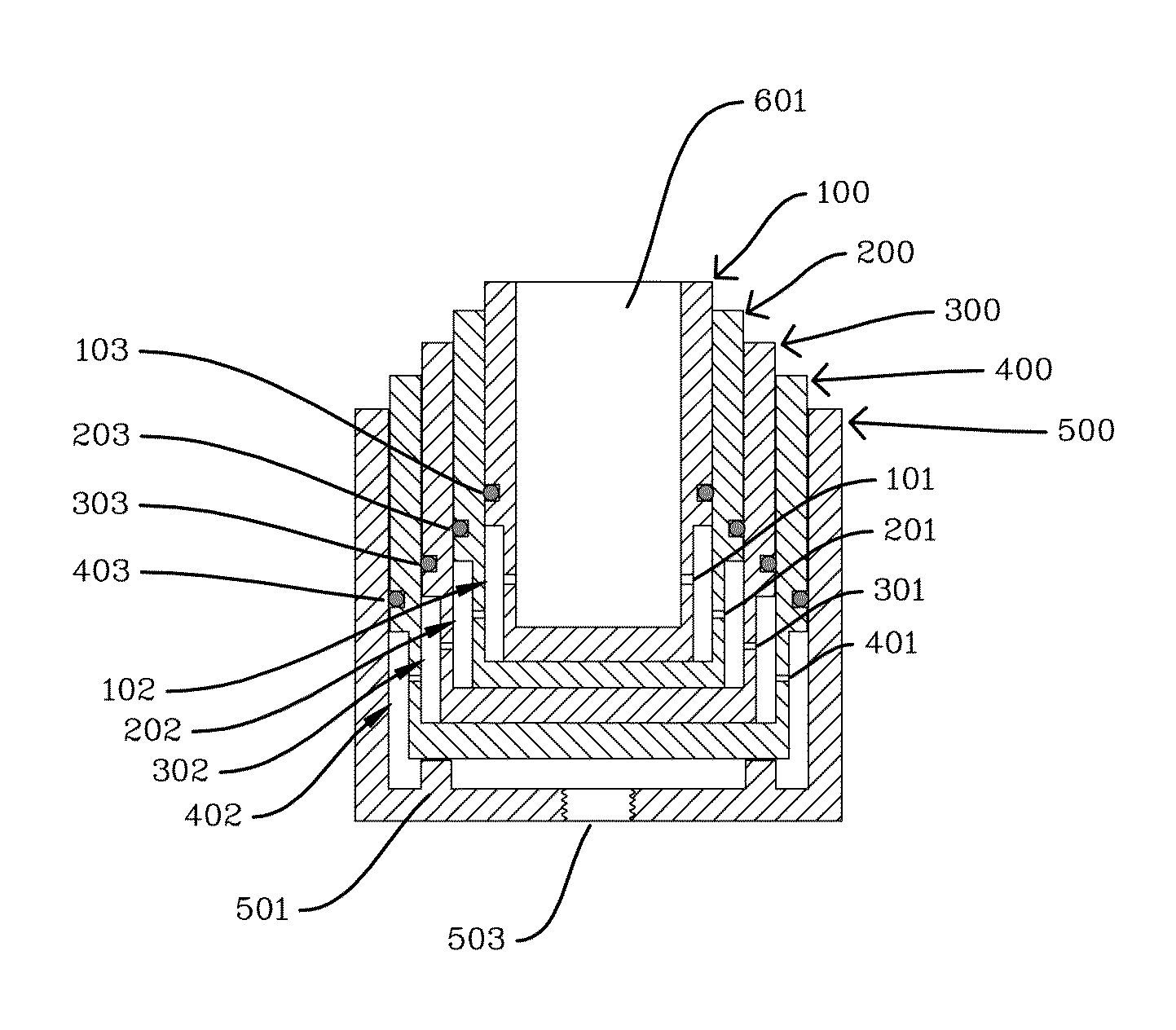

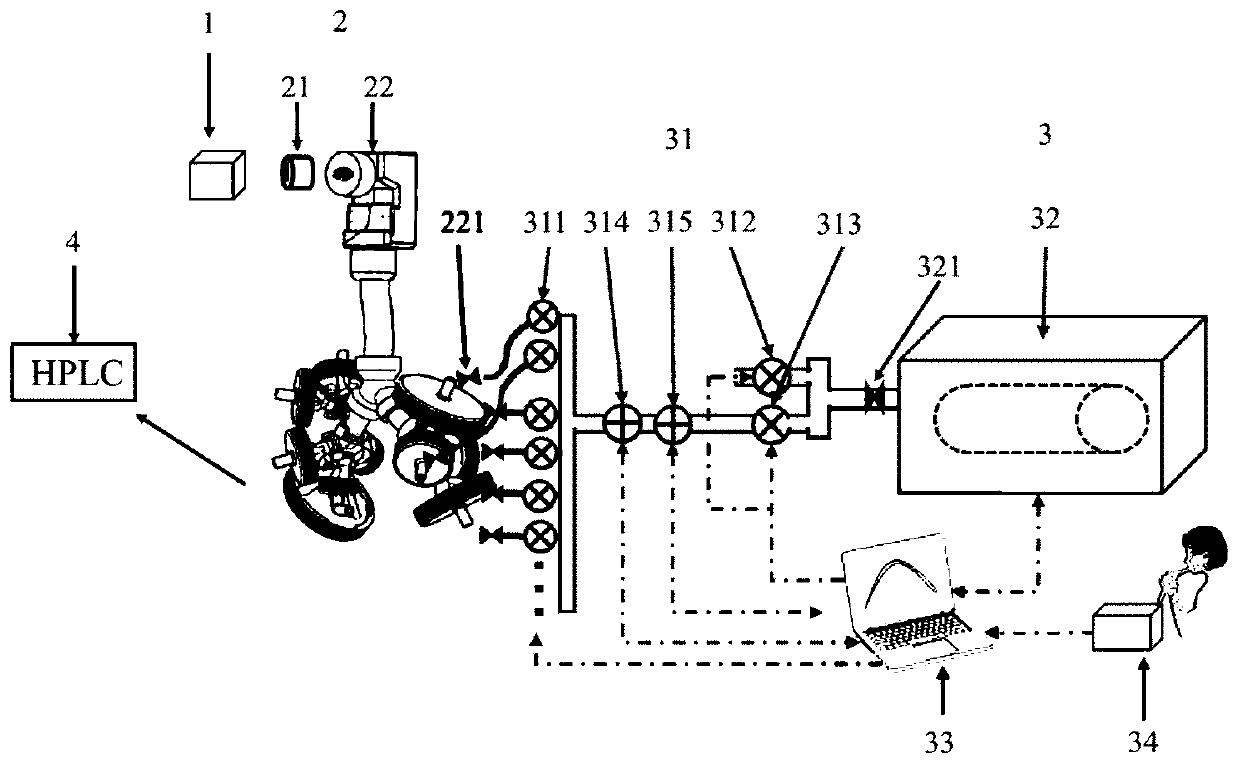

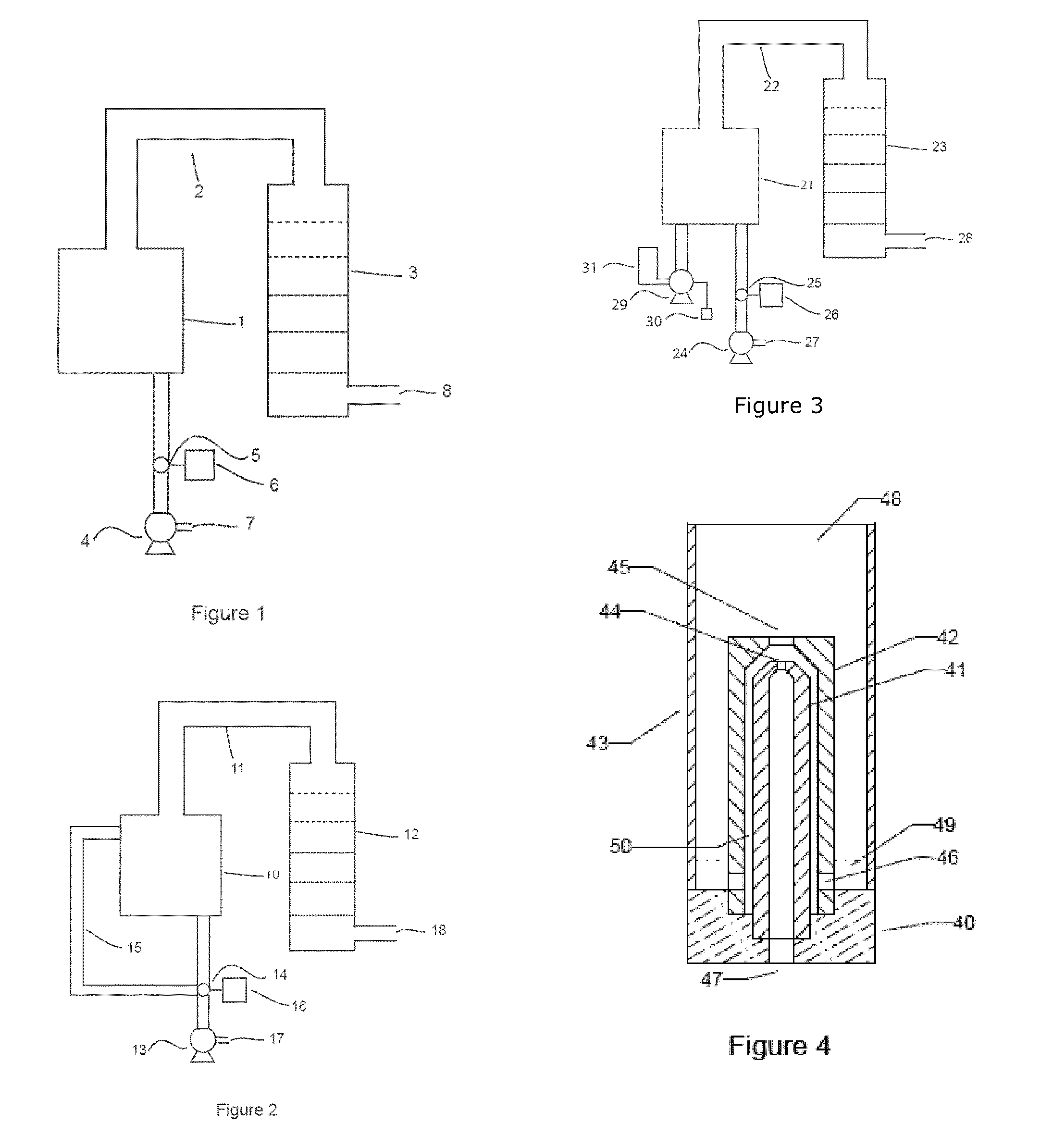

Test method and device for improving in-vivo and in-vitro correlation of inhaled preparation

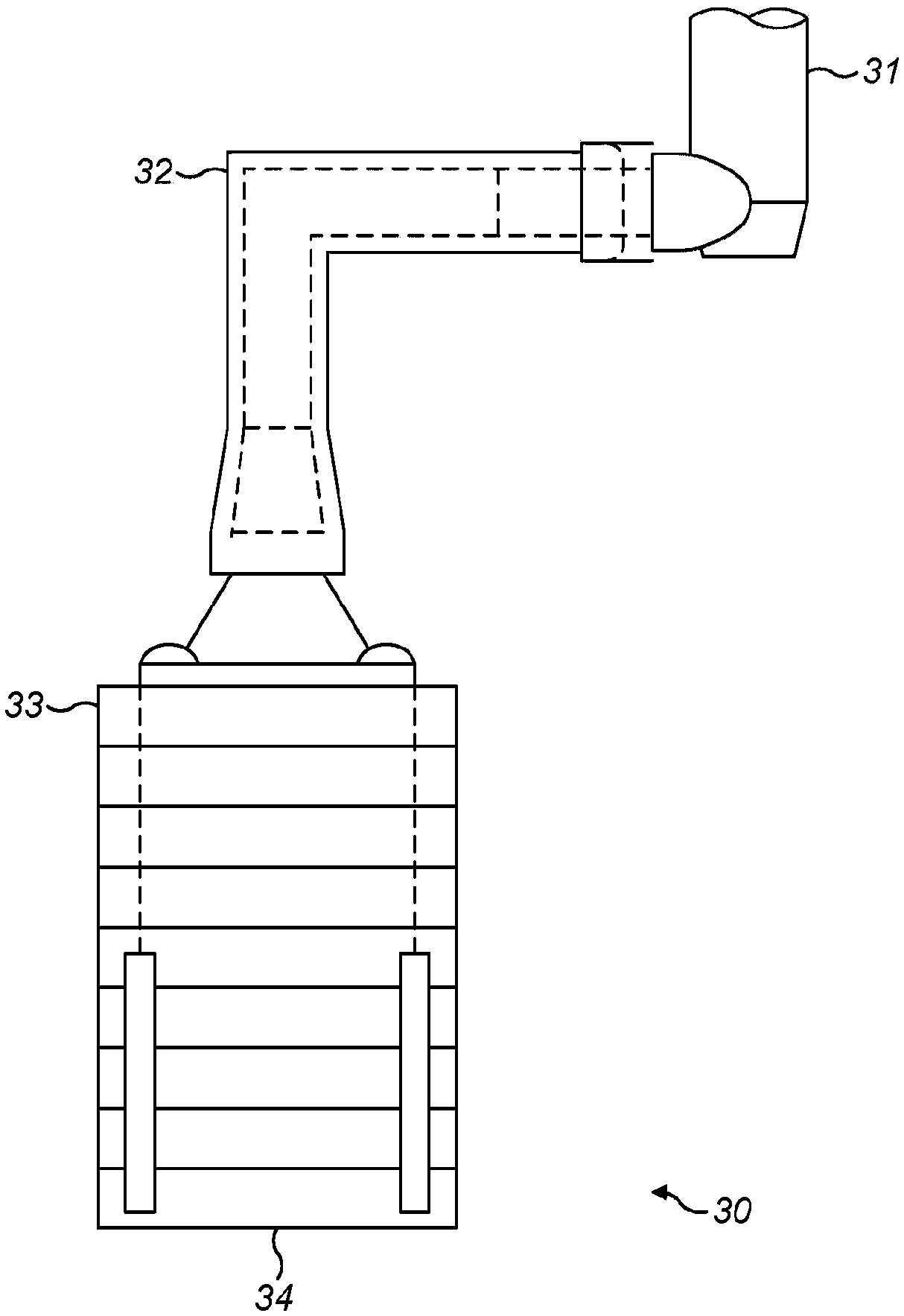

In order to solve a plurality of defects of the aerodynamic characteristic determination of the micro-particles of the preparation by adopting a cascade impactor, the invention provides a test devicefor improving the in-vivo and in-vitro correlation of an inhaled preparation. The device comprises a drug delivery device 1, a human respiratory tract model 2 and a breathing simulator 3, wherein thehuman respiratory tract model 2 comprises an adapter 21 and a real human respiratory tract 3D solid model 22, the breathing simulator 3 comprises a connection control assembly 31, a piston type movement device 32, a control system 33 and a breathing data acquisition device 34, and the device is characterized in that the real human respiratory tract 3D solid model 22 is provided with a plurality offirst quick-connection interfaces 221, the plurality of first quick-connection interfaces 221 are finally converged into a total air path through a plurality of air paths and then connected to the inlet end of the connection control assembly 31, the outlet end of the connection control assembly 32 is connected to the piston type movement device 32; and the connection control assembly 31 comprisesa first solenoid valve 311, a second solenoid valve 312, a third solenoid valve 313, an electronic flow meter 315, and a main body air path.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

Cascade impactor plate coating

InactiveCN109073523AReduce evaporationOrganic active ingredientsLiquid dispersion analysisSpray nozzleCascade impactor

The present invention relates to a cascade impactor for measuring particle size distribution of an aerosol comprising nicotine, the cascade impactor comprising: an induction port for receiving an inhaler; and at least one sample collection stage comprising a nozzle assembly and a collection means; wherein the collection means of at least one sample collection stage is coated with isopropyl alcohol.

