A kind of diode and its manufacturing method

A manufacturing method and diode technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of excessive pulse voltage and large energy loss at the moment of turn-on, so as to speed up turn-on speed and reduce the impact of withstand voltage , the effect of strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

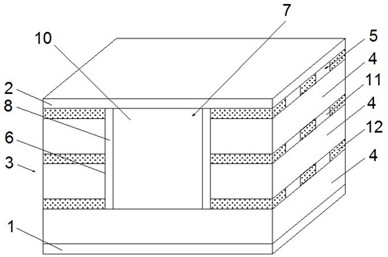

[0033] like figure 1 As shown, a diode includes a cathode layer 1, an anode layer 2 and a diode body 3. The diode body 3 includes more than two groups of substrate layers 4 and more than two groups of intermediate layers 5, and a A group of intermediate layers 5, or a group of substrate layers 4 is arranged between every two groups of intermediate layers 5, and the numbers of the substrate layers 4 and the intermediate layers 5 can be the same or different. When the numbers of the substrate layers 4 and the intermediate layers 5 are different, The difference between the two numbers is one, and more than one set of trenches 6 are opened on the diode body 3 , and the trenches 6 run through all the intermediate layers 5 , and the sidewalls of the trenches 6 are provided with connection layers 7 .

[0034] In this embodiment, the substrate layer 4 is used as the first layer, and the combination is carried out in such a way that the intermediate layer 5 and the substrate layer 4 ar...

Embodiment 2

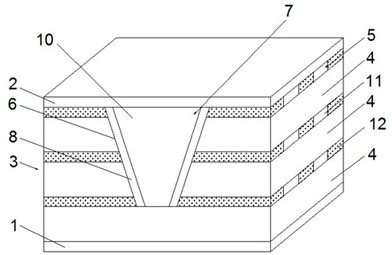

[0042] like figure 2 As shown, a diode includes a cathode layer 1, an anode layer 2 and a diode body 3. The diode body 3 includes more than two groups of substrate layers 4 and more than two groups of intermediate layers 5, and a A group of intermediate layers 5, or a group of substrate layers 4 is arranged between every two groups of intermediate layers 5, and the numbers of the substrate layers 4 and the intermediate layers 5 can be the same or different. When the numbers of the substrate layers 4 and the intermediate layers 5 are different, The difference between the two numbers is one, and more than one set of trenches 6 are opened on the diode body 3 , and the trenches 6 run through all the intermediate layers 5 , and the sidewalls of the trenches 6 are provided with connection layers 7 .

[0043] In this embodiment, the substrate layer 4 is used as the first layer, and the combination is carried out in such a way that the intermediate layer 5 and the substrate layer 4 a...

Embodiment 3

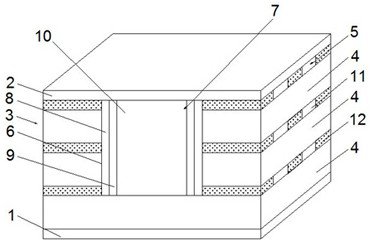

[0052] like image 3 As shown, the connection layer 7 includes a first semiconductor layer 8, a second semiconductor layer 9 and an insulating filling layer 10, the first semiconductor layer 8 is disposed on the sidewall of the trench 6, and the second semiconductor layer 9 is disposed on the first semiconductor layer 8 is away from the side wall of the trench 6, the insulating filling layer 10 is arranged between the second semiconductor layer 9, the plane where the side wall of the trench 6 is located is perpendicular to the plane where the middle layer 5 is located, and the first semiconductor layer 8 and the middle layer Layer 5 is of the same type of semiconductor material, and the second semiconductor layer 9 is of the same type of semiconductor material as substrate layer 4 .

[0053] like Figure 5 As shown, the intermediate layer 5 includes an epitaxial layer 11 and a doped layer 12, wherein the epitaxial layer 11 is an N-type semiconductor material having the same d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com