Lithium battery electrode surface defect classification method

A technology of electrode surface and classification method, which is applied in the direction of instruments, character and pattern recognition, computer components, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

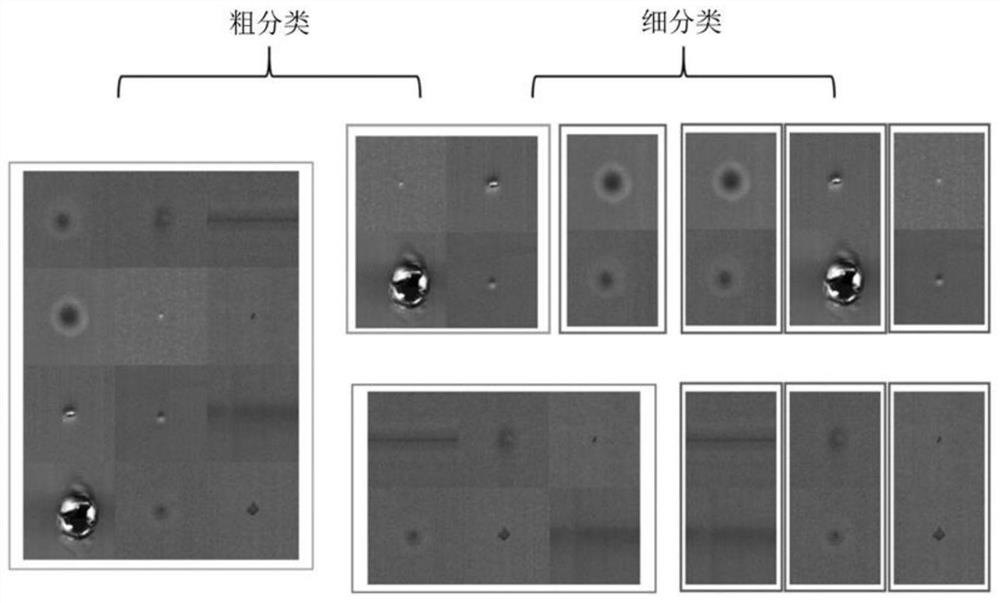

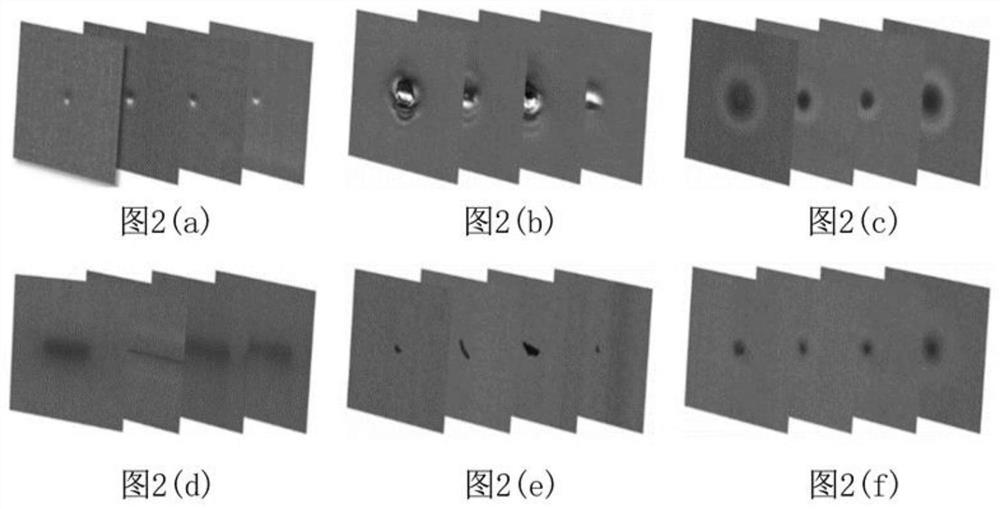

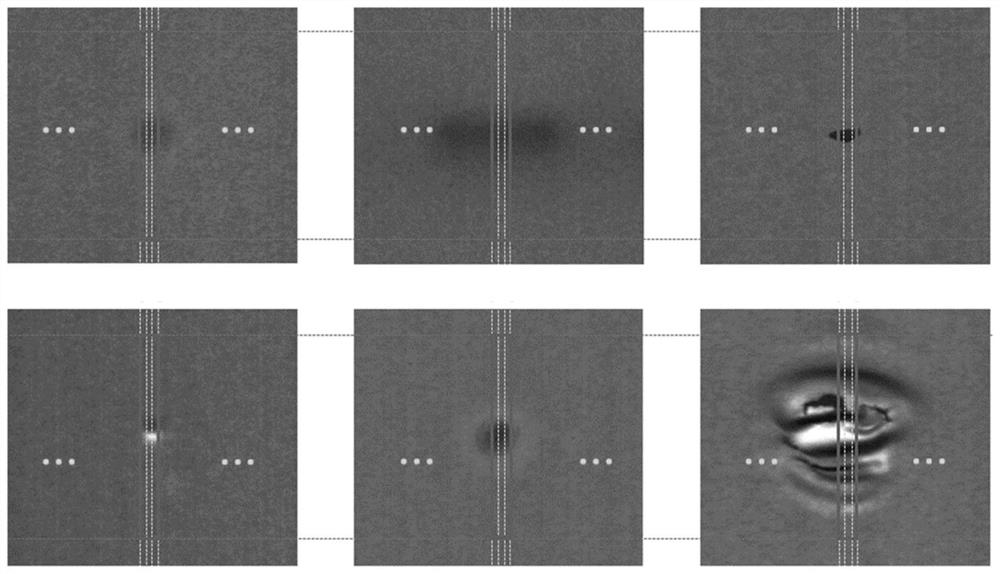

[0068] This embodiment mainly proposes a classification method for the surface defects of lithium battery electrodes, which is used to classify bright defects and dark defects on the surface of lithium battery electrodes. Among them, bright defects include bright spots, metal leakage, and bubbles, and dark defects include black spots. , streaks, decarburization. The classification method first uses the change of the gray value of the specified area, combined with the ring mask method to classify the six types of defect images into bright defect data sets and dark defect data sets; The extracted features are subdivided into the two categories of bright defect data set and dark defect data set to obtain the final classification result.

[0069] figure 1 It is a flow chart of a method for classifying surface defects of lithium battery electrodes disclosed in this embodiment, which will be described through specific embodiments below. The classification method in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com