Owner:KIND CONSUMER LIMITED

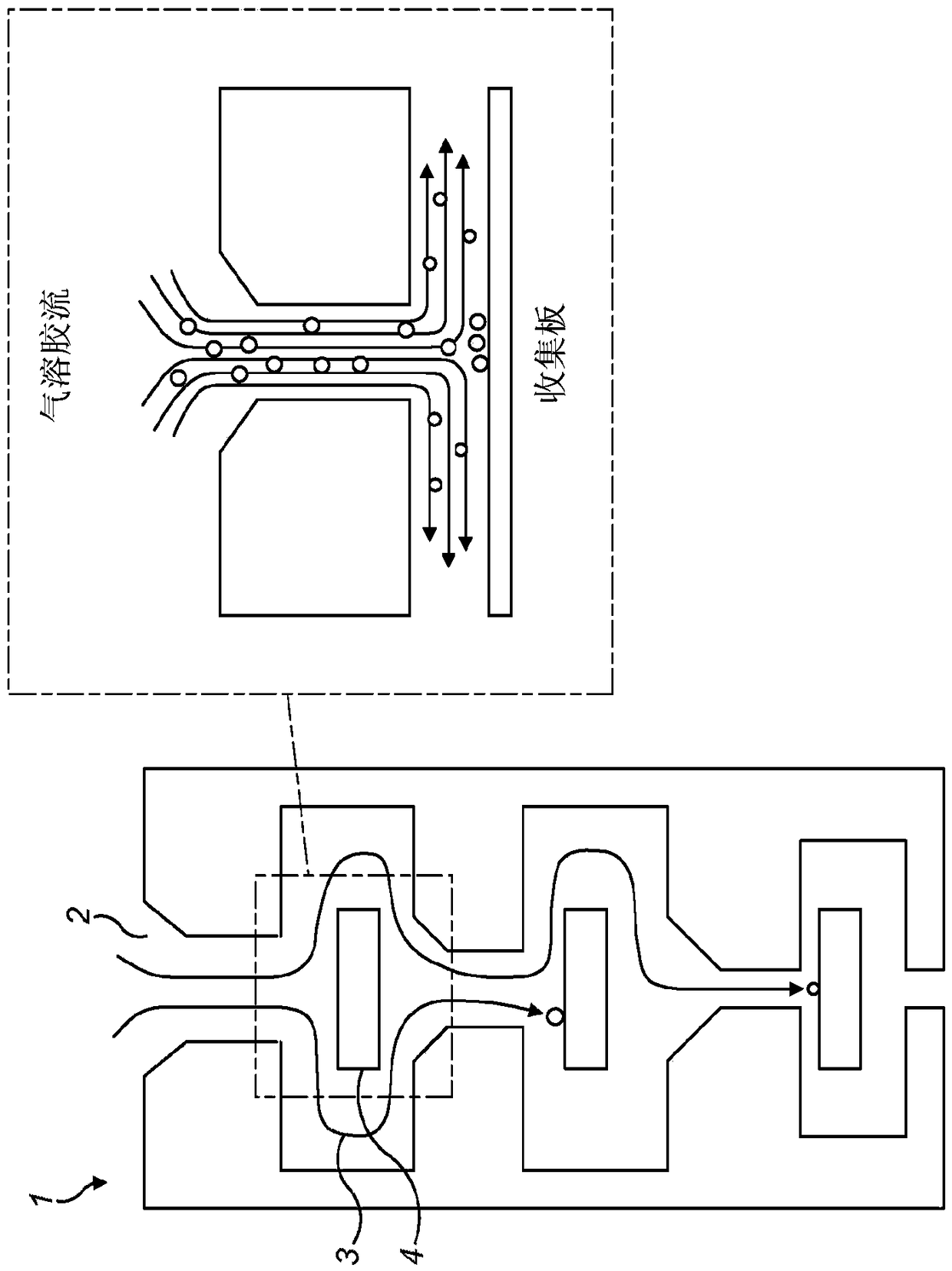

Process and apparatus for localized coating of assembled cascade impactor particle collection surfaces

Methods are presented for applying a coating material to the particle collecting regions and surfaces of the stages of a cascade impactor after the impactor is assembled for use. The methods comprise generation of a multimodal droplet aerosol of liquid coating material and delivering it into the impactor. The modes of coating droplet aerosol are selected to produce droplets that span the range of cutoff diameters for the stages of the cascade impactor. The coating substance improves the trapping of particles on the stages. The methods limit the total amount of coating material applied and confine it to the regions of particle impact opposite the stage orifices, thereby reducing the possibility of chemical interference when analyzing a test aerosol.

Owner:WITHAM CLYDE L

Method for testing bacterial filtration efficacy of fabrics

PendingUS20220186280A1Efficiently determinedBacteriaMicrobiological testing/measurementBiotechnologyNebulizer

The present invention relates to method of testing the bacterial filtering efficiency of a fabric, the method including the steps of preparing a solution including bacteria, peptone water and NaCl, feeding said solution including bacteria to a nebulizer, generating an aerosol of said bacterial solution and flowing said solution through a cascade impactor to provide a plurality of bacteria colonies in a plurality of plates present in a plurality of stages of said cascade impactor, characterized in that the concentration of NaCl in the peptone water used to prepare said bacterial solution is in the range of 30 g / L to 150 g / L and in that the temperature of said cascade impactor is in the range of −15° C. to 15° C.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Filterability detection process for epidemic prevention mask produced based on melt-blown cloth

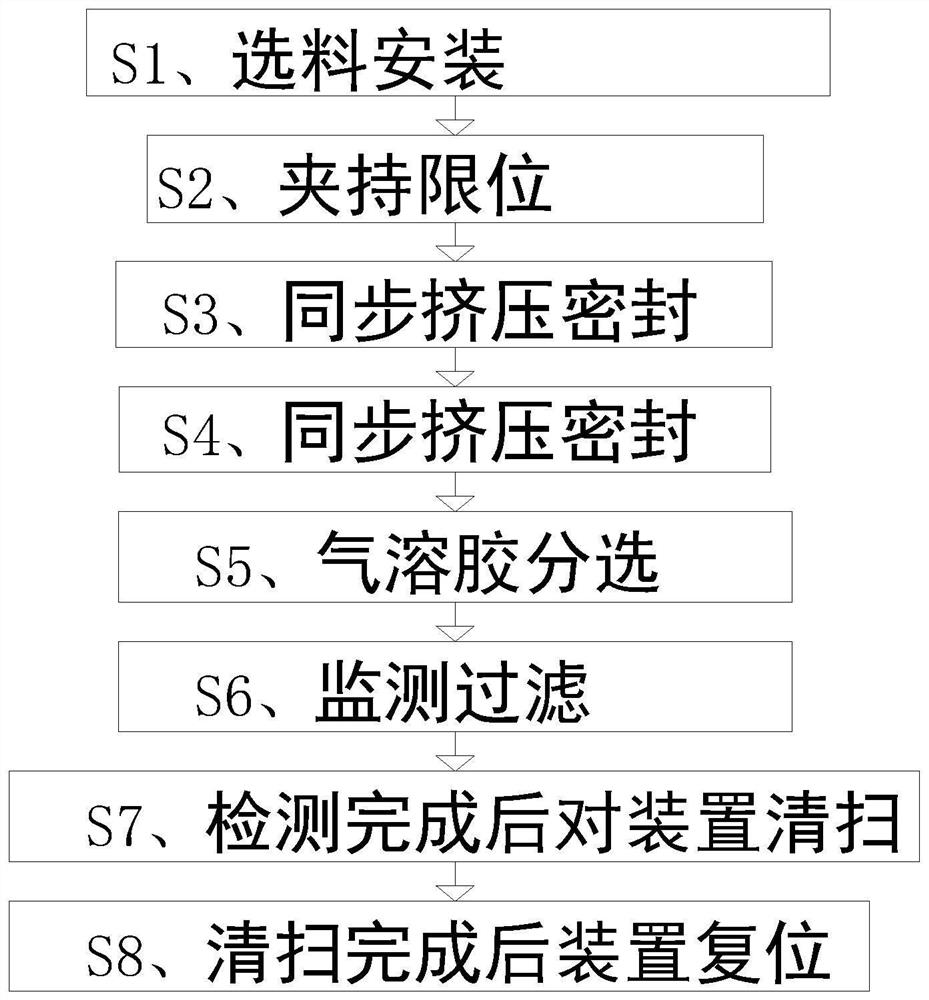

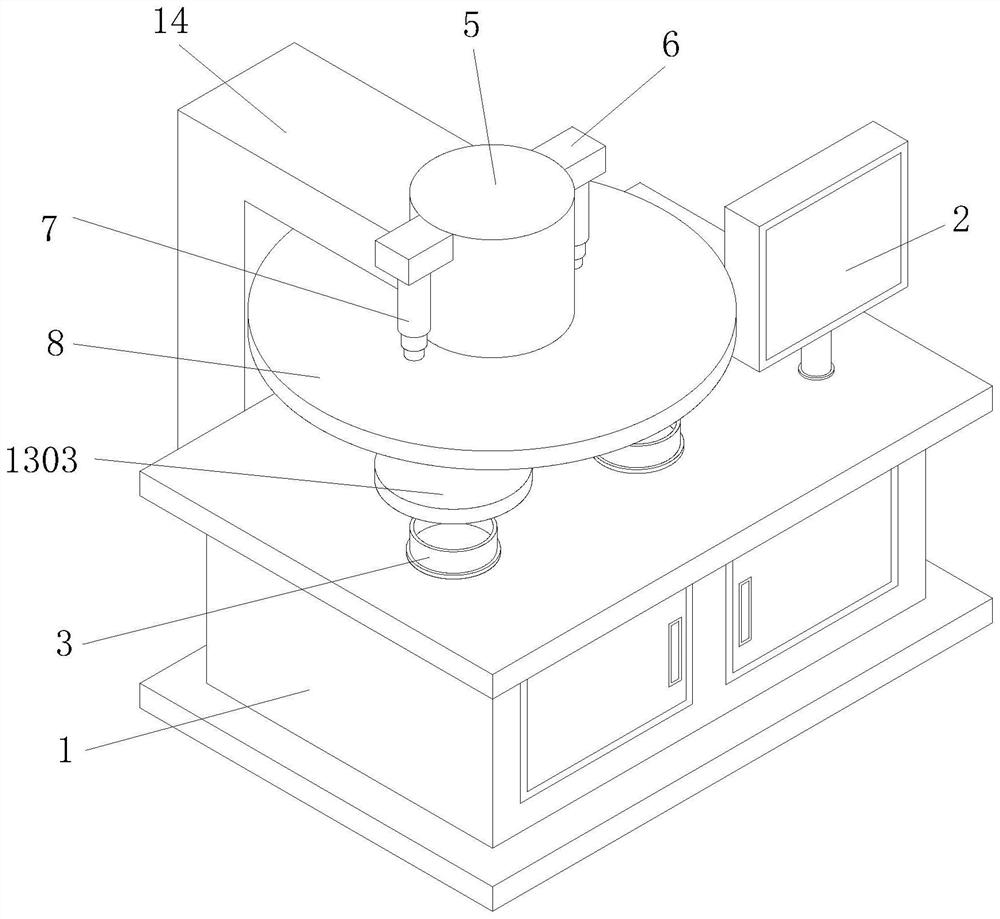

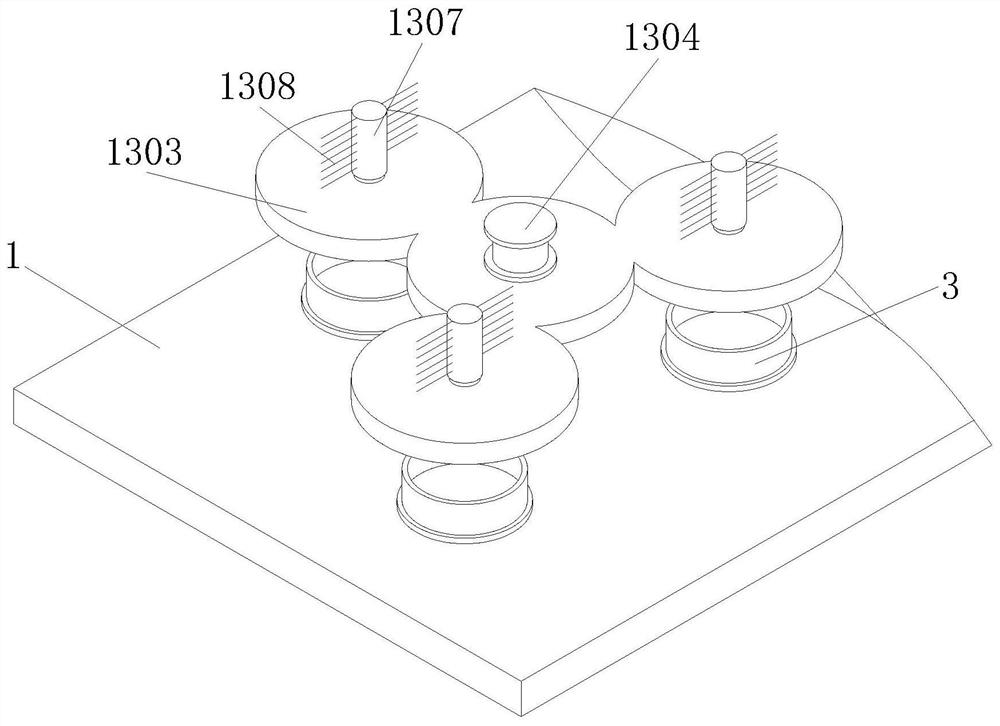

InactiveCN113670796APrevent deviationConvenience and stability of contrast detectionParticle suspension analysisPermeability/surface area analysisHydraulic cylinderCascade impactor

The invention belongs to the field of epidemic prevention mask production, and particularly relates to a filterability detection process for epidemic prevention mask production based on melt-blown cloth, which comprises the following steps: S1, material selection and installation: a worker places selected materials needing to be detected on each test base one by one; S2, clamping and limiting: stable clamping and limiting are performed on the selected materials placed on each test base in the step S1, small hydraulic cylinders are controlled to be started, at the moment, under the working action of the small hydraulic cylinders on the two sides, a mounting plate can be pushed to stably move downwards on a cascade impactor in combination with corresponding hydraulic rods, the small hydraulic cylinder and the hydraulic rods can drive all fixing barrels at the bottom of a mounting plate to move downwards at the same time, stable cooperation work can be conducted with corresponding test bases. Convenient and stable comparison detection work is conducted on multiple selected materials at the same time, deviation of the detection result of the selected materials can be effectively prevented, andthe use stability and accuracy of the device are improved.

Owner:李知竹

Modified collection plates for a cascade impactor

ActiveUS11137324B1Suitable for useEfficient captureWithdrawing sample devicesParticle size analysisLiquid mediumCascade impactor

A collection plate for a cascade impactor is provided that includes: a container; an absorbent layer including a bottom surface and a top surface, the absorbent layer residing within the container, the absorbent layer further including a liquid medium within the absorbent layer; and an impaction membrane placed on the top surface of the absorbent layer, such that the impaction membrane is in fluidic communication with the absorbent layer. The absorbent layer is configured to hydrate the impaction membrane for at least four hours in a temperature of about 78° F. at 37% RH. The collection plate may be utilized as a component in a cascade impactor and / or in a method of collecting a biological sample with a cascade impactor.

Owner:UNITED STATES OF AMERICA

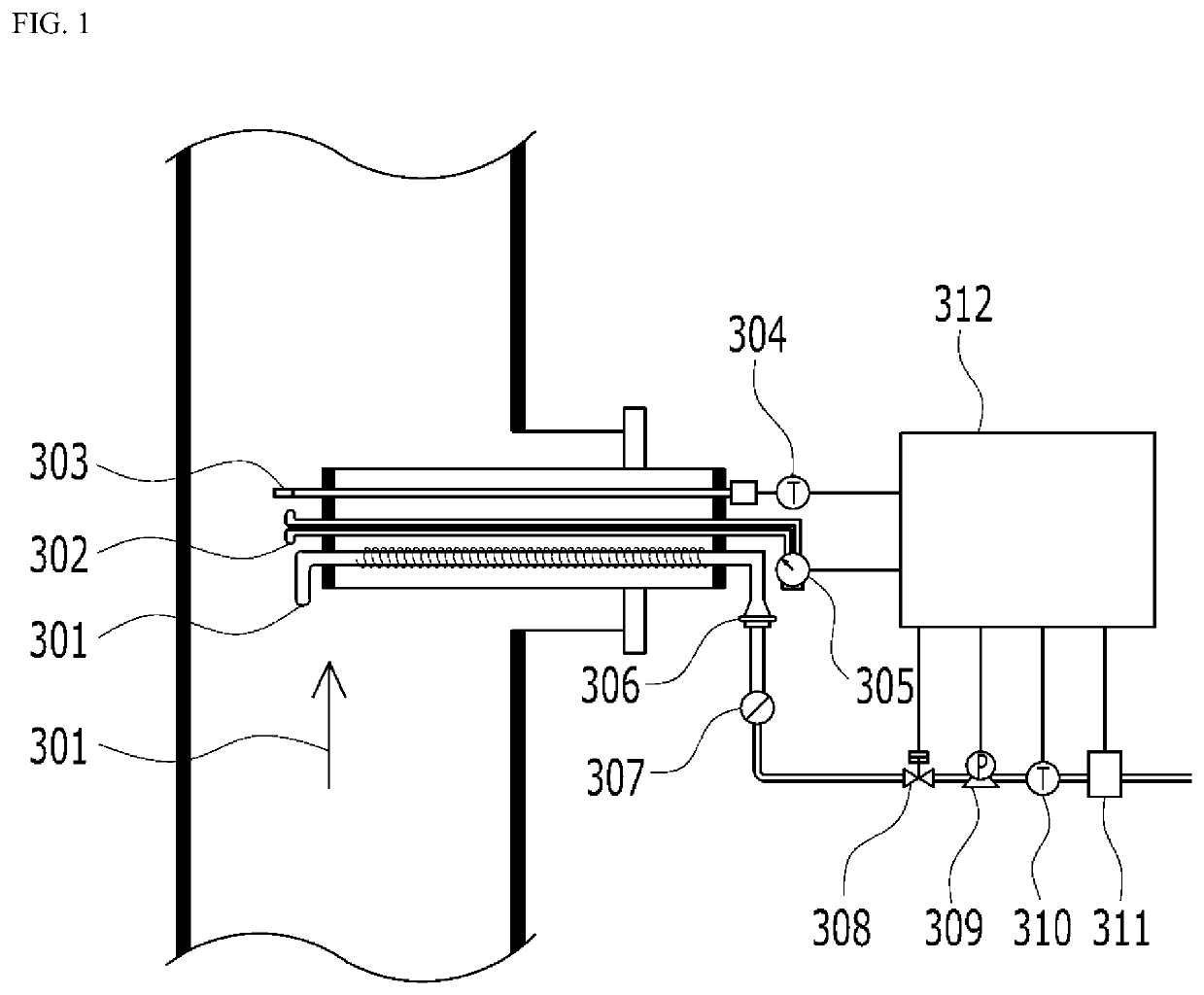

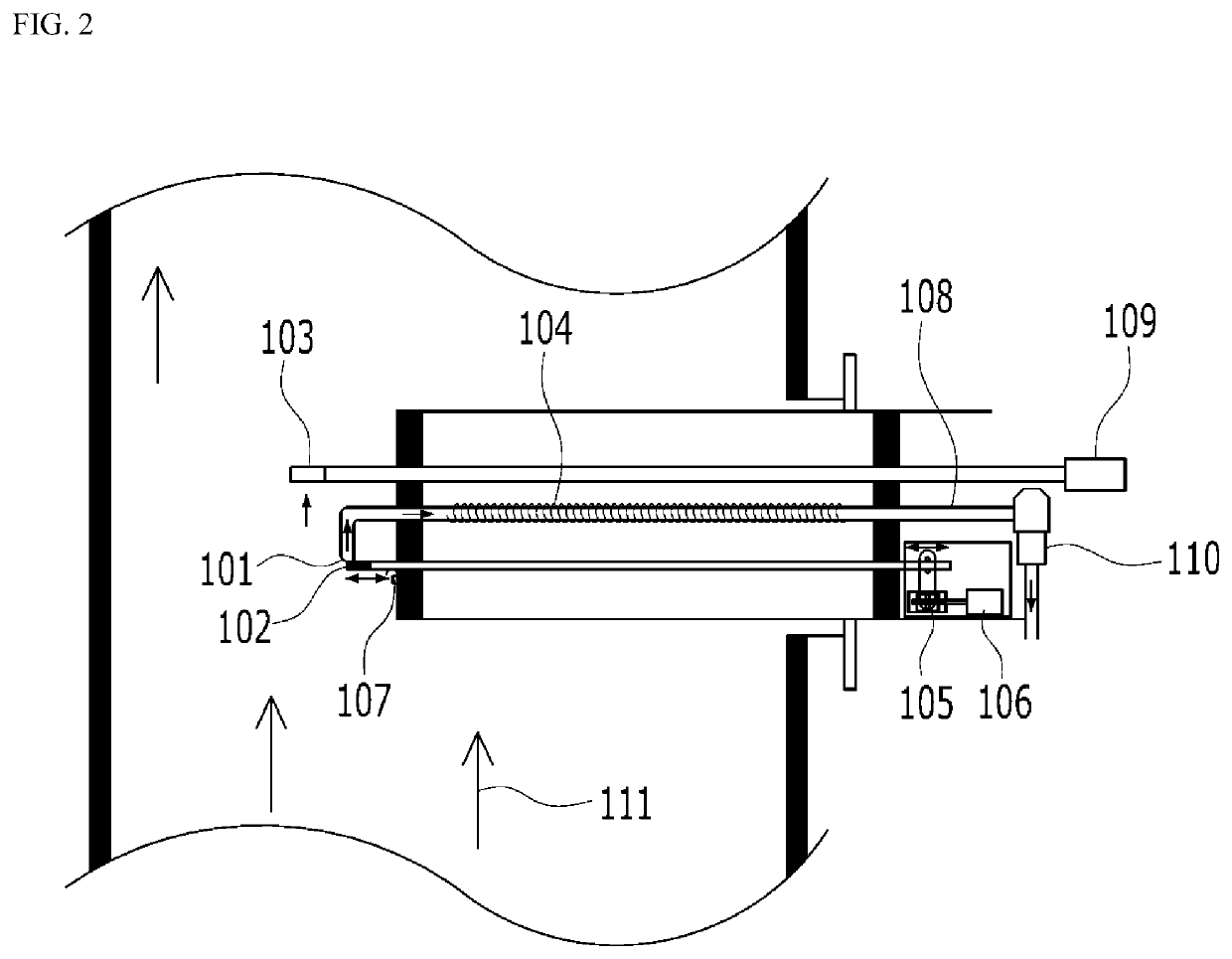

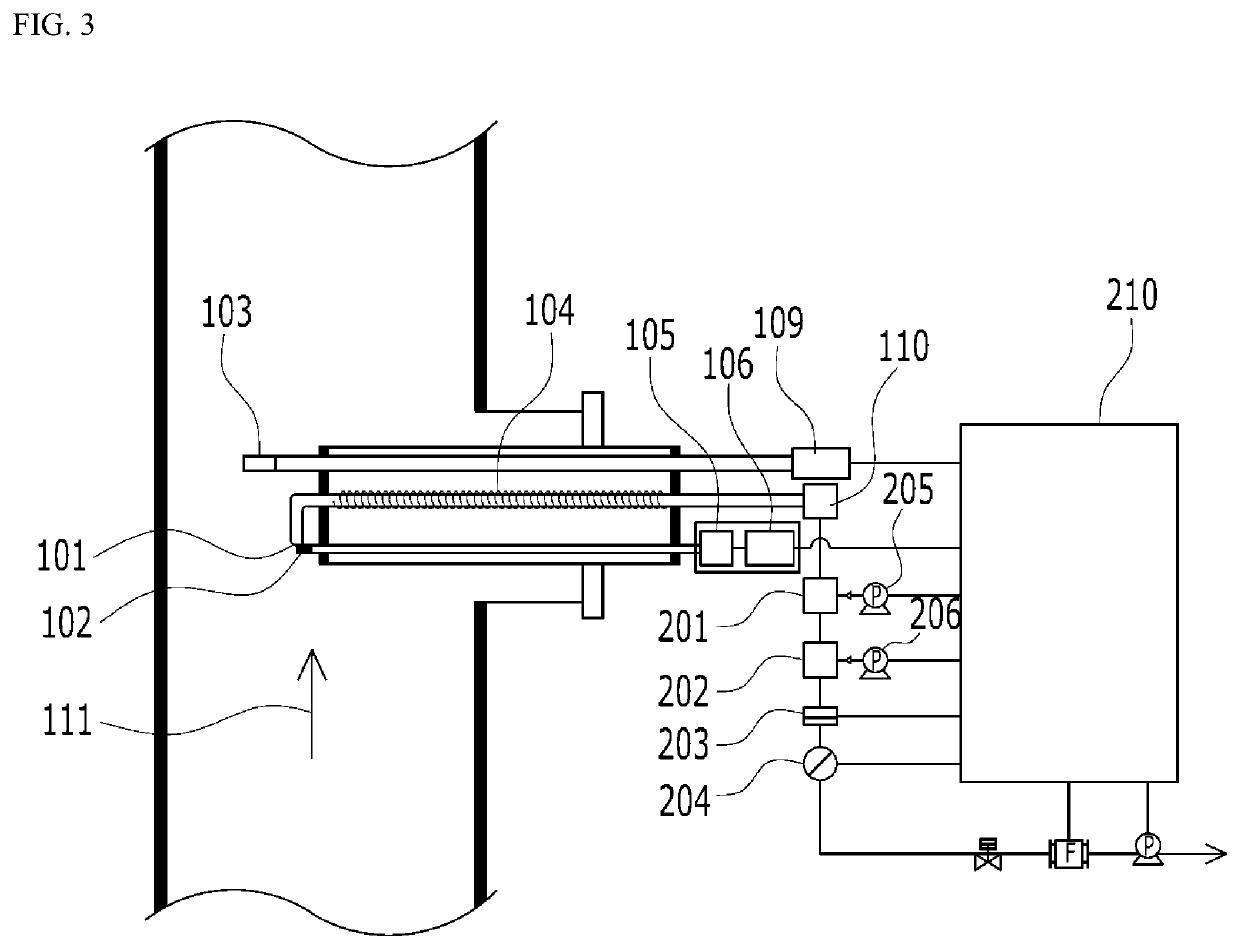

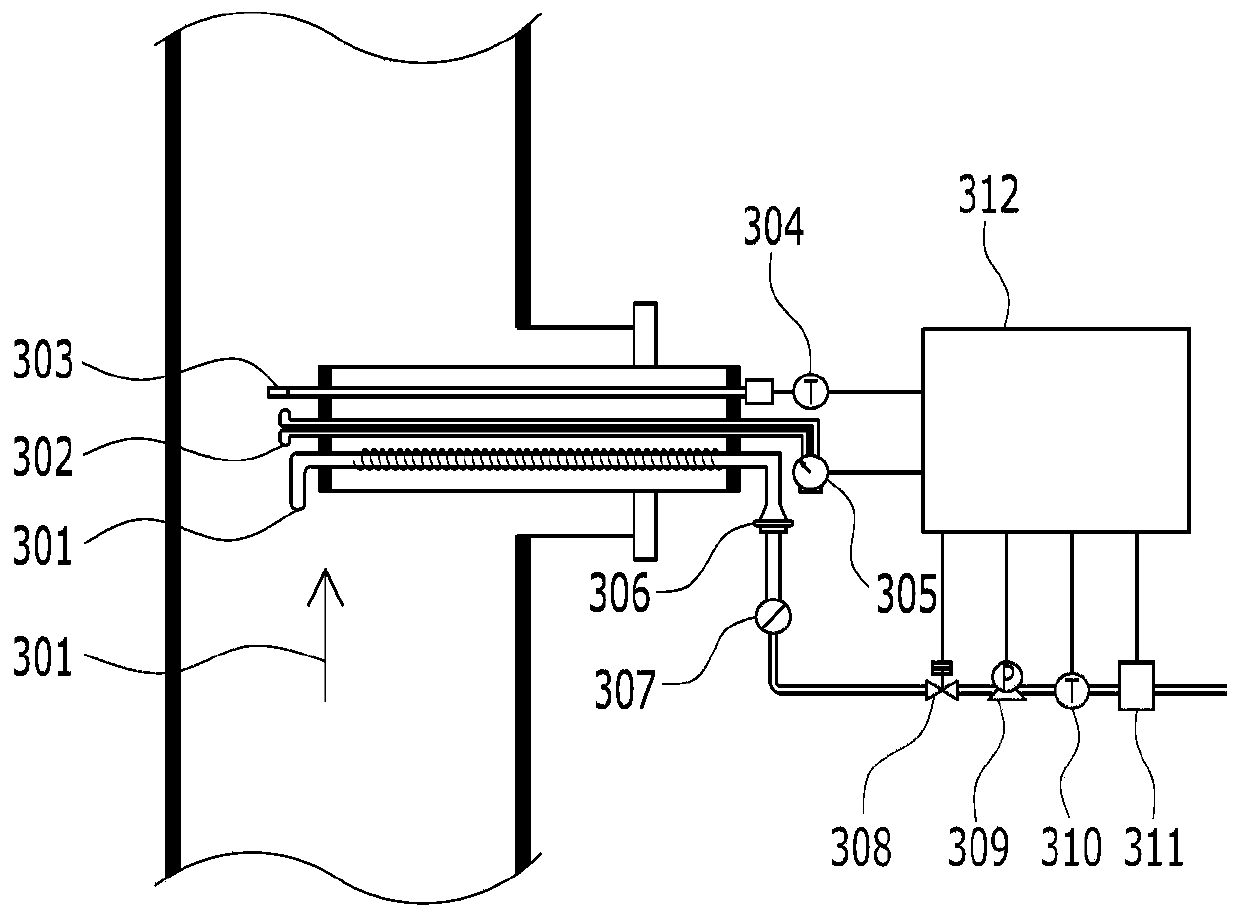

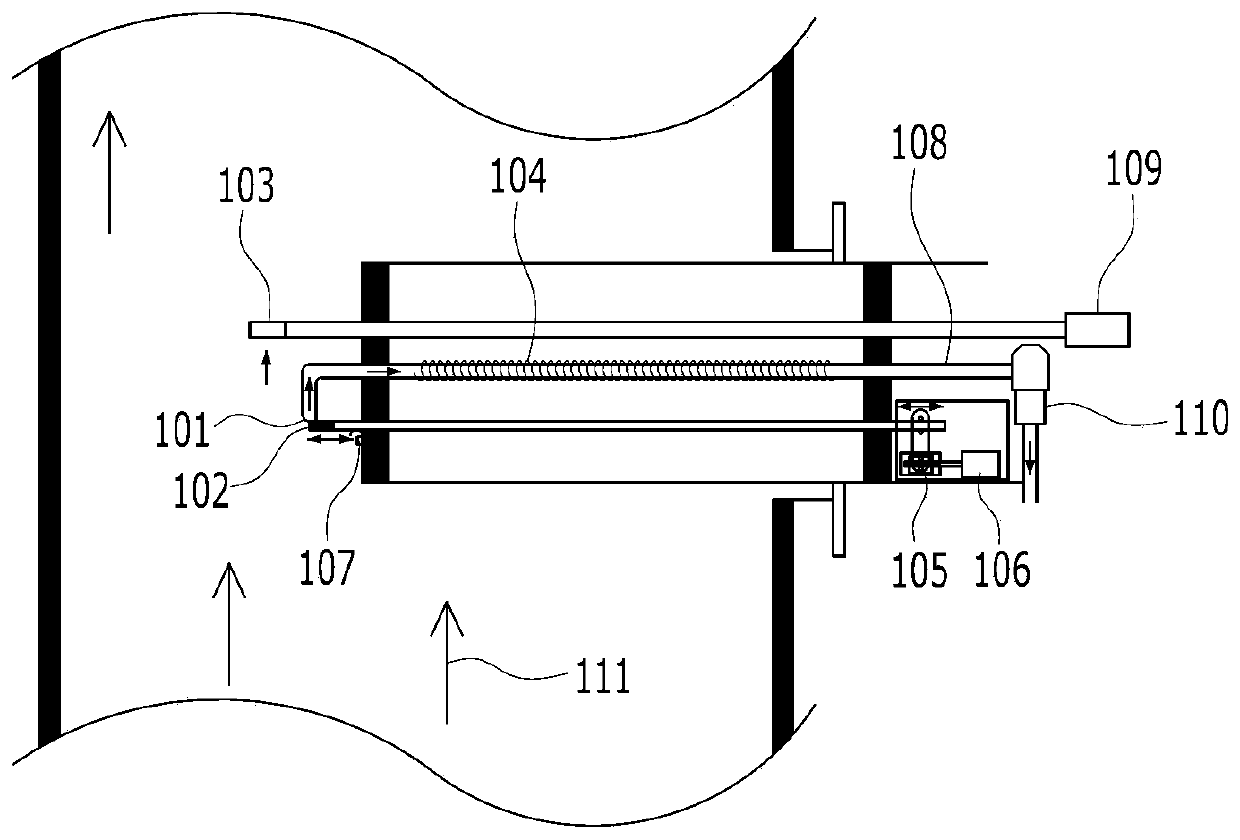

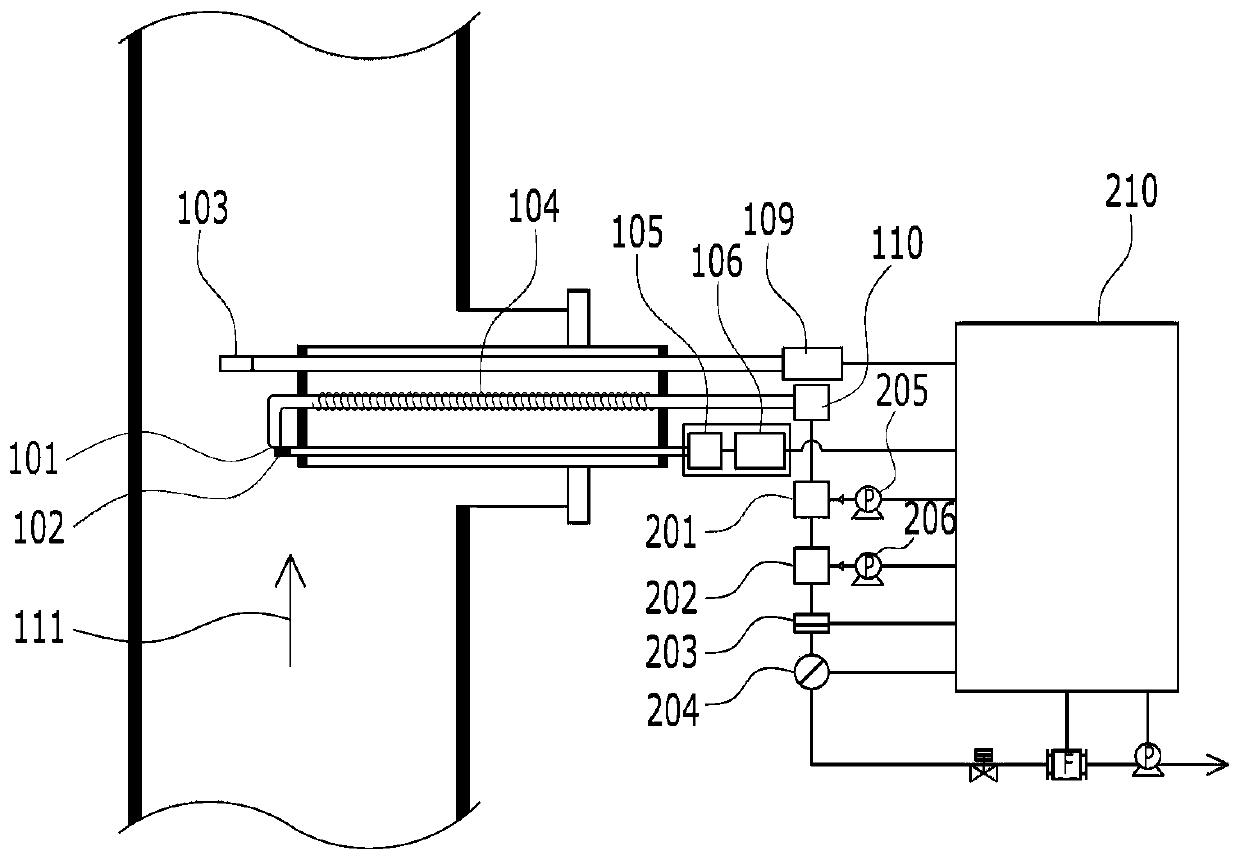

Continuous isokinetic sample device for stack gas having suction nozzle to which sectional area control device is attached, and automatic continuous measurement system for fine dust in stack gas comprising same combined therewith

ActiveUS11137325B2Minimize measurement errorEffectively reduce the fine dustWithdrawing sample devicesSuspended particlesFlue gas

Provided is a continuous isokinetic sampling device of a stack gas having a suction nozzle to which a cross-sectional area control device is attached, and a continuous automatic measurement system of fine dusts in the stack gas combined with the same, the device and system being configured to continuously separate and automatically measure the suspended particles into PM10 (Particulate Matter Less than 10 μm) and PM2.5 (Particulate Matter Less than 2.5 μm) by introducing a suction gas into a particle size separation device (cascade Impactor) at a constant flow rate of 16.67 l / min, simultaneously with removing an measurement error caused due to inertia force of the suspended particles by automatically adjusting the cross-sectional area of the suction nozzle to suck the sample at the same flow rate as that of the stack gas in the stationary source emissions.

Owner:CHUNG ENG

Chimney exhaust gas fine powder continuous automatic measuring device

The present invention relates to a method for sampling particulate matter contained in stack gas and, more particularly, to a continuous isokinetic sampling device for stack gas having a suction nozzle to which a sectional area control device is attached, and an automatic continuous measurement system for fine dust in stack gas comprising the same combined therewith, wherein: in order to suction asample at the same rate as the flow rate of stack gas in a stack gas emission source, the sectional area of a suction nozzle is automatically controlled so as to suction a sample at the same rate asthe flow rate in the emission source, whereby measurement errors due to the inertial force of particulate matter are eliminated; and particulate matter is introduced into a cascade impactor at a constant flow rate of suction gas of 16.67 l / min so as to continuously separate the particulate matter into particulate matter less than 10 [mu]m (PM10) and particulate matter less than 2.5 [mu]m (PM2.5) and automatically measure the PM10 and the PM2.5. The present invention can satisfy both conditions for a sampling device and a cascade impactor for particulate matter in stack gas, which are in conflict with each other, and thus can perform both sampling and automatic continuous measurement of particulate matter in stack gas while minimizing measurement errors.

Owner:CHUNG ENG

Apparatus for Localized Coating of Cascade Impactor Particle Collection Surfaces

InactiveUS20120009330A1Satisfies needVacuum evaporation coatingSputtering coatingTrappingCascade impactor

The invention relates to apparatuses and methods for applying a coating material to the collection surfaces of the stages after an impactor is assembled for use. The apparatuses and methods comprise generation of a multimodal droplet aerosol of liquid coating material and delivering it into the impactor. The coating substance improves the trapping of particles on the stages. The apparatuses and methods limit the total amount of coating material applied and confine it to the regions of particle impact opposite the stage orifices, thereby reducing the possibility of chemical interference when analyzing a test aerosol.

Owner:WITHAM CLYDE L

Automated cascade impactor

An automated cascade impactor is disclosed and comprises a vertical array of a plurality of impactor stages, and a vertical array of isolation stages, wherein the vertical array of the isolation stages comprises pairs of isolation stages between which impactor plates, removed from respective ones of the impactor stages are effectively sandwiched between each pair of isolation stages. Still further, each compactor stage is likewise sandwiched between and upper and a lower pair of the isolation stages.

Owner:LAB AUTOMATE TECH

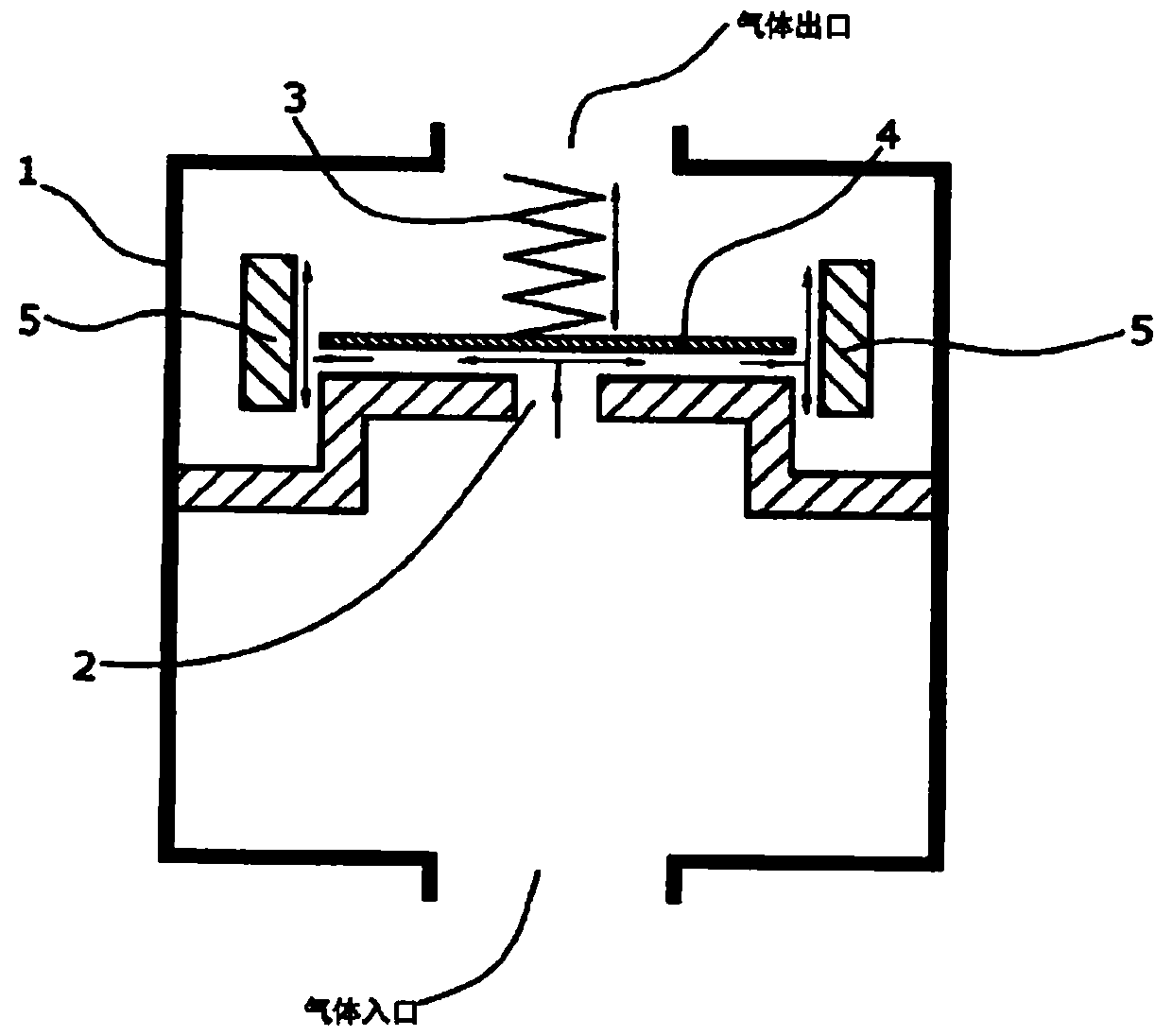

cascade impactor

ActiveCN106574529BCombustion-air/fuel-air treatmentDispersed particle separationCascade impactorEngineering

The invention relates to a cascade impactor having a first stage comprising a plate (2) with fixed bores as gas inlet and at least a first impact wall (4) with a variable distance from the plate (2) as well as at least a second stage having a fixed second impact wall (5), which is arranged in the flow direction downstream of the first impact wall (4).

Owner:德国保利达塑料有限两合公司

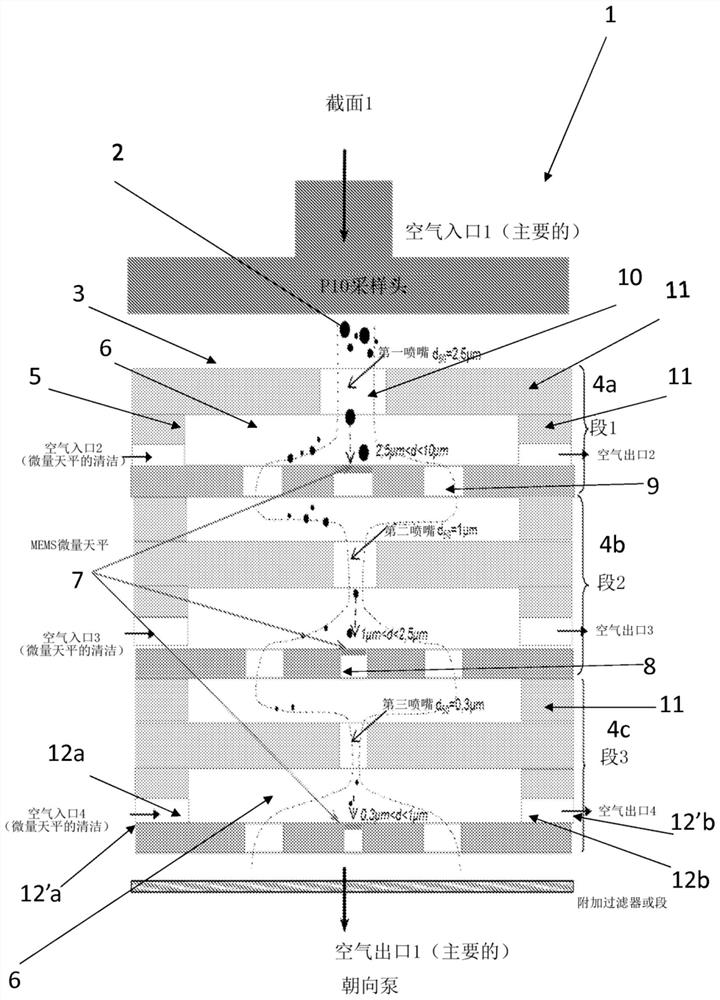

Fine particle sensor with cascaded microscales

PendingCN113728219ATight controlMonitoring continuous and real-timeWeighing apparatus using elastically-deformable membersWithdrawing sample devicesCascade impactorSilicon

Owner:科学和技术中心 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